A kind of airtight adhesive used for anti-puncture of tire and preparation method thereof

An anti-puncture and airtight adhesive technology, which is applied to tire parts, transportation and packaging, vehicle parts, etc., can solve the problems of easy aging and falling off of cold patch, heavy metal poisoning and corrosion, and the effect of tire repair needs to be improved. Achieve the effects of eliminating poison and corrosion, improving repair performance, and improving physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

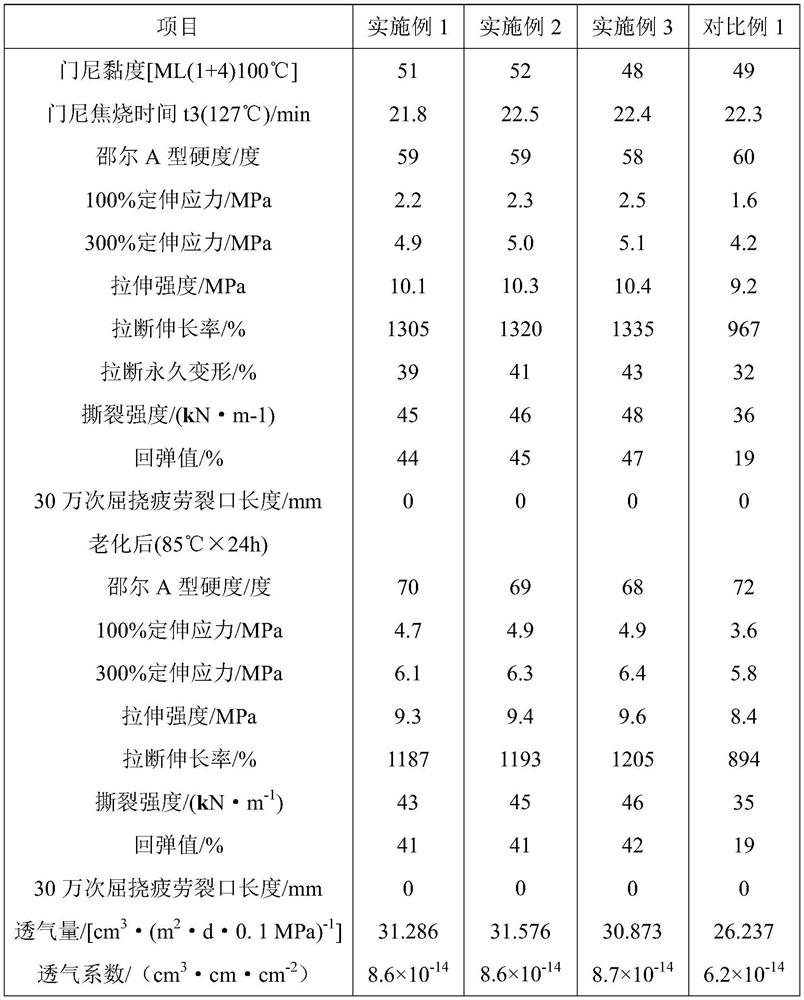

Examples

Embodiment 1

[0048] At this time, the roller spacing should be properly adjusted, and a certain amount of accumulated glue should be maintained above the roll gap, so that the roll glue layer is continuous,

Embodiment 2

[0058] The high-ammonia natural latex is a natural latex with an ammonia content greater than 1.2%.

[0068] At this moment, the roller spacing should be properly adjusted, and a certain amount of accumulated glue should be maintained above the roll gap, so that the roll glue layer is continuous,

Embodiment 3

[0078] The high-ammonia natural latex is a natural latex with an ammonia content greater than 1.2%.

[0088] At this time, the roller spacing should be properly adjusted, and a certain amount of accumulated glue should be maintained above the roll gap, so that the roll glue layer is continuous,

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com