Intelligent reaction system and method for preparing N-methyl sodium taurate

A technology of sodium methyl taurine and reaction system, which is applied in the field of intelligent reaction systems for preparing sodium N-methyl taurine, can solve industrial cost, large equipment cost loss, high labor intensity of operators, and manual addition of catalysts and other problems, to achieve the effect of high labor intensity, reducing labor intensity of workers, and improving the level of automated production and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

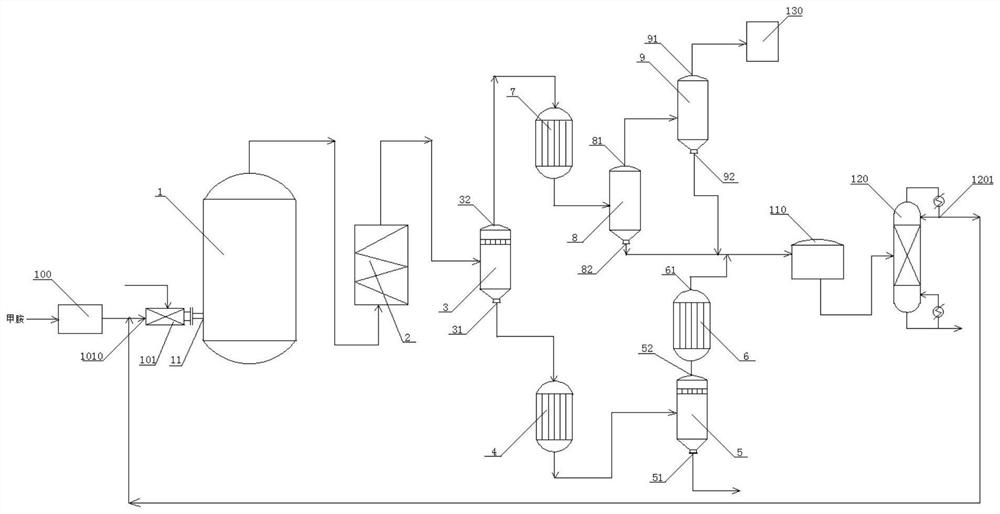

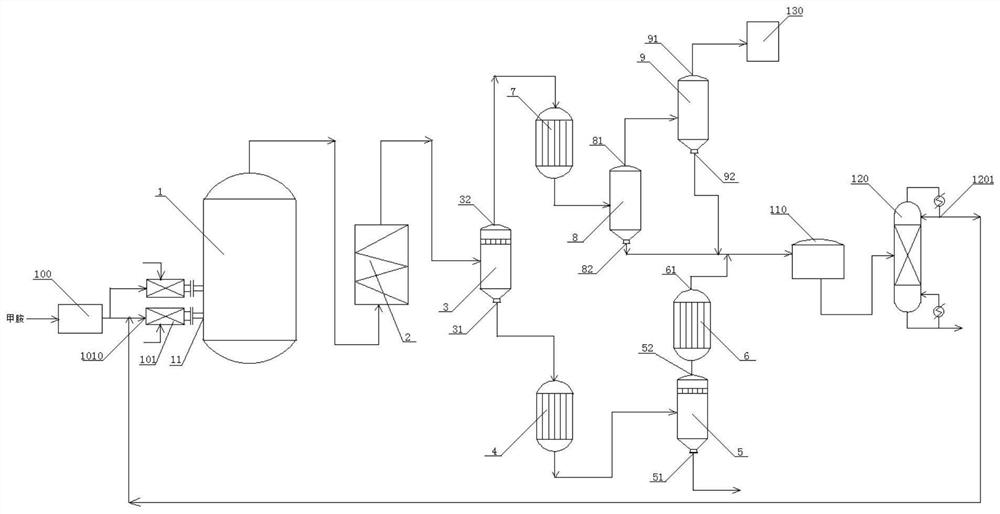

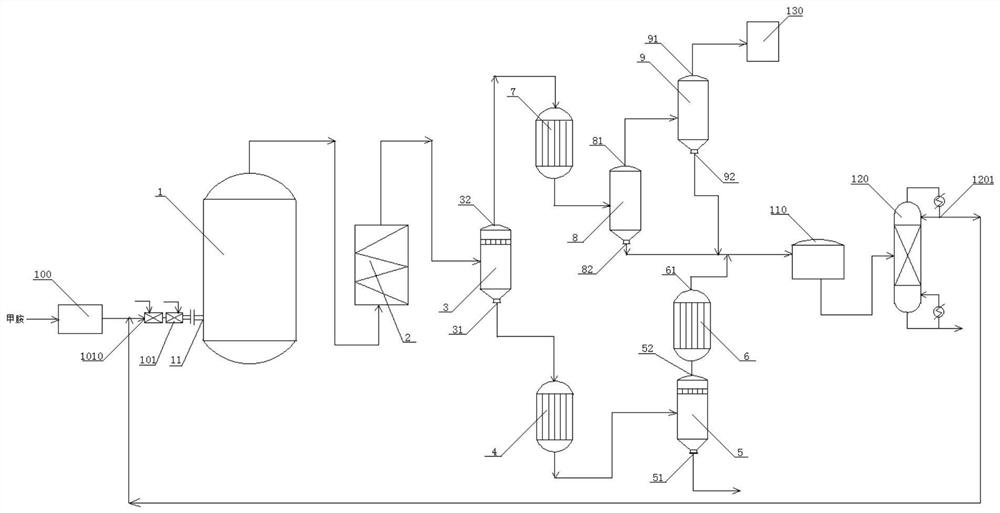

[0066] refer to figure 1 Shown, be the reaction system of the preparation N-methyl taurate sodium of the present invention, it has included amination reaction kettle 1, the amination reaction product that comes out from amination reaction kettle enters the first after the reaction of tubular reactor 2 A gas-liquid separation tank 3, specifically, the side wall of the amination reaction kettle 1 is provided with a raw material inlet 11, and the raw material inlet 11 is provided with a micro-interface generator 101 for dispersing and crushing materials into microbubbles, and the micro-interface generator 101 A methylamine inlet 1010 is provided on the side wall, and the methylamine inlet 1010 is connected to the vaporizer 100 for vaporizing methylamine and then entering the micro-interface generator 101 .

[0067] It can be understood that the number and type of micro-interface generators 101 are not specifically limited in this embodiment, and they can be selected from one of p...

Embodiment 2

[0083] This embodiment is different from Embodiment 1 only in the number of micro-interface generators, the temperature and pressure settings of the system, the number of micro-interface generators in this embodiment is 2 and set in parallel from top to bottom, the system temperature Set to 220°C and pressure to 7MPa. The output of sodium N-methyl taurate was detected, and the conversion rate of methylamine was calculated to be 98%.

Embodiment 3

[0085] This embodiment is different from Embodiment 1 only in the number of micro-interface generators, the temperature and pressure settings of the system. The number of micro-interface generators in this embodiment is 2 and the horizontal direction is connected in series. Set to 250°C and pressure to 10MPa. The output of sodium N-methyl taurate was detected, and the conversion rate of methylamine was calculated to be 97%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com