N-heterocyclic carbene functionalized porous organic polymer supported copper catalyst, preparation method thereof and application of catalyst

A nitrogen-heterocyclic carbene and porous polymer technology, applied in the field of catalyst preparation, can solve the problems of corrosion of reaction equipment, poor recycling performance, and easy loss of active components, etc., and achieve good application prospects and excellent recycling performance , the effect of strong coordination ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Example 1 The application of a nitrogen-heterocyclic carbene functionalized porous organic polymer-supported copper catalyst in the oxidative carbonylation of liquid alcohols, the steps are as follows:

[0048] (1) Preparation of carrier (PNHC-1)

[0049] Mix 10 g of 1-butyl-3-methylimidazolium chloride salt and 2.5 g of deionized water at room temperature to obtain a 1-butyl-3-methylimidazolium chloride salt solution, and then add 0.461g of bis(1-imidazolyl)methane and 0.739g of 1,3,5-tri(bromomethyl)benzene were stirred and reacted at room temperature (25°C, the same below) for 2 hours for prepolymerization, and then the reaction The temperature of the solution was raised to 100°C, and the mixture was stirred and reacted at 100°C for 36 hours to carry out polymerization; after the reaction was completed, a massive solid was obtained, which was washed with water for 6 times, then washed with absolute ethanol for 3 times, and then filtered to obtain a solid The porous ...

Embodiment 2

[0056] Example 2 The application of a nitrogen-heterocyclic carbene functionalized porous organic polymer-supported copper catalyst in the oxidative carbonylation of liquid alcohols, the steps are as follows:

[0057] (1) Preparation of carrier (PNHC-2)

[0058] 15g of 1-propyl-3-methylimidazolium bromide and 3.0g of deionized water were fully stirred at room temperature to obtain a 1-propyl-3-methylimidazolium bromide solution, and then 0.953 g of bis(1-imidazolyl)methane and 1.447g of 1,2,4,5-tetrakis(bromomethyl)benzene were stirred and reacted at room temperature for 1 hour for pre-polymerization, and then the temperature of the reaction solution was raised to 90°C, Stir the reaction at 90°C for 48 hours to carry out polymerization; after the reaction is completed, blocky solids are obtained. The blocky solids are washed with water for 6 times, and then washed with ethanol for 3 times. After filtering, the obtained solids are vacuum-dried overnight at 60°C to obtain The p...

Embodiment 3

[0064] Example 3 The application of a nitrogen-heterocyclic carbene functionalized porous organic polymer-supported copper catalyst in the oxidative carbonylation of liquid alcohols, the steps are as follows:

[0065] (1) Preparation of carrier (PNHC-3)

[0066] 20g of 1-hexyl-3-methylimidazole nitrate and 2.8g of deionized water were fully stirred at room temperature to obtain a 1-hexyl-3-methylimidazole nitrate solution, and then 0.960g of Bis(1-imidazolyl)methane and 1.540g of 1,3,5-tri(bromomethyl)benzene were stirred and reacted at room temperature for 1 hour for pre-polymerization, and then the temperature of the reaction solution was raised to 115°C. Under stirring reaction 24 hours carry out polymerization; Obtain block solid after reaction is finished, block solid is washed 6 times with water earlier, then cleans with ethanol 3 times, filters, and gained solid obtains porous polymer carrier after 60 ℃ of vacuum drying overnight ( PNHC-3), the mass of PNHC-3 is 2.52g,...

PUM

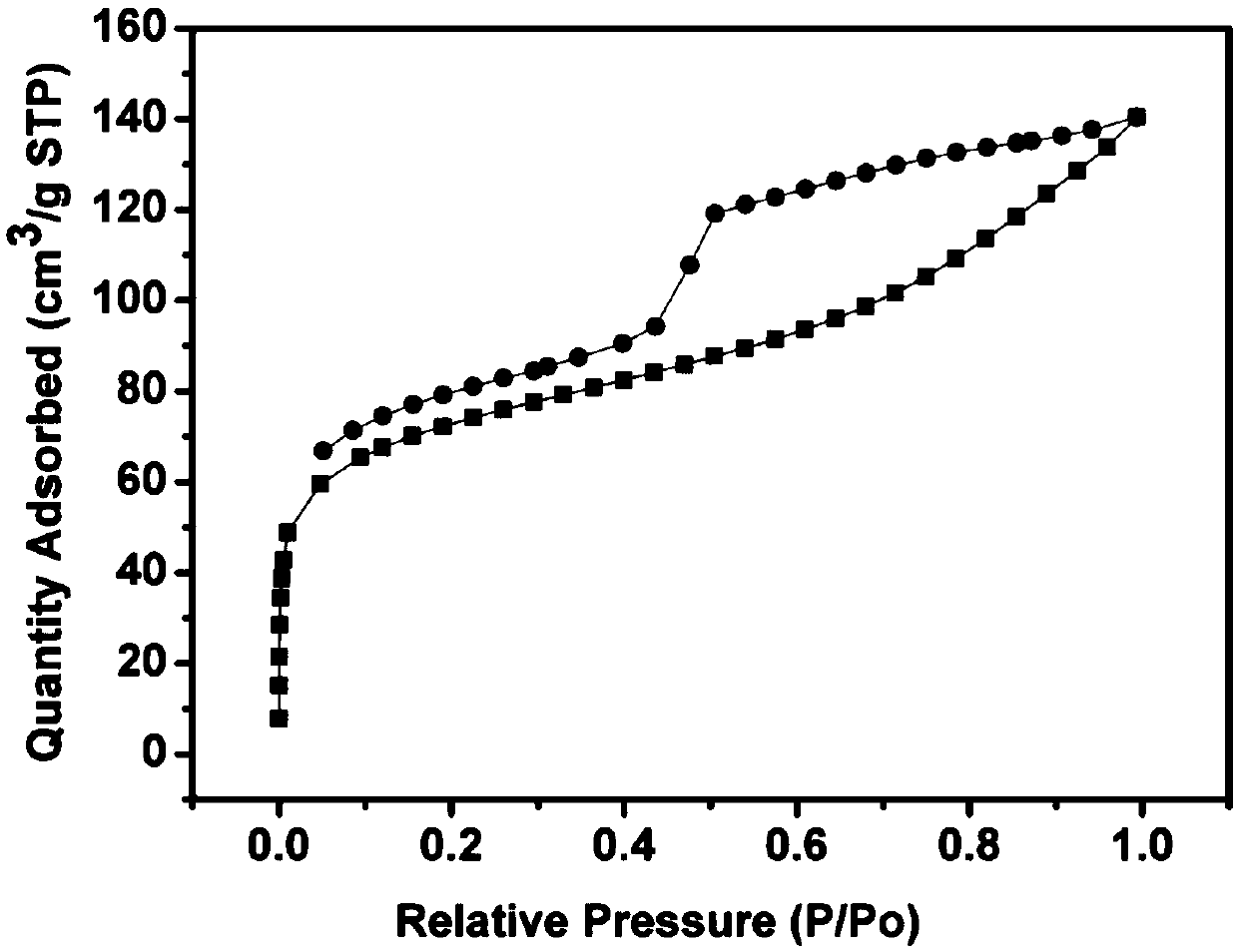

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com