Intelligent reaction system and process for synthesizing dimethyl carbonate through liquid-phase oxidative carbonylation of methanol

A technology of liquid-phase oxidation of dimethyl carbonate, which is applied in the fields of carbon monoxide and oxygen preparation, chemical/physical/physical-chemical reactors, chemical/physical/physical-chemical processes, etc., can solve the problems of low system reaction efficiency and achieve improvement Effects of reaction efficiency, mass transfer enhancement, and guaranteed reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

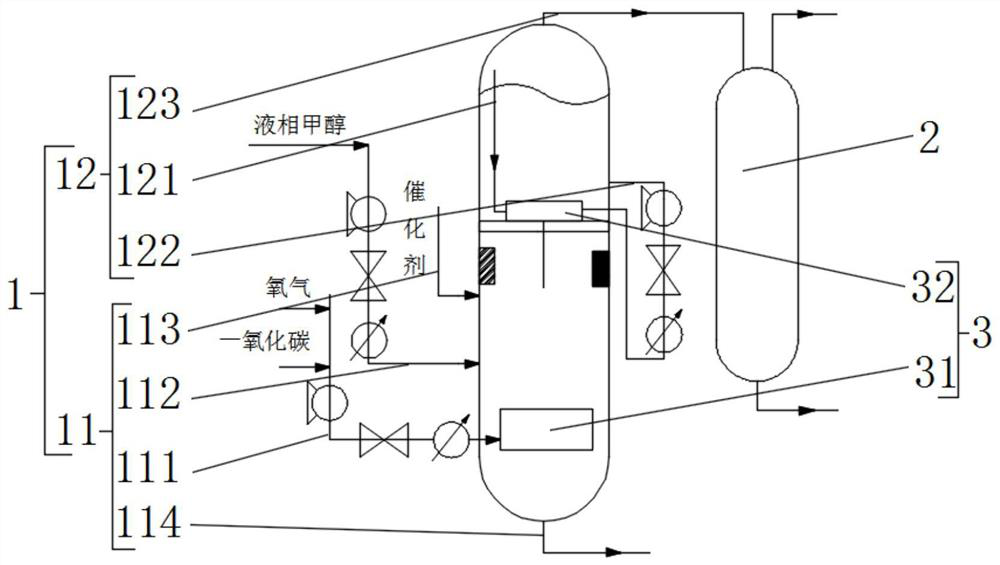

[0098] Methanol liquid phase oxide synthesis of dimethyl carbonate is carbonate using the above system and process.

[0099] Catalysts in the process are polyvinylpyridine load chloride catalysts;

[0100] The feed molar ratio of oxygen and carbon monoxide is 7: 9, and the liquid phase methanol is 0.6h. -1 ;

[0101] In the process, the reaction tower reaction temperature is 100 ° C, and the reaction pressure is 1 MPa;

[0102] The first micro-interface generator inner gas ratio is 700: 1, and the second micro interface generator is 300: 1.

Embodiment 2

[0104] Methanol liquid phase oxide synthesis of dimethyl carbonate is carbonate using the above system and process.

[0105] Catalysts in the process are polyvinylpyridine load chloride catalysts;

[0106] The feed molar ratio of oxygen and carbon monoxide is 7: 9.3, and the liquid phase methanol is 0.65 h. -1 ;

[0107] In the process, the reaction tower reaction temperature is 108 ° C, and the reaction pressure is 1.1 MPa;

[0108] The first micro-interface generator inner gas ratio is 740: 1, the second micro interface generator inner gas ratio is 360: 1.

Embodiment 3

[0110] Methanol liquid phase oxide synthesis of dimethyl carbonate is carbonate using the above system and process.

[0111] Catalysts in the process are polyvinylpyridine load chloride catalysts;

[0112] The feed molar ratio of oxygen and carbon monoxide is 7.5: 9, and the liquid phase methanol is 0.67 h. -1 ;

[0113] In the process, the reaction tower reaction temperature is 116 ° C, and the reaction pressure is 1.2 MPa;

[0114] The first micro-interface generator inner gas ratio is 780: 1, the second micro interface generator inner gas ratio is 420: 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com