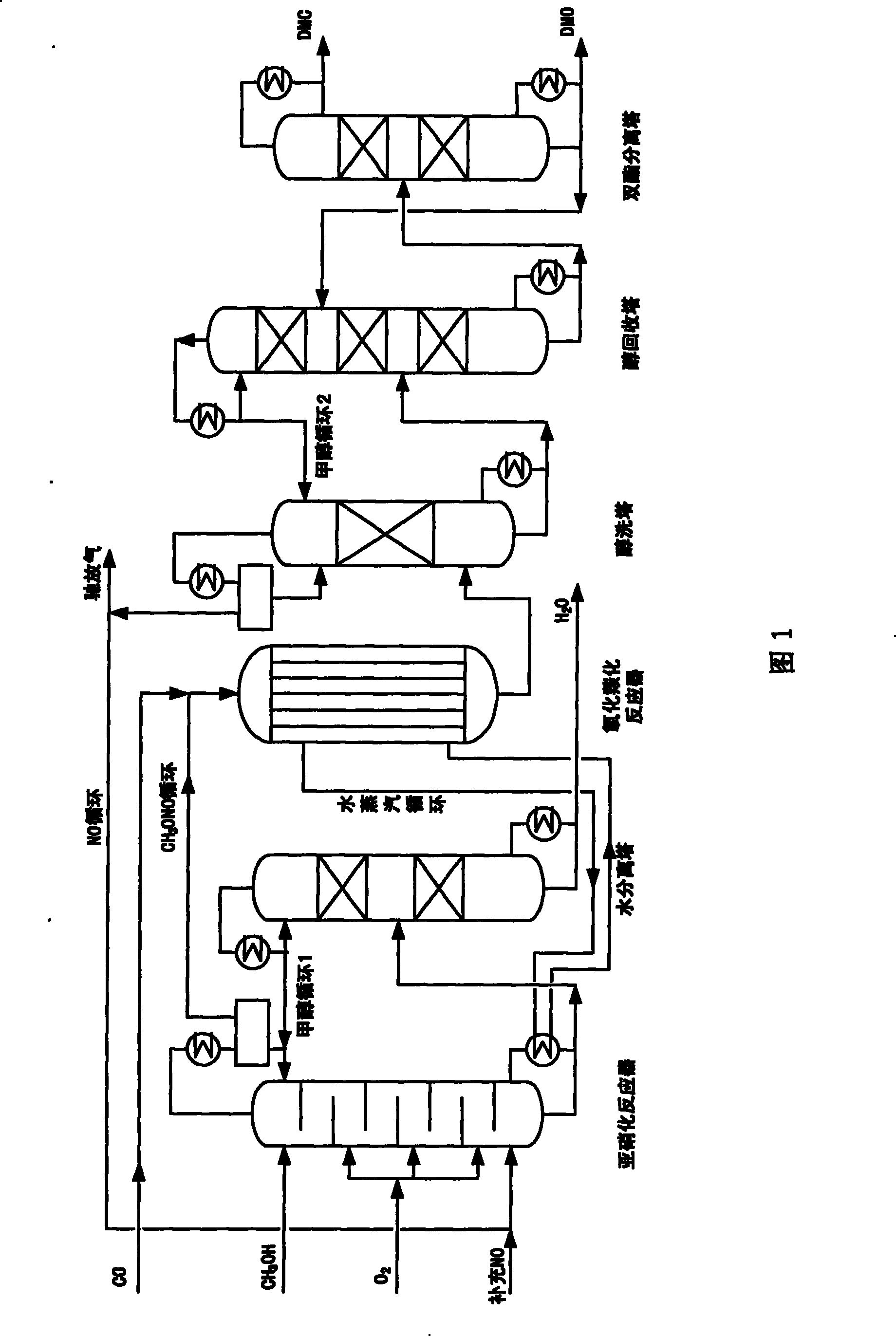

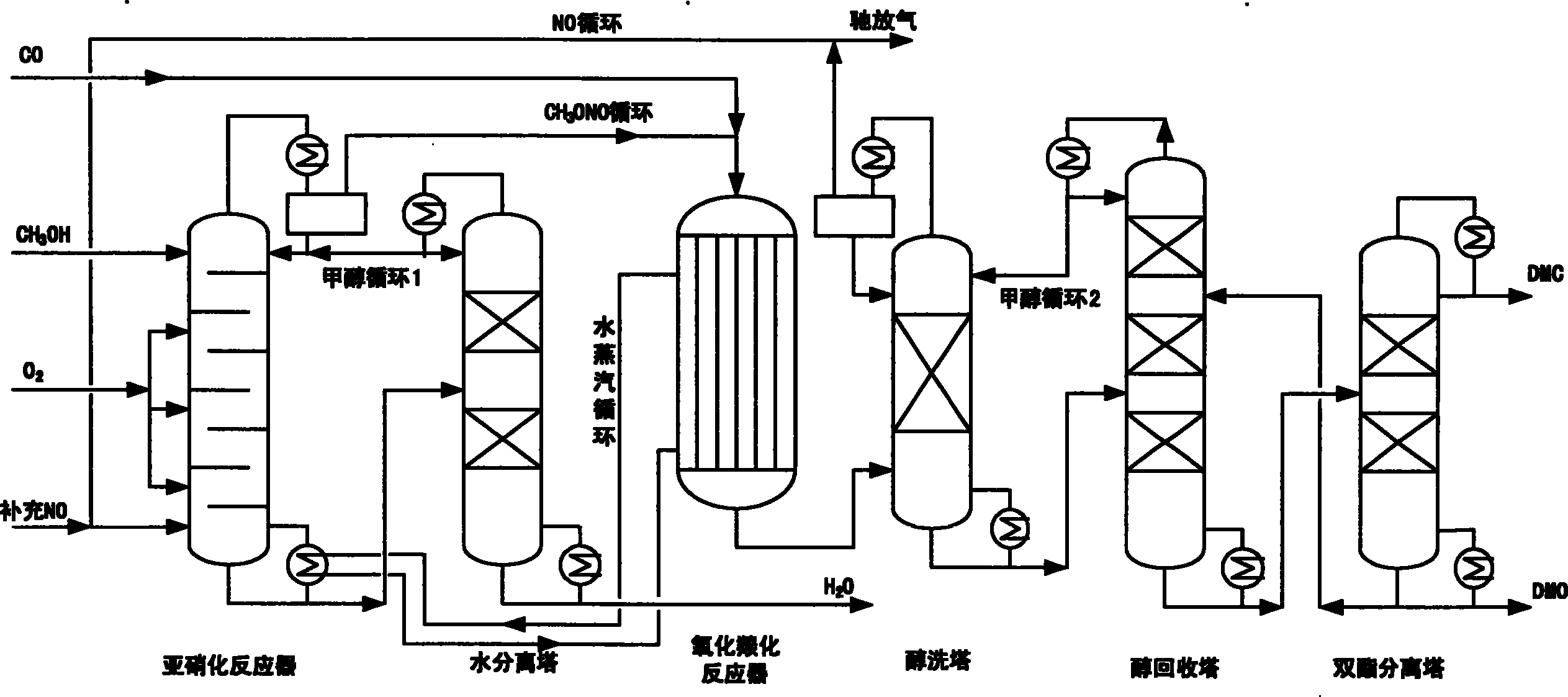

Method for synthesizing dimethyl oxalate and coproducing dimethyl carbonate

A technology for synthesizing dimethyl oxalate and dimethyl carbonate, which is applied in the preparation of carbonate/haloformate, chemical instruments and methods, and the preparation of organic compounds, and can solve problems such as failure to handle well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

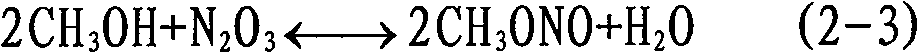

Method used

Image

Examples

Embodiment 1

[0083] The present embodiment is the scale of annual output of 5000 tons of dimethyl oxalate.

[0084] CO is 98.5% pure, the rest as N 2 .

[0085] o 2 The purity is also 98.5%, the rest is N 2 .

[0086] The purity of methanol is 99.9%, and the rest is water.

[0087] Supplementing NO is supplemented by the method of generating methyl nitrite from sodium nitrite, sulfuric acid and methanol.

[0088] In this example, the composition of the purge gas is: NO = 15%, CO = 10%, nitrite = 2%, methanol = 8%, N 2 = 65%. From raw gas CO and O 2 N brought into the system 2 The exhausted NO loss is 0.052 kmol / h, the CO loss is 0.03 kmol / h, and the methanol is 0.03 kmol / h.

[0089] In addition, in the nitrosation reactor, the selectivity of producing nitric acid is 2%, therefore, the amount of nitric acid produced per hour is 0.17 kmol / h, and the equivalent loss of NO is 0.17 kmol / h. It can be seen that the total NO loss is 0.22kmol / h, which is supplemented by the reaction of so...

Embodiment 2

[0103] The present embodiment is the scale of annual production of 10,000 tons of dimethyl oxalate.

[0104] CO is 98.5% pure and the remainder is N2.

[0105] The O2 purity is also 98.5%, and the rest is N2.

[0106] The purity of methanol is 99.9%, and the rest is water.

