Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

263 results about "Aluminium alkyl" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rare earth catalyst for preparing polyisoprene and preparation method and method for preparing polyisoprene

This invention belongs to rare earth catalyzer for preparing polyisoprene, and its preparation method. This catalyzer is composed by carboxylic acid neodymium, aluminium alkyl, chloride, conjugated diolefine. Mixture ratio of aluminium alkyl, chloride, conjugated diolefine,and carboxylic acid neodymium is 5 - 30:1.0 -4.0:5 - 20:1. This invention could obtain homogeneous phase and stable rare earth catalyzer. This catalyzer possess higher catalytic activity, trigger off isoprene polymerization at higher polymerization temperature, obtain polyisoprene that has high content of syn- 1, 4 structure( not less than 96 percent) and narrow molecular weight distribution ( less than 3.0), and possess tensile crystallinity trait.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

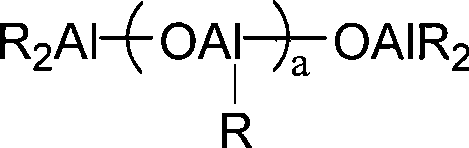

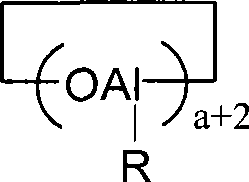

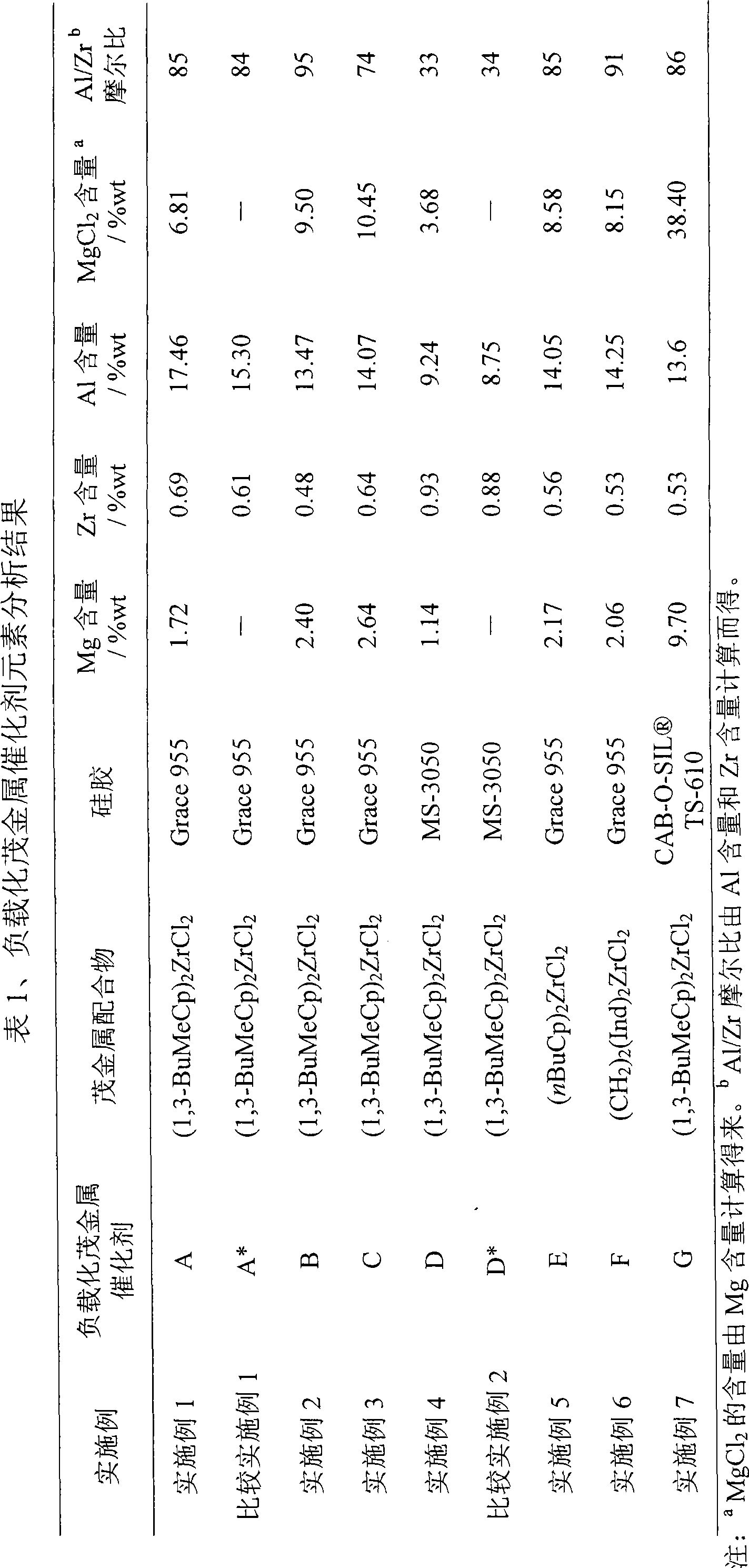

Supported metallocene catalyst component and preparation method thereof and use

The invention discloses a loading metallocene catalyst composition which is obtained through adopting an alkyl aluminoxane / magnesium chloride / silica gel carrier as a carrier and loading a metallocene catalyst precursor, and a preparation method thereof. The catalyst system consisting of the catalyst composition catalyzes ethylene to polymerize or copolymerize and has high polymerization activity. Compared with a common loading metallocene catalyst with an alkyl aluminoxane / silica gel carrier, the activity can be doubled or more. The carrier is simple to prepare; the prepared loading catalyst granule has good shape and adjustable size; and the obtained polythene powdery material has high stacking density.

Owner:CHINA PETROLEUM & CHEM CORP +1

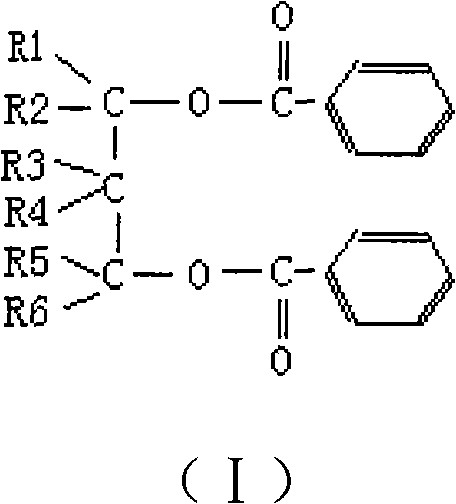

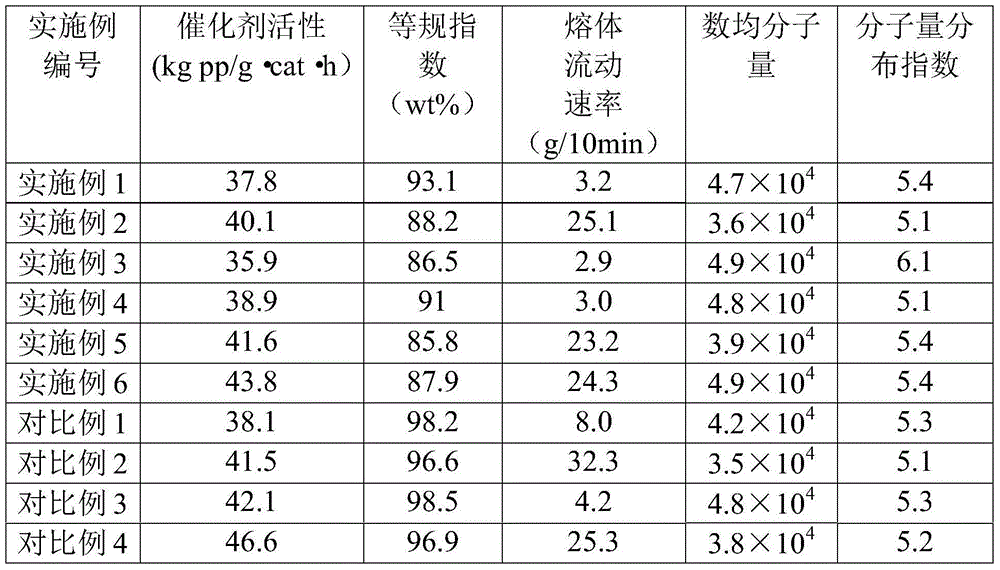

Preparation method of polypropylene with wide molecular weight distribution and polymer thereof

