Engine oil-resistant low-pressure-change addition type liquid fluorinated silicone rubber and preparation method thereof

A liquid fluorosilicone and addition molding technology, which is applied in the field of rubber materials, can solve the problems of large compression permanent deformation of fluorosilicone rubber, poor curing effect of fluorosilicone rubber, and inability to obtain low pressure deformation, etc., so as to reduce compression permanent deformation and low production cost , to avoid the effect of breaking and slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

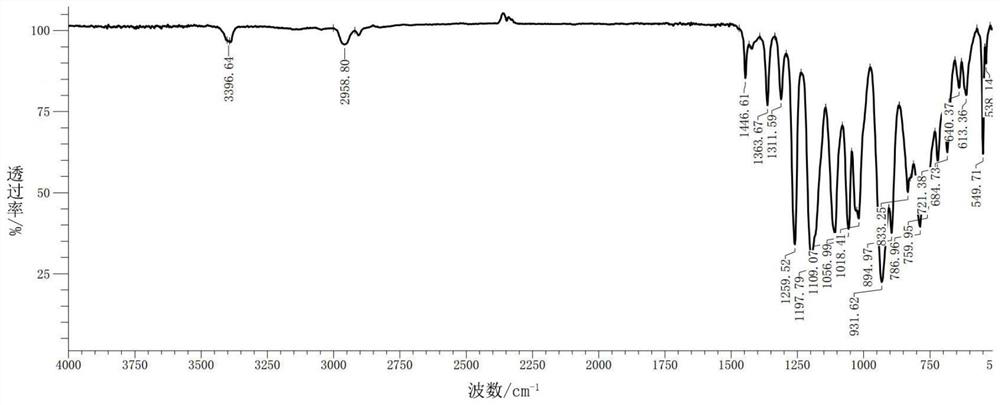

[0076] The preparation method of hydroxyfluorosilicone oil is as follows:

[0077] Add 220g of ammonia water (concentration 25%) and 460g of distilled water into the reaction kettle equipped with mechanical stirring, thermometer, condenser tube and constant pressure dropping funnel, start stirring to mix the materials evenly, and use frozen brine to reduce the temperature of the kettle to about 0°C , and then drop 300g of trifluoropropylmethyldichlorosilane into the kettle for hydrolysis reaction, the reaction is exothermic, the temperature of the kettle is controlled at 0-10°C during the dropping process, and the stirring reaction is continued for 1-2 hours after the dropping is completed; then the The system was allowed to stand for stratification, and the lower organic phase was removed and neutralized with 10 wt% dilute hydrochloric acid until the system became neutral, then 100 g of distilled water was added to the organic phase, and the organic phase was kept at 40-50 °C ...

Embodiment 1

[0089] The preparation method of oil-resistant low-pressure variable addition molding liquid fluorosilicone rubber comprises the following steps:

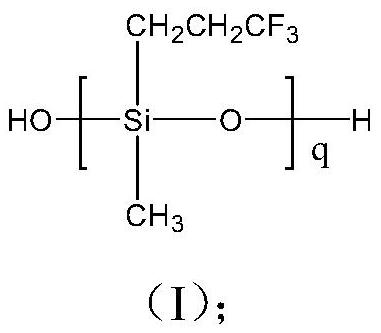

[0090] (1) Add 1000g fluorosilicone base rubber (viscosity 57000mPa.s, vinyl mass fraction 0.15%), 50g fumed silica (specific surface area 200m2) into the vacuum kneader 2 / g), 50g precipitated silica (specific surface area 200m 2 / g) and 10g of the hydroxyfluorosilicone oil of the formula (I) structure were kneaded and mixed for 0.5h, and then the remaining 100g of fumed silica, 100g of the precipitated silica, and 35g of the hydroxyfluorosilicone oil of the formula (II) were divided into three batches. Fluoropropylmethylcyclosilazane and 1.5g of divinyltetramethyldisilazane were successively added into the kneader, with an interval of 0.5h for each batch of kneading. After all the materials were added, continue kneading and mixing at room temperature. refining 2h;

[0091] (2) Add 16g of water to the mixing system, turn on the ...

Embodiment 2

[0098] The preparation method of oil-resistant low-pressure variable addition molding liquid fluorosilicone rubber comprises the following steps:

[0099] (1) Add 1000g fluorosilicone base rubber (viscosity 57000mPa.s, vinyl mass fraction 0.15%), 50g fumed silica (specific surface area 200m2) into the vacuum kneader 2 / g), 50g precipitated silica (specific surface area 200m 2 / g) and 20g of the hydroxyfluorosilicone oil of the formula (I) structure were kneaded and mixed for 0.5h, and then the remaining 100g of fumed silica, 100g of the precipitated silica, and 30g of the 30g of the structure of the formula (II) were divided into three batches. Add fluoropropylmethylcyclosilazane and 1g of divinyltetramethyldisilazane into the kneader in turn, kneading interval of each batch is 0.5h, after all materials are added, continue kneading and mixing at room temperature 2h;

[0100] (2) Add 14g of water to the mixing system, turn on the heating, heat the rubber material to 180°C for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com