Acid and alkali resistant duralumin type metal stranded wire

A duralumin and stranded wire technology, which is applied in the direction of conductors, insulated cables, electrical components, etc., can solve the problems of low strength of galvanized steel stranded wires, shorten the service life of wires, and poor corrosion resistance, so as to avoid water accumulation Icing, reduced installation cost, good fixation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

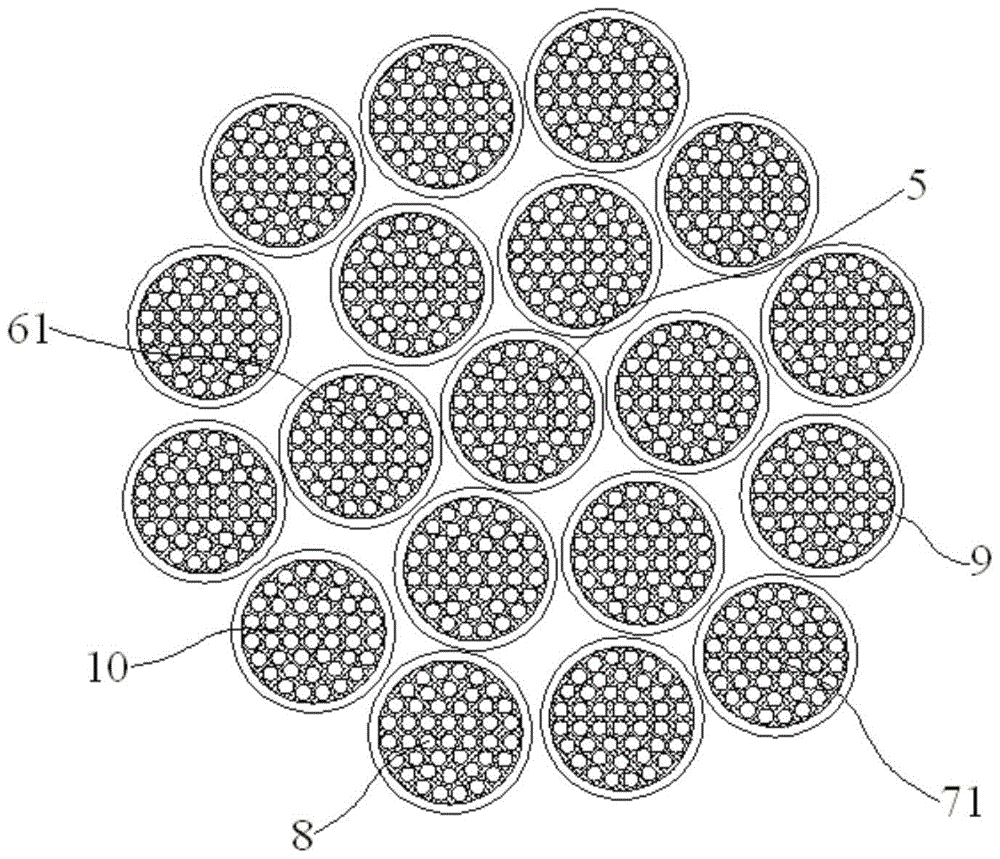

[0048] Embodiments 1-3: An acid and alkali-resistant duralumin-type metal strand, including a stress unit 1 located in the center and a first aluminum conductive layer 2 and a second aluminum conductive layer twisted on the outer surface of the stress unit 1 in sequence 3 and the third aluminum conductive layer 4;

[0049] The first aluminum conductive layer 2 is formed by twisting 14 first trapezoidal duralumin wires 21, the second aluminum conductive layer 3 is formed by twisting 21 second trapezoidal duralumin wires 31, and the third The aluminum conductive layer 4 is formed by twisting 27 third trapezoidal duralumin wires 41; the cross sections of the first trapezoidal duralumin wire 21, the second trapezoidal duralumin wire 31 and the third trapezoidal duralumin wire 41 are trapezoidal;

[0050] The stress unit 1 includes a first carbon fiber single wire 5 located in the center and an intermediate stress layer 6 twisted by six second carbon fiber single wires 61 twisted o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com