Telescopic reed device of warping machine for screen processing

A telescopic reed and warping machine technology, applied in the field of warping machines, can solve the problems of yarn winding, low degree of automation, uneven distribution of yarn, etc., and achieve the effect of round shaft surface, high flexibility and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

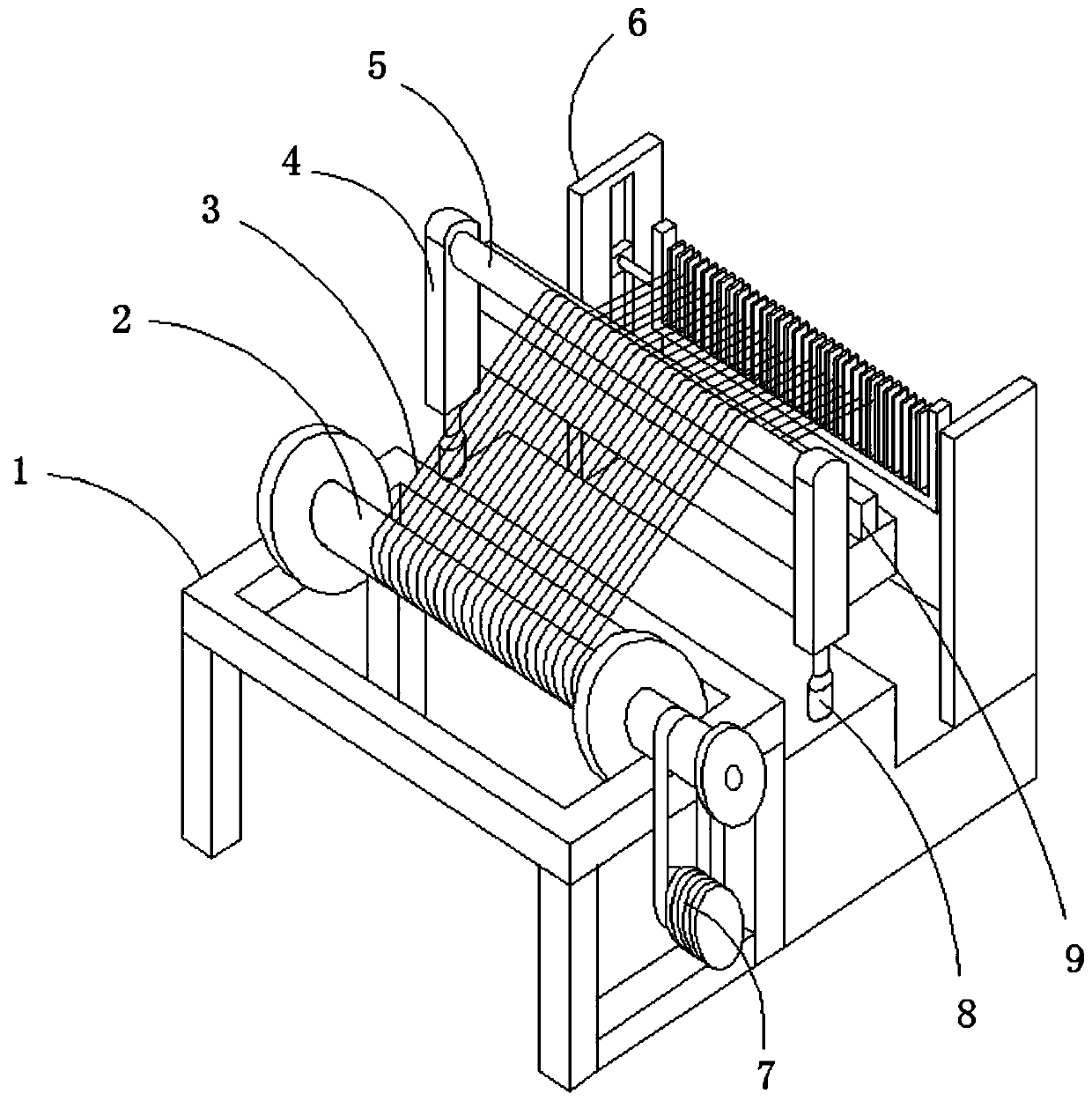

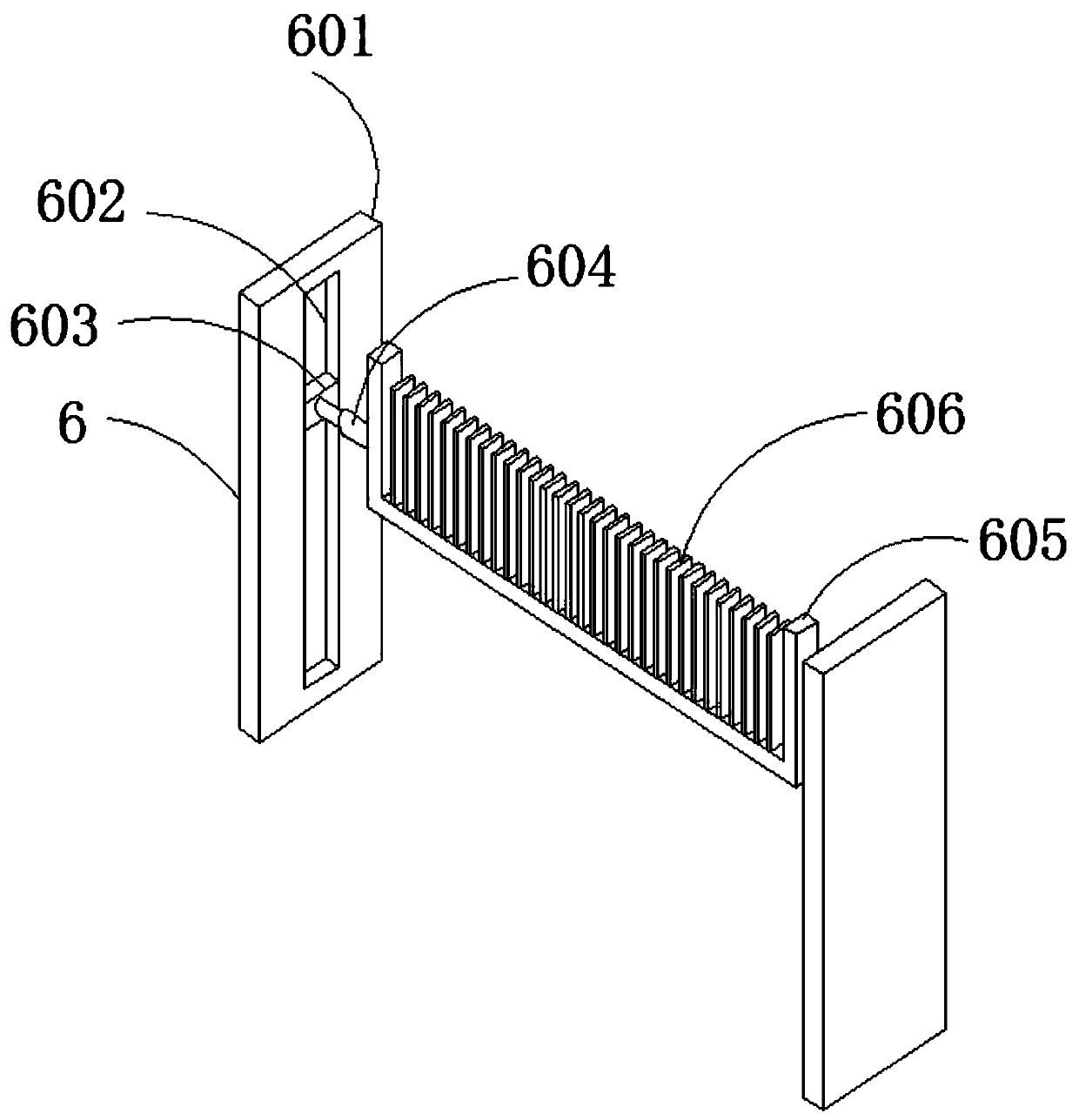

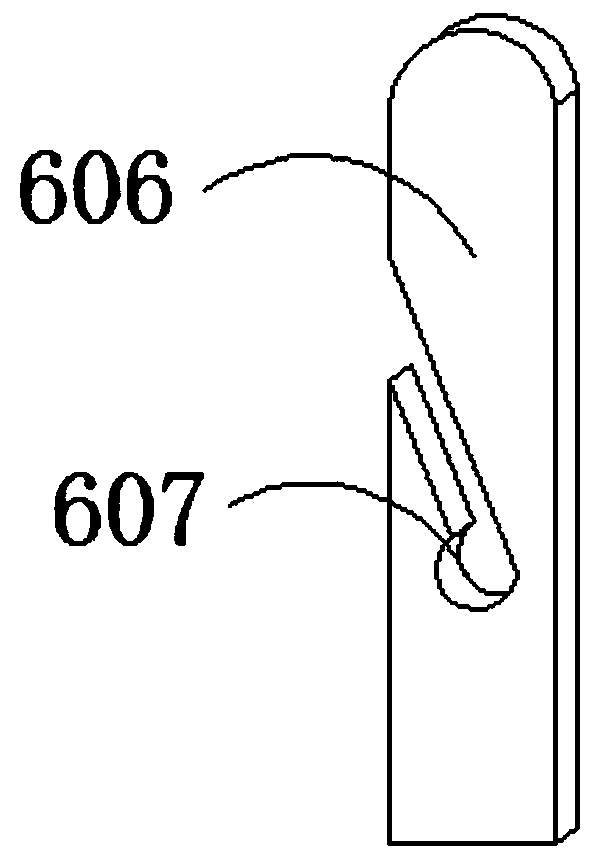

[0024] Such as Figure 1-5 As shown, a telescopic reed device for warping machines for screen processing includes a fixed base 1, a yarn barrel 2, a threading mechanism 6 and a telescopic reed mechanism 9, and the top side of the fixed base 1 is provided with a yarn barrel 2 , and one side of the yarn bobbin 2 is connected to the driving motor 7 through a belt, the driving motor 7 is fixed on the bottom of the fixed base 1, and the top of the fixed base 1 is located on one side of the yarn bobbin 2 and connected by two hydraulic telescopic rods 8 There are support rods 4, a support shaft 5 is fixed on the top between the two support rods 4, a telescopic reed mechanism 9 is