Preparation of organic/inorganic nano media pores hybridization catalyst utilized for synthesizing methyl carbonate as well as its application

A technology of dimethyl carbonate and inorganic nanometers, which is applied in the preparation of organic compounds, organic compound/hydride/coordination complex catalysts, carbonate/haloformate preparation, etc., can solve the problem of equipment corrosion, Poor solubility, low reaction efficiency and other problems, to achieve the effect of improving catalytic efficiency and reducing acidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

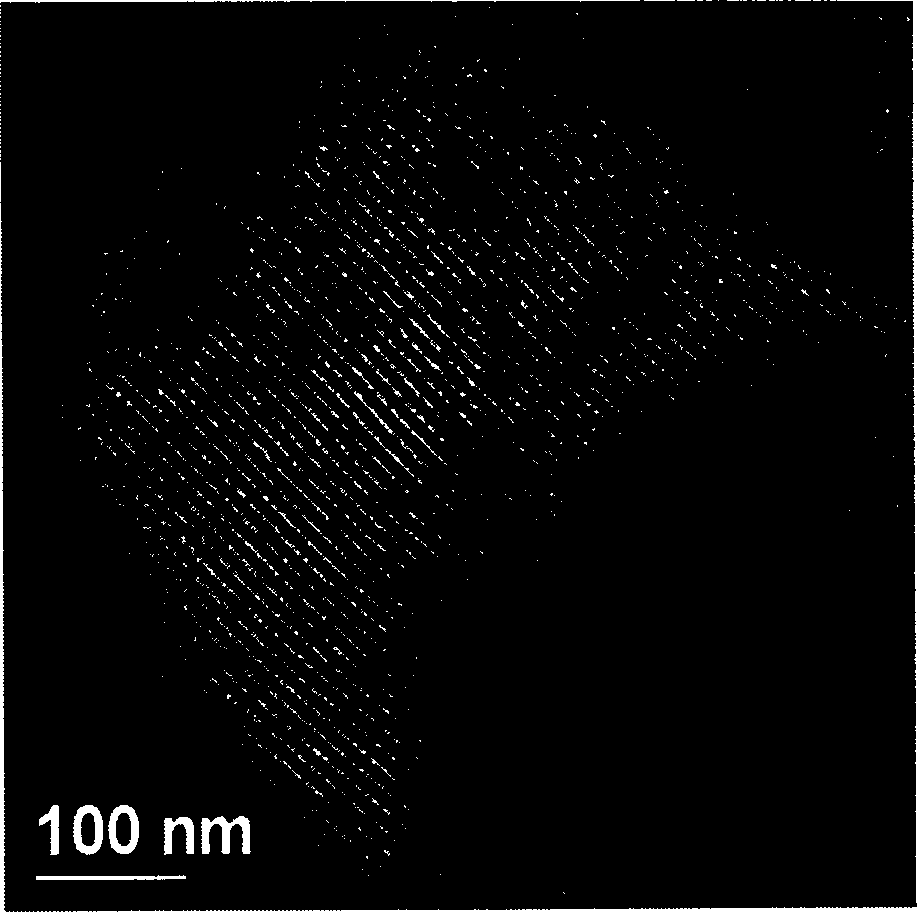

Image

Examples

Embodiment 1

[0015] Add 10g of MCM-41 sample that has been pretreated for 10 hours at 200°C into 100mL of freshly steamed toluene, stir well, then add 40mL (EtO) 3 Si(CH 2 ) 3 NH2 and 50mL of anhydrous ethyl formate, heated to 120°C, continuously stirred and refluxed for 12h, washed with absolute ethanol several times, filtered with suction, and dried in a vacuum oven; the above product was added to 100mL of ethanol, Then add 3g CuCl 2 , stirred and refluxed for 10h, washed the reaction product several times with absolute ethanol, and dried in vacuum to obtain 12g CuCl 2 -amide-MCM-41 nano mesoporous hybrid catalyst (Cu content: 3wt%).

[0016] In a 500ml autoclave, add 100ml methanol, 8g CuCl 2 -amide-MCM-41 nanometer mesoporous hybrid catalyst, with mixed gas (O 2 : 8%, CO: 92%) to replace the air in the reactor, and then use this gas to pressurize to 3.0MPa at room temperature. The reaction was carried out at 120° C. for 3 hours. After cooling, it was analyzed by gas chromatograp...

Embodiment 2

[0018] Add 4g of MCM-41 sample pretreated at 200°C for 10h into 100mL of freshly distilled toluene, stir well, then add 40mL (EtO) 3 Si(CH 2 ) 3 NHCH 2 CH 2 NH 2 and 50mL of anhydrous ethyl formate, heated to 120°C, continuously stirred and refluxed for 12h, washed with absolute ethanol several times, filtered with suction, and dried in a vacuum oven; the above product was added to 100mL of ethanol, Then add 3g CuCl 2 , stirred and refluxed for 10h, washed the reaction product several times with absolute ethanol, and dried in vacuum to obtain 12g CuCl 2 - diamide-MCM-41 nano-mesoporous hybrid catalyst (Cu content: 10 wt%).

[0019] In a 500ml autoclave, add 100ml methanol, 8g CuCl 2 -diamide-MCM-41 nanometer mesoporous hybrid catalyst, with mixed gas (O 2 : 8%, CO: 92%) to replace the air in the reactor, and then use this gas to pressurize to 3.0MPa at room temperature. The reaction was carried out at 120° C. for 3 hours. After cooling, it was analyzed by gas chromat...

Embodiment 3

[0023] Add 10g of HMS sample after 10h pretreatment at 200℃ into 100mL of freshly distilled toluene, stir well, add 40mL (EtO) 3 Si(CH 2 ) 3 NHCH 2 CH 2 NH 2 and 50mL of anhydrous ethyl formate, heated to 120°C, continuously stirred and refluxed for 12h, washed with absolute ethanol several times, filtered with suction, and dried in a vacuum oven; the above product was added to 100mL of ethanol, Then add 5g CuCl, stir and reflux for 10h, wash the reaction product several times with absolute ethanol, and vacuum dry to obtain 12g CuCl-diamide-HMS nano-mesoporous hybrid catalyst (Cu content: 4wt%).

[0024] In 500ml autoclave, add 100ml methyl alcohol, 8g CuCl-diamide-HMS nano mesoporous hybrid catalyst, with mixed gas (O 2 : 8%, CO: 92%) to replace the air in the reactor, and then use this gas to pressurize to 3.0MPa at room temperature. The reaction was carried out at 120° C. for 4 hours. After cooling, it was analyzed by gas chromatography. The selectivity of dimethyl ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com