Nanometer array and method for forming the same

A nano-array and nano-technology, applied in the direction of nano-technology, nano-technology, nano-structure manufacturing, etc., can solve the problems of nano-structure damage, polymer structure deformation, high process cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The invention utilizes the concept of polymer film imprinting and can be widely used in thermoplastic polymer materials without melting the polymer materials in organic solvents, avoiding structural deformation and environmental protection problems caused by solvent removal and solvent volatilization in the future.

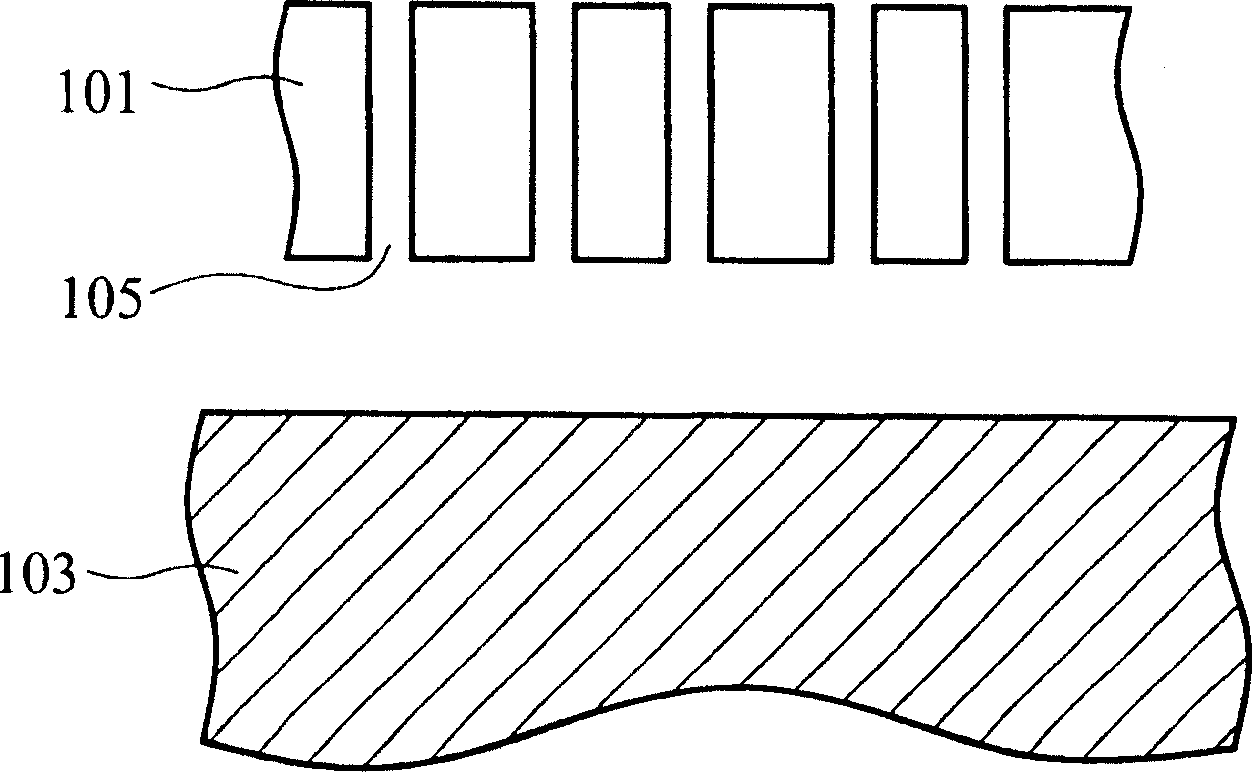

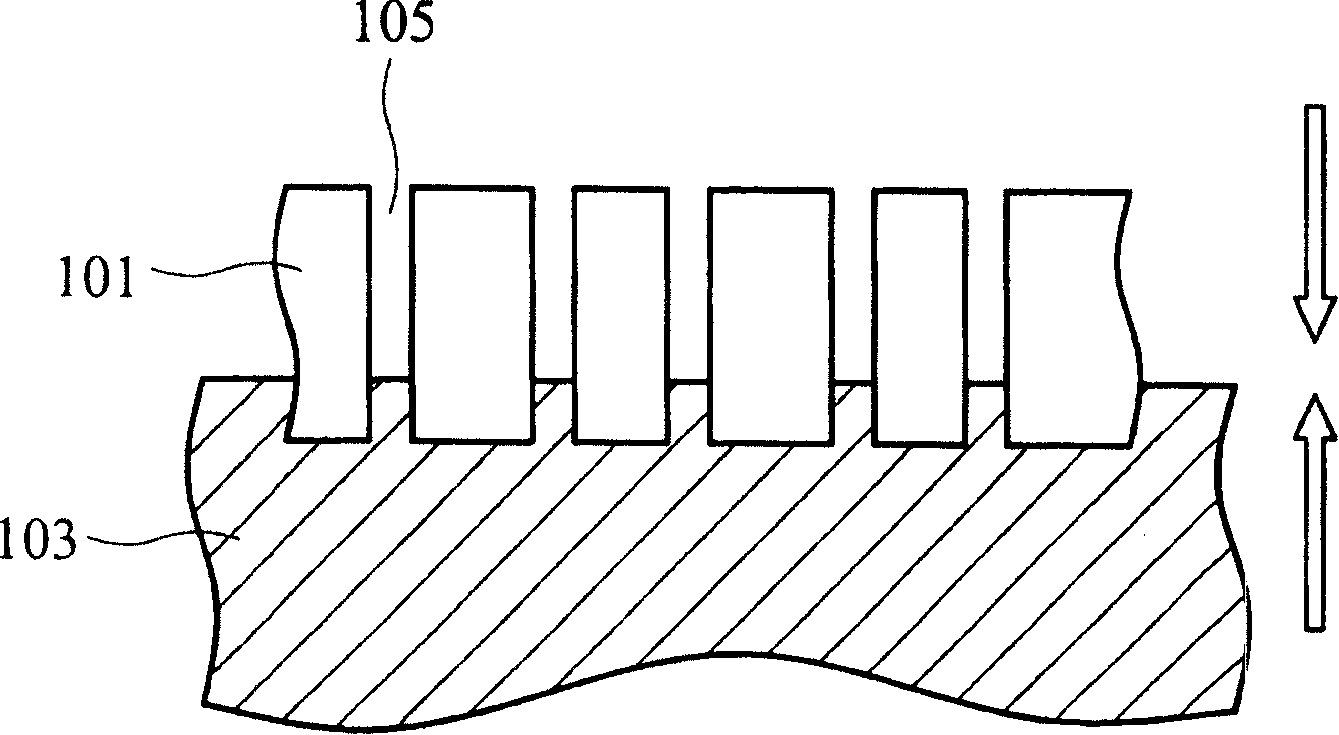