The invention provides a preparation method of molecular weight distribution polypropylene and a polymer thereof. By using the method, polymerization reaction is carried out in a single reactor or a plurality of series reactors in the presence of catalysts, wherein the catalysts are reactants containing the following components: (1) at least one solid catalyst component comprising magnesium, titanium, halogen and at least two electron donors of a and b, wherein the electron donor a is selected from a diol ester compound; the electron donor b is selected from unitary or multi-element aliphatic carboxylic ester, aromatic aliphatic carboxylic ester or diether compounds; and the weight ratio of the electron donor a to the electron donor b is 2-80; (2) an alkyl aluminum compound; and (3) optimally, an external electron donor component. The acrylic polymer has the advantages of wide molecular weight distribution, high isotacticity and the like; meanwhile, the preparation method has simple operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

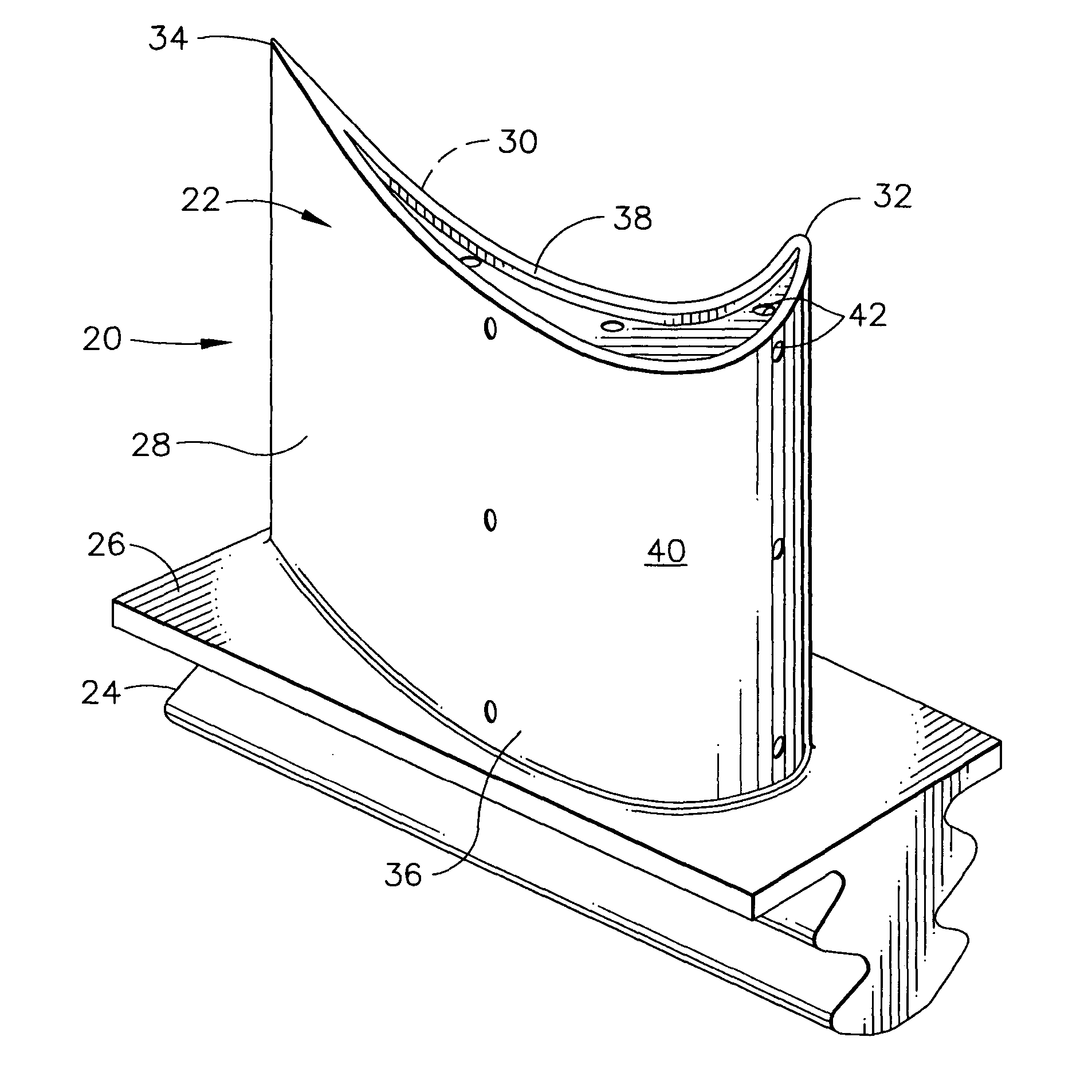

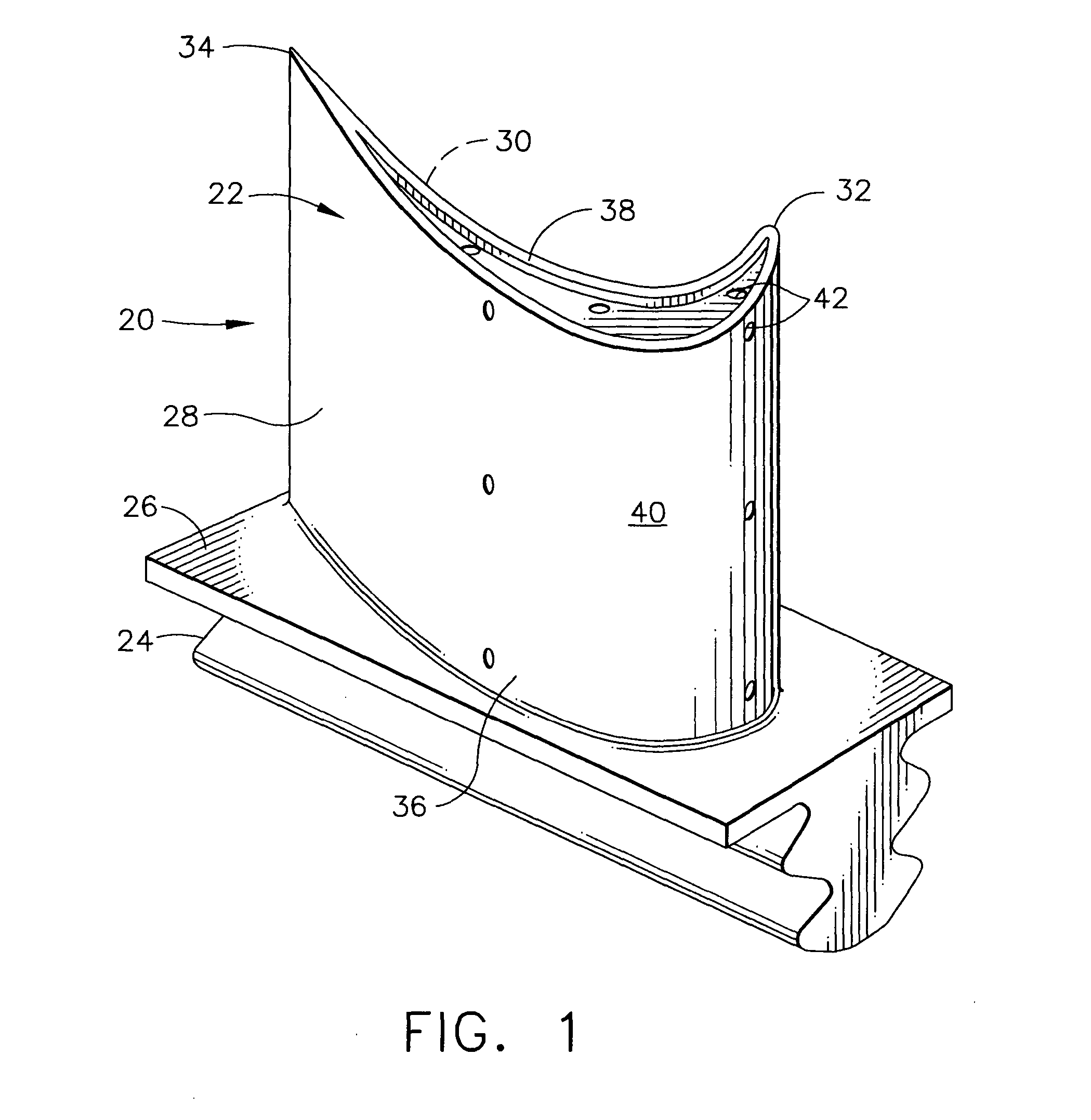

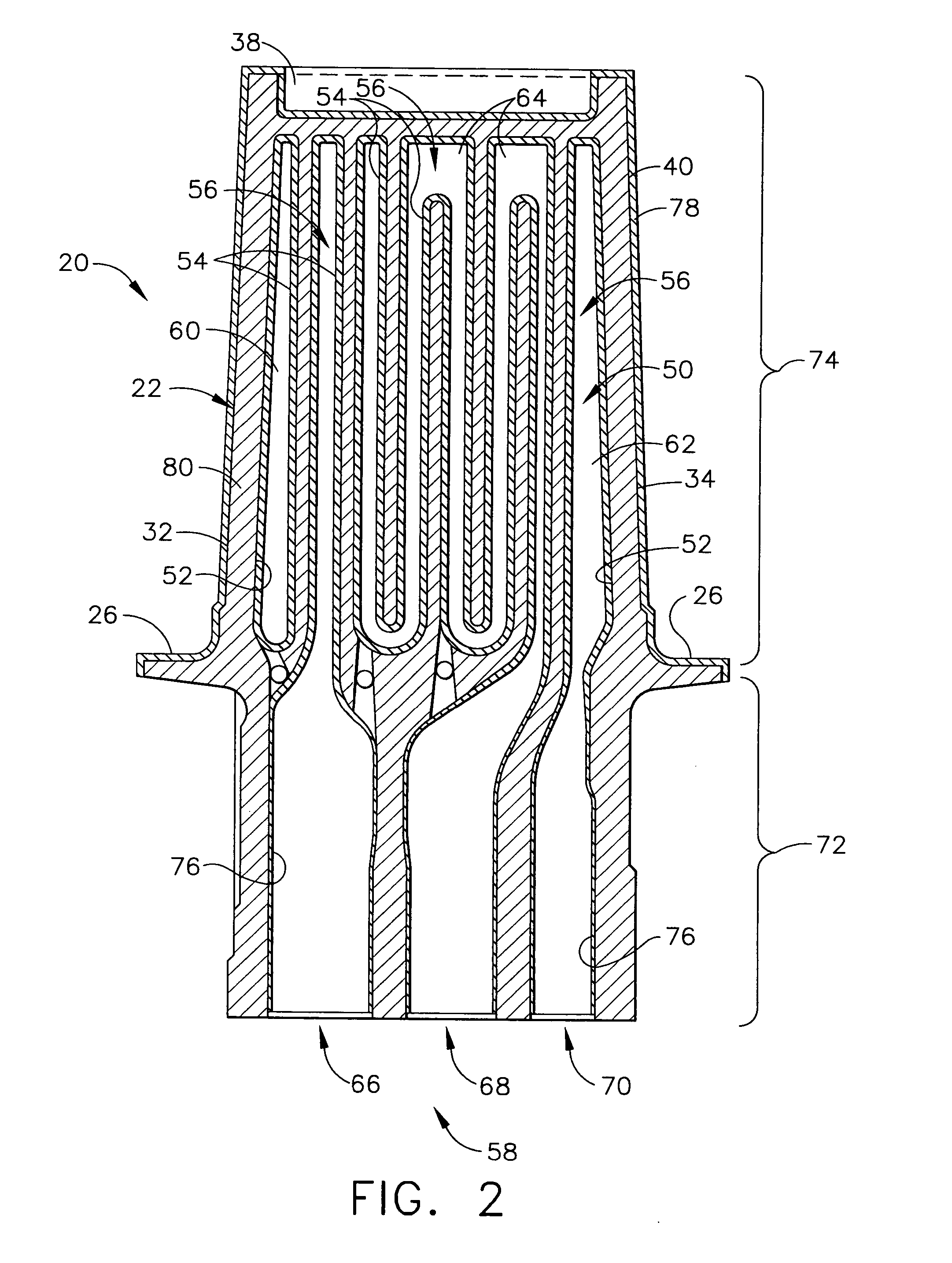

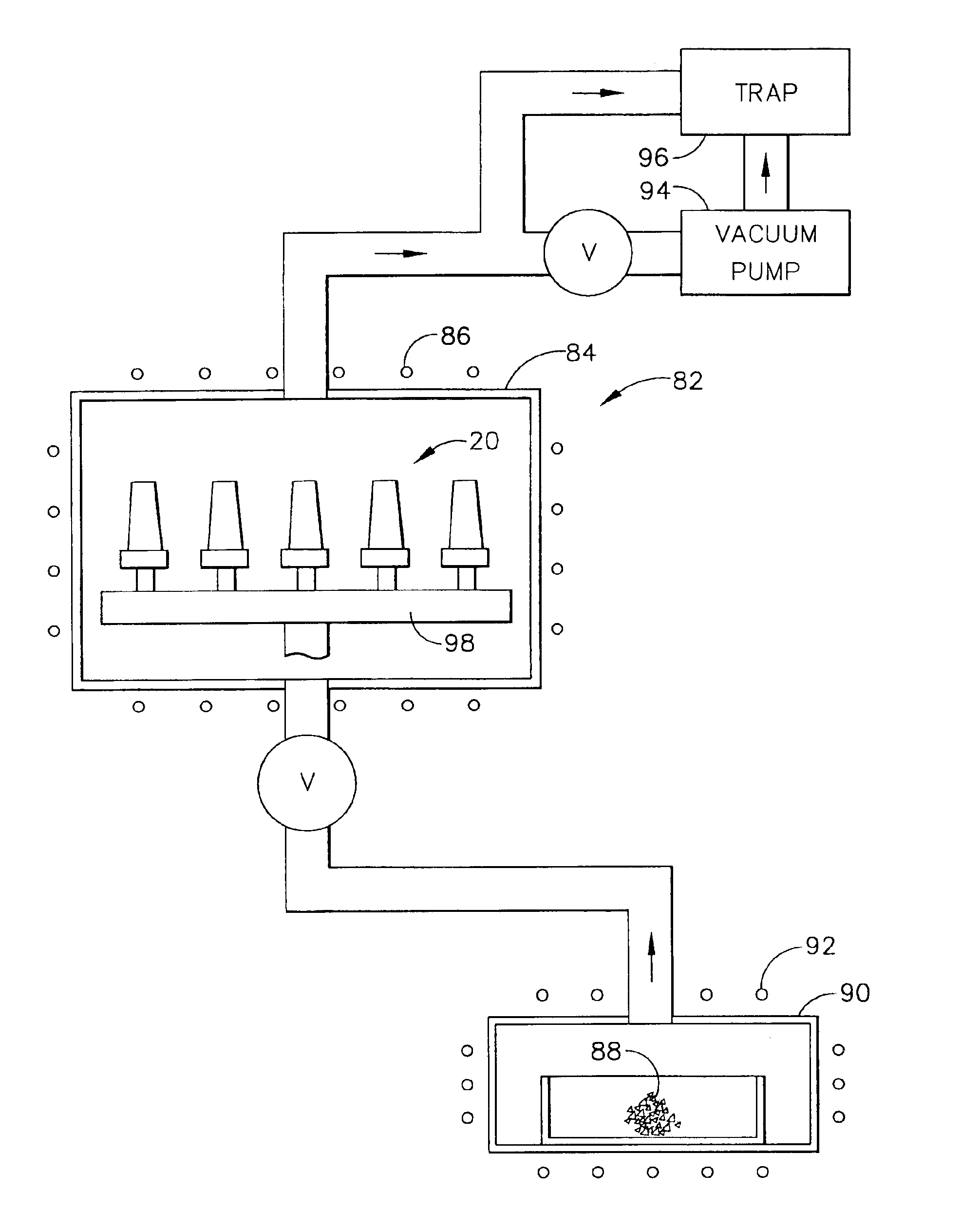

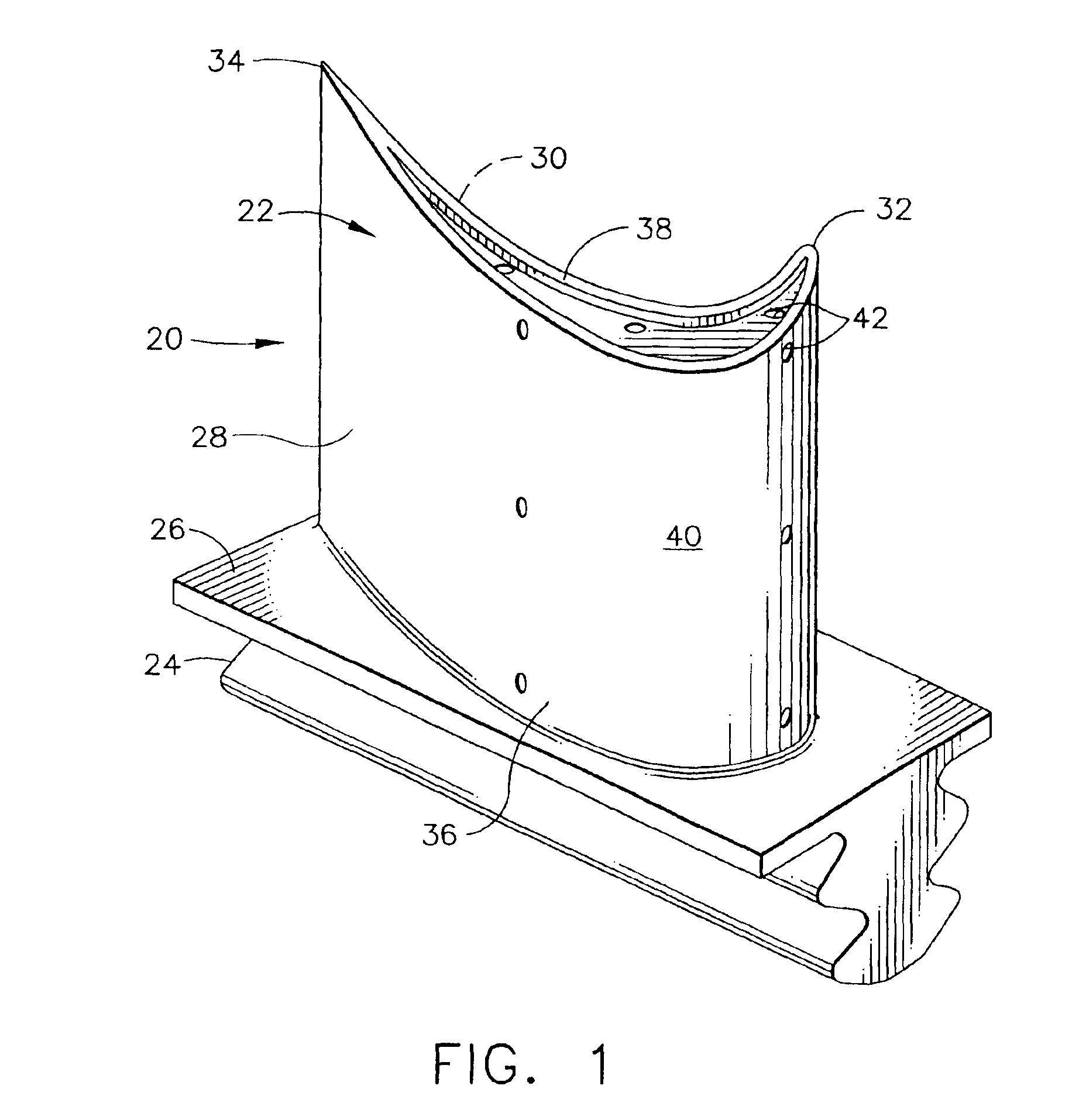

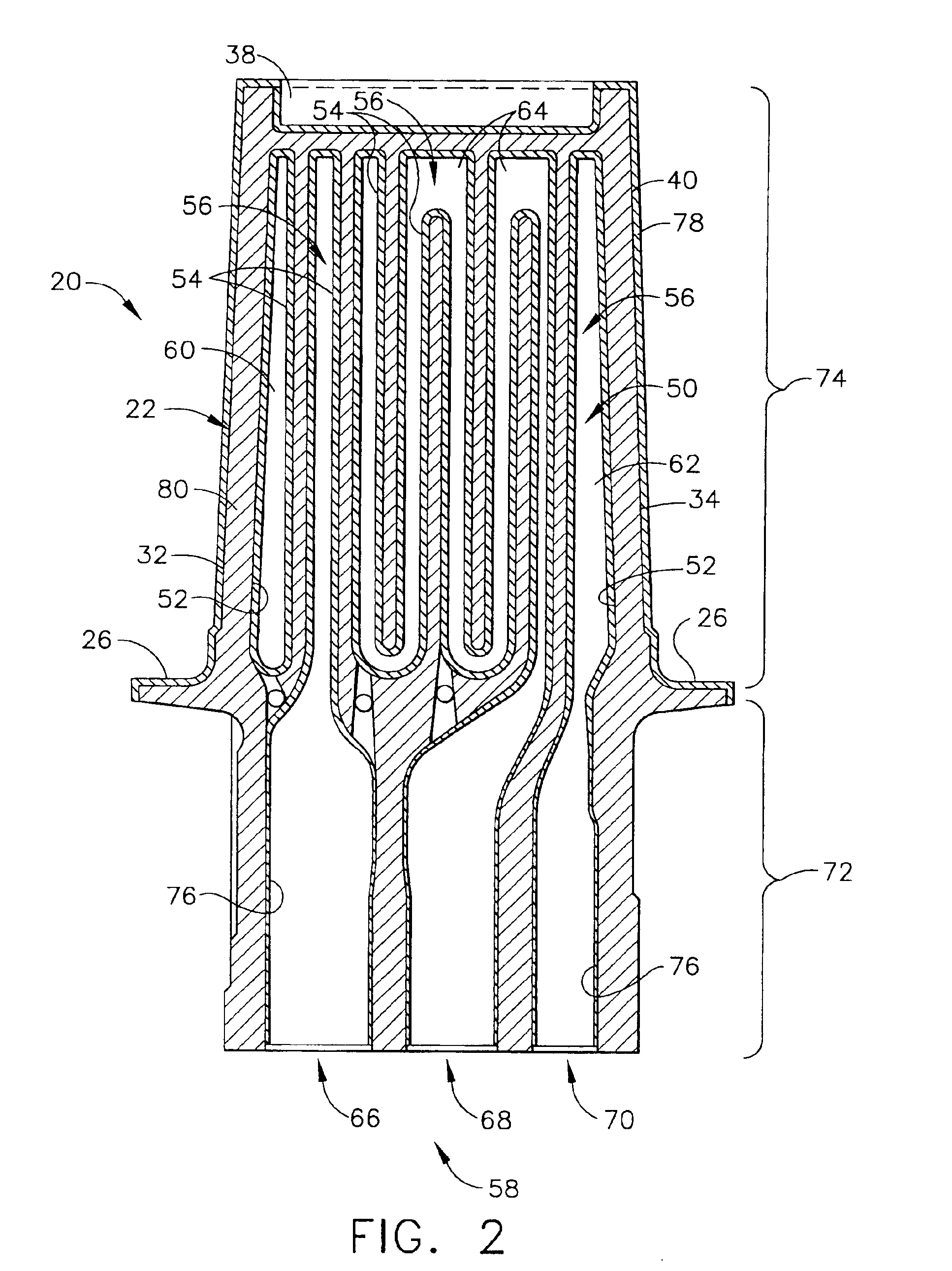

Aluminide coating of turbine engine component

A method for forming an aluminide coating on a turbine engine component having an external surface and an internal cavity defined by an internal surface that is connected to the external surface by at least one hole. The method is conducted in a vapor coating container having a hollow interior coating chamber, and includes the steps of loading the coating chamber with the component to be coated; flowing a tri-alkyl aluminum coating gas into the loaded coating chamber at a specified temperature, pressure, and time to deposit an aluminum coating on the external and internal surfaces of the component; and heating the component in a nonoxidizing atmosphere at a specified temperature and time to form an aluminide coating on the external and internal surfaces. The coated component is typically then maintained at an elevated temperature in the presence of oxygen to form an oxide coating on the external and internal surfaces of the component. In one embodiment, the turbine engine component is a turbine engine blade having an external surface and an internal cooling cavity having an internal surface that is connected to the external surface by cooling holes.

