Top-mounted gas-liquid enhanced emulsification fixed bed reaction device and method

A fixed-bed reaction and fixed-bed reactor technology, applied in chemical instruments and methods, mixing methods, transportation and packaging, etc., can solve the problems of high safety risk, high investment, high material consumption, etc., and achieve low process severity and production. The effect of high safety and low cost per ton of product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

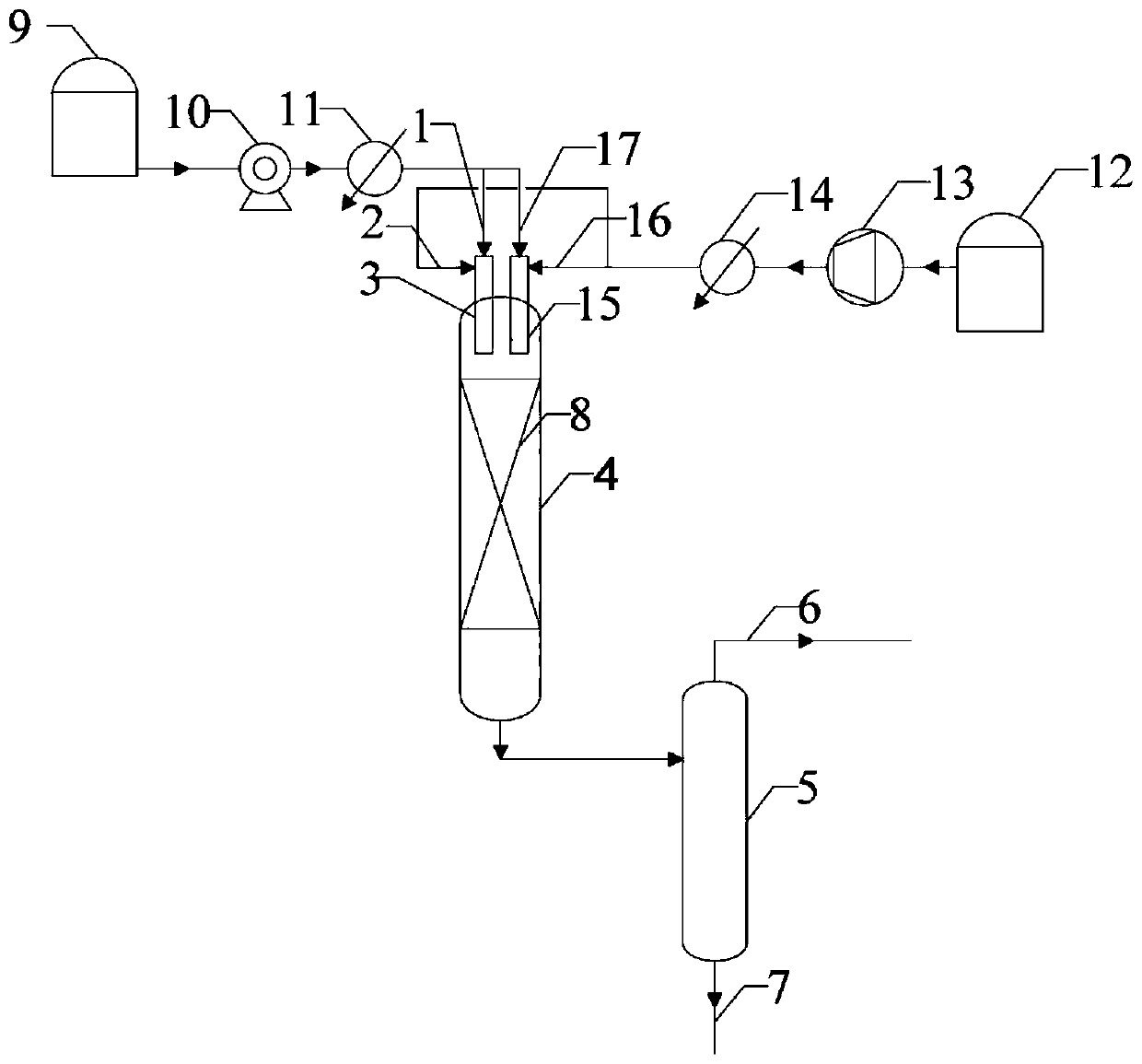

[0034] Such as figure 1 The above-mounted gas-liquid enhanced emulsification fixed-bed reaction device includes:

[0035] The fixed-bed reactor 4 is provided with a catalyst bed 8 inside and a second outlet at the bottom; the catalyst bed 8 can be one or more layers, and when a multi-layer catalyst bed is used, heat exchange is provided between the beds. device.

[0036] The air intake device includes a gas raw material buffer tank 12, a compressor 13 and a gas raw material preheater 15 connected in sequence, for raw gas transportation;

[0037] The liquid inlet device includes a liquid raw material tank 9, a feed pump 10 and a liquid raw material preheater 11 connected in sequence, for raw material liquid delivery;

[0038]At least one bubble breaker is arranged on the top of the fixed bed reactor, and the bubble breaker is provided with a gas phase inlet, a liquid phase inlet and a first discharge port, and the first discharge port is connected to the fixed bed reactor; th...

Embodiment 2

[0042] This example specifically illustrates the method of using the device in Example 1 to carry out the gas-liquid intensified reaction.

[0043] The fresh hydrogen and kerosene enter through the gas phase inlet 2 of the gas-liquid linkage bubble breaker and the liquid phase inlet 1 of the gas-liquid linkage bubble breaker respectively at a standard volume ratio of 0.3:1 and are installed above the shell of the fixed bed reactor 4 In the gas-liquid linkage type bubble breaker 3, the other way enters the fixed bed reactor through the gas phase inlet 17 of the pneumatic bubble breaker and the liquid phase inlet 16 of the pneumatic bubble breaker respectively at a standard volume ratio of 900:1. 4 in the pneumatic bubble breaker 15 above the housing interior. Under the action of the gas-liquid linkage bubble breaker 3 and the pneumatic bubble breaker 15, the hydrogen is broken into microbubbles with an average diameter of 300-400 μm, and the gas-liquid is violently mixed to for...

Embodiment 3

[0046] Fresh hydrogen and aviation kerosene go through the gas phase inlet 2 of the gas-liquid linkage bubble breaker and the liquid phase inlet 1 of the gas-liquid linkage bubble breaker respectively at a standard volume ratio of 0.28:1 and enter the shell installed in the fixed bed reactor 4 In the gas-liquid linkage type bubble breaker 3 above, the other channel enters the fixed bed reaction through the gas phase inlet 17 of the pneumatic bubble breaker and the liquid phase inlet 16 of the pneumatic bubble breaker respectively at a standard volume ratio of 950:1. In the pneumatic bubble breaker 15 above the housing interior of the device 4. Under the action of the gas-liquid linkage bubble breaker 3 and the pneumatic bubble breaker 15, the hydrogen is broken into microbubbles with an average diameter of 300-600 μm, and the gas-liquid is violently mixed to form a gas-liquid emulsion, which enters the top of the fixed-bed reactor 4 , flows from top to bottom, passes through a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com