Oil-resistant and mud-resistant irradiation-crosslinking flame-retardant cable material

A flame-retardant cable and mud-resistant technology, which is applied in the direction of circuits, electrical components, plastic/resin/wax insulators, etc., can solve the problems of large equipment investment, large smoke generation, and cumbersome processes, so as to improve mechanical properties and eliminate hair loss. Viscosity, the effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

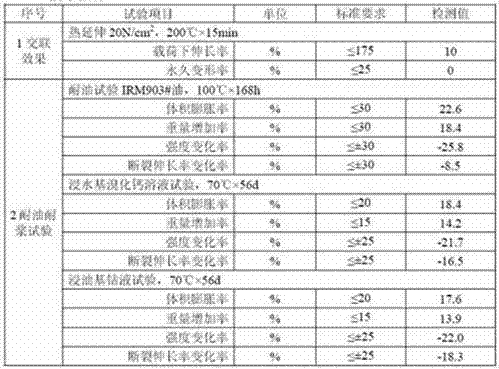

[0032] Example: an oil-resistant and mud-resistant radiation cross-linked flame-retardant cable material, the material formula:

[0033]

[0034] Preparation Process

[0035] The first step: Mix the ethylene vinyl acetate copolymer EVA, ethylene-vinyl acetate-carbon monoxide terpolymer, polyethylene and polyethylene grafted maleic anhydride copolymer in a high-speed mixer for 30 seconds at high speed according to the formula weight Then, it is mixed and plasticized by a twin-screw granulator. The processing temperature is: 120-130°C in the conveying section, 140-155°C in the melting section, 160-170°C in the mixing section, and 155-165°C in the exhaust section. The heating section is 155-165°C, and the head is 160-170°C.

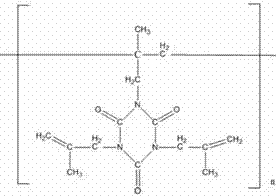

[0036]The second step: Add the above materials into carbon black, aluminum hydroxide flame retardant, magnesium hydroxide flame retardant, silane coupling agent, cross-linking sensitizer trimethallyl isocyanate TMAIC prepolymerized by formula weight com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| oil absorption value | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com