Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

119 results about "Oxidative carbonylation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oxidative carbonylation is a class of reactions that use carbon monoxide in combination with an oxidant to generate esters. These transformations utilize transition metal complexes as homogeneous catalysts. Many of these reactions employ palladium catalysts.

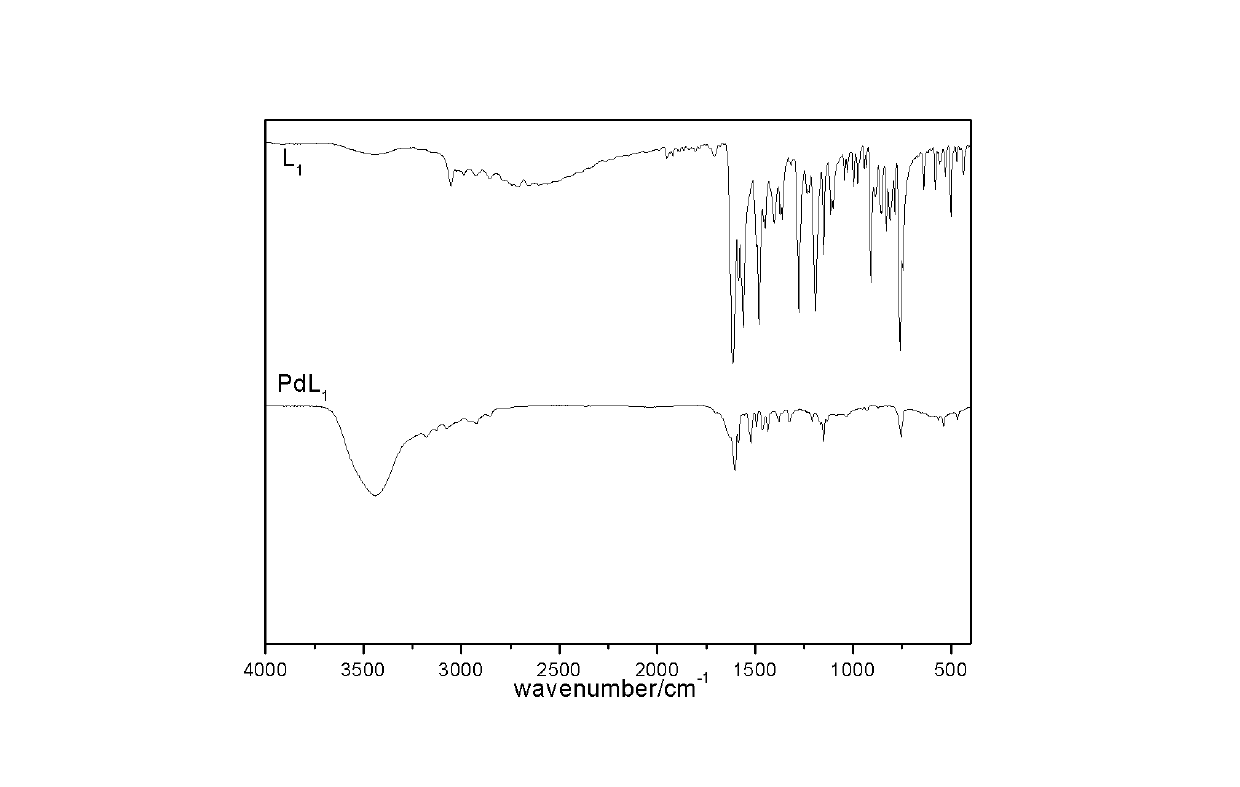

Complex catalyst for synthesizing carbonate ester by using homogeneous oxidation carbonylation of alcohol (S), its prepn. tech. and use

InactiveCN1792453ASimple preparation processHigh activityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsQuaternary ammonium cationProtein carbonyl

A complex catalyst for preparing carbonate from alcohol by homogeneous oxidizing-carbonylating reaction has a chemical formula MXnLm, where M is metal, X is chosen from halogen, SO4 (or HSO4) radical, CO3 (or HCO3) radical, etc, L is chosen from RN4 ion, RP4 ion, pyridine, etc, and m=1-12. It is prepared through complex reaction between quaternary ammonium (or phosphorus) salt and metal salt. Its application method is also disclosed.

Owner:NANJING UNIV OF TECH

High-molecular complex as catalyst for synthesizing dimethyl carbonate and its preparing process and application

InactiveCN1376665ASimple preparation processHigh activityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsOxygenHigh pressure

Owner:FUDAN UNIV

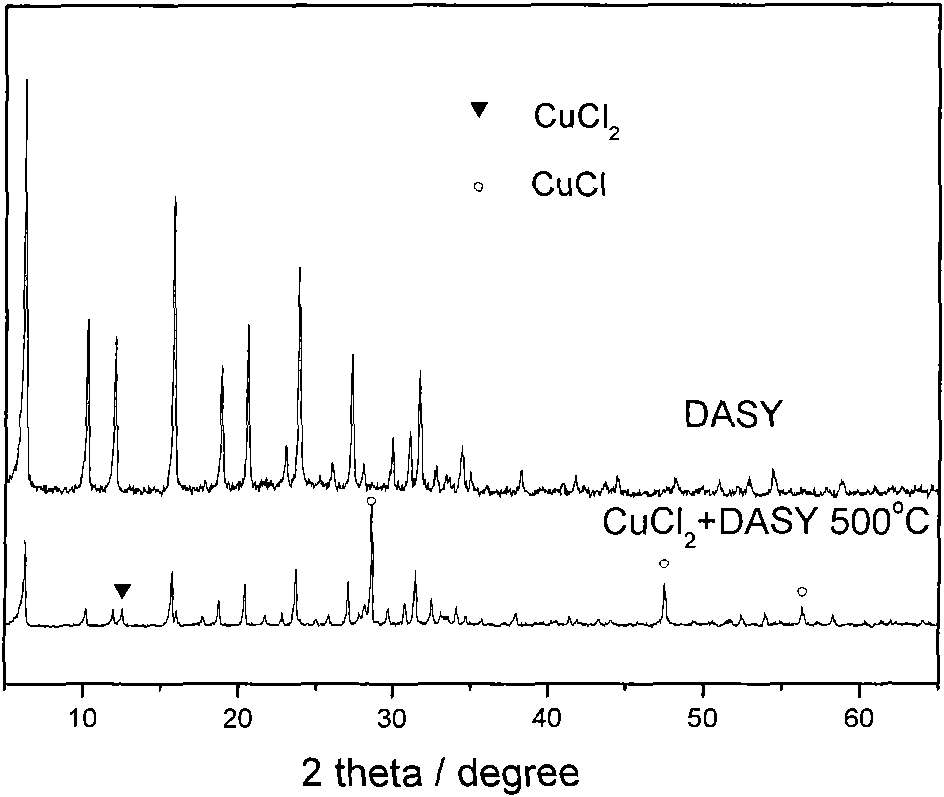

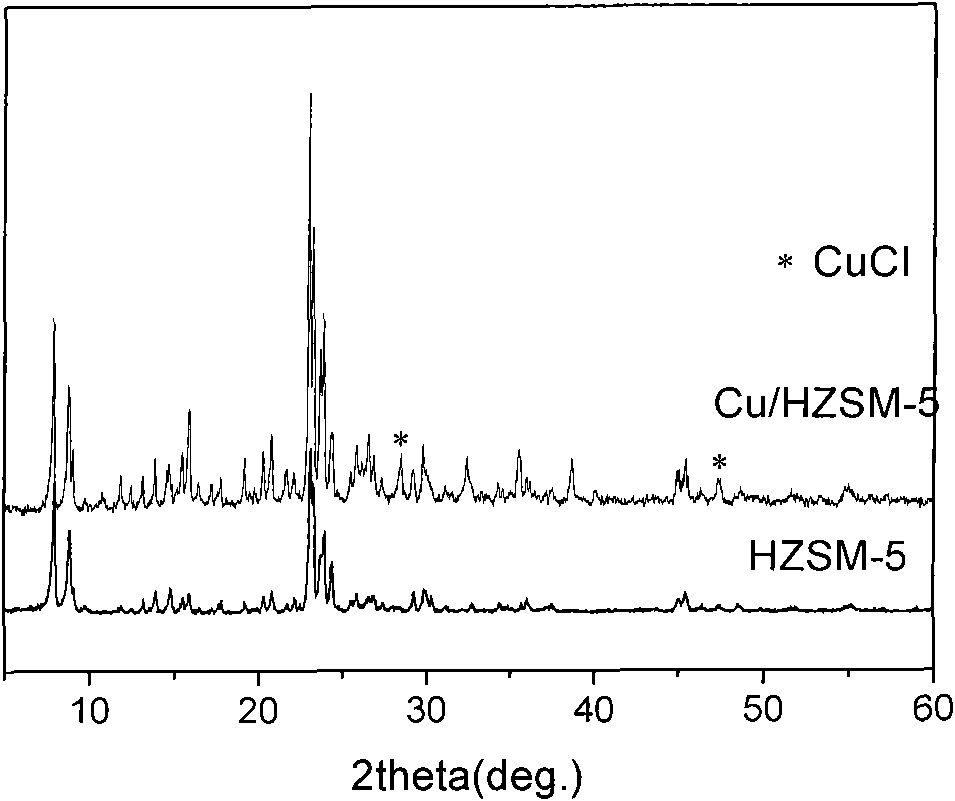

Method for preparing CuCl and Cu loaded solid phase catalyst

The invention discloses a method for preparing a CuCl and Cu loaded solid phase catalyst, which comprises the following steps: evenly mixing bivalent chlorate of copper CuCl2 and a solid carrier according to a mass ratio of between 10:1 and 1:10; and in a protective atmosphere of inert gas, heating the mixture up to the temperature of between 300 and 800 DEG C for solid phase reaction for 1 to 100 hours to prepare the CuCl and Cu loaded solid phase catalyst. The method has the advantages of using the bivalent chlorate of copper with stable property and low price to replace the univalent chlorate of copper with unstable property and high price as a raw material, saving the intermediate process of preparing the CuCl, and avoiding the generation of waste water and waste gas in large amount, along with simple preparation process, environmental protection, low cost, higher reaction activity and stability; moreover, the solid phase catalyst prepared by the method can be used for an adsorbent separating CO by pressure swing adsorption, and also be used as catalysts for synthesis of methyl carbonate by oxidative carbonylation of methanol and for catalytic reduction of NOx with hydrocarbons, so that the solid phase catalyst has quite wide industrial application prospect.

Owner:TAIYUAN UNIV OF TECH

Double component carried catalyst for synthesizing diphenyl carbonate and its preparing method

InactiveCN1391986AHigh catalytic activityGood repeatabilityMolecular sieve catalystsOrganic compound preparationPhenolOxidative carbonylation

The present invention relates to double-component carried catalyst PdCl2-Cu(OAc)2 / zeolite for synthesizing diphenyl carbonate and its preparation. The catalyst consists of zeolite in 50-100 weight portions, PdCl2 in 0.1-10 weight portions and Cu(OAc)2 in 0.1-30 weight protions. It is prepared through equi-volume soaking and roasting at 250-750 deg.c. The catalyst system has also metal acetate as inorganic oxidation-reduction assistant, hydroquinone as organic oxidation-reduction assistant, and tetrabutyl ammonium bride as surfactant. The catalyst has very high catalytic activity and excellent selectivity to liquid phenol in synthesizing diphenyl carbonate. The catalyst is easy to separate from product, easy to recover and regenerate and has simple preparation process.

Owner:HEBEI UNIV OF TECH

Non-noble metal homogeneous catalysis system for alcohol oxidation carbonylation and using method thereof

InactiveCN101856625AHigh activityHigh selectivityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsChemical industryPtru catalyst

The invention belongs to the field of chemical industry and discloses a non-noble metal homogeneous catalysis system for alcohol oxidation carbonylation and a using method thereof. The system consists of a composite catalyst MNC and a solvent NS (IV) which dissolves the composite catalyst, wherein the composite catalyst MNC is compounded by a metal complex MXn-Lm (I), a metal salt synergistic aid N (II) and / or an alkaline aid C (III). The general formula of the system is I+II+III+IV, I+II+IV, or I+III+IV. The catalyst has the advantages of simple process, mild reaction, high catalytic activity, good selectivity and stability, and low corrosion on production equipment. Meanwhile, the homogeneous system formed by the composite catalyst and the solvent can perform liquid phase circulation and has industrial application prospects.

Owner:NANJING UNIV OF TECH

Copper-based catalyst prepared by ammonia distillation method and application of copper-based catalyst in oxidation carbonylation synthesis of alkyl carbonate

ActiveCN103084201AImprove stabilityReduced activityMolecular sieve catalystsOrganic compound preparationEthyl ChlorideProtein carbonyl

The invention discloses a copper-based catalyst prepared by an ammonia distillation method and an application of the copper-based catalyst in a reaction system for oxidation carbonylation synthesis of alkyl carbonate. The use of a chlorine-containing compound is completely avoided in the preparation process of the catalyst, so that the problems of equipment corrosion and deactivation caused by chlorine loss are completely solved; and the catalyst prepared by the ammonia distillation method is high in selectivity, long in service life, low in preparation cost and relatively simple in process.

Owner:TIANJIN UNIV

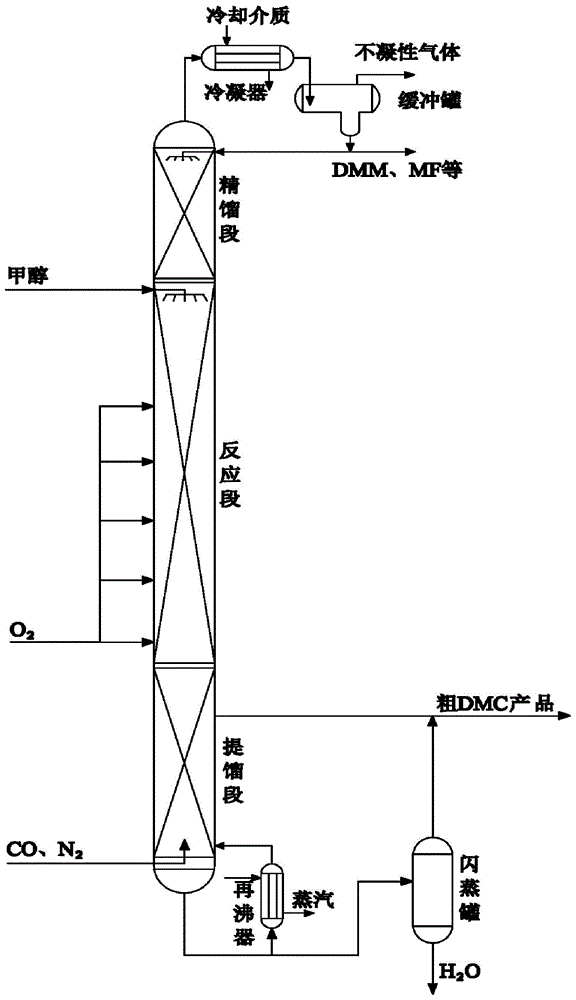

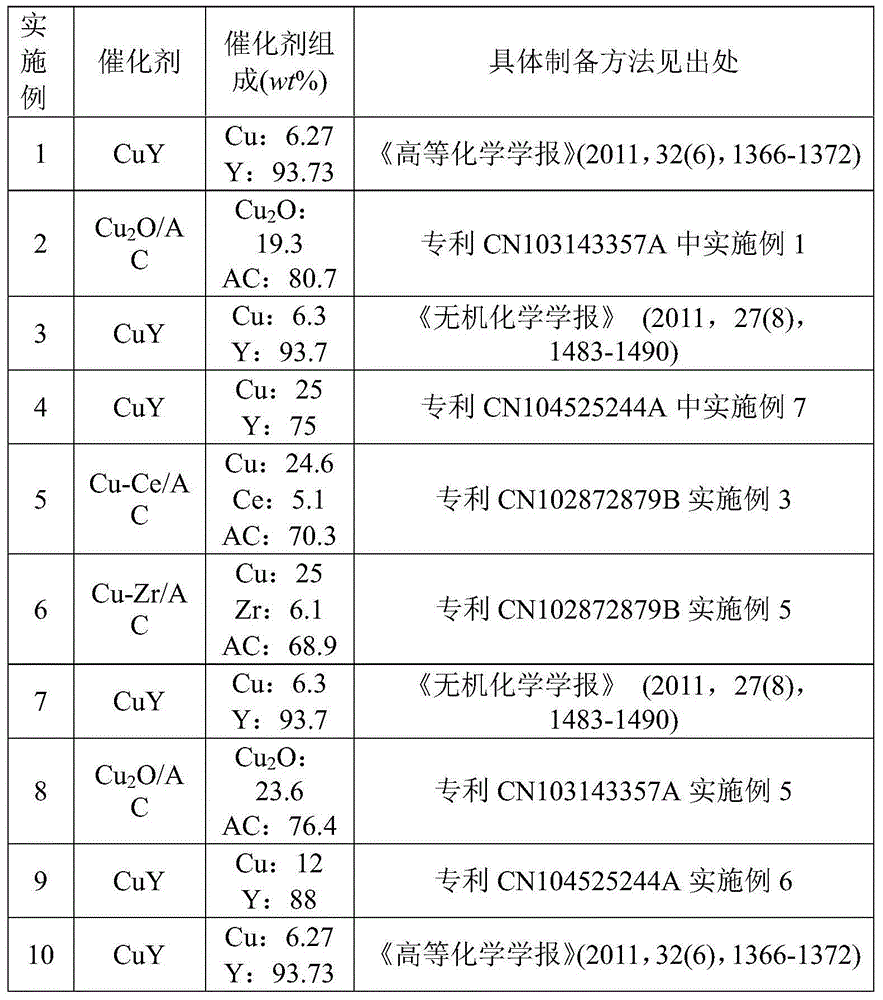

A process of preparing dimethyl carbonate by oxidative carbonylation of methanol

ActiveCN104892423AExtend your lifeSolution to short lifeOrganic compound preparationChemical industryRefluxBoiling point

A process of preparing dimethyl carbonate by oxidative carbonylation of methanol adopts a catalytic rectification column as the main reacting device. The upper part of the catalytic rectification column is adopted as a rectification section, the middle part of the catalytic rectification column is adopted as a reacting section and the lower part of the catalytic rectification column is adopted as a distillation section. A reboiler is disposed at the bottom of the distillation section. A condensation reflux device is disposed at the top of the rectification section. Liquid methanol is fed from the top of the reacting section of the catalytic rectification column. Pressurized CO and nitrogen are fed from the bottom of the distillation section. O2 is divided into 1-5 parts and fed from the reacting section in a staged manner. Descending methanol and ascending CO / O2 in the reacting section are subjected to countercurrent contact, and react continuously to produce the dimethyl carbonate product in a catalyst filler bed layer in the reacting section. The rectification section mainly separates unreacted methanol from byproducts with low boiling points. A crude dimethyl carbonate product is obtained by rectification in the upper part of the distillation section. The process is advantageous in that the synthetic process is simple, the methanol conversion rate is high and purity of the dimethyl carbonate product is high.

Owner:TAIYUAN UNIV OF TECH

Complex catalyst for synthesizing carbonate ester by using homogeneous oxidation carbonylation of alcohol (S), its preparation technology and use method

InactiveCN100388978CSimple preparation processHigh activityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsHydrogen SulfatePtru catalyst

A complex catalyst for preparing carbonate from alcohol by homogeneous oxidizing-carbonylating reaction has a chemical formula MXnLm, where M is metal, X is chosen from halogen, SO4 (or HSO4) radical, CO3 (or HCO3) radical, etc, L is chosen from RN4 ion, RP4 ion, pyridine, etc, and m=1-12. It is prepared through complex reaction between quaternary ammonium (or phosphorus) salt and metal salt. Its application method is also disclosed.

Owner:NANJING TECH UNIV

Catalyst for synthesizing dimethyl carbonate through continuous oxidative carbonylation of liquid phase methanol and preparation method and application of catalyst

InactiveCN103143357ASolve corrosiveNot easy to agglomerate and sinterOrganic compound preparationMetal/metal-oxides/metal-hydroxide catalystsActivated carbonPtru catalyst

The invention relate to a catalyst for synthesizing dimethyl carbonate through continuous oxidative carbonylation of liquid phase methanol. The catalyst comprises 5.0-25.0wt% of Cu2O serving as an active component and 75.0-95.0wt% of activated carbon. The catalyst has the advantages of good stability, high activity, no corrosion and no pollution.

Owner:TAIYUAN UNIV OF TECH

Preparation of organic/inorganic nano media pores hybridization catalyst utilized for synthesizing methyl carbonate as well as its application

InactiveCN1446632AReduced activityStrong alkalineOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsMethyl carbonateCopper

A nano-class organic / inorganic mesoporous hybridizing catalyst for preparing dimethyl carbonate by liquid-phase oxidization and carbonylation of methanol contains copper halides and the carrier whichis a nano-class organic / inorganic mesoporous hybridizing material with specially treated surface for effectively dispersing the copper halides on it. The said dimethyl carbonate is prepared from methanol, catalyst, CO and O2 through reaction at 110-140 deg.C and 2.0-5.0 MPa. Its advantages are high selectivity, activity and stability, low corrosion and cyclic use of catalyst.

Owner:FUDAN UNIV

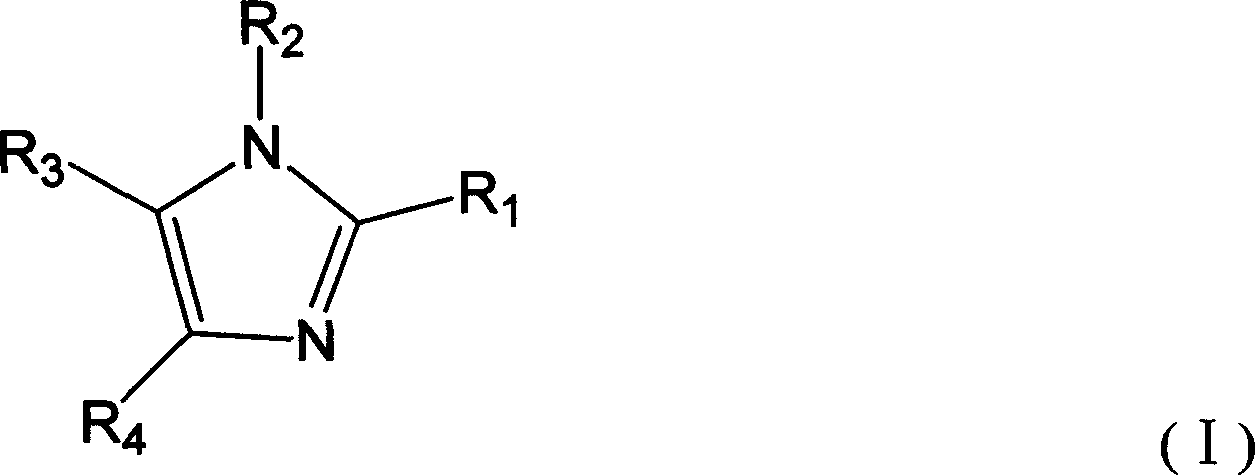

Catalyst for synthesizing dimethyl carbonate by methanol liquid-phase oxidative carbonylation and methods

InactiveCN107694609AHigh selectivityReduce corrosionOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsHalogenMethyl carbonate

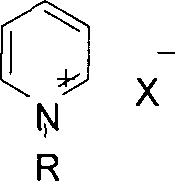

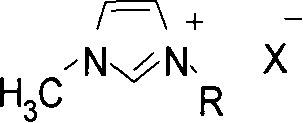

The invention discloses a catalyst for synthesizing dimethyl carbonate by methanol liquid-phase oxidative carbonylation and methods. The catalyst comprises a copper halide and an ionic liquid; the mass ratio of the copper halide to the ionic liquid is 1:(1-10); a cation of the ionic liquid is an imidazole cation, a quaternary ammonium salt cation or a pyridine cation; and an anion of the ionic liquid is a halogen ion. The catalyst disclosed by the invention has relatively high methanol conversion ratio and high dimethyl carbonate selectivity and has an industrial application prospect. In addition, due to the addition of the ionic liquid, corrosion to stainless steel reaction equipment can be relieved.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

Process for preparing dimethyl carbonate catalyst by liquid-phase oxidation carbonylation of methanol

InactiveCN105080610ASimple preparation processHigh activityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsNitrogenous heterocyclic compoundMethyl carbonate

The invention relates to a process for preparing a dimethyl carbonate catalyst by liquid-phase oxidation carbonylation of methanol. The process comprises the following steps: respectively dispersing or dissolving cuprous halide and one or more of nitrogenous heterocyclic compounds and nitrogen-containing polymers in an organic solvent; adding a solution / suspension into another solution / suspension at a certain temperature and stirring speed, continuously stirring for a certain period to form a coordination complex; transferring the suspension into a vacuum drier, removing the organic solvent at a certain temperature and vacuum degree to obtain a solid powdered catalyst, and grinding the catalyst to 100-200 meshes; and adding a dry powder catalyst, methanol, CO and O2 into a batch reactor, and synthesizing dimethyl carbonate at a temperature of 90-130 DEG C and pressure of 2.0-3.0MPa, wherein the per-pass conversion is more than or equal to 30 percent, and the selectivity of the target product dimethyl carbonate is more than or equal to 99.9 percent. The catalyst is simple in preparation process, cannot be easily caked, and has good activity, selectivity and stability.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

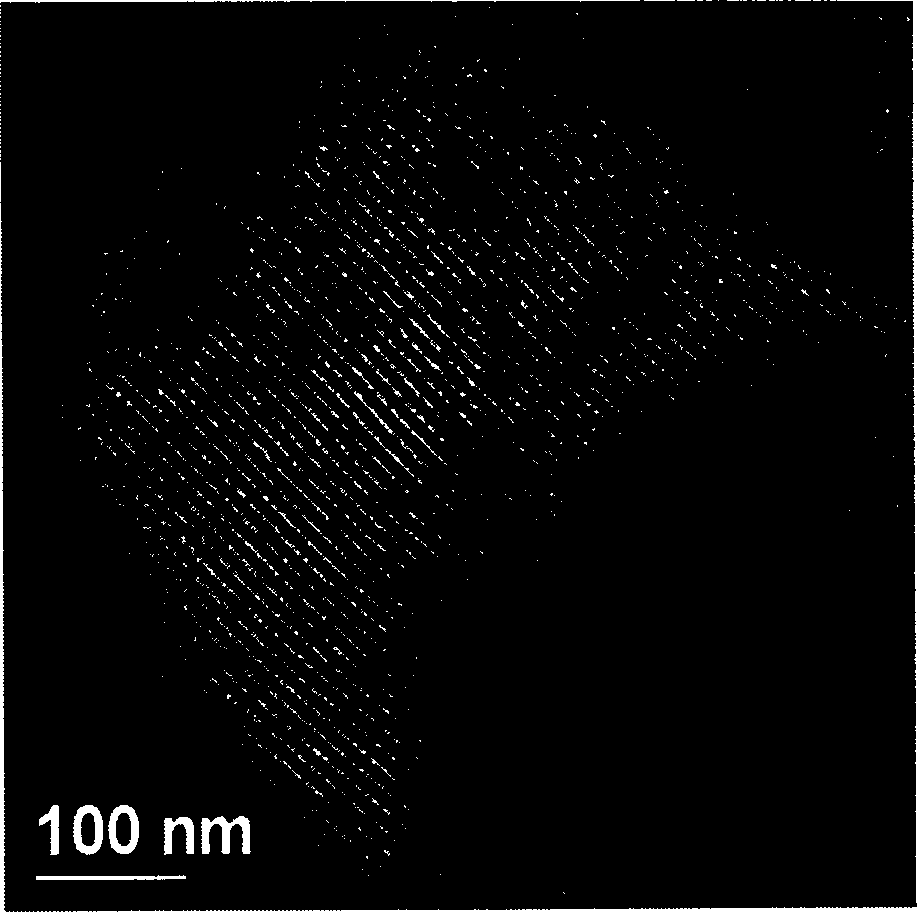

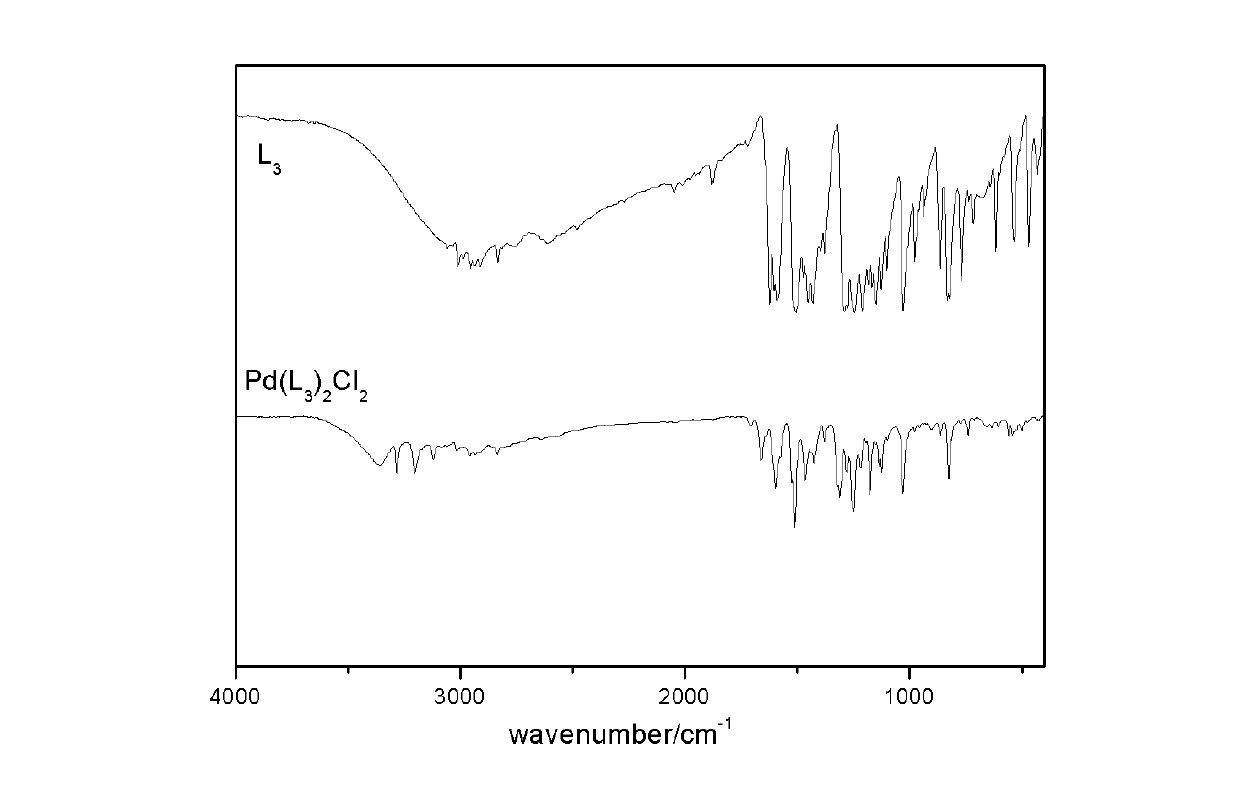

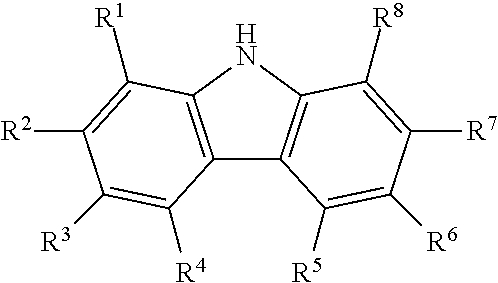

Schiff base complex catalyst for synthesizing diphenyl carbonate through oxidative carbonylation of phenol

InactiveCN102580775ASimple preparation processShort preparation timeOrganic compound preparationGroup 8/9/10/18 element organic compoundsRedoxPhenol

The invention discloses a catalyst for synthesizing diphenyl carbonate through liquid-phase oxidative carbonylation of phenol. The catalyst is of a homogeneous system taking a Schiff base palladium complex as a major catalyst and further comprises an inorganic redox assistant, an organic redox assistant and a surfactant, wherein the molar ratio of materials is as follows: the palladium: the inorganic redox assistant:the organic redox assistant: the surfactant=1:(5-20):(20-60):(80-120). Compared with the traditional catalyst for the liquid-phase oxidative carbonylation of the phenol, the catalyst disclosed by the invention is simple in preparation process and short in preparation time; the activity of the catalyst can be adjusted by altering the structure of the palladium complex; moreover, the catalyst has very high catalytic activity and selectivity; and the yield and selectivity of diphenyl carbonate can reach 60.0% and 95.9% at most.

Owner:HEBEI UNIV OF TECH

Catalyst for synthesizing diphenyl carbonate used in non-homogeneuos oxidation carbonylation and method for preparing the same

InactiveCN101147870AHigh catalytic activityNo pollution in the processProductsReagentsManganeseOxygen compound

The present invention relates to a catalyst for synthesizing diphenyl carbonate by utilizing heterogeneous oxidation carbonylation and preparation method of said catalyst. Said preparation method includes the following steps: making palladium salt be loaded on the manganese series composite metal oxide carrier, said manganese series composite metal oxide carrier is formed from manganese oxygen compound and metal oxide of any one kind or more than one kind of La, Ce, Ti, Zr, V, Cr, Mo, W, Fe, Co, Ni, Cu, Ag, Zn, Bi, Pb and Sn, the loaded quantity of active component Pd is 0.01wt%-10wt%, utilizing impregnating process, precipitation process or mixed fuel burning process to make the active component palladium salt be loaded on the manganese series composite metal oxide carrier, drying and calcining for 1-8h at 200-600deg.C so as to obtain the invented solid catalyst. Said catalyst can be used for preparing diphenyl carbonate, its productivity is up to 22.0% and its selectivity is up to 98.3%.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Process for preparing benzaldehyde by benzene oxidation and carbonylation

InactiveCN1594258AImprove economyLess corrosiveCarbonyl compound preparation by oxidationPhosphoniumBenzaldehyde

The invention discloses a process for preparing benzaldehyde by benzene oxidation and carbonylation by using benzene as reaction raw material, cobalt acetate as catalyst, trichloroacetic acid as solvent, oxygen as oxidizing agentconducting oxidation carbonylation reaction at the presence of nitrogen-containing or phosphonium-containing ligand, wherein the pressure of oxygen is 4-15 atm, the pressure of carbon monoxide is 8-40 atm, the reaction temperature is 50-150 deg. C, the reaction time is 10-72 hrs.

Owner:ZHEJIANG UNIV

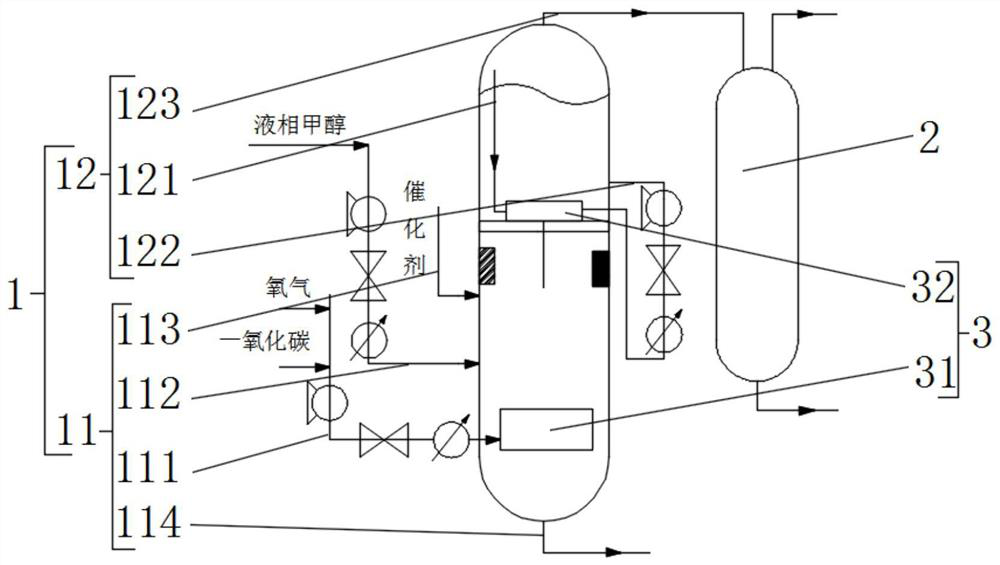

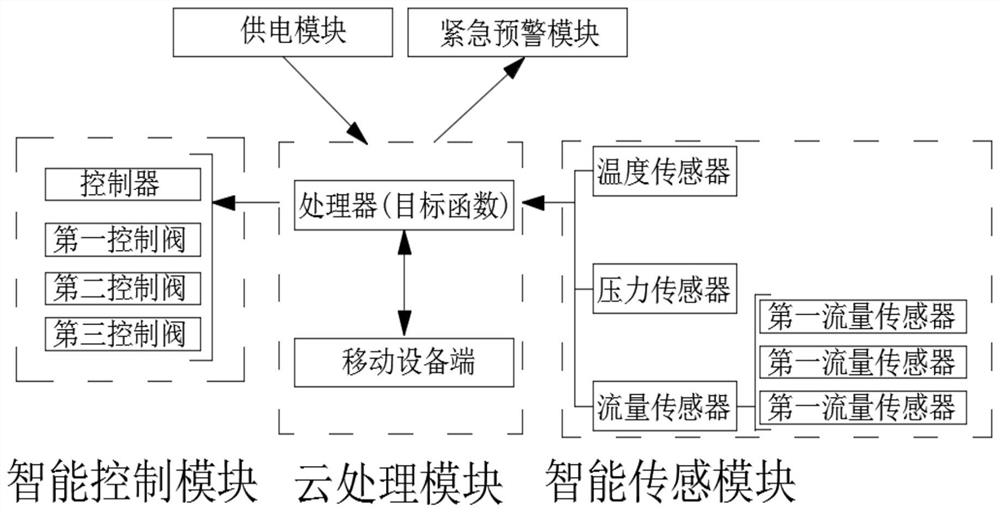

Intelligent reaction system and process for synthesizing dimethyl carbonate through liquid-phase oxidative carbonylation of methanol

InactiveCN112473566AImprove Oxylation EfficiencyIncreased phase boundary areaChemical/physical/physico-chemical microreactorsPreparation from carbon monoxide and oxygenEmulsionFluid phase

The invention relates to an intelligent reaction system and process for synthesizing dimethyl carbonate through liquid-phase oxidative carbonylation of methanol. The intelligent reaction system comprises a reaction tower, a buffer tank, micro-interface generators and an intelligent control unit. Oxygen and carbon monoxide are crushed to form micron-scale bubbles, so the reaction rate of oxygen andcarbon monoxide with liquid-phase methanol is increased; meanwhile, a gas-liquid emulsion is conveyed back to a reaction area through a second micro-interface generator for opposite impacting with agas-liquid emulsion output by a first micro-interface generator, and therefore, the retention time of the micron-scale bubbles in the reaction area is prolonged, gas and liquid phases are subjected toa secondary reaction, and the conversion rate of liquid-phase methanol is increased; and through the intelligent control unit, a worker can know the real-time situation of all data sent back by an intelligent sensing module at any time through a mobile device, and the inner temperature and the inner pressure of the whole reaction tower can be accurately controlled by changing preset values, so reaction efficiency is further improved.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

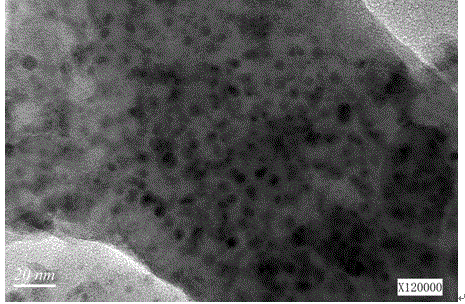

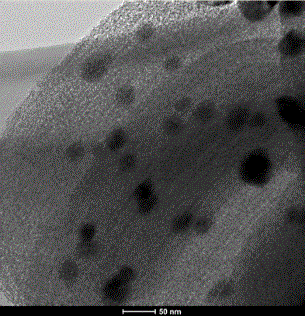

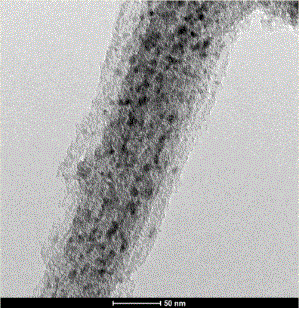

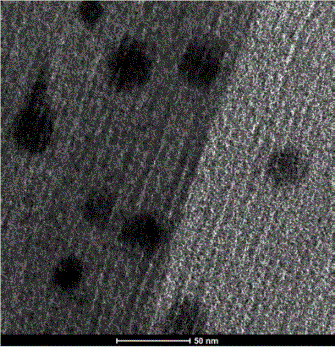

Preparation method of Cu nanoparticles-embedded ordered mesoporous carbon catalyst

InactiveCN105521782AUniform and orderly channelsLarge specific surface areaOrganic compound preparationPreparation from carbon monoxide and oxygenDispersityPtru catalyst

The invention discloses a preparation method of a Cu nanoparticles-embedded ordered mesoporous carbon catalyst and belongs to the field of chemical heterogeneous catalysis. The preparation method comprises the following steps: Step 1, template mesoporous silica material SBA-15 filling-rolling over; Step 2, carbonization; and Step 3, silica removal. The process of template mesoporous silica material SBA-15 filling-rolling over comprises impregnation, dispersion, drying, pre-carbonization and single repetitive operation. The problem that catalytic activity of a catalyst will decrease with the reaction process is solved. The prepared chloride-free copper-based catalyst of the invention is a nanoscale catalyst with 5-25nm copper particles embedded in pores of and on the surface of the ordered mesoporous carbon. Dispersity is good, and migration and agglomeration are not easy to occur in the reaction process. The catalyst has high reaction activity and good stability when used in an atmospheric continuous fixed bed for methanol gaseous oxidative carbonylation for synthesis of dimethyl carbonate.

Owner:CHINA UNIV OF MINING & TECH

Method for preparing dialkyl carbonates

ActiveCN101323572AHigh activityHigh yieldOrganic-compounds/hydrides/coordination-complexes catalystsPreparation from organic carbonatesAlcoholReaction rate

The invention relates to a preparation method of diester carbonate. The diester carbonate is produced through oxidation and carbonylation reaction of alcohols compound under the condition of the existence of a carbon monoxide, oxygen and liquid phase catalyzing system, wherein, the liquid phase catalyzing system contains a catalyst, at least one cocatalyst and at least one ion liquid consists of a positive ion and a negative ion, and the positive ion of the ion liquid has a nitrogen heterocyclic ring structure. The preparation method of the invention mainly uses the cocatalyst and ion liquid to enhance the activity of the catalyst and to further improve the catalysis efficiency, and has effects of improving reaction rate and increasing yield.

Owner:CHINA PETROCHEM DEVMENT

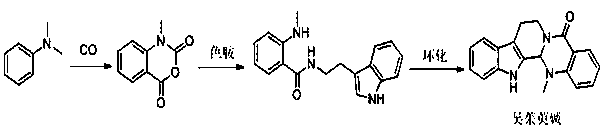

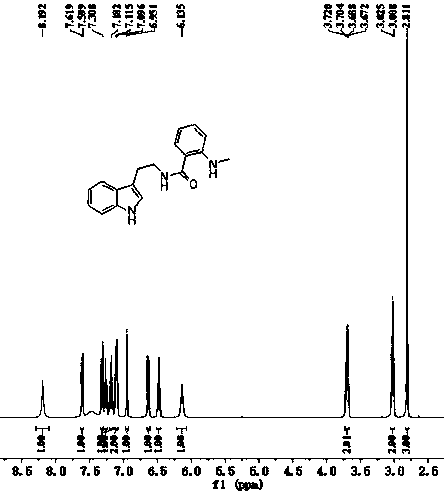

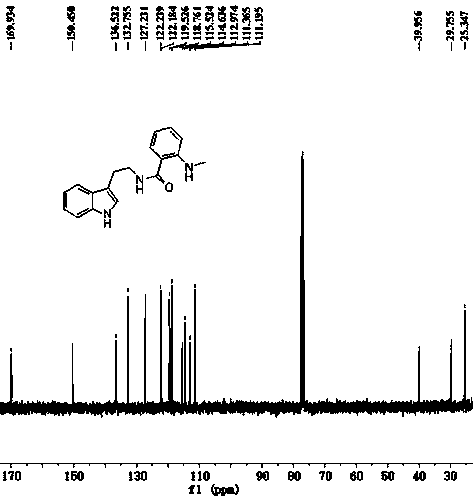

Method for synthesizing evodiamine by carbonylation reaction three-step method

ActiveCN107629051ANovel method of synthesisSimple operation processOrganic chemistryEvodiamineDimethylaniline N-oxide

The invention discloses a method for synthesizing evodiamine by a carbonylation reaction three-step method. The method comprises that N, N-dimethylaniline as a reaction material undergoes an oxidativecarbonylation reaction to produce N-methylisatoic anhydride, the N-methylisatoic anhydride undergoes an aminolysis reaction to produce N-(2-indolylethyl)-2-(methylamino)benzamide and the N-(2-indolylethyl)-2-(methylamino)benzamide undergoes a cyclization reaction to produce an evodiamine compound. The method is a novel synthesis method, utilizes simple and easily available reaction raw materials,has simple synthesis processes, is carried out under mild reaction conditions, is easy to operate, satisfies the development requirements of green chemistry, and successfully synthesizes the evodiamine.

Owner:蛮力蛮广州医药科技有限公司

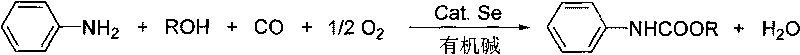

Method for synthesizing phenyl carbamate

InactiveCN101747234ASimple structureLow costCarbamic acid derivatives preparationOrganic compound preparationCarbamateAlcohol

The invention relates to a method for synthesizing phenyl carbamate and the method uses selenium as catalyst, organic base as cocatalyst and aniline and alcohol as reactants. The method comprises the step of performing an oxidative carbonylation reaction under carbon monoxide and oxygen in an autoclave to obtain phenyl carbamate. The invention has simple process, easy operation, high atom economy, environmental friend, cheap and accessible raw materials and catalyst, low cost and high yield, the product is easy to separate and purify, the catalyst is easy to separate and reclaim and can be recycled.

Owner:HENAN NORMAL UNIV

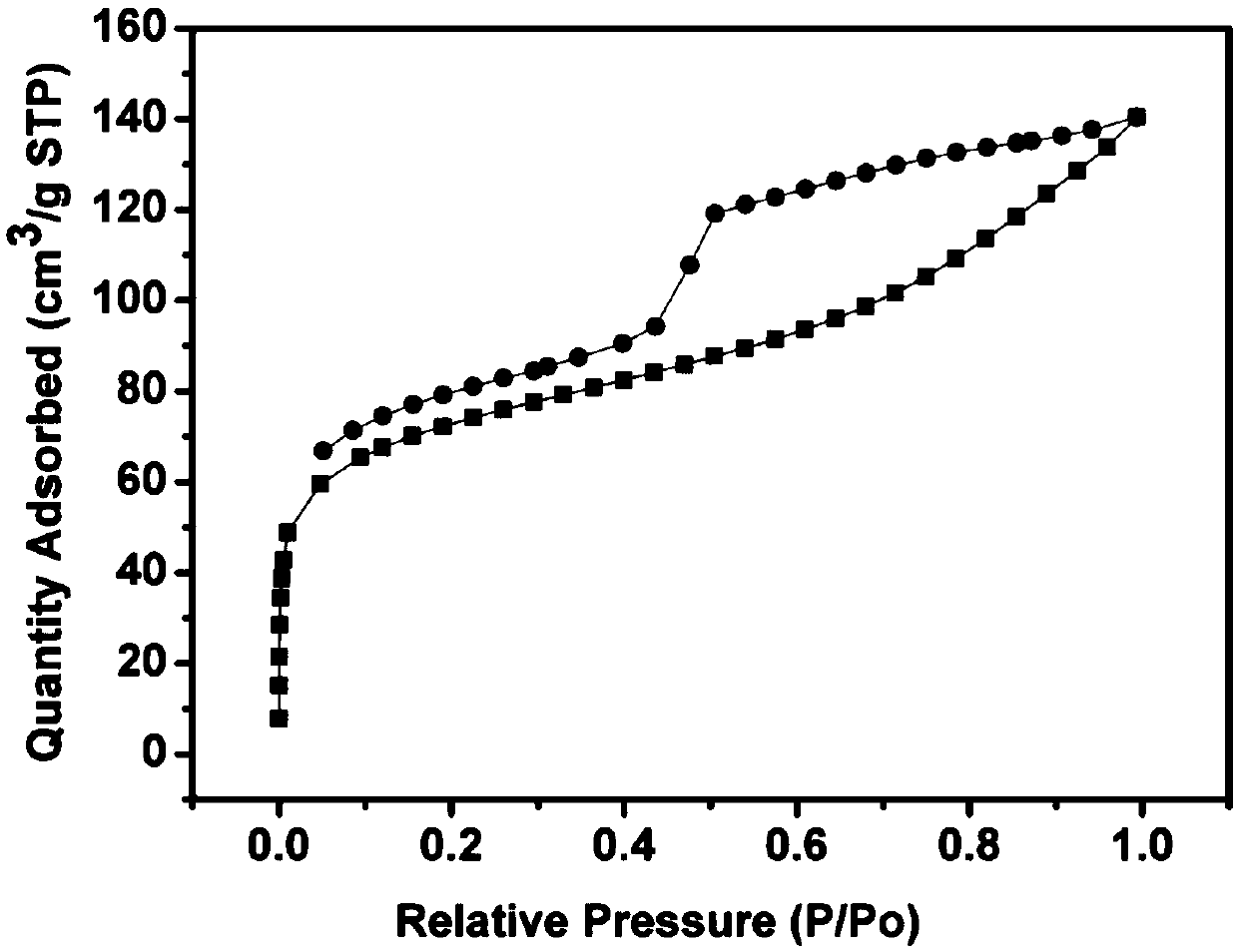

N-heterocyclic carbene functionalized porous organic polymer supported copper catalyst, preparation method thereof and application of catalyst

ActiveCN109746043AIncrease the areaLarge pore volumeOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsCarbeneCuprous salt

The invention relates to the technical field of catalyst preparation, in particular to an n-heterocyclic carbene functionalized porous organic polymer supported copper catalyst, a preparation method thereof and an application of the catalyst. Imidazolium ionic liquid serves as a solvent, water serves as a co-solvent, bis(1-imidazolyl) methane and polybrominated methyl aromatic hydrocarbon serve asco-monomers, pre-polymerization is performed for 0.5-3 hours at room temperature, polymerization reaction is performed for 12-48 hours at the temperature of 80-140 DEG C to obtain a porous polymer containing imidazolium salt, and then cuprous salt is supported on the porous polymer under alkaline conditions to obtain the n-heterocyclic carbene functionalized porous organic polymer supported copper catalyst. The porous catalyst has the advantages of large specific surface area and wide pore diameter distribution, and methanol and ethanol oxidative carbonylation can be efficiently catalyzed tosynthesize dialkyl carbonate. Compared with a traditional supported catalyst, the catalyst is high in activity, not easily lost, long in recycling life and expected to be used for practical industrialproduction.

Owner:南京宇源新能碳中和科技有限公司

Method for reactivating a deactivated catalyst composition

The present invention is directed to a method for reactivating a deactivated carbonylation catalyst composition previously used in a carbonylation reaction involving an aromatic hydroxy compound, carbon monoxide and oxygen, such that the reactivated catalyst composition is effective at carbonylating an aromatic hydroxy compound in a subsequent oxidative carbonylation reaction.

Owner:GENERAL ELECTRIC CO

Carried catalyst synthesizing diphenyl carbonate and its preparing method

InactiveCN1391985AHigh catalytic activityLow priceOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPhenolOxidative carbonylation

The present invention provides carried non-mobile metal compound catalyst Cu(OAc)2 / zeolite for synthesizing diphenyl carbonate and its preparation. The catalyst consists of zeolite in 50-100 weight portions and Cu(OAc)2 in 0.1-30 weight portions. It is prepared through equi-volume soaking and roasting at 250-750 deg.C. The catalyst system has metal acetate as inorganic oxidation-reduction assistant, hydroquinone as organic oxidation-reduction assistant, and tetrabutyl ammonium bridge as surfactant. The catalyst has very high catalytic activity and excellent selectivity to liquid phenol in synthesizing diphenyl carbonate. The catalyst is easy to separate from product, easy to recover and regenerate and has simple preparation process.

Owner:HEBEI UNIV OF TECH

Method for producing dialkyl carbonate

ActiveCN101234965AImprove conversion rateHigh selectivityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAlcoholMetal catalyst

Disclosed is a method for producing dialkyl carbonate comprising: using organic halide metal catalyst fit with at least one catalyst promoter containing nitrogen atoms to form a catalyst system in the presence of alcohol compound, carbon monoxide and oxygen gas, and carrying out a liquid-phase oxidative carbonylation reaction to obtain dialkyl carbonate. The method for producing dialkyl carbonate uses organic halide metal catalyst fit with the catalyst promoter containing nitrogen atoms, thereby improving the conversion rate, selectivity of catalysis, and reaction yield, and reducing catalyst consumption and reduce the corrosion on reactor.

Owner:CHINA PETROCHEM DEVMENT

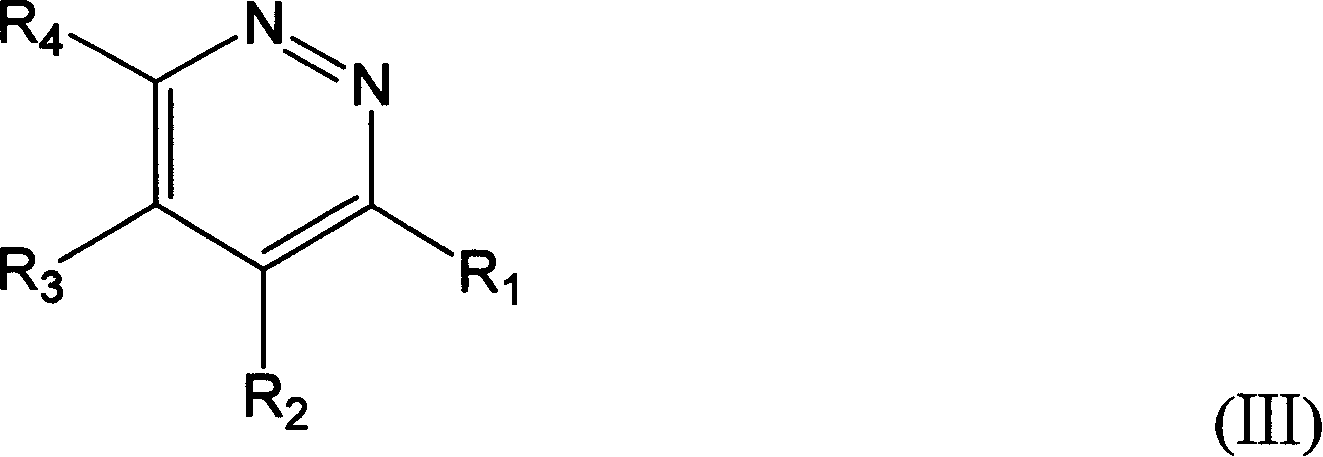

Process for producing diaryl carbonates

ActiveUS20110152558A1High reaction conversion rateLow reaction pressureOrganic compound preparationPreparation from carbon monoxide and oxygenNitrogenous heterocyclic compoundNitrogen

The present invention relates to a process for producing diaryl carbonates, which is to synthesize diaryl carbonates by oxidative carbonylation of phenols with carbon monoxide and oxygen, and in particular, to synthesize diphenyl carbonate from phenol. The present invention is characterized in that a catalytic system comprising a metal halide catalyst and one or more cocatalysts of nitrogenous heterocyclic compounds is used to increase the convertibility, selectivity and yield of this catalytic reaction.

Owner:CHINA PETROCHEM DEVMENT

Method for reactivating a catalyst composition

The present invention is directed to a method for reactivating a deactivated carbonylation catalyst composition previously used in a carbonylation reaction involving an aromatic hydroxy compound, carbon monoxide and oxygen, so that the re-activated catalyst composition is effective at carbonylating an aromatic hydroxy compound in a subsequent oxidative carbonylation reaction.

Owner:SABIC INNOVATIVE PLASTICS IP BV

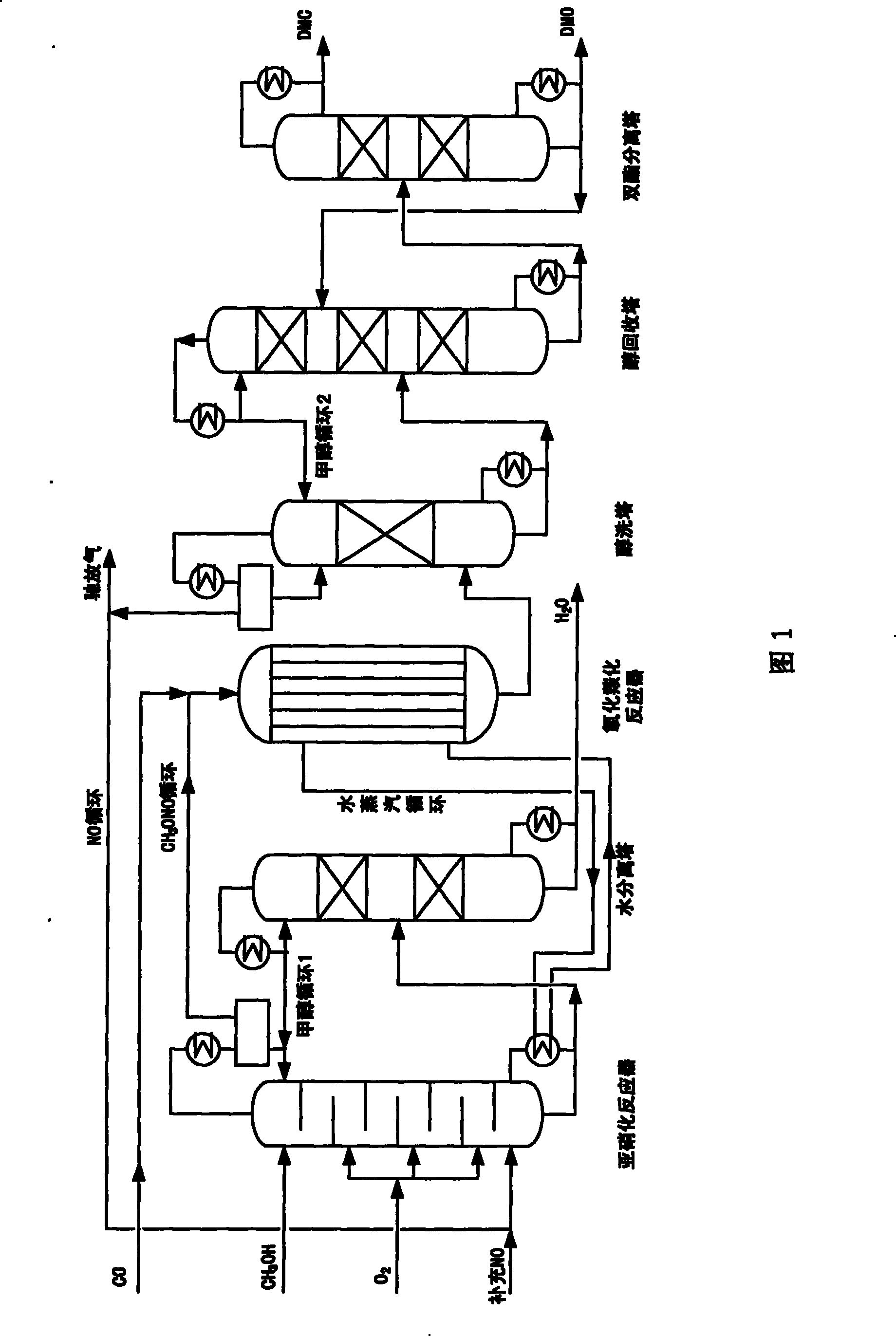

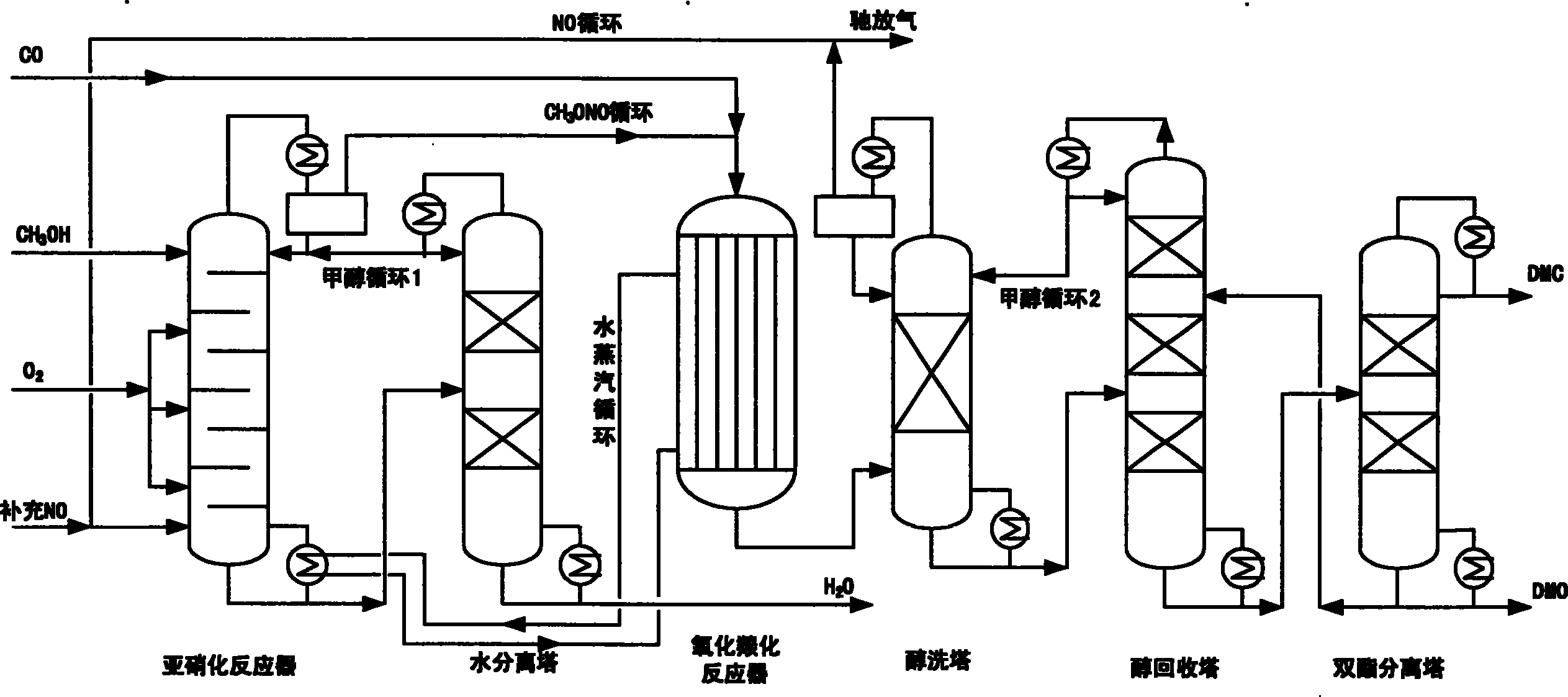

Method for synthesizing dimethyl oxalate and coproducing dimethyl carbonate

ActiveCN101190884BOrganic compound preparationPreparation by carbon monoxide or formate reactionAlcoholMethyl carbonate

The invention discloses a method for synthesizing dimethyl oxalate and by-producing dimethyl carbonate, which adopts industrial grade CO and O2 with a purity of more than 98 percent and industrial grade methanol with a purity higher than 99.5 percent as raw materials and NO as auxiliary material, so as to prepare dimethyl oxalate and by-produce dimethyl carbonate through nitrosation, oxidative carbonylation, and extraction and rectification circulation. The invention comprises four circulation loops: an NO / CH3ONO circulation loop consisting of an oxidative carbonylation reactor and a nitrosation reactor, a methanol circulation loop 1 consisting of a nitrosation reactor and a water separation tower, a water / steam circulation loop consisting of an oxidative carbonylation reactor and a nitrosation reactor, and a methanol circulation loop consisting of a methanol cleaning tower and a methanol circulation tower. The invention provides a method used for synthesizing dimethyl oxalate and by-producing dimethyl carbonate from the CO with industrialized development value.

Owner:SHANGHAI HUAYI ENERGY CHEM +1

Method for reactivating a deactivated catalyst composition

The present invention is directed to a method for reactivating a deactivated carbonylation catalyst composition previously used in a carbonylation reaction involving an aromatic hydroxy compound, carbon monoxide and oxygen, so that the re-activated catalyst composition is effective at carbonylating an aromatic hydroxy compound in a subsequent oxidative carbonylation reaction.

Owner:SABIC INNOVATIVE PLASTICS IP BV

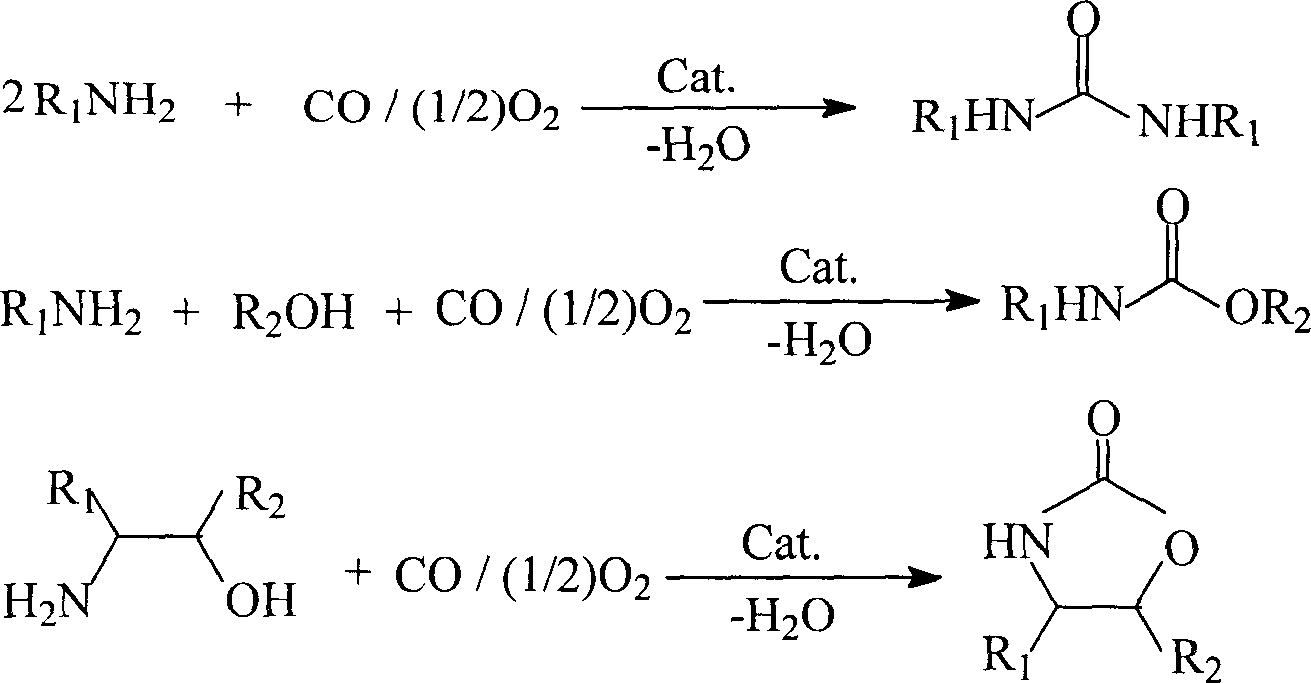

Process for preparing carbamate, urea and their derivatives as well as 2-oxzolidone

InactiveCN1900055AHigh selectivityEasy to manufactureUrea derivatives preparationCarbamic acid derivatives preparationCarbamatePhosphate

The present invention discloses preparation of nitrogen containing carbonyl compound, and is especially the process of preparing carbamate, urea and their derivatives as well as 2-oxazolidone through oxidizing and carbonylating organic amine compound in the presence of one kind of multifunctional catalyst. By using salt of VIII metal and Cu as main metal catalyst and the ionic solution of halogenated pyridine salt, quaternary ammonium salt or quaternary phosphate salt as co-catalyst and through oxidizing and carbonylating organic amine compound, carbamate, urea and their derivatives as well as 2-oxazolidone may be prepared at oxygen pressure of 0.2-1.0 MPa, CO pressure of 1.0-4.0 MPa, reaction temperature of 80-220 deg.c, and in reaction time of 0.5-4 hr. Compared with the technological process adopting traditional catalyst, the present invention has the advantages of simple system, easy preparation, mild reaction condition and high selectivity.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparation method used for combining dimethyl carbonate efficient catalysts

InactiveCN102836714AHigh selectivityHigh yieldOrganic compound preparationMetal/metal-oxides/metal-hydroxide catalystsEfficient catalystOxidative carbonylation

The invention discloses a preparation method for combining dimethyl carbonate efficient catalysts. The preparation method for combining the dimethyl carbonate efficient catalysts comprises the following steps of dipping activated carbons into aqueous solutions of copper compounds, dropwise adding reducing agent solutions to the aqueous solutions to carry out reduction, stirring in magnetic mode and keeping certain reduction temperature, after reduction, filtering and washing until washed filtrate is neutral, then drying. At last people can obtain the catalysts, wherein active components of the catalysts are copper Cu and carriers of the catalysts are active carbons. Compared with the prior art, when the catalysts which are prepared by the preparation method for combining the dimethyl carbonate efficient catalysts are used for dimethyl carbonate combined by methanol liquid-phase oxidative carbonylation, the catalysts are provided with the higher selectivity and yield of the dimethyl carbonate and have the advantages of greatly reducing corrosion of equipment, improving product quality, and lowering product cost.

Owner:HANGZHOU INST OF ADVANCED MATERIAL BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com