Owner:GENERAL ELECTRIC CO

Catalyst for propene polymerization

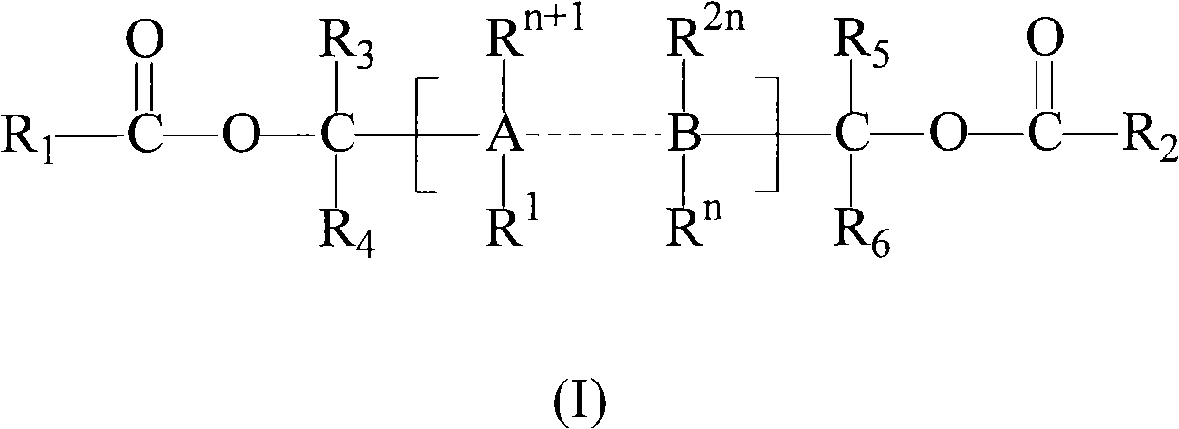

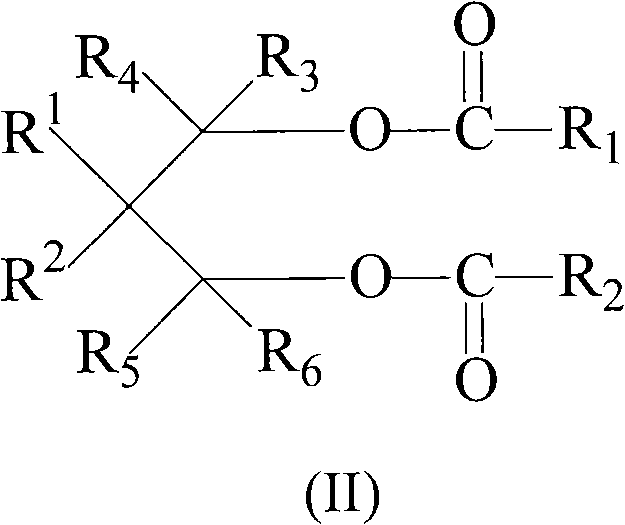

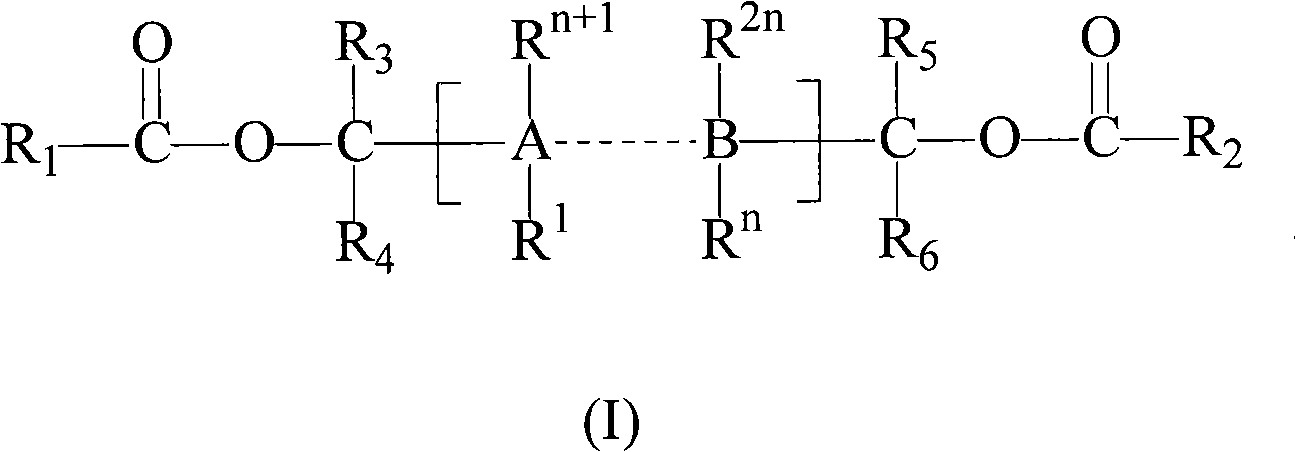

The invention provides a catalyst for propene polymerization, which comprises the following components: A, a titanium-containing solid catalyst component, B, an alkylaluminium compound, and C, an organosilicone compound; and the invention also provides a method for preparing the titanium-containing solid catalyst component A. The titanium-containing solid catalyst component comprises titanium, magnesium, halogen, a surface modifier and a polyol ester compound with a special structure, or the polyol ester compound with the special structure which is taken as an electron doner and an electron doner compound with another structure are reasonably compatible with each other and are used in a catalyst system which is modified by the surface modifier to prepare a catalyst component and a catalystwith better comprehensive performance. Particularly, the catalyst provided by the invention shows high polymerization activity and stereospecificity when used for olefin polymerization, in particularthe propene polymerization; and simultaneously, the prepared polymer has wide molecular weight distribution and more facilitates the processing and application.

Owner:CHINA PETROLEUM & CHEM CORP +1

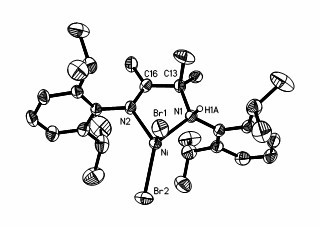

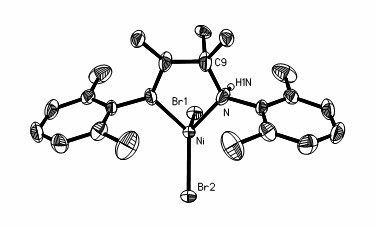

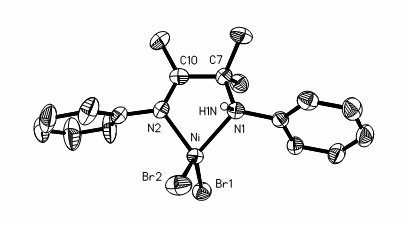

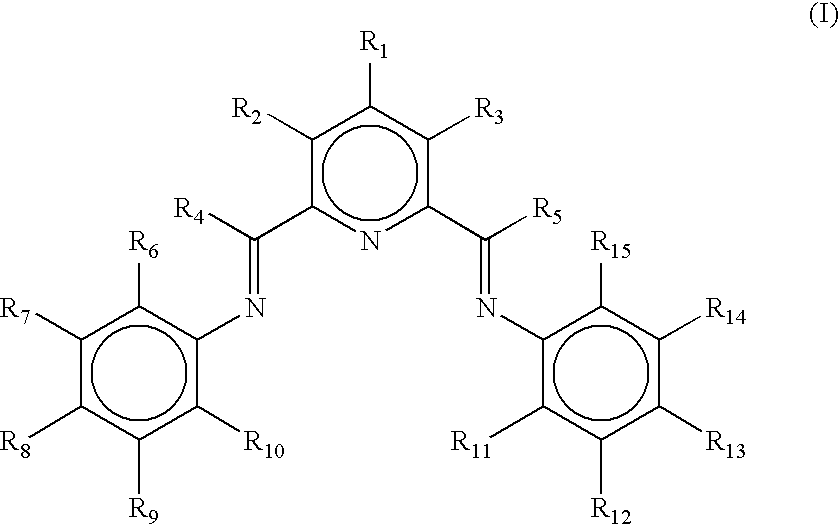

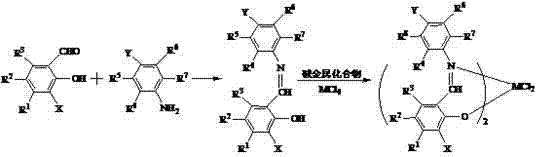

