Liquid crystal polymer/ semi-aromatic nylon alloy material and preparation method thereof

A semi-aromatic nylon, liquid crystal polymer technology, applied in the field of engineering plastics, can solve the problems of poor strength, rigidity, heat resistance, poor fluidity, etc., and achieve improved mechanical and thermal properties, improved dispersion effect, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

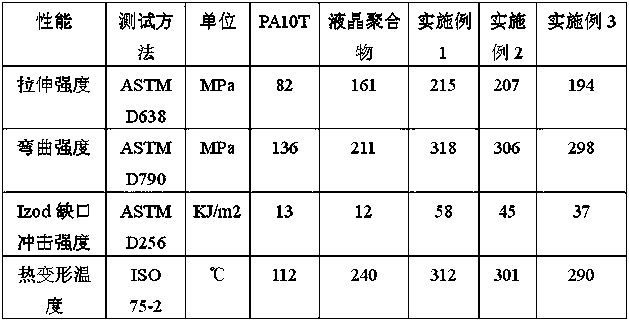

Embodiment 1

[0036] The liquid crystal polymer / semi-aromatic nylon alloy material of the present embodiment is made of raw material components comprising the following parts by weight: 45 parts of semi-aromatic nylon PA10T, 20 parts of liquid crystal polymer C130, and 0.5 parts of compatibilizer maleic anhydride , 45 parts of alkali-free glass fiber 568H, 1 part of calcium stearate lubricant, 0.5 part of processing aid, wherein the processing aid includes antioxidant and filler, and the antioxidant is tetrakis [β-(3,5-di tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, that is, antioxidant 1010, the filler is heavy barium sulfate, and the weight ratio of the two is 1:1.

[0037] The preparation method of the liquid crystal polymer / semi-aromatic nylon alloy material in this embodiment:

[0038] (1) Vacuum dry the above semi-aromatic nylon PA10T and liquid crystal polymer C130 at 120°C and 130°C for 8 hours respectively;

Embodiment 2

[0045] The liquid crystal polymer / semi-aromatic nylon alloy material of the present embodiment is made of raw material components comprising the following parts by weight: 50 parts of semi-aromatic nylon PA10T, 15 parts of liquid crystal polymer C130, and 0.5 parts of compatibilizer maleic anhydride , 40 parts of alkali-free glass fiber 568H, 1 part of calcium stearate lubricant, 0.5 part of processing aid, wherein the processing aid includes antioxidant and filler, and the antioxidant is tetrakis [β-(3,5-di tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, that is, antioxidant 1010, the filler is heavy barium sulfate, and the weight ratio of the two is 1:1.

[0046] The preparation method of the liquid crystal polymer / semi-aromatic nylon alloy material in this embodiment:

[0047] (1) Vacuum dry the above semi-aromatic nylon PA10T / liquid crystal polymer C130 at 120°C and 130°C for 8 hours;

[0048] Calcium stearate, antioxidant 1010, and heavy barium sulfate wer...

Embodiment 3

[0054] The liquid crystal polymer / semi-aromatic nylon alloy material of the present embodiment is made of the raw material components comprising the following parts by weight: 55 parts of semi-aromatic nylon PA10T, 10 parts of liquid crystal polymer C130, 0.5 part of compatibilizer maleic anhydride , 35 parts of alkali-free glass fiber 568H, 1 part of calcium stearate lubricant, 0.5 part of processing aid, wherein the processing aid includes antioxidant and filler, and the antioxidant is tetrakis[β-(3,5-di tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, that is, antioxidant 1010, the filler is heavy barium sulfate, and the weight ratio of the two is 1:1.

[0055] The preparation method of the liquid crystal polymer / semi-aromatic nylon alloy material in this embodiment:

[0056] (1) Vacuum dry the above semi-aromatic nylon PA10T / liquid crystal polymer C130 at 120°C and 130°C for 8 hours;

[0057] Calcium stearate, antioxidant 1010, and heavy barium sulfate were ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com