Biological fuel oil-resistant rubber sealing element material and preparation method thereof

A rubber seal, bio-resistant technology, applied in the rubber field, can solve the problems of long oil regeneration time and non-renewable fuel, achieve good mechanical properties and bio-fuel resistance, resist swelling corrosion, and reduce the effect of impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

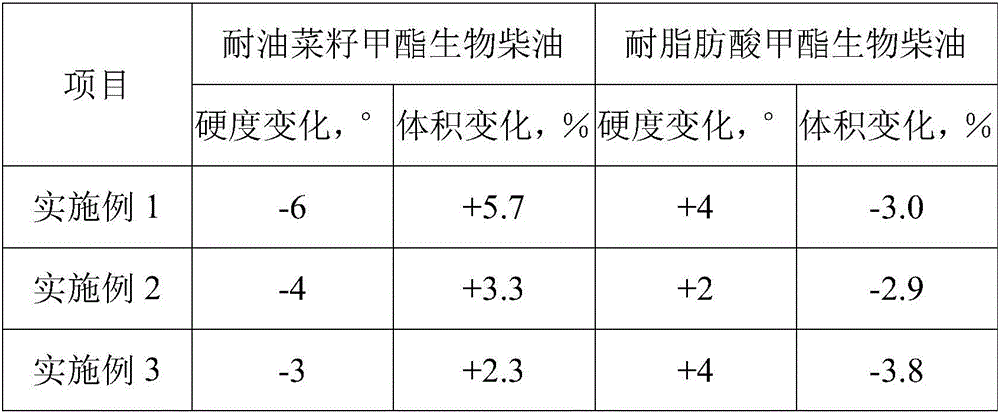

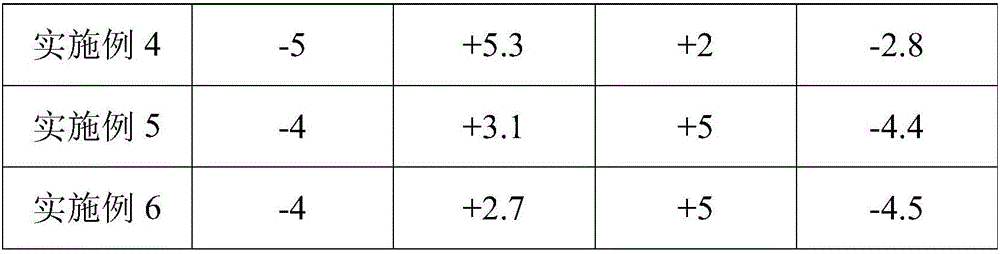

Examples

Embodiment 1

[0020] A bio-fuel-resistant rubber seal material, the raw materials of which by weight include: 100 parts of a mixture of nitrile rubber and polyvinyl chloride, 60 parts of fast pressing carbon black, 5.5 parts of indirect zinc oxide, 1.5 parts of stearic acid, 2,2,4-trimethyl-1,2-dihydroquinoline polymer 2 parts, 4,4'-bis(α,α-dimethylbenzyl)diphenylamine 2 parts, polyester plasticizer 7 parts, 5.5 parts of calcium hydroxide, 4 parts of ultra-high molecular weight polyethylene, 2 parts of paraffin wax, 1.5 parts of sulfur, 1 part of accelerator TMTD, 2 parts of accelerator CBS.

[0021] The preparation method of the above-mentioned bio-fuel-resistant rubber sealing material includes the following steps: mixing the above-mentioned raw materials and mixing to obtain a synthetic rubber; taking the synthetic rubber, carrying out mixing and molding, and then adding it into a mold to vulcanize to obtain a bio-fuel-resistant rubber seal material.

Embodiment 2

[0023] A bio-fuel-resistant rubber seal material, the raw materials of which by weight include: 100 parts of a mixture of nitrile rubber and polyvinyl chloride, 50 parts of fast pressing carbon black, 3 parts of indirect method zinc oxide, 1 part of stearic acid, 1 part of 2,2,4-trimethyl-1,2-dihydroquinoline polymer, 1 part of 4,4'-bis(α,α-dimethylbenzyl)diphenylamine, polyester plasticizer 10 parts, 3 parts of calcium hydroxide, 3 parts of 300 mesh UHMWPE, 1 part of paraffin wax, 1 part of sulfur, 1.5 parts of accelerator TMTD, 1 part of accelerator CBS;

[0024] Among them, in the mixture of nitrile rubber and polyvinyl chloride, the content of polyvinyl chloride is 25% by weight, and the content of acrylonitrile in nitrile rubber is 50% by weight;

[0025] The molecular weight of UHMWPE is 2 million.

[0026] The preparation method of the above-mentioned bio-fuel-resistant rubber seal material includes the following steps: mixing the above-mentioned raw materials and mixing to o...

Embodiment 3

[0028] A bio-fuel-resistant rubber seal material, the raw materials of which by weight include: 100 parts of a mixture of nitrile rubber and polyvinyl chloride, 60 parts of fast pressing carbon black, 5 parts of indirect method zinc oxide, 1.5 parts of stearic acid, 2,2,4-trimethyl-1,2-dihydroquinoline polymer 2 parts, 4,4'-bis(α,α-dimethylbenzyl)diphenylamine 2 parts, polyester plasticizer 8 parts, 5 parts of calcium hydroxide, 4 parts of 600 mesh ultra-high molecular weight polyethylene, 2 parts of paraffin wax, 1.5 parts of sulfur, 1 part of accelerator TMTD, 2 parts of accelerator CBS;

[0029] Among them, in the mixture of nitrile rubber and polyvinyl chloride, the content of polyvinyl chloride is 30% by weight, and the content of acrylonitrile in nitrile rubber is 45% by weight;

[0030] The molecular weight of UHMWPE is 3 million.

[0031] The preparation method of the above-mentioned bio-fuel-resistant rubber seal material includes the following steps: mixing the above-menti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com