provided at one end of the two support rods 4, and a threading mechanism 6 is provided at the top of the fixed base 1 and at one end of the telescopic reed 9 The yarn 3 driven by the outside of the yarn drum 2 passes through the support shaft 5, the retractable reed mechanism 9 and the threading mechanism 6 ...

Embodiment 2

[0028] Such as Figure 1-5 As shown, a telescopic reed device for warping machines for screen processing includes a fixed base 1, a yarn barrel 2, a threading mechanism 6 and a telescopic reed mechanism 9, and the top side of the fixed base 1 is provided with a yarn barrel 2 , and one side of the yarn bobbin 2 is connected to the driving motor 7 through a belt, the driving motor 7 is fixed on the bottom of the fixed base 1, and the top of the fixed base 1 is located on one side of the yarn bobbin 2 and connected by two hydraulic telescopic rods 8 There are support rods 4, a support shaft 5 is fixed on the top between the two support rods 4, a telescopic reed mechanism 9 is provided at one end of the two support rods 4, and a threading mechanism 6 is provided at the top of the fixed base 1 and at one end of the telescopic reed 9 The yarn 3 driven by the outside of the yarn drum 2 passes through the support shaft 5, the retractable reed mechanism 9 and the threading mechanism 6 ...

Embodiment 3

[0032] Such as Figure 1-5 As shown, a telescopic reed device for warping machines for screen processing includes a fixed base 1, a yarn barrel 2, a threading mechanism 6 and a telescopic reed mechanism 9, and the top side of the fixed base 1 is provided with a yarn barrel 2 , and one side of the yarn bobbin 2 is connected to the driving motor 7 through a belt, the driving motor 7 is fixed on the bottom of the fixed base 1, and the top of the fixed base 1 is located on one side of the yarn bobbin 2 and connected by two hydraulic telescopic rods 8 There are support rods 4, a support shaft 5 is fixed on the top between the two support rods 4, a telescopic reed mechanism 9 is provided at one end of the two support rods 4, and a threading mechanism 6 is provided at the top of the fixed base 1 and at one end of the telescopic reed 9 The yarn 3 driven by the outside of the yarn drum 2 passes through the support shaft 5, the retractable reed mechanism 9 and the threading mechanism 6 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com