[0107] The method of supplementing NO is supplemented by ammonia oxidation.

[0108] In this example, the composition of the purge gas was: NO = 10%, CO = 10%, nitrite = 1%, methanol = 5%, and N2 was 74%. The N2 brought into the system by the raw material gas CO and O2 is 0.4kmol / h, and it is discharged through the purge gas. The NO loss is 0.073kmol / h, the CO loss is 0.073kmol / h, and the methanol is 0.036kmol / h.

[0109] In addition, in the nitrosation reactor, the selectivity of producing nitric acid is 1.2%, therefore, the amount of nitric acid produced per hour is 0.2 kmol / h, and the equivalent loss of NO is 0.2 kmol / h. It can be seen that the total NO loss is 0.273kmol / h, supplemented by the ammon...

Embodiment 3

[0123] The present embodiment is the scale of annual production of 1000 tons of dimethyl oxalate.

[0124] CO is 98.5% pure and the remainder is N2.

[0125] The O2 purity is also 98.5%, and the rest is N2.

[0126] The purity of methanol is 99.9%, and the rest is water.

[0127] The method of supplementing NO is supplementing with purchased NO cylinder gas.

[0128] In this example, the composition of the purge gas is: NO = 20%, CO = 10%, nitrite = 3%, methanol = 10%, N2 is 57%. The N2 brought into the system by the raw material gas CO and O2 is 0.04kmol / h, and it is discharged through the purge gas. The NO loss is 0.016kmol / h, the CO loss is 0.007kmol / h, and the methanol is 0.007kmol / h.

[0129] In addition, in the nitrosation reactor, the selectivity of producing nitric acid is 2.0%, therefore, the amount of nitric acid produced per hour is 0.02 kmol / h, and the equivalent loss of NO is 0.02 kmol / h. It can be seen that the total NO loss is 0.036kmol / h, equivalent to 0.81...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com