Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Improve surface affinity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

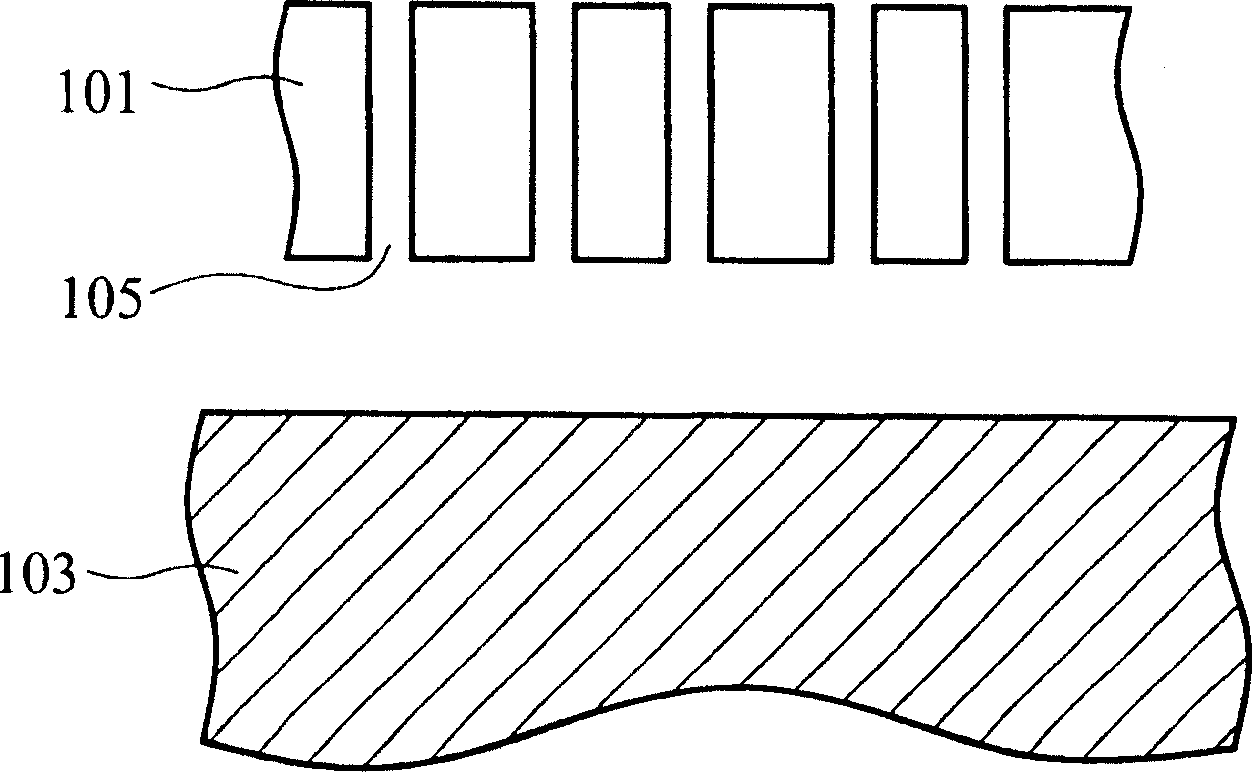

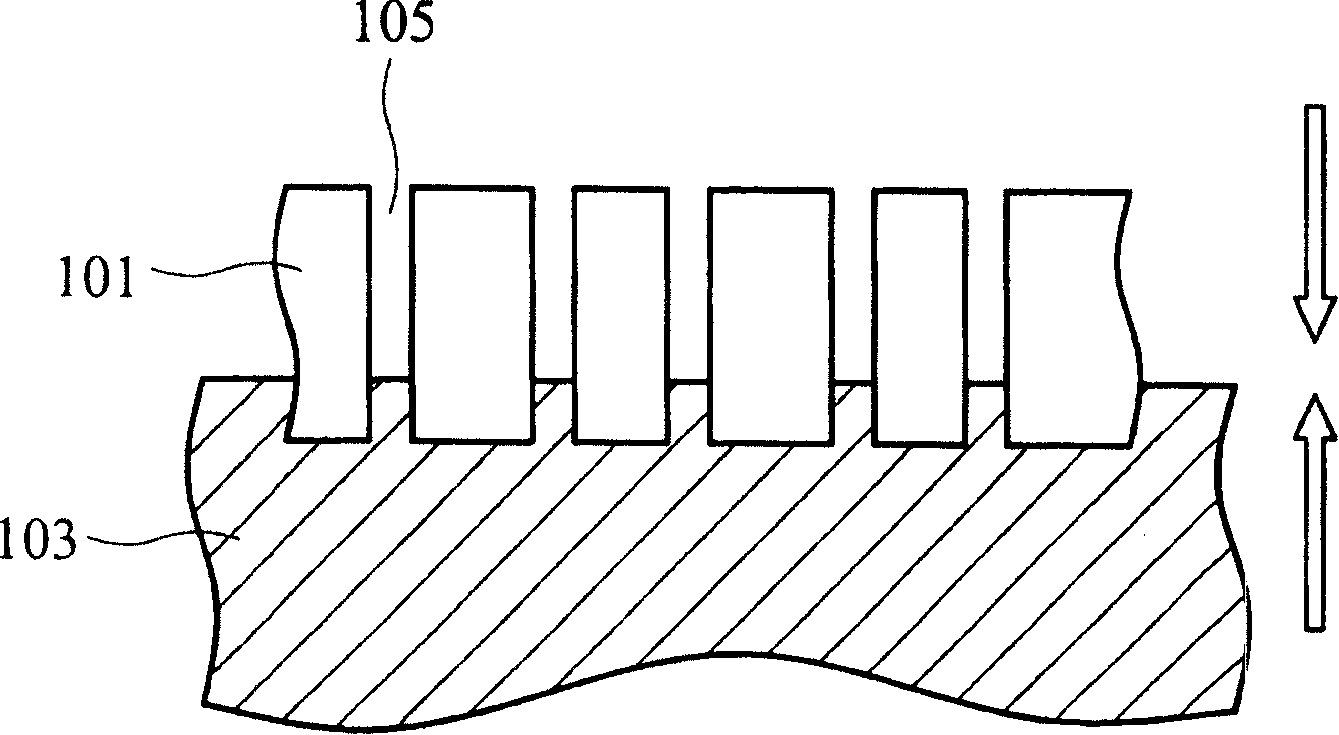

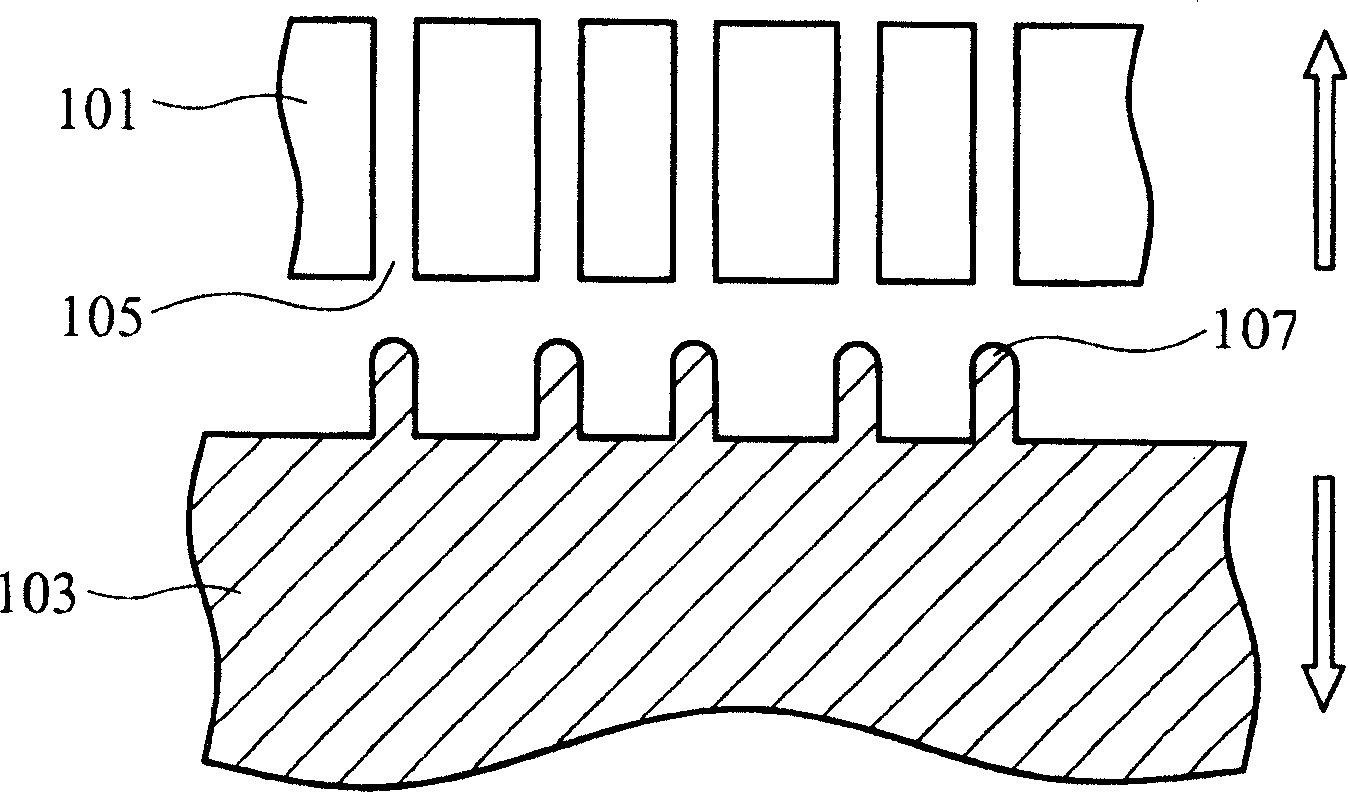

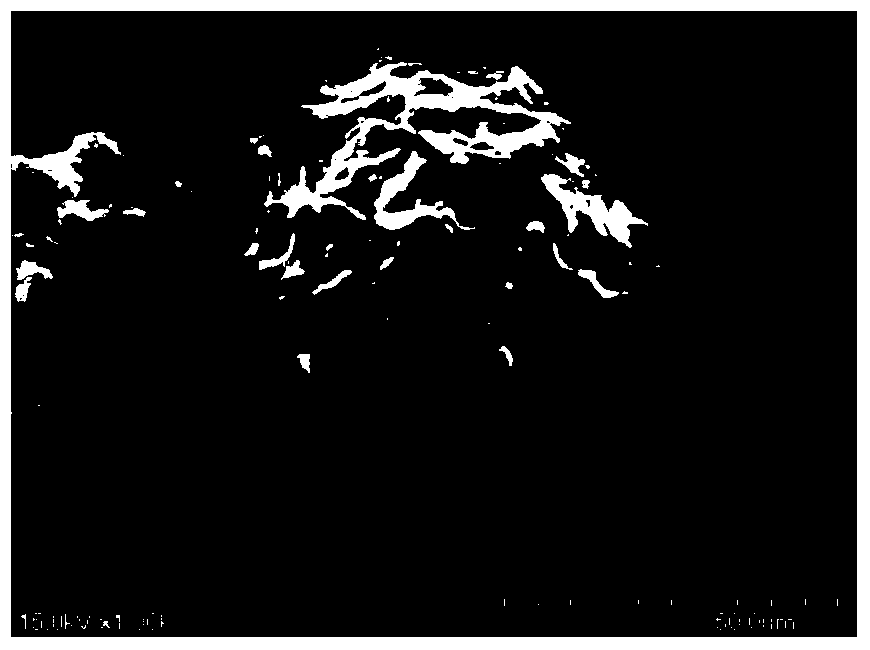

Nanometer array and method for forming the same

InactiveCN101177237AReduce surface reflectivityImprove surface affinityIndividual molecule manipulationCoatingsNanometreMaterials science

The invention provides a method forming nanometer array, which comprises a template with a plurality of nanometer holes; which is characterized in that pressing art is performed on a macromolecule base material for the template; the template is stripped, thereby a plurality of bulges on the macromolecule base material are formed.

Owner:IND TECH RES INST

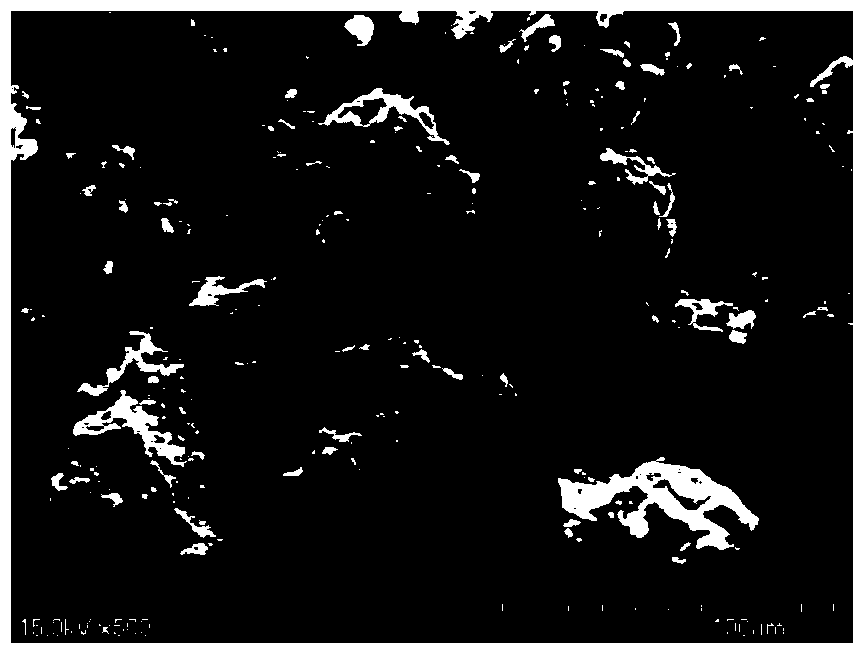

Organic/inorganic composite microspheres with core-shell structures and preparation method and application thereof

InactiveCN103626897AImprove surface affinityEasy to useMicroballoon preparationPigment treatment with macromolecular organic compoundsEmulsionControllability

The invention relates to organic / inorganic composite microspheres with core-shell structures and a preparation method and application thereof. The preparation method of the organic / inorganic composite microspheres comprises the steps of firstly, carrying out surface activation treatment on inorganic particles by using an organic coupling agent, so as to prepare lipophilic active inorganic particles with molecular bridges; adding the active inorganic particles into a homogeneous good solution where an organic polymer is dissolved, and thoroughly stirring and mixing, so as to form a monodisperse emulsion; slowly adding a non-solvent into the emulsion, so as to enable the organic polymer in the solution to be uniformly attached to the surfaces of the inorganic particles through the molecular bridges, repeatedly washing with the non-solvent, and drying, thereby preparing free-flowing organic / inorganic composite microspheres with the core-shell structures. Compared with the prior art, the preparation method disclosed by the invention has the characteristics of rapidness, simplicity, convenience, flexibility, controllability and the like, and can be applied to the preparation of any composite microsphere with an inorganic core-organic shell structure.

Owner:SHANGHAI RES INST OF CHEM IND

Road surface repairng material and its making method and use

InactiveCN1514063AReduce violenceImprove surface affinityRoads maintainenceEpoxy resin adhesivesRoad surfaceWear resistance

Owner:熊瑛

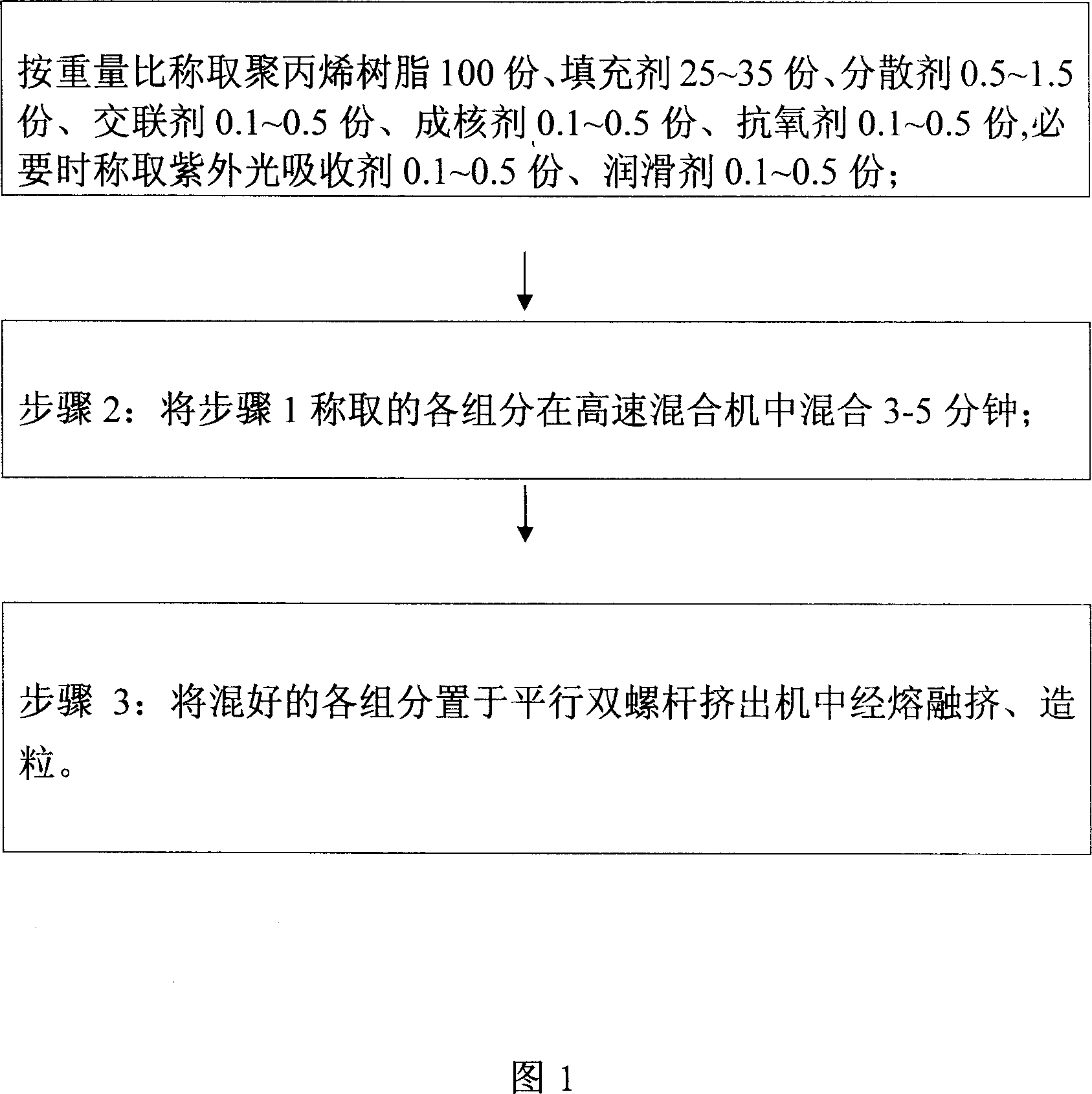

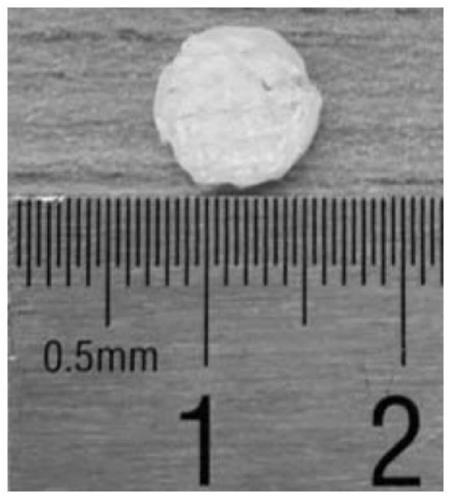

High glaze polypropylene material and preparation method thereof

A high-lustre polypropylene material and its production are disclosed. The material consists of polypropylene resin 100 proportion, filler nanometer calcium carbonate 25-35 proportion, dispersant 0.5-1.5 proportion, cross-linking agent diisopropylzene 0.1-0.5 proportion, beta-crystal nucleation agent 0.1-0.5 proportion, and antioxidant 0.1-0.5 proportion. It costs low, has better toughness and surface brightness on surface.

Owner:SHENZHEN KEJU NEW MATERIAL

PPS (polyphenylene sulfite)/LCP (liquid crystal polymer) composite material and preparation method thereof

The invention discloses a PPS (polyphenylene sulfite) / LCP (liquid crystal polymer) composite material and a preparation method thereof. The method comprises the following raw materials in parts by weight: polyphenylene sulfide, a liquid crystal polymer, a compatilizer, a filling and reinforcing agent, a lubricating agent and other aids. The preparation method comprises the following steps of: (a) respectively drying polyphenylene sulfide resin and the liquid crystal polymer; (b) uniformly mixing the filling and reinforcing agent, the lubricating agent and other aids; (c) mixing the raw materials processed in the steps (a) and (b) at a high speed, then adding the compatilizer and uniformly mixing; and (d) melting and extruding the mixed raw materials in the step (c) by using a double-screw extruder and granulating. The invention provides the PPS / LCP composite material having high strength and rigidity and also provides the preparation method of the PPS / LCP composite material with simple preparation process, low cost and good economic benefits.

Owner:SHENZHEN KEJU NEW MATERIAL

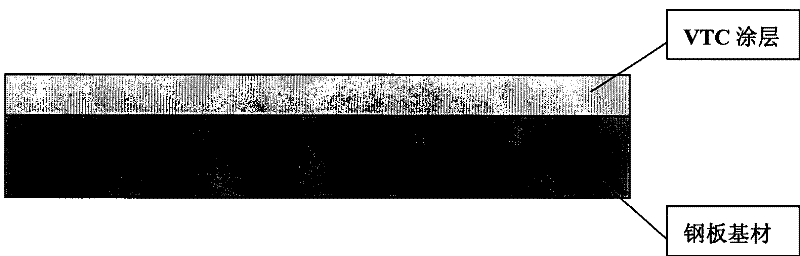

VCI-containing flake cold-plating zinc and aluminum protective coating on steel structure surface and preparation method thereof

ActiveCN101397413AHarsh salt spray resistanceGood anti-ultraviolet aging performanceAnti-corrosive paintsEpoxy resin coatingsCoating systemZinc

A squama type cold galvanizing aluminum coating used on the surface of steel structure and containing VCI (Vapor corrosion inhibitor). Besides, the invention also provides a VCI squama type cold galvanizing aluminum complex coating system on the surface of steel structure and prepared from the coating.