Preparation method and application of amido-imine nickel vinyl polymerization catalyst

ActiveCN102250152AThe synthesis method is simpleRaw materials are cheap and easy to getNickel organic compoundsAnilineBiological activation

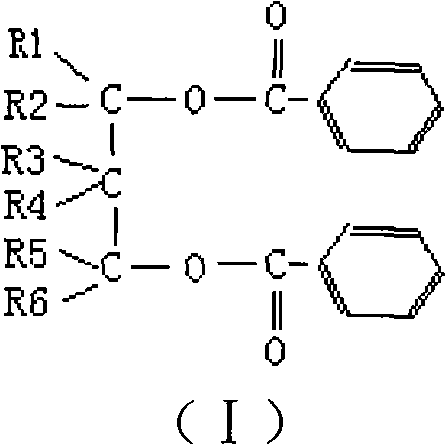

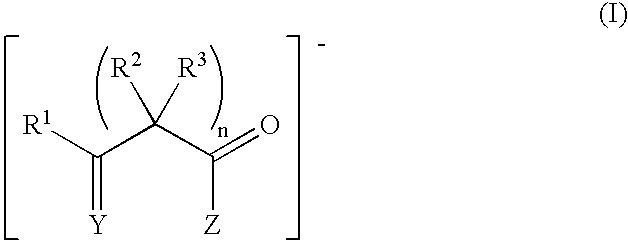

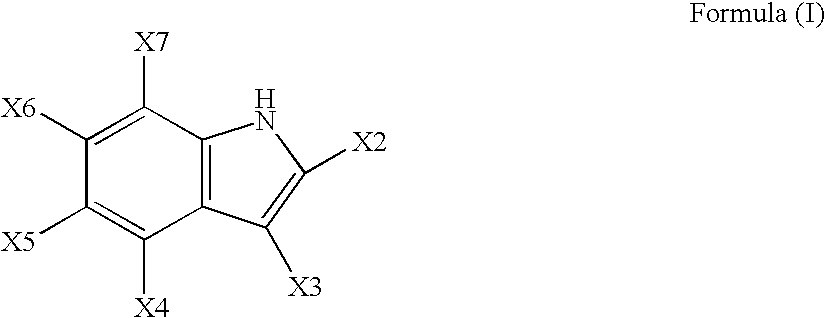

The invention discloses a preparation method of an amido-imine nickel catalyst and application of the amido-imine nickel catalyst to catalyzing vinyl polymerization. The complex has the structures of a formula (I) and a formula (II) shown in the specification, wherein R1 is hydrogen or alkyl, R2 is hydrogen or alkyl, R3 is hydrogen or alkyl, R4 is hydrogen or alkyl, and X is halogen. The preparation method of the complex comprises the following steps of: carrying out condensation reaction on a diketone compound and phenylamine through ketoamine to obtain an diimine compound; then reacting with trimethyl aluminum, and hydrolyzing to obtain an amido-imine ligand; finally carrying out coordination reaction on the amido-imine ligand and (DME)NiX2 under the condition without water and oxygen to obtain a nickel complex. The complex disclosed by the invention has a specific ligand replacement structure and can be used for catalyzing the vinyl polymerization under the activation of modified methyl aluminium oxane or alkyl aluminum, showing the characteristics of living polymerization under specific conditions and obtaining the high-molecular-weight narrowly-distributed branched polyethylene.