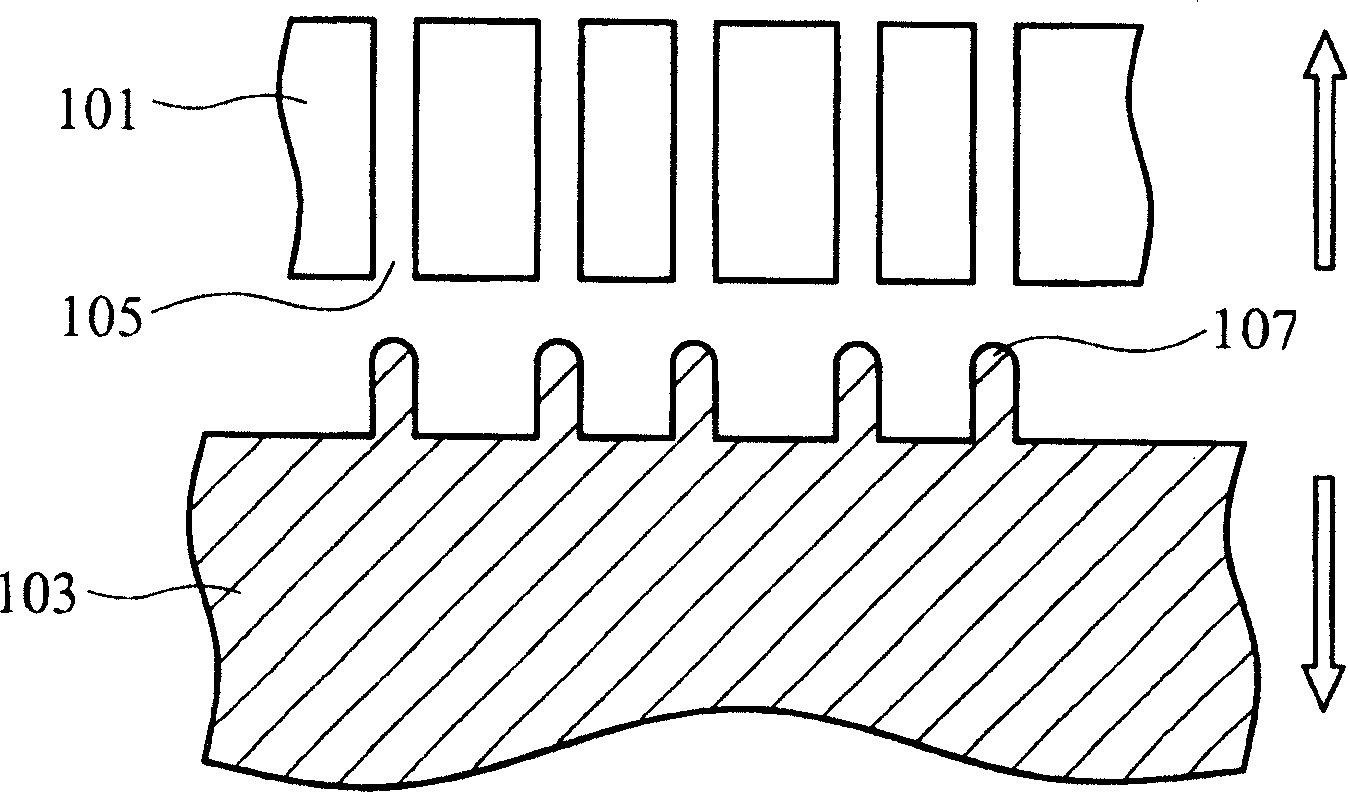

[0037] Figure 1 to Figure 3 It shows the flow chart of the present invention using the hot-pressing nano-imprinting method and using porous anodized aluminum as the imprinting template to form the nano-array. Such as figure 1 As shown, the aluminum oxide template 101 is formed by anodizing pure aluminum and has a plurality of nano-holes 105. Secondary anodizing can also be used to increase the uniformity of the nano-hole diameter, so as to precisely control the nano-pores formed after the imprinting process. The error of the array diameter, in one embodiment, the diameter of the nanoholes is about less than 200 nm, preferably between about 20 nm and 150 nm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com