Owner:AVIC BIAM NEW MATERIALS TECH ENG

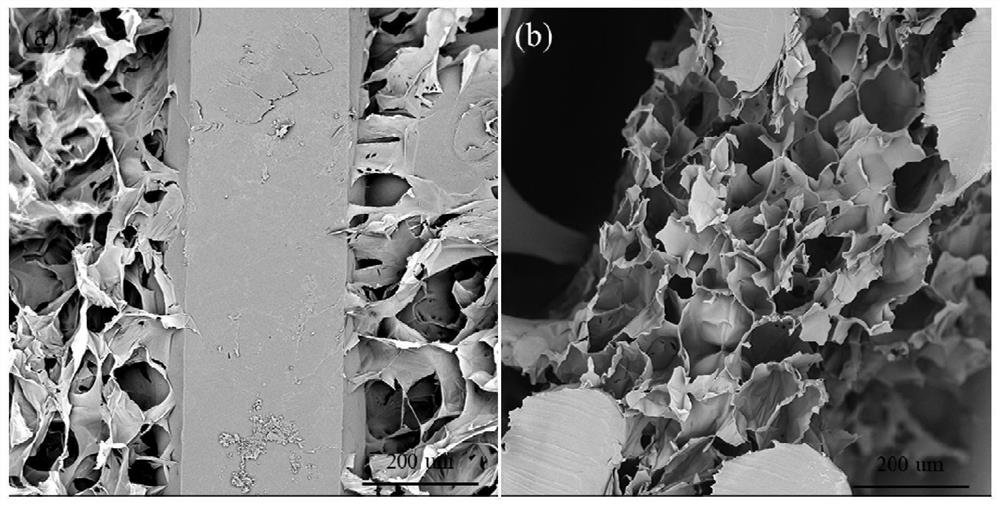

3D-printed degradable macromolecular scaffold and photo-crosslinked hydrogel composite scaffold

ActiveCN111166933AGood mechanical propertiesMany biologically active sitesTissue regenerationProsthesisPolymer scienceCell adhesion

The invention relates to a 3D-printed degradable macromolecular scaffold and photo-crosslinked hydrogel composite scaffold. The 3D-printed degradable macromolecular scaffold and photo-crosslinked hydrogel composite scaffold comprises a 3D-printed degradable macromolecular scaffold, wherein the interior of the 3D-printed degradable macromolecular scaffold comprises photo-crosslinked hydrogel with high substitution degree and photo-crosslinked hydrogel with low substitution degree, the photo-crosslinked hydrogel with high substitution degree is crosslinked with the photo-crosslinked hydrogel with low substitution degree, and preferably, a polycaprolactone (PCL) scaffold and methacrylic anhydride gelatin (GelMA) with different substitution degrees are crosslinked and compounded. In the composite scaffold, the 3D-printed degradable macromolecular scaffold has good mechanical properties; the photo-crosslinked hydrogel with high substitution degree has high crosslinking degree, can form a fiber network and micropores, and well supports cells; and the photo-crosslinked hydrogel with low substitution degree has multiple active sites, is beneficial to cell adhesion growth, and can adsorb alarge amount of nutrient solution. Through cooperation of the 3D-printed degradable macromolecular scaffold, the photo-crosslinked hydrogel with high substitution degree and the photo-crosslinked hydrogel with low substitution degree, the composite scaffold is suitable for cell growth and vascularization from an inner layer to an outer layer, and when the composite scaffold is used for medical human body repair, scaffold integration is realized to promote regeneration of new tissues.

Owner:NOVAPRINT THERAPEUTICS SUZHOU CO LTD

VCI-containing flake cold-plating zinc and aluminum protective coating on steel structure surface and preparation method thereof

ActiveCN101397413BNo pollution in the processImprove shielding effectAnti-corrosive paintsEpoxy resin coatingsCoating systemZinc

A squama type cold galvanizing aluminum coating used on the surface of steel structure and containing VCI (Vapor corrosion inhibitor). Besides, the invention also provides a VCI squama type cold galvanizing aluminum complex coating system on the surface of steel structure and prepared from the coating.

Owner:AVIC BIAM NEW MATERIALS TECH ENG

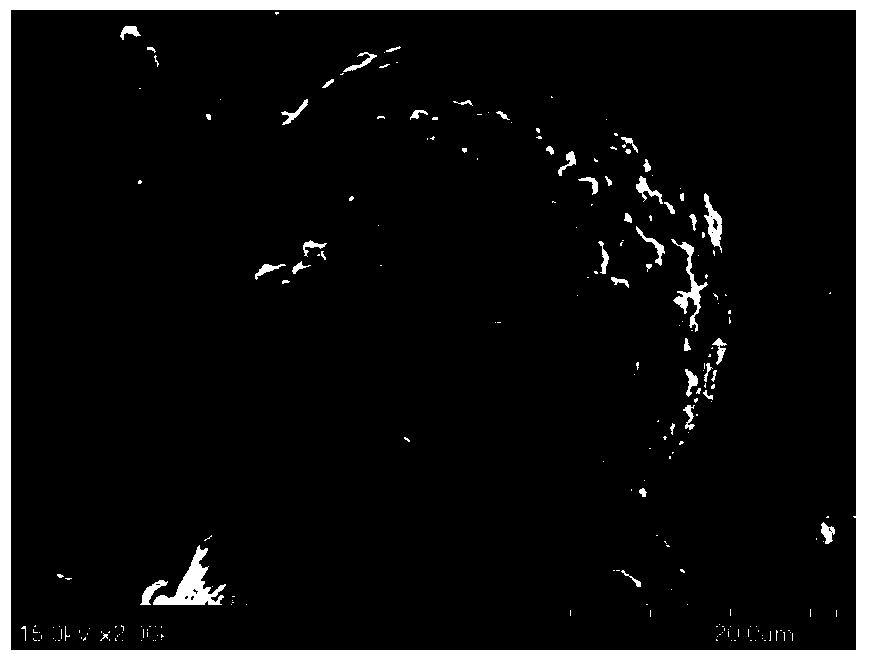

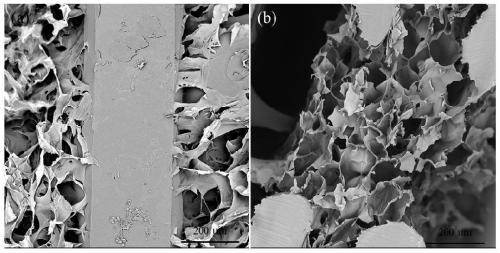

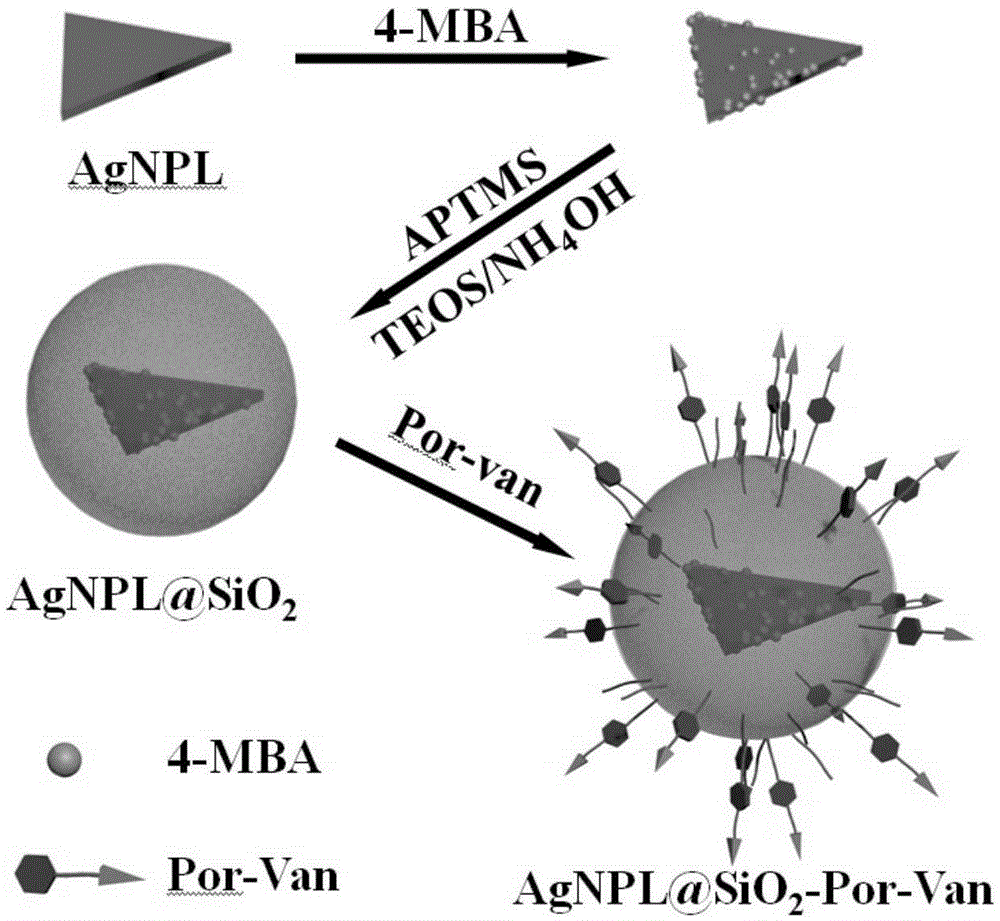

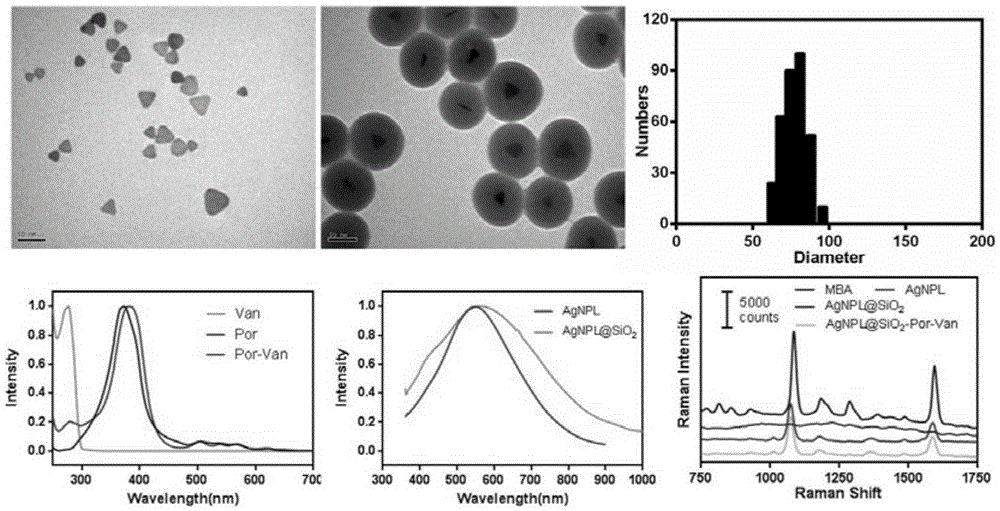

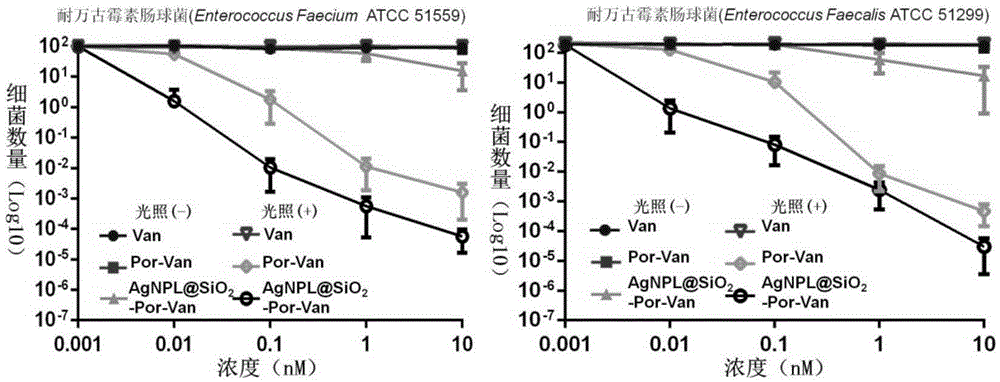

Composite nanometer antibacterial material used for treating vancomycin drug resistant pathogenic bacteria

InactiveCN105412940AImprove surface affinityHigh affinityAntibacterial agentsEnergy modified materialsSilica particlePorphyrin molecule

The invention discloses a composite nanometer antibacterial material and a preparing method thereof. The composite nanometer antibacterial material is used for solving the problems that conventional target photosensitive drugs are complex to synthesize and poor in biocompatibility. The nanometer antibacterial material is formed by a triangle silver nanometer sheet of a core-shell structure, silicon dioxide particles and vancomycin-porphyrin molecules on the surface. A core of the triangle silver nanometer sheet serves as a host material to form a surface enhanced Raman scattering (SERS) signal, a silicon dioxide shell serves as a rigid platform to couple the vancomycin-porphyrin molecules to form a poly mode. The synthesis cost of the nanometer antibacterial material is low, the preparing method is simple, and the material has good biocompatibility and tissue permeability; in addition, the invention further discloses application to Raman images and photodynamics treatment of vancomycin drug resistant pathogenic bacteria.

Owner:LUDONG UNIVERSITY

Openpore coating for cold-hot combined machine

InactiveCN101705050ASimple recipeImprove surface affinityPolyurea/polyurethane coatingsHot stampingAcrylic resin

The invention relates to an openpore coating for a cold-hot combined machine, in particular to an openpore coating which can improve surface affinity during printing and belongs to the field of coatings. The openpore coating is prepared by mechanically and physically stirring the following raw materials in part by weight: 35 to 45 parts of waster-based acrylic resin, 40 to 50 parts of waster-based polyurethane resin, 2 to 6 parts of ethanol, 2 to 6 parts of isopropanol, 0.5 to 1.5 parts of defoaming agent and 0.2 to 1 part of wetting agent. The openpore coating has the characteristics of achieving high surface affinity, realizing a process of firstly printing and secondly stamping in the cold-hot stamping process, greatly decreasing production cost, improving production speed and the like.

Owner:浙江爱迪尔包装股份有限公司

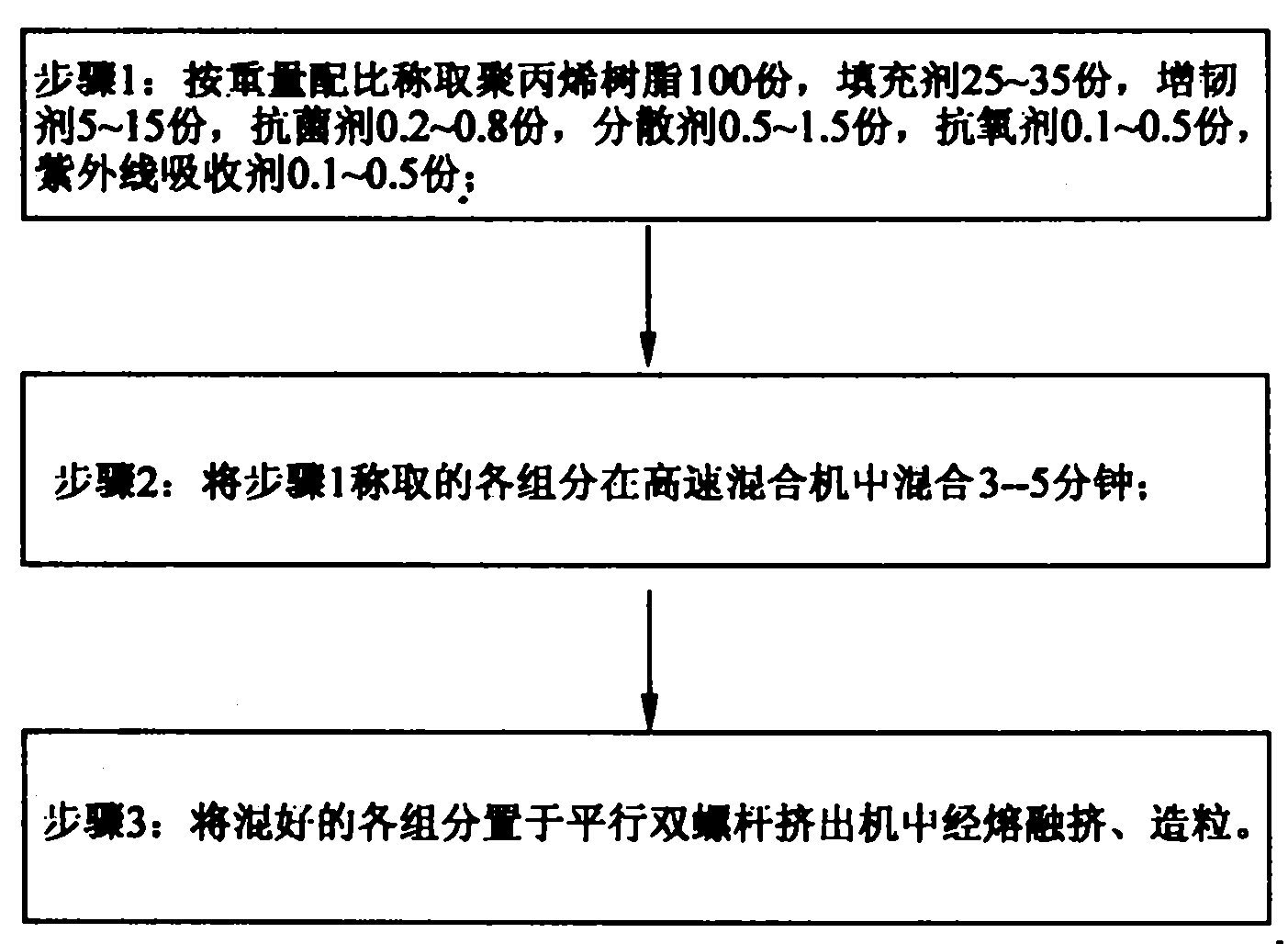

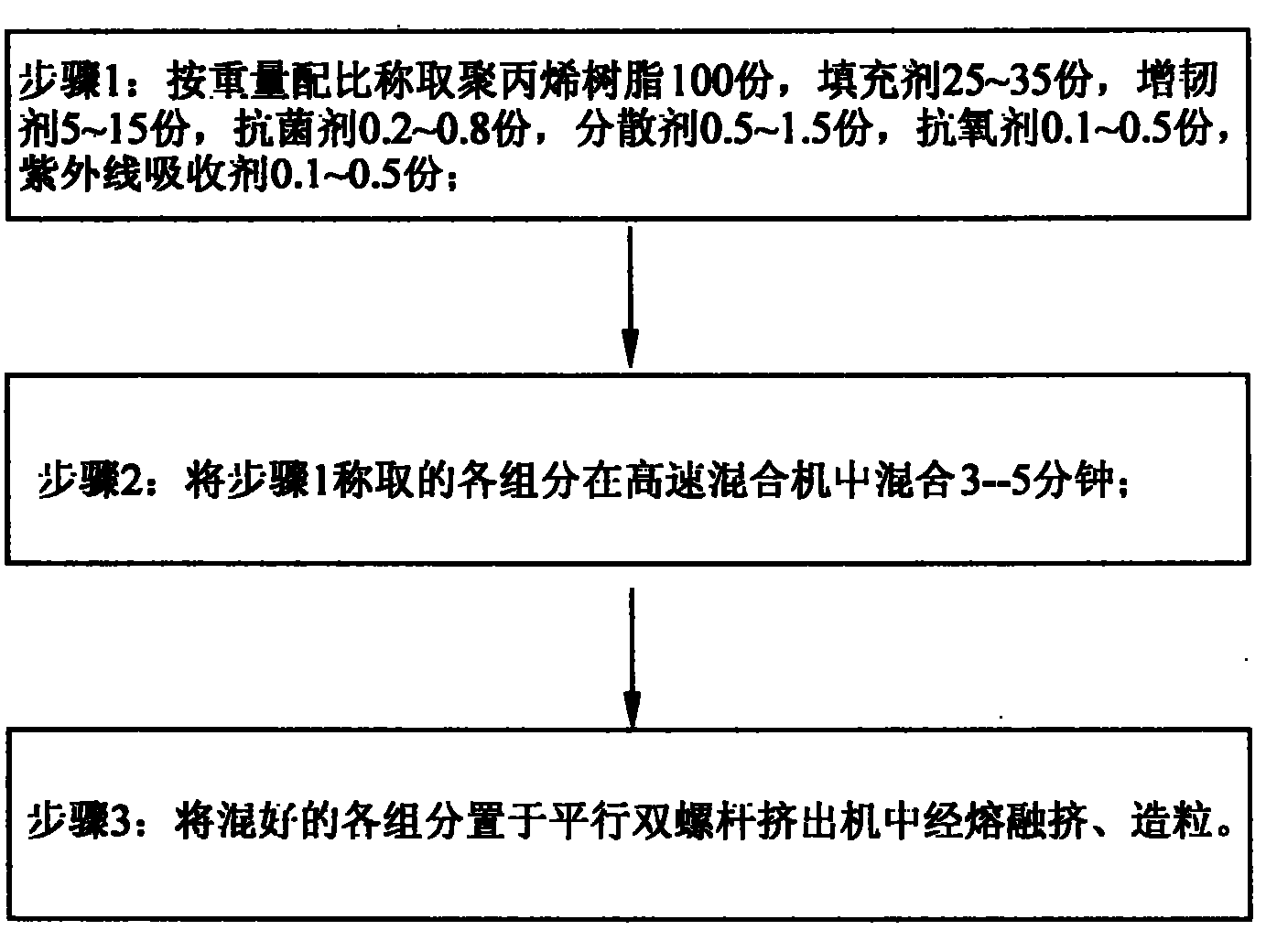

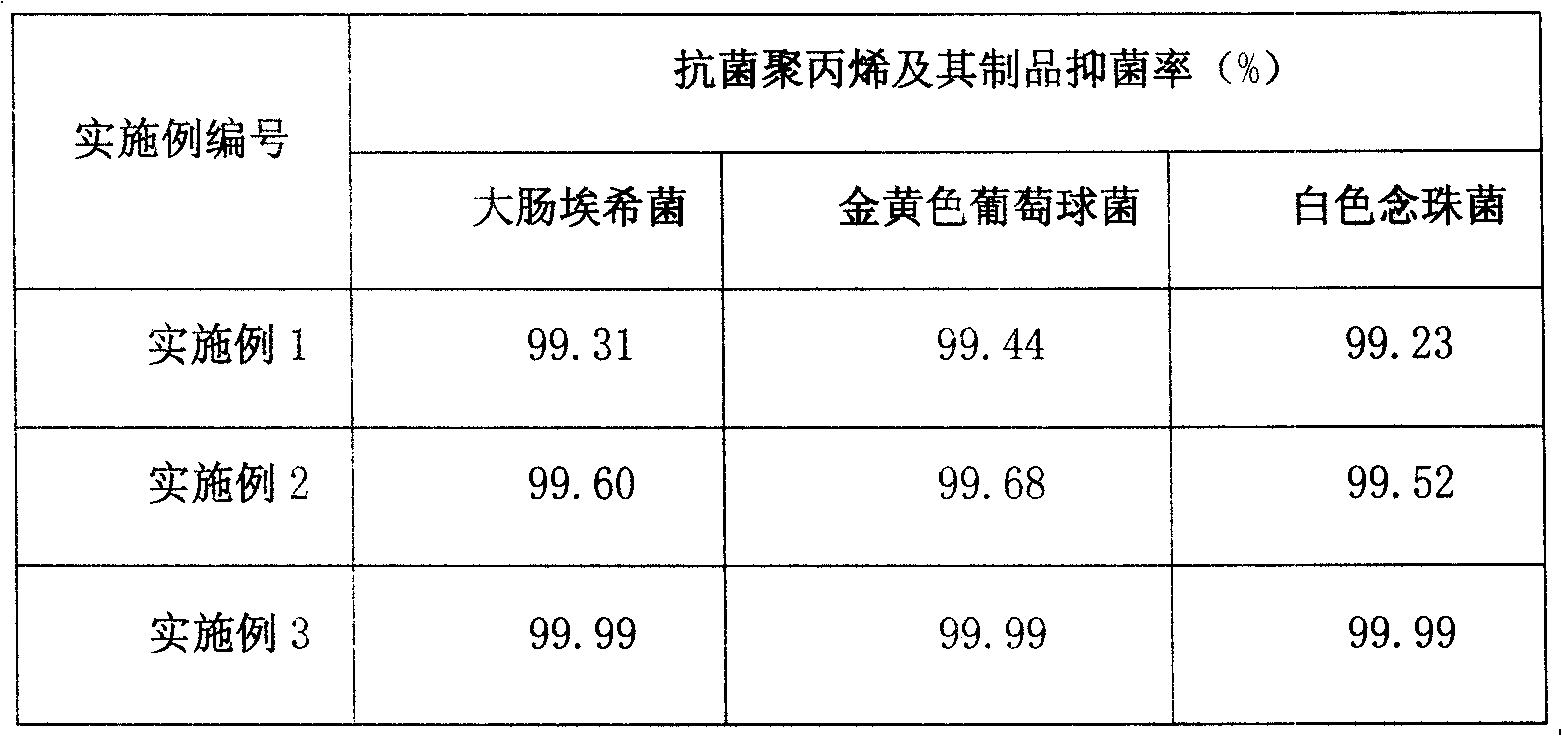

Antibacterial polypropylene material and its preparation process

InactiveCN101089038BReduce manufacturing costHigh surface glossBiocideAnimal repellantsUltravioletPolypropylene

The antibacterial polypropylene material consists of polypropylene resin 100 weight portions, stuffing 25-35 weight portions, toughening agent 5-15 weight portions, antiseptic 0.2-0.8 weight portion, dispersant 0.5-1.5 weight portions, antioxidant 0.1-0.5 weight portion and ultraviolet absorber 0.1-0.5 weight portion. The polypropylene resin is homopolypropylene, and the antiseptic is compounded with nanometer silver and organosilicon antiseptic. The present invention also provides the preparation process of the antibacterial polypropylene material with low production cost, excellent antiseptic performance.

Owner:SHENZHEN KEJU NEW MATERIAL

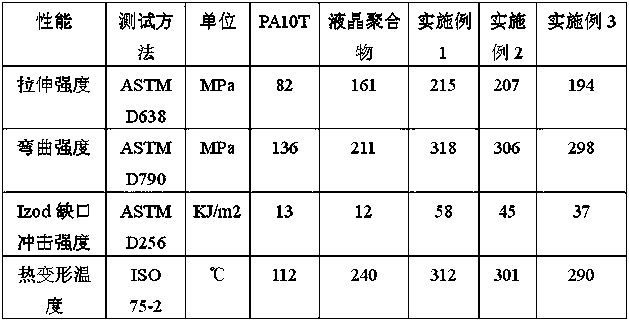

Liquid crystal polymer/ semi-aromatic nylon alloy material and preparation method thereof

InactiveCN103804901AImprove toughnessIncrease the rate of crystallizationProcedure AgentsLiquid-crystal display

The invention discloses a liquid crystal polymer / semi-aromatic nylon alloy material and a preparation method thereof. The alloy material is prepared through the raw materials of semi-aromatic nylon, a liquid crystal polymer, a compatilizer, a filling reinforcing agent, a lubricating agent and other processing aids. The preparation method comprises the following steps of: (1) respectively drying the semi-aromatic nylon and the liquid crystal polymer, uniformly mixing the lubricating agent with the processing aids, and drying; (2) adding all raw materials processed in step (1), mixing in a high-speed mixer at a high speed, then adding the compatilizer, and uniformly mixing; and (3) adding the filling reinforcing agent to the materials mixed in step (2), performing melt extrusion through a twin-screw extruder, and then pelletizing. The liquid crystal polymer / semi-aromatic nylon alloy material has the advantages of high strength, high rigidity and resistance to high temperature; and the preparation method is simple in process, low in cost and high in economic benefit.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Easily secondarily modified polydopamine coated modified calcium carbonate powder with high reaction activity and preparation method of powder

InactiveCN106590044AHigh oil absorptionGood dispersionPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsTitanateChemistry

The invention discloses easily secondarily modified polydopamine coated modified calcium carbonate powder with high reaction activity. A polydopamine film is modified on the surface of calcium carbonate, the surface of the polydopamine film contains a large number of active functional groups, more possibility is provided for further modification of the calcium carbonate powder, the modified powder is modified by titanate coupling agents, modification effects are more excellent, oil absorption, dispersibility and surface affinity of the obtained calcium carbonate powder are effectively improved, reaction activity with various systems is higher, and the powder is more economical and efficient and wider in use range.

