Punching-free stainless steel glass handrail support

A technology of glass railings and handrail brackets, which is applied in the direction of railings, railing posts, building structures, etc., which can solve the problems of high installation costs and troublesome processing and production, and achieve the effects of saving assembly costs, avoiding incompatibility, and convenient adjustment of angles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

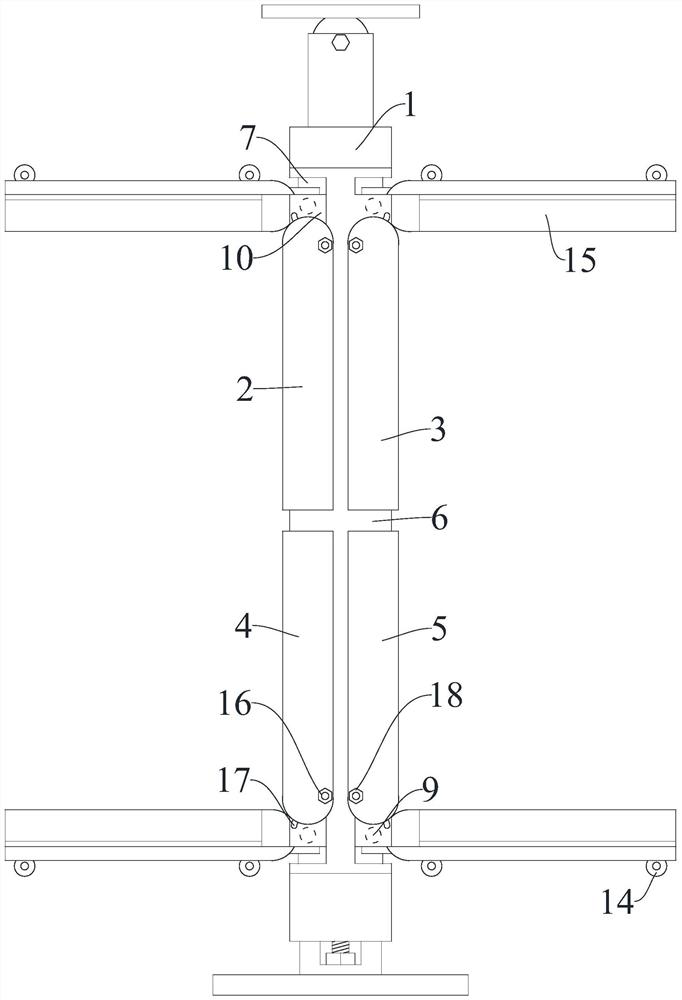

[0022] Example: People first turn the first lateral assembly plate 2, the second lateral assembly plate 3, the third lateral assembly plate 4 and the fourth lateral assembly plate 5 outwards, and then insert them under the force of the inner spring 12. Laterally adjust the inside of the groove 7, and then insert the inside of the lateral installation card groove 8 to fix the upper and lower ends of the protective glass, and form an installation frame on the upper and lower ends of the protective glass through the lateral assembly plates on the front and back side walls, and then cooperate Mounting bolts inserted laterally into the lateral mounting plate 14 clamp and secure it to the protective glass.

[0023] Further, in order to cooperate with assembly and fixation, the cross-section of the first lateral assembly plate 2, the second lateral assembly plate 3, the third lateral assembly plate 4 and the fourth lateral assembly plate 5 is an L-shaped structure. A mounting plate 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com