Micro-embedded self-lubricating texture on surfaces of gear and cam and preparation method thereof

A cam surface, self-lubricating technology, applied in the field of gear and cam lubrication, to achieve the effect of saving the use cost, suppressing the negative thermal effect, and stabilizing the pulse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

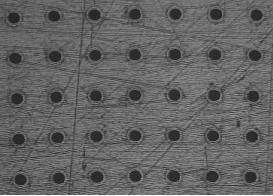

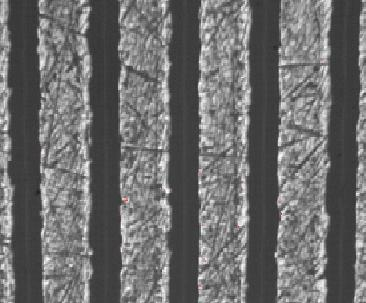

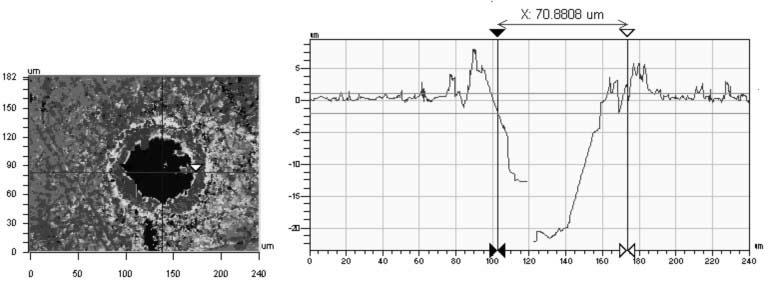

[0045] The ideal microcavity and microgroove were obtained by laser micromachining on the surface of the quenched 45 steel specimen, respectively as figure 1 and figure 2 As shown, the cavities and grooves are neatly arranged and uniform in size. The dimensions of microcavity and microgroove measured by VYKO morphology instrument are as follows: image 3 and Figure 4 As shown, the diameter of the microcavity obtained by laser micromachining on the surface of the sample is 70.8808 μm, the depth is 20 μm, and the width is 50 μm. It shows that the processing quality of the micro-texture is good, which creates good conditions for the embedding of solid lubricants. Through the processes of uniform mixing-powder drying-surface pretreatment-molding embedding of solid lubricant filler-sintering molding-surface post-treatment, the uniform filling and molding of solid lubricants is realized, and the embedding effect is as follows: Figure 5 and Figure 6 As shown, the lubricant i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com