Owner:QINGYANG COUNTY YONGCHENG CALCIUM IND

Preparation method of high-retention decorative-laminated-paper titanium oxide powder

InactiveCN107254197AHigh glossImprove retentionInorganic pigment treatmentPhosphoric acidALUMINUM PHOSPHATE

The invention discloses a preparation method of titanium dioxide for decorative laminated paper with high retention rate, and belongs to the technical field of titanium dioxide production. The invention firstly uses aluminum sulfate octadecahydrate as a raw material, controls the precipitation morphology through ammonia water, and obtains nano-flaky alumina, which is modified by tin tetrachloride, a silane coupling agent and the like and used as a template, and then titanium tetrachloride is used as a template. As a titanium source, the nano-sheet alumina is coated, and then the aluminum phosphate layer and the alumina layer are sequentially coated to obtain a mixed solution of re-coated titanium dioxide. The titanium dioxide for decorative laminated paper with high retention rate can be obtained by grinding. The titanium dioxide prepared by the invention can improve the light resistance, dispersibility and hiding power of the titanium dioxide in the laminated paper very well, and can meet the requirements of titanium dioxide for laminated paper. requirements.

Owner:朱文杰

High-strength toughened silver mirror production process

The invention discloses a high-strength toughened silver mirror production process comprising the following steps: pretreatment, polishing, sensitization, hypersensitization, redox, passivation, paintspraying, and formation of a finished product. The process overcomes the deficiencies in the prior art, and can effectively improve the surface affinity of a toughened glass and a silver layer; the toughened silver mirror prepared by the process has the advantages of high strength, impact resistance, high safety, high thermal stability and the like of the toughened glass, and also has the characteristics of no deformation, no distortion, high reflectivity, corrosion resistance and the like; by improving the conventional silver mirror production process and using environment-friendly materials, the process reduces pollution and lowers energy consumption.

Owner:合肥市老兵玻璃有限公司

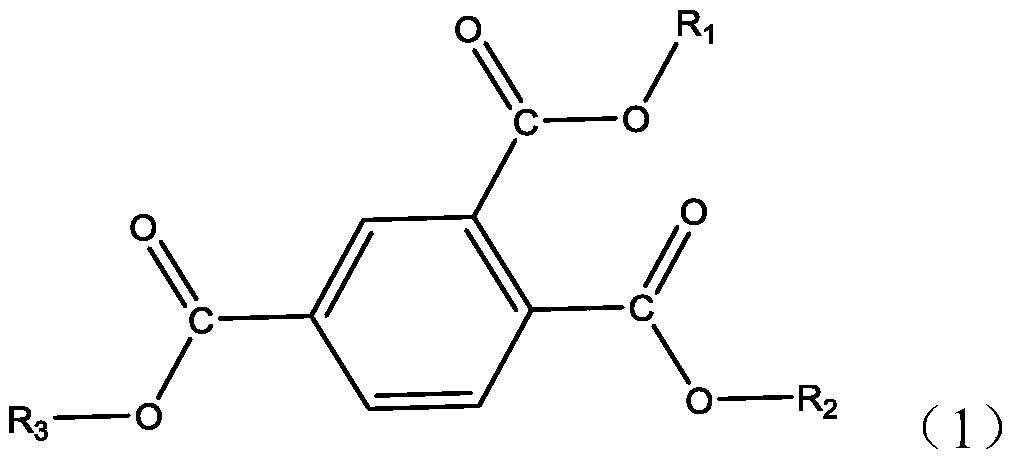

Silicon-free oiling agent for carbon fiber precursor

ActiveCN110670350AEnsure uniformity of qualityAvoid softeningFibre typesFibre chemical featuresBenzoic acidPolymer science

The invention discloses a silicon-free oiling agent for carbon fiber precursor. The silicon-free oiling agent comprises an aqueous emulsion prepared by dispersing aromatic ester compounds, aromatic polyoxyethylene ether and amine compounds, by the mass ratio of (50-80):(10-35):(1-5), in water; the aromatic ester compounds include one or more of benzene tricarboxylic acid esters, benzene dioctyl phthalate esters, hydroxy-benzoate esters and bisphenol ethoxide high-grade fatty acid esters; aromatic polyoxyethylene ether includes one or more of alkylphenol polyoxyethylene and bisphenol-A polyoxyethylene ether; the amine compounds include one or more of lauramide ethoxide, aliphatic long-chain quaternary ammonium; the survival rate of mass of the aromatic ester compounds is 80-98% at the temperature of 300 DEG C in the atmosphere of air, and the mass ratio of the aromatic ester compounds in involatile components of the oiling agent is 50-80%. Roll banding degree of the precursor in production can be reduced effectively, doubling and adhering of PAN filaments in the pre-oxidation process can be avoided, and the silicon-free oiling agent has certain hydrophilicity and heat resistance.

Owner:HENGSHEN

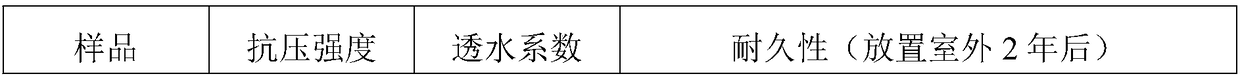

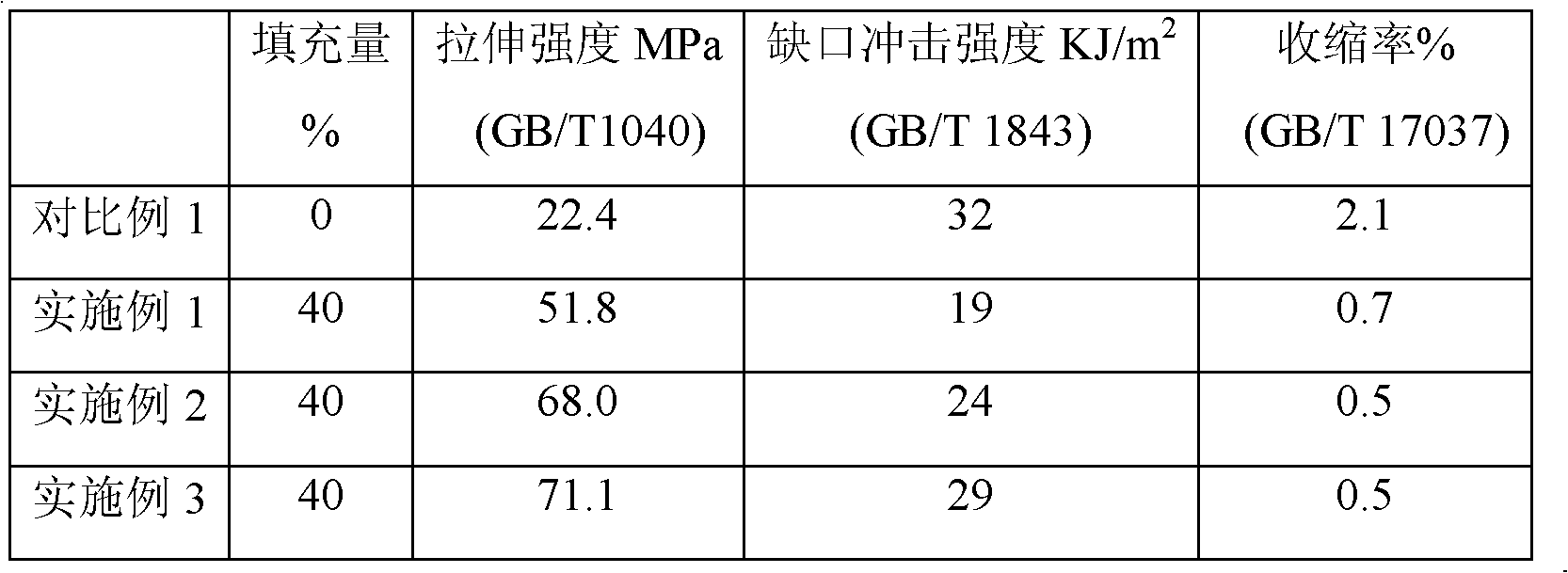

Carbon fiber reinforced water permeable concrete and preparation method thereof

The invention relates to carbon fiber reinforced water permeable concrete and a preparation method thereof. The technical problems that water permeable concrete in the prior art has low compressive strength, poor durability, a poor water permeation effect and a short service life. According to the provided carbon fiber reinforced water permeable concrete and the preparation method thereof, the concrete is prepared from, by weight, 130-170 parts of cement, 20-30 parts of steel slag, 15-22 parts of magnesium oxide, 13-15 parts of calcium oxide, 16-30 parts of coal gangue, 15-30 parts of fly ash,2-6 parts of epoxy acrylate resin, 2-2.5 parts of polypropylene fiber, 10-30 parts of chopped carbon fiber, 40-60 parts of gravel, 20-30 parts of coarse sand, 0.5-0.8 part of lithium carbonate, 2-5 parts of nonionic surfactant and 170-182 parts of water; at the same time, the preparation method of the concrete is also provided. The carbon fiber reinforced water permeable concrete and the preparation method thereof are widely used in the technical field of road materials.

Owner:威海南海碳材料科技研究院有限公司

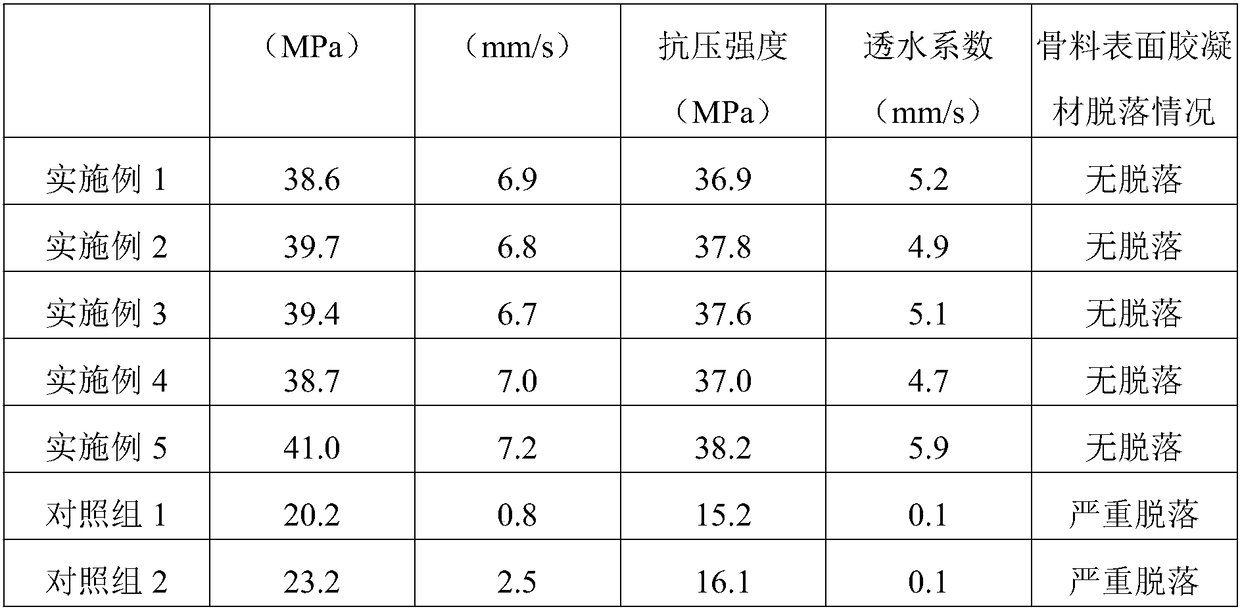

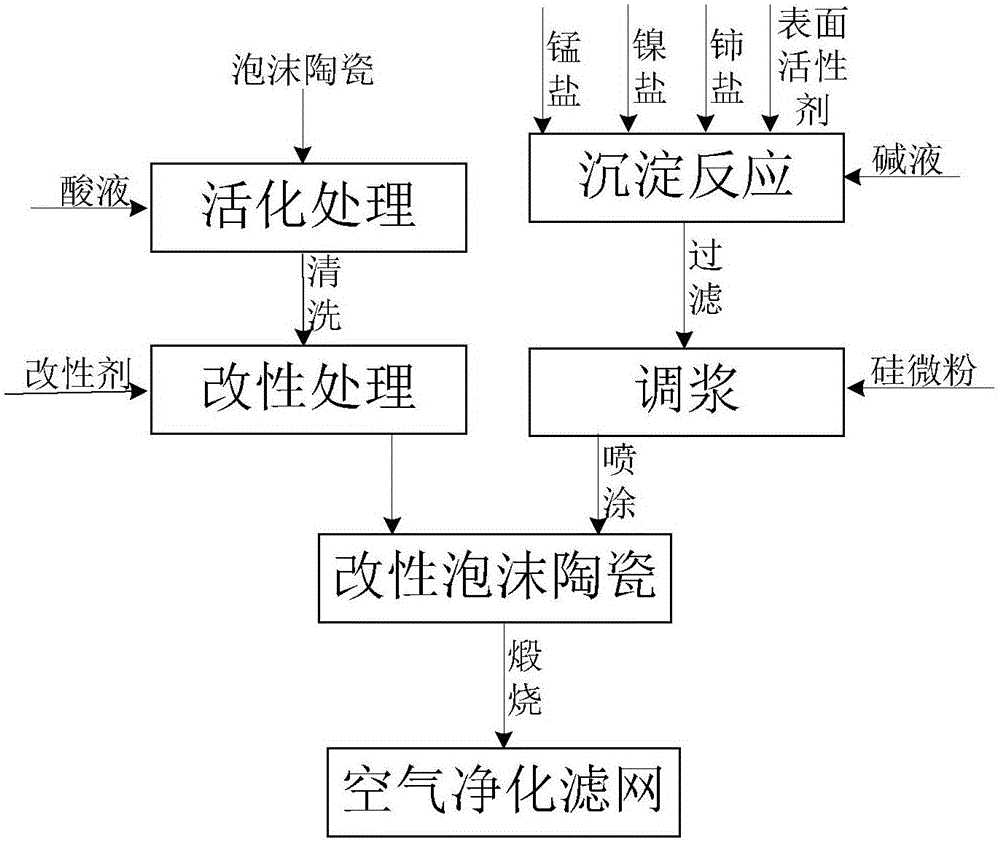

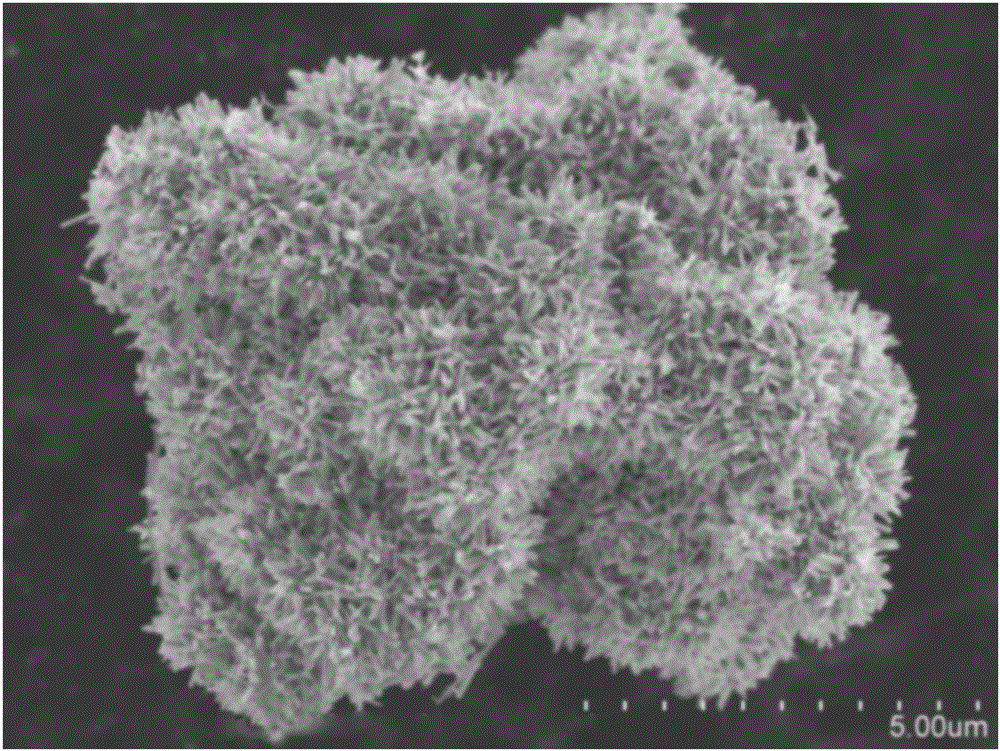

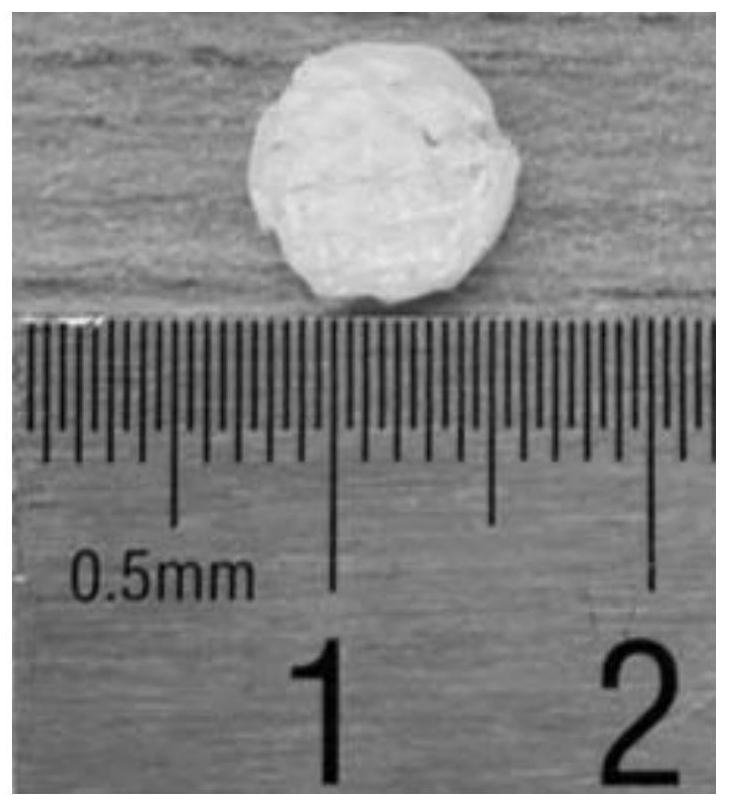

Air purifying filter screen and preparation method thereof

ActiveCN106110763AImprove purification efficiencyImprove the safety of useHeterogenous catalyst chemical elementsFiltration separationNickel saltSlag

The invention discloses an air purifying filter screen and a preparation method thereof; the air purifying filter screen is composed of a carrier and a catalyst; the carrier is composed of foam ceramics, and the foam ceramics are activated by an acid activator and then are subjected to surface modification by a surface modification agent; the catalyst comprises manganese oxide, nickel oxide and cerium oxide. The preparation method of the air purifying filter screen comprises the steps: soaking the foam ceramics with the acid activator, carrying out activating treatment of the surface and internal gaps of the foam ceramics with the acid activator, then soaking the cleanly washed foam ceramics with the surface modification agent, dissolving a manganese salt, a nickel salt, a cerium salt and a surfactant in water, stirring the components at room temperature, then adding a strong alkali, adjusting the pH to 8.0-10.5, carrying out a reaction for 1-30 h, then filtering, and mixing the obtained filter slag with a silica micro-powder to obtain slurry; spaying the slurry to the surface and the pore passage interior of the carrier by a spraying machine; and finally, calcining for 0.5-6 h at the temperature of 200-450 DEG C. The prepared purifying filter screen has the characteristics of small wind resistance, firm adhesion and high purification efficiency.

Owner:UCHEER PURIFICATION & POLLUTION CONTROL TECH ZHEJIANG CO LTD

Method for improving dyeing rate of flax blended fiber fabric

PendingCN110804885AImprove surface affinityFacilitates adsorption and diffusionDyeing processFlax fiberDyeing

The invention relates to the technical field of dyeing and environmental protection, and discloses a method for improving the dyeing rate of a flax blended fiber fabric. Through the study of a fiber structure and a dyeing principle, the problems that in an existing process, flax blended fibers are adopted to process a fabric, the dyeing efficiency is low, dyeing is uneven and the cost is over highare solved, and the method comprises the steps of preparation of a dyeing accelerant, pretreatment before dyeing of the flax blended fiber fabric, dyeing process and air drying and washing. The prepared dyeing accelerant has a nano-scale titanium dioxide coating shell structure. The surface affinity of the flax fibers can be remarkably improved, and dye molecules can rapidly penetrate into the fibers. Diffusion and adsorption of the dye on the surface of a fiber fabric are promoted, and the dyeing is facilitated; the dyeing rate of the flax blended fiber fabric can be improved, and the dyed product is uniform in color and high in firmness; the application range of the flax fibers in the textile field is expanded; and by the process, the defects in the dyeing process of an existing flax blended fiber fabric can be overcome well.

Owner:界首市苏澳纺织科技有限公司

High-surface adhesion coating for rattan wickerwork

The invention discloses high-surface adhesion coating for a rattan wickerwork, and relates to the technical field of wickerwork treatment. The high-surface adhesion coating is prepared from the following components: a silicone-acrylic emulsion, glucosan-modified polyvinyl alcohol, beta-hydroxyalkylamide, a composite filler, an emulsifier and water. The silicon-acrylic emulsion is used as a basic component of the coating; through addition of the beta-hydroxyalkylamide in the coating system, the surface affinity of the prepared coating to the rattan wickerwork can be effectively improved, and the adhesion of the rattan wickerwork to the coating can be improved; through use of the glucosan-modified polyvinyl alcohol, the glucosan-modified polyvinyl alcohol can be chemically bonded with the molecular chain of a film-forming substance which forms the coating in the coating system, so that the structure of the whole coating system is greatly improved; meanwhile, the glucosan-modified polyvinyl alcohol has more significant adsorption, and can greatly improve the surface adhesion of the coating to the rattan wickerwork; through addition of the composite filler, the coating hardness is effectively improved.

Owner:阜南县中泰工艺品有限公司

Tire repairing agent and preparation method thereof

The invention discloses a tire repairing agent and a preparation method thereof. The tire repairing agent consists of the following raw materials: deionized water, polyvinyl alcohol, methylcellulose,turpentine oil, triethylamine, azodiisobutyronitrile, sodium hydrogen persulfate, bamboo powder, nano-calcium carbonate, an alcohols antifreezing agent, rubber granules, calcined gypsum, sodium nitrite and natural latex. The grain size of the bamboo powder is 0.1-2 mm; the grain size of the rubber granules is 0.1-2 mm; the polymerization degree of the polyvinyl alcohol is 1,500-2,500; and the massratio of the turpentine oil, the triethylamine, the azodiisobutyronitrile and the sodium hydrogen persulfate is (0.5-3): (0.1-1): (0.1-1): (0.1-1), and the tire repairing agent is prepared by the steps of mixing of multiple layers of raw materials, stirring and the like. Compared with the prior art, the product has the characteristic that the airtightness and injection performance are further improved.

Owner:CHANGSHA WUDAO IND DESIGN CO LTD

A composite scaffold of 3D printed degradable polymer scaffold and photocrosslinked hydrogel

ActiveCN111166933BIncrease the degree of cross-linkingImprove mechanical propertiesTissue regenerationProsthesis3d printPolymer science

The invention relates to a 3D-printed degradable macromolecular scaffold and photo-crosslinked hydrogel composite scaffold. The 3D-printed degradable macromolecular scaffold and photo-crosslinked hydrogel composite scaffold comprises a 3D-printed degradable macromolecular scaffold, wherein the interior of the 3D-printed degradable macromolecular scaffold comprises photo-crosslinked hydrogel with high substitution degree and photo-crosslinked hydrogel with low substitution degree, the photo-crosslinked hydrogel with high substitution degree is crosslinked with the photo-crosslinked hydrogel with low substitution degree, and preferably, a polycaprolactone (PCL) scaffold and methacrylic anhydride gelatin (GelMA) with different substitution degrees are crosslinked and compounded. In the composite scaffold, the 3D-printed degradable macromolecular scaffold has good mechanical properties; the photo-crosslinked hydrogel with high substitution degree has high crosslinking degree, can form a fiber network and micropores, and well supports cells; and the photo-crosslinked hydrogel with low substitution degree has multiple active sites, is beneficial to cell adhesion growth, and can adsorb alarge amount of nutrient solution. Through cooperation of the 3D-printed degradable macromolecular scaffold, the photo-crosslinked hydrogel with high substitution degree and the photo-crosslinked hydrogel with low substitution degree, the composite scaffold is suitable for cell growth and vascularization from an inner layer to an outer layer, and when the composite scaffold is used for medical human body repair, scaffold integration is realized to promote regeneration of new tissues.

Owner:NOVAPRINT THERAPEUTICS SUZHOU CO LTD

High-performance layering-resistant pavement rubber concrete

The invention provides high-performance layering-resistant pavement rubber concrete which is prepared from the following raw materials: cement, fly ash, river sand, rubber aggregate, modified rubber powder, steel slag coarse aggregate, a water reducing agent, a reinforcing auxiliary agent and water, has the characteristics of high loading capacity, high deformation resistance, high toughness and high durability, and can be used for highway pavement engineering under heavy traffic.

Owner:沃克豪斯(黄冈)绿色建材有限公司

High-gloss and high-impact resistance PS / PP composite for manufacturing telephone case and preparation method thereof

The invention discloses a high-gloss and high-impact resistance PS / PP composite for manufacturing a telephone case and a preparation method thereof. The composite is mainly prepared by the following raw materials by weight portion: 100 portions of PS resin, 20-60 portions of PP resin, 5-15 portions of compatilizer, 3-30 portions of flexibilizer, 0.1-0.9 portion of nucleator and 0.1-0.9 portion of antioxidant. The PS raw material and the PP raw material are fused together by the special compatilizer. The prepared composite has the high-gloss and high-impact resistance features and excellent physical and mechanical properties, and can be used for replacing ABS to manufacture the telephone case. The composite has the characteristics of simple preparation technology, stable size, high gloss, high impact resistance, low cost, and the like.

Owner:ANHUI KEJU NEW MATERIALS

Preparation method of core-shell talc powder-polypropylene composite material

The invention relates to a preparation method of a core-shell talc powder-polypropylene composite material. The method comprises the following steps of: mixing talc powder with a coupling agent for 3-10 minutes to obtain talc powder activated by using the coupling agent; adding toluene and a catalyst, introducing propylene gas till propylene is dissolved in a balanced way, keeping the total pressure of a system at 140kPa, keeping the temperature at 30-60 DEG C, and undergoing a polymerization reaction with stirring for 1-3 hours; and filtering a product, washing repeatedly with alcohol, drying in vacuum at the temperature of 40-70 DEG C, and weighing to obtain the core-shell talc powder-polypropylene composite material. The material surface of the core-shell talc powder-polypropylene composite material prepared with the method is uniformly coated by polypropylene, a special structure connected through the covalent bond of the coupling agent is formed between the polypropylene and talcum powder, the core-shell talc powder-polypropylene composite material is used for filling polypropylene and has high compatibility, the strength, toughness, heat resistance and blocking property of the polypropylene can be greatly improved, and the size stability of a product is improved.

Owner:HEFEI GENIUS NEW MATERIALS

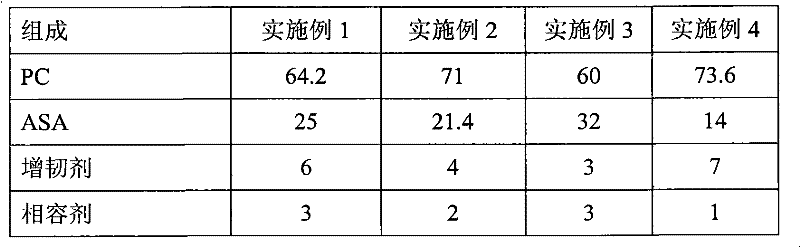

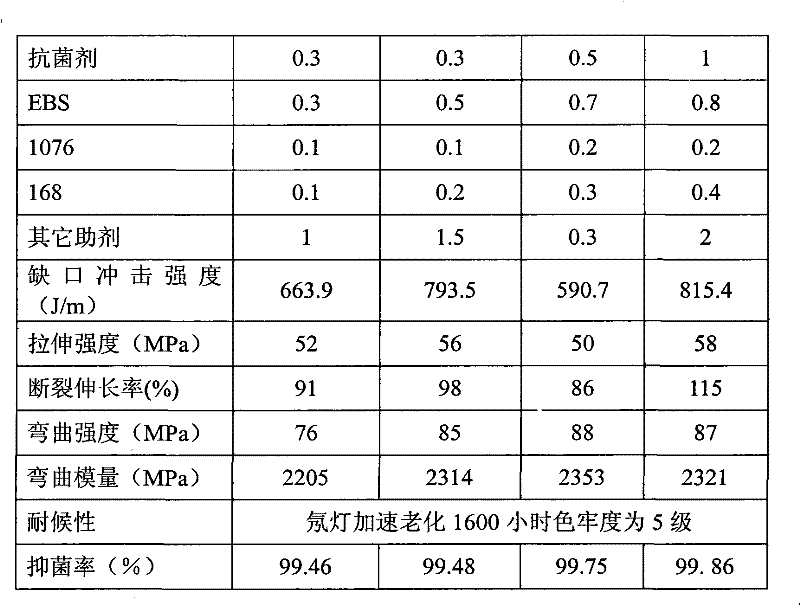

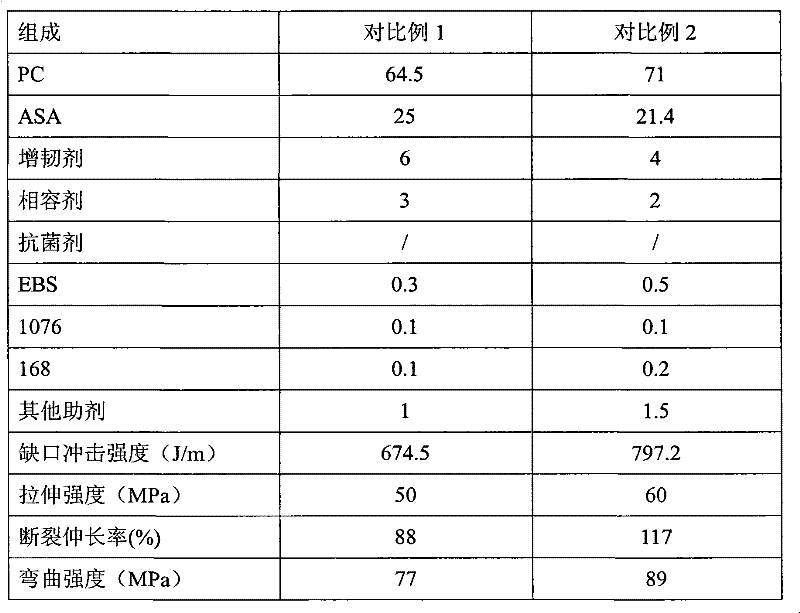

Weatherproof and antibacterial polycarbonate engineering plastic and preparation method thereof

The invention discloses a weatherproof and antibacterial polycarbonate engineering plastic and a preparation method thereof. The engineering plastic is prepared from the following raw materials in part by weight: polycarbonate, weatherproof resin ASA, an antibacterialagent, a flexibilizer, a compatilizer, a dispersing agent, an antioxygen and other aids. The preparation method comprises the following steps: a, respectively performing force air drying on the polycarbonate and the weatherproof resin ASA; b, weighing the antibacterialagent and the dispersing agent, and mixing the two uniformly; c, weighing the flexibilizer, the compatilizer, the antioxygen and other aids, and putting into a super mixer for dry mixing, together with raw materials in step a and step b; and d, putting the mixedmaterials in the step c into a twin-screw extruder, and performing melt extrusion for granulation. The weatherproof and antibacterial polycarbonate engineering plastic has the advantages of ageing resistance, yellowing resistance, good weatherability, and durable antibacterial function.

Owner:SHENZHEN KEJU NEW MATERIAL

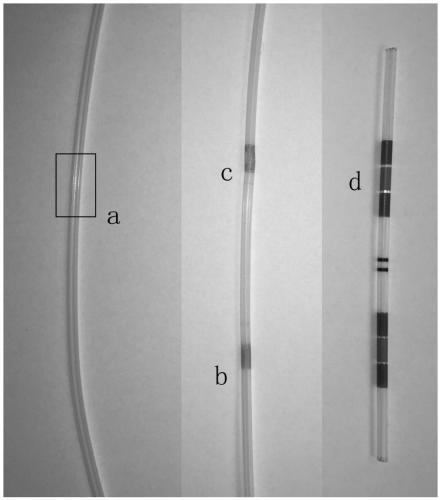

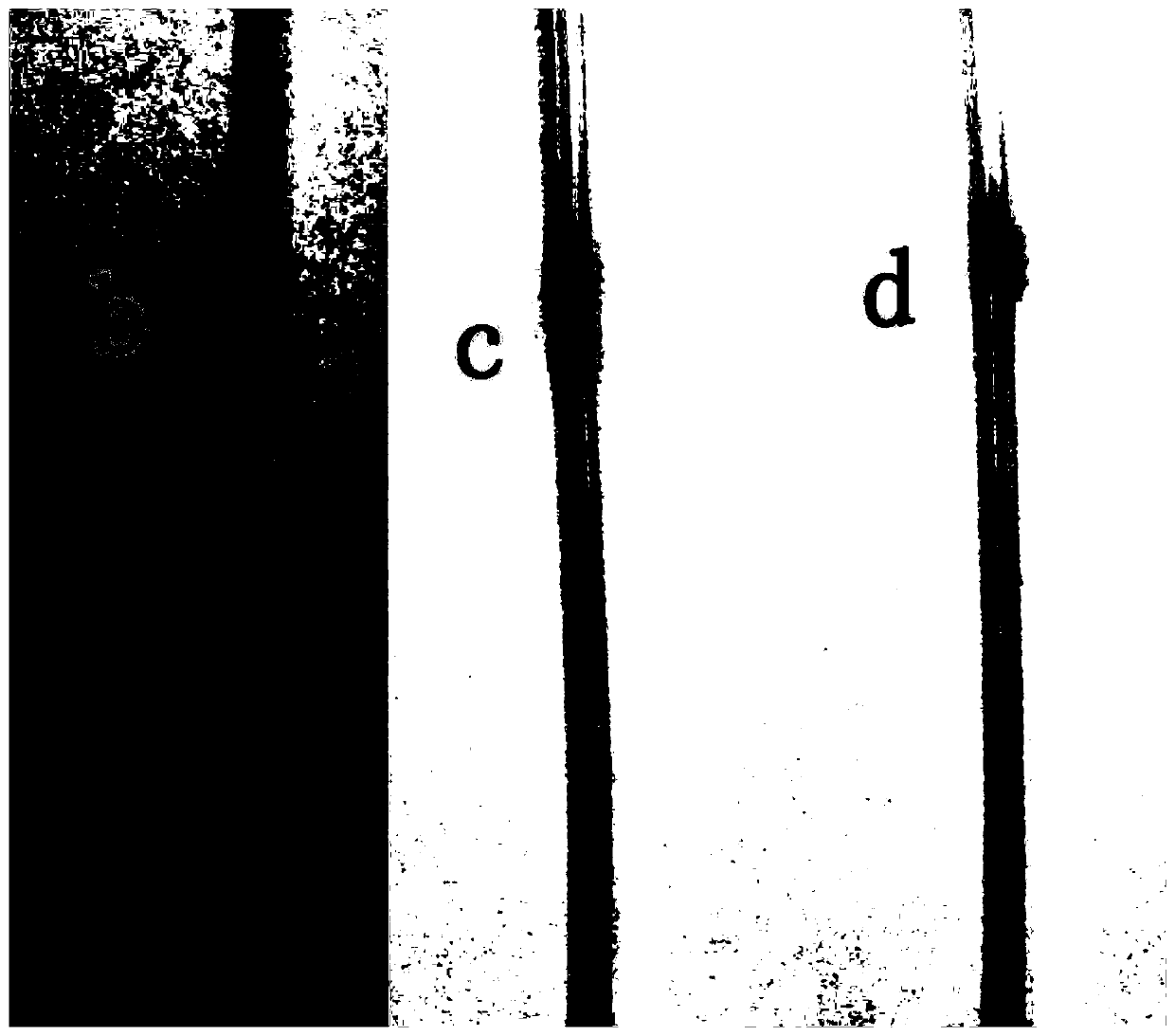

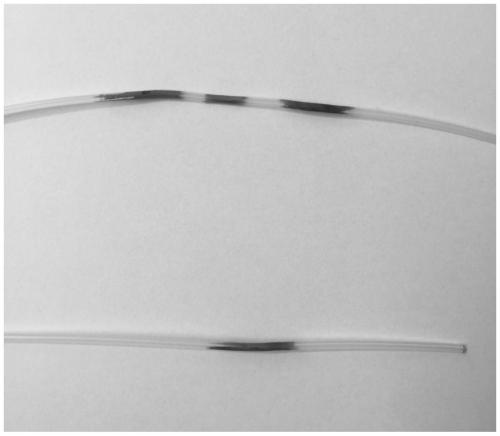

Polytetrafluoroethylene tube ribbon coating preparation method and polytetrafluoroethylene tube

ActiveCN109942867ALower surface energyImprove surface reactivityVacuum evaporation coatingSputtering coatingPediatricsMarine navigation

The invention discloses a polytetrafluoroethylene tube polytetrafluoroethylene tube ribbon coating preparation method and a polytetrafluoroethylene tube. A modified coating material is manufactured, and tube surface treatment is conducted; by additionally arranging an annular ribbon identification coating on the polytetrafluoroethylene tube, the navigation and positioning of medical staff in endoscopy medicine can be improved.

Owner:青岛汉兴新材料有限公司

A kind of airtight adhesive used for anti-puncture of tire and preparation method thereof

The invention discloses an airtight adhesive used for tire puncture prevention and a preparation method thereof, belonging to the technical field of tire manufacture and repair. The airtight rubber of the present invention is based on chloroprene rubber, natural rubber, bamboo powder, tackifying resin RX-80, high ammonia natural latex, KN4006 naphthenic rubber oil, rosin, zinc oxide, modified pineapple leaf fiber, accelerator DETU , silane coupling agent Si‑563, dispersant WB212, stearic acid SA, polyphenyl polymethylene polyisocyanate, antioxidant RD, sodium persulfate, biphenyl yellow G as raw materials. The present invention adopts high-ammonia latex, chloroprene rubber with good airtightness and natural rubber with good processability as the mixing system, and the properties of the colloids complement each other. At the same time, the modified pineapple leaf fiber is added to improve the rubber layer and the mouth glue during molding. The viscosity between the materials improves the tensile and tear strength of the rubber, and the various compounding agents cooperate with each other to jointly improve the bonding and repair performance of the product.

Owner:山东宝力科技有限公司

Road surface repairng material and its making method and use

InactiveCN1240773CReduce violenceImprove surface affinityRoads maintainenceEpoxy resin adhesivesRoad surfaceWear resistance

Owner:熊瑛

A kind of air purification filter screen and preparation method thereof

ActiveCN106110763BImprove purification efficiencyImprove the safety of useHeterogenous catalyst chemical elementsFiltration separationNickel saltSlag

The invention discloses an air purifying filter screen and a preparation method thereof; the air purifying filter screen is composed of a carrier and a catalyst; the carrier is composed of foam ceramics, and the foam ceramics are activated by an acid activator and then are subjected to surface modification by a surface modification agent; the catalyst comprises manganese oxide, nickel oxide and cerium oxide. The preparation method of the air purifying filter screen comprises the steps: soaking the foam ceramics with the acid activator, carrying out activating treatment of the surface and internal gaps of the foam ceramics with the acid activator, then soaking the cleanly washed foam ceramics with the surface modification agent, dissolving a manganese salt, a nickel salt, a cerium salt and a surfactant in water, stirring the components at room temperature, then adding a strong alkali, adjusting the pH to 8.0-10.5, carrying out a reaction for 1-30 h, then filtering, and mixing the obtained filter slag with a silica micro-powder to obtain slurry; spaying the slurry to the surface and the pore passage interior of the carrier by a spraying machine; and finally, calcining for 0.5-6 h at the temperature of 200-450 DEG C. The prepared purifying filter screen has the characteristics of small wind resistance, firm adhesion and high purification efficiency.

Owner:UCHEER PURIFICATION & POLLUTION CONTROL TECH ZHEJIANG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com