Waste toner recovering apparatus and image forming apparatus

A technology of waste toner and recycling device, which is applied in the fields of electric recording technology using charge pattern, equipment for electric recording technology using charge pattern, and electrography, and can solve the problem of waste toner collapse, toner overflow, and difficulty in storage To prevent the toner from overflowing or not being filled, improve the accumulation limit, and prolong the replacement cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

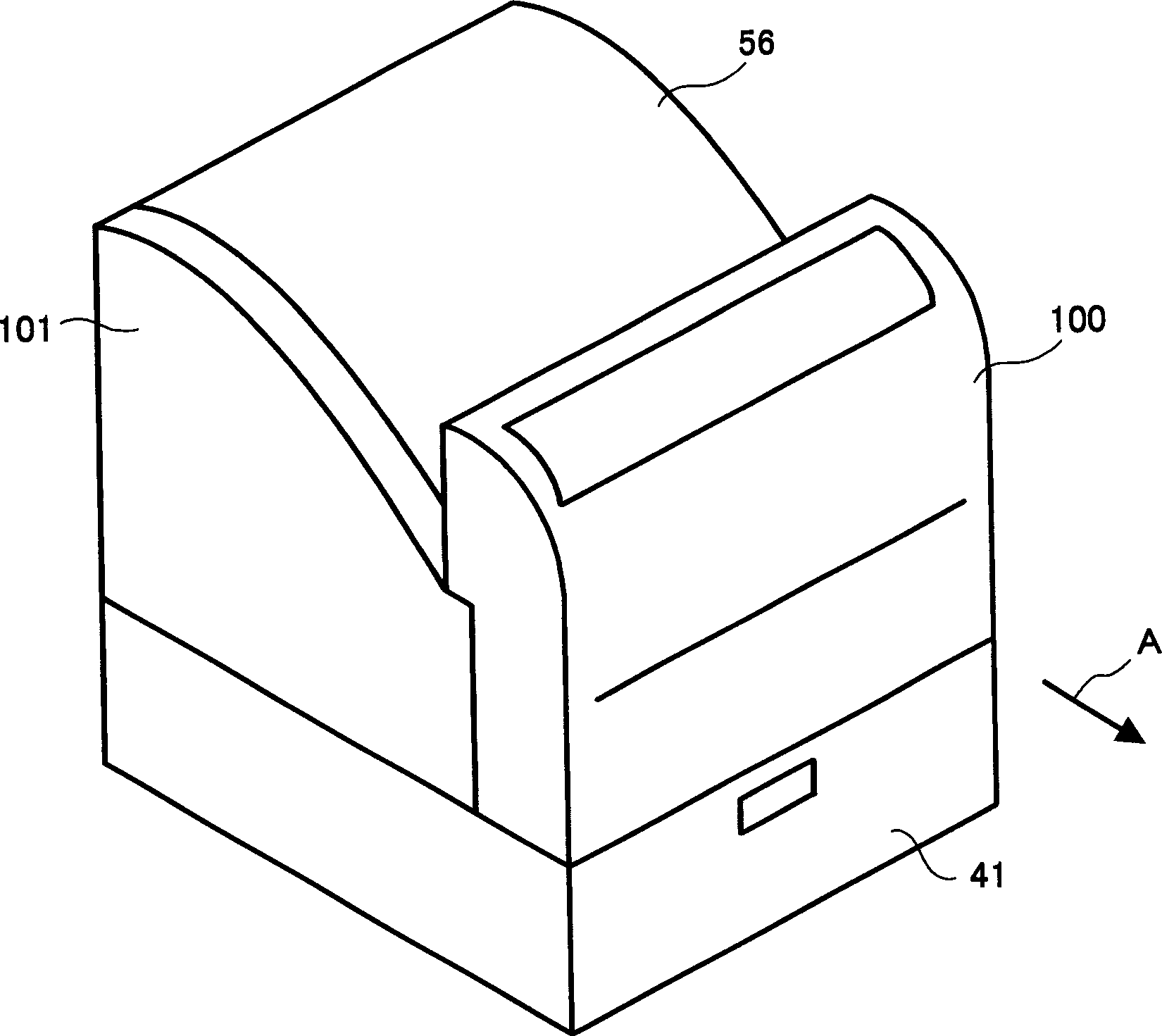

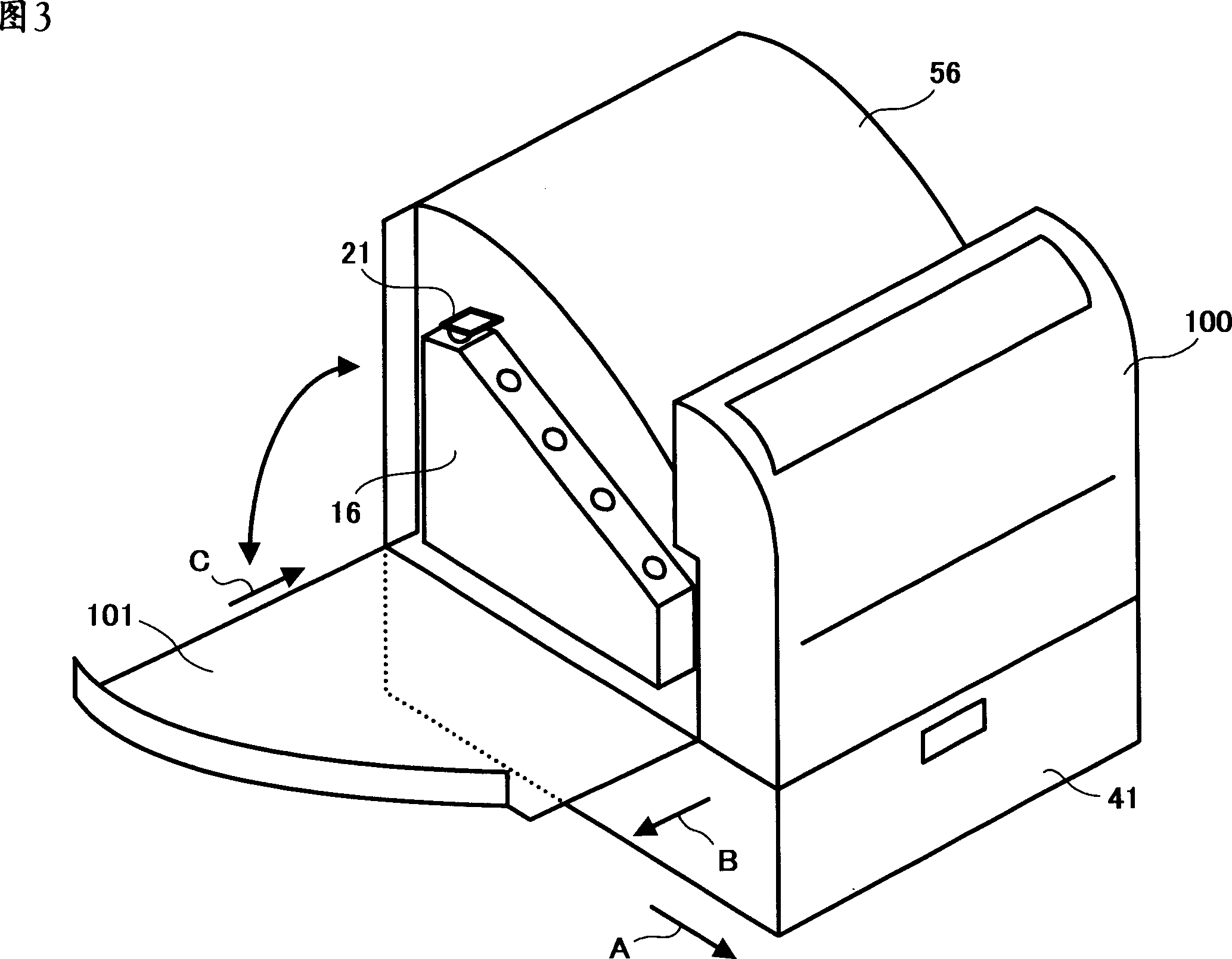

[0058] figure 1 Indicates a color printer as an image forming apparatus. Such as figure 1 As shown, the color printer is equipped with a paper feeding cassette 41 serving as a paper feeding section at the lower part of the device body for storing transfer paper P as a recording material. The transfer paper P in the cassette 41 is conveyed into the apparatus main body 100 by a paper feed roller 43 and a transport roller 44 provided near the paper feed cassette 41 . In the transfer paper conveying path between the conveying roller 44 and the secondary transfer unit 37 , a registration roller 45 is arranged to control the delivery timing of the transfer paper P to the secondary transfer unit 37 .

[0059] Inside the device body 100, there are:

[0060] The imaging cartridges 10Y, 10C, 10M, and 10K respectively form yellow, cyan, magenta, and black toner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com