Weatherproof and antibacterial polycarbonate engineering plastic and preparation method thereof

A technology of polycarbonate and engineering plastics, applied in the field of polycarbonate engineering plastics and its preparation, to achieve the effects of good weather resistance, increased strength, and excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

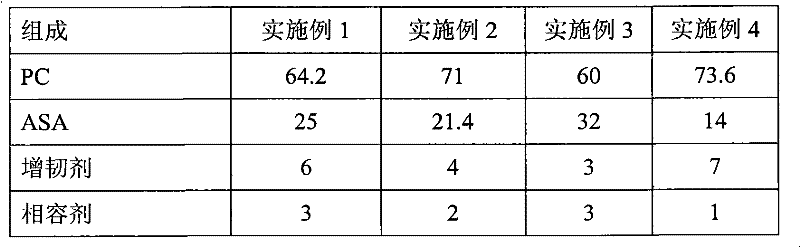

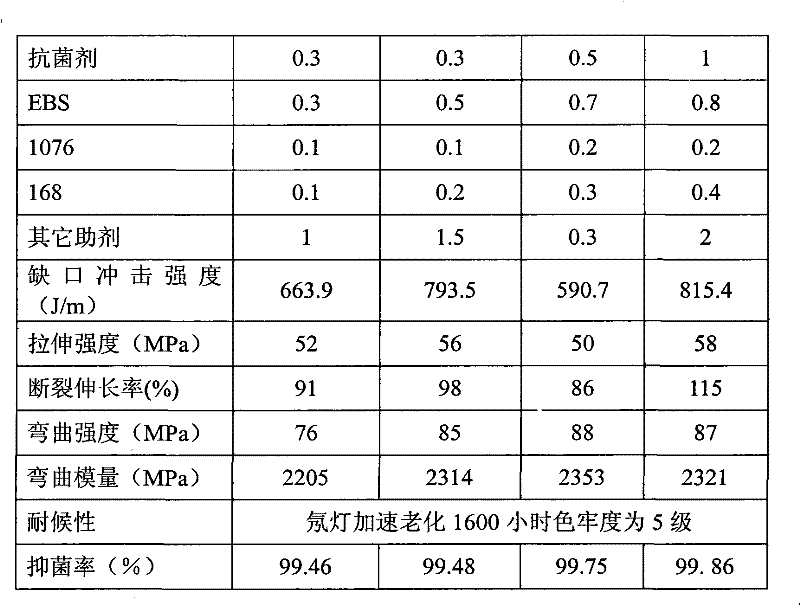

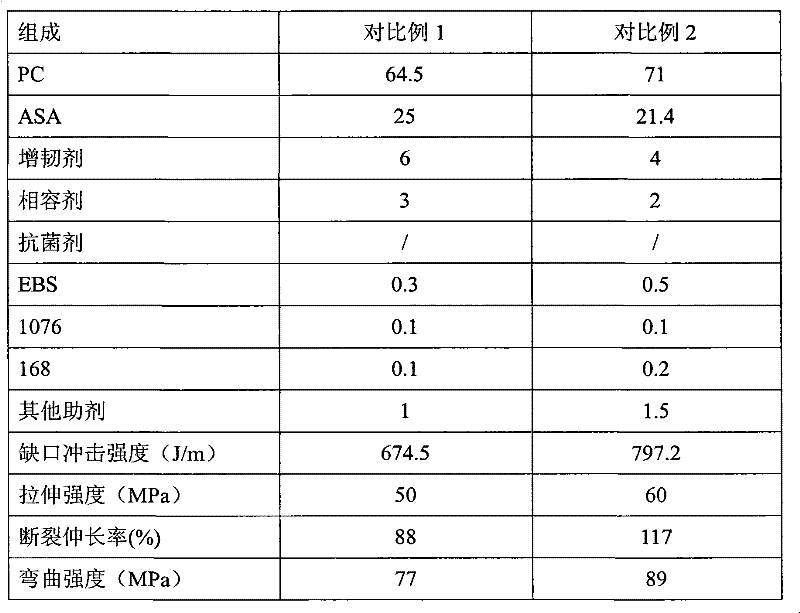

Embodiment 1

[0044] A weather-resistant and antibacterial polycarbonate engineering plastic, made of the following raw materials in parts by weight: 64.2 parts of polycarbonate, 25 parts of acrylonitrile-styrene-acrylate resin, 0.3 parts of inorganic silver-ion-loaded plastic antibacterial and antifungal agent Parts, 6 parts of MBS core-shell impact modifier (EXL-2691A), 3 parts of random copolymer of styrene and maleic anhydride, 0.3 parts of EBS, β-(4-hydroxy-3,5-di 0.1 part of n-octadecyl propionate, 0.1 part of tris(2,4-di-tert-butylphenyl) phosphite, other additives include lubricant PE wax, heat stabilizer zinc stearate, A total of 1 part of UV absorber UV5411. In the terpolymer of acrylonitrile-styrene-acrylate resin, the content of acrylate is 30% by weight.

[0045] A preparation method for weather-resistant and antibacterial polycarbonate engineering plastics, comprising the steps of:

[0046] a: First dry polycarbonate and acrylonitrile-styrene-acrylate resin at 120°C and 80°C...

Embodiment 2

[0051] A weather-resistant and antibacterial polycarbonate engineering plastic, made of the following raw materials in parts by weight: 71 parts of polycarbonate, 21.4 parts of acrylonitrile-styrene-acrylate resin, 0.3 parts of inorganic silver-ion-loaded plastic antibacterial and antifungal agent Parts, 4 parts of MBS core-shell impact modifier (C223A), 2 parts of random copolymer of styrene and maleic anhydride, 0.5 part of EBS, β-(4-hydroxy-3,5-di-tert-butyl 0.1 part of n-octadecyl phenyl) propionate, 0.2 part of tris(2,4-di-tert-butylphenyl) phosphite, other additives include lubricant PE wax, heat stabilizer zinc stearate, ultraviolet light Total 1.5 parts of absorber UV5411. In the terpolymer of acrylonitrile-styrene-acrylate resin, the content of acrylate is 30% by weight.

[0052] A preparation method for weather-resistant and antibacterial polycarbonate engineering plastics, comprising the steps of:

[0053] a: First dry polycarbonate and acrylonitrile-styrene-acryl...

Embodiment 3

[0058] A weather-resistant and antibacterial polycarbonate engineering plastic, made of the following raw materials in parts by weight: 60 parts of polycarbonate, 32 parts of acrylonitrile-styrene-acrylate resin, 0.5 parts of inorganic silver ion-loaded plastic antibacterial and antifungal agent 3 parts, 3 parts of MBS core-shell impact modifier (C223A), 3 parts of random copolymer of styrene and maleic anhydride, 0.7 parts of EBS, β-(4-hydroxy-3,5-di-tert-butyl 0.2 parts of n-octadecyl phenyl) propionate, 0.3 parts of tris(2,4-di-tert-butylphenyl) phosphite, other additives include lubricant PE wax, heat stabilizer zinc stearate, ultraviolet light Total 0.3 parts of absorber UV5411. In the terpolymer of acrylonitrile-styrene-acrylate resin, the content of acrylate is 30% by weight.

[0059] A preparation method for weather-resistant and antibacterial polycarbonate engineering plastics, comprising the steps of:

[0060] a: First, dry polycarbonate and acrylonitrile-styrene-a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com