Owner:SUN YAT SEN UNIV

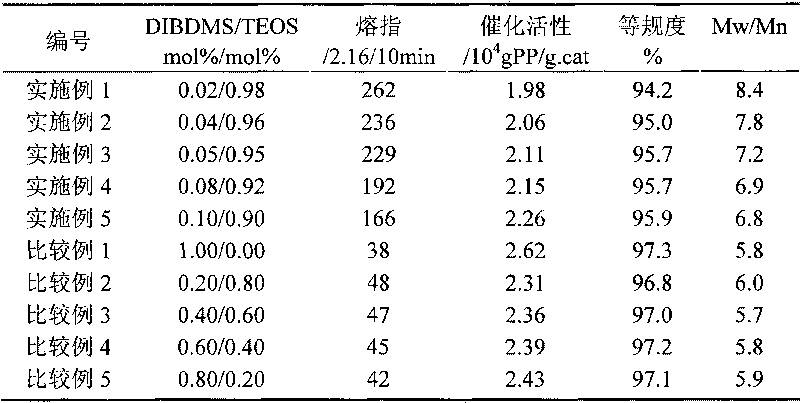

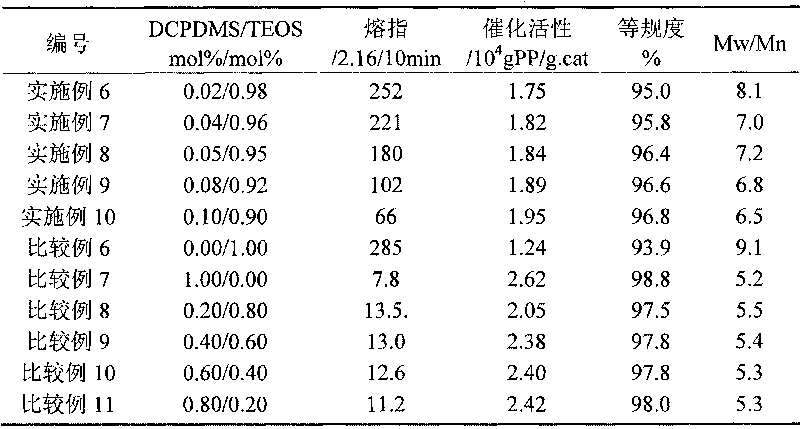

Method for preparing high-fluidity wide-distribution polypropylene and product thereof

The invention discloses a method for preparing high-fluidity wide-distribution polypropylene and a product thereof. The method uses propylene for homopolymerization or copolymerization. A catalyst system consists of a component A, a component B and a component C, wherein the component A is a supported solid Ziegler-Natta catalyst taking magnesium, titanium, halogen and an internal electron donor as main components; the component B is an alkyl aluminum cocatalyst; and the component C is an external electron donor, and is a mixture of tetraethoxy silane and dicyclopentyl dimethoxy silane or diisobutyldimethoxysilane, wherein the dicyclopentyl dimethoxy silane or the diisobutyldimethoxysilane accounts for 0.1 to 10 percent of the total molar weight of the mixture; the component A, the component B and the component C are expressed by the content of Ti, the content of Al and the content of Si, and the molar ratio of Si to Ti is 1 to 100, and the molar ratio of Al to Si is 1 to 100 respectively; the polydispersity index of the product is between 6 and 20; and the melt index of the product with the mass of 2.16kg at the temperature of 230 DEG C is between 20 and 200g / 10min.

Owner:PETROCHINA CO LTD

Polymerization of olefins

InactiveUS6506861B2Group 4/14 organic compounds without C-metal linkagesOrganic-compounds/hydrides/coordination-complexes catalystsElastomerThermoplastic

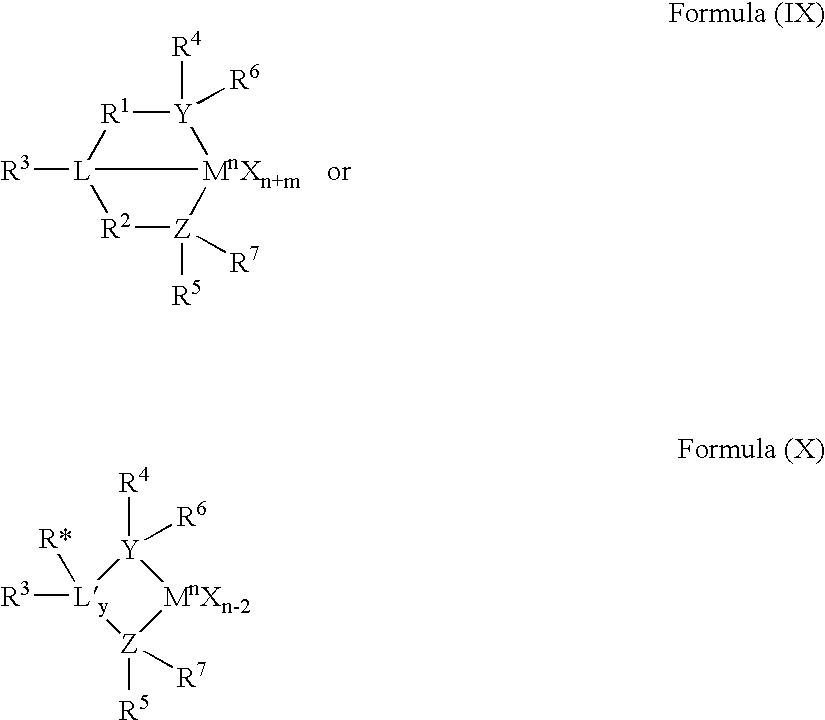

Olefins are polymerized by novel transition metal complexes of selected iminocarboxylate and iminoamido ligands, sometimes in the presence of cocatalysts such as alkylaluminum compounds or neutral Lewis acids. Olefins which may be (co)polymerized include ethylene, alpha-olefins, and olefins containing polar groups such as olefinic esters for example acrylate esters. Also described are certain "Zwitterionic" transition metal complexes as polymerization catalysts for making polar copolymers. The resulting polymers are useful as thermoplastics and elastomers.

Owner:EI DU PONT DE NEMOURS & CO

Metal composite catalyst for alkene polymerization and preparation method thereof

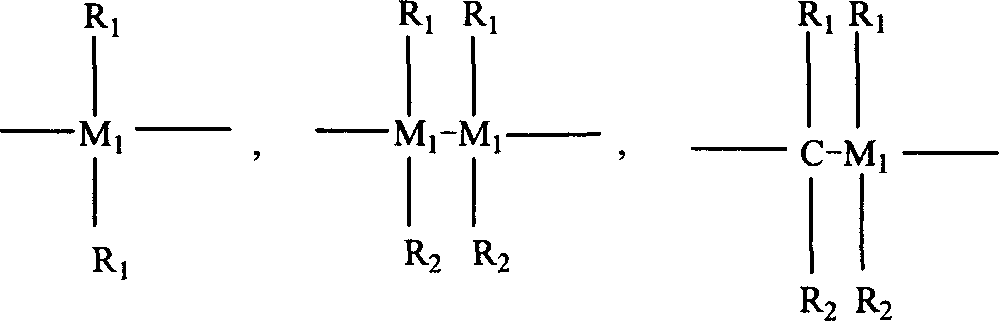

This invention relates to a preparation method of metal composite catalyst usd for olefinic polymerization. This metal composite catalyst includes : component I: a sort of Ti compound free of metal -PI bond; component II: one or more Ti at least containing one metal - PI bond, Zr, transition metal compound of V or Hf; component III: a sort of magnesium halide; component IV: : a sort of aluminium alkyl oxygen alkane or aluminium alkyl; component V: a sort of inside electron donor. This invention compound not homogeneous phase Ziegler - Natta catalyzer with metallocene catalyst component, not only be able to obtain polymer that has adjustable molecular weight at very widely extension and metabolic molecular weight distribution, furthermore may be able to may be able to adequate to production of adjustable polyolefine alloying, possess extensive application prospects.

Owner:INST OF CHEM CHINESE ACAD OF SCI

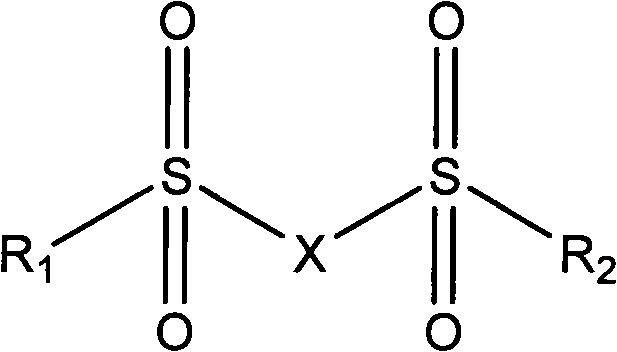

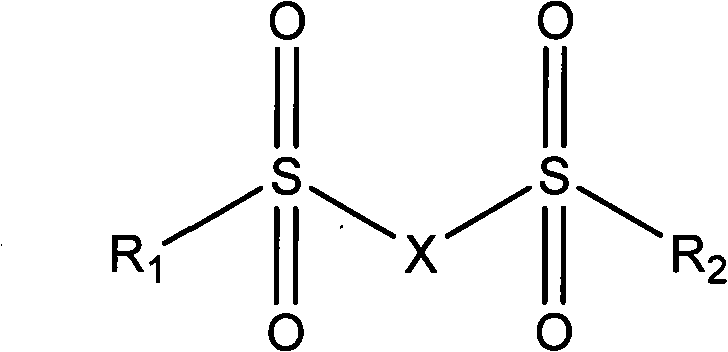

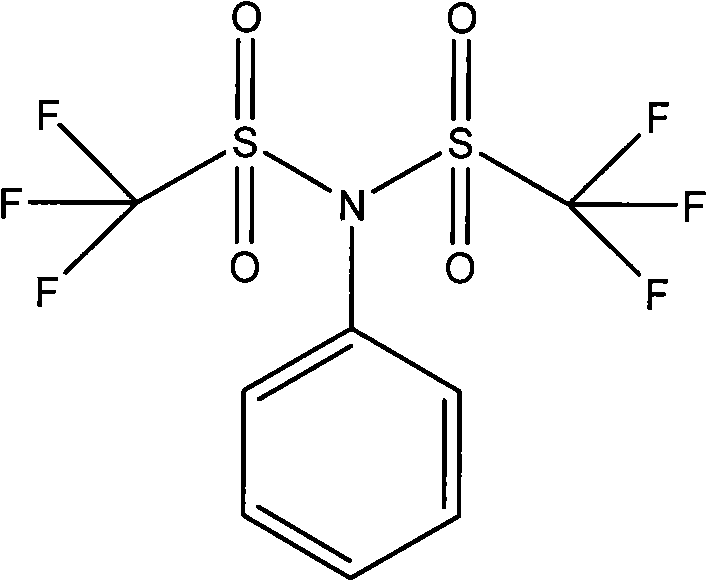

Olefin polymerizing catalyst, preparation and use thereof

The invention relates to a catalyst used for olefin polymerization, a preparation method and an application thereof. The components of the catalyst comprises an activated magnesium halide (1), a titanium compound (2) that has at least one Ti-halide bond and is loaded on the activated magnesium halide (1), and an electron donor (3) that is chosen from one or a plurality of sulfonyl compounds with a general formula (I). The two preparation methods for the solid catalyst with the components are that: one method comoprises the following steps of processing the grains of the activated magnesium halide (1) with alkyl aluminium, then adding the electron donor (3), processing with the titanium compound (2) solution for one or a plurality of times so as to obtain the catalyst; the other method comprises the following steps of adding spherical grains of magnesium chloride alcoholates and the electron donor (3) into the titanium compound (2) solution in sequence and processing with the titanium compound (2) for one or a plurality of times so as to obtain the catalysis. The catalyst system disclosed by the invention comprises the components of the solid catalyst, a cocatalyst (alkyl aluminium compounds) and an external electron donor.

Owner:PETROCHINA CO LTD

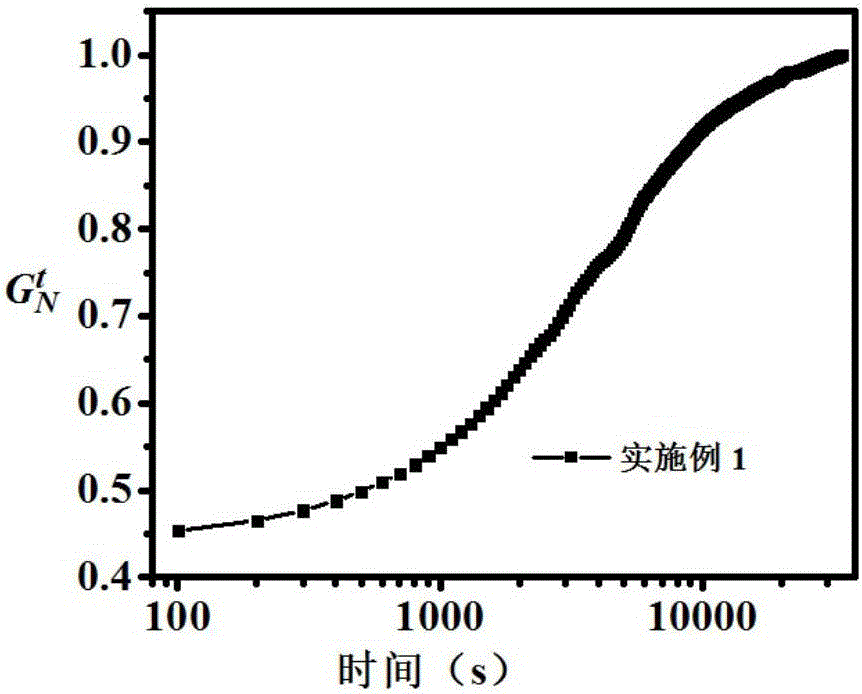

Preparation method of Ziegler-Natta catalyst for efficiently preparing low entanglement polyethylene and application

ActiveCN106543301AElimination of bimetallic deactivationHigh polymerization activityPolymer scienceZiegler–Natta catalyst

The invention relates to a preparation method of a Ziegler-Natta catalyst for efficiently preparing low entanglement polyethylene and an application. The preparation method comprises the following steps that a prepared alcohol absorbing porous carrier and a prepared polyhedral oligomeric silsesquioxane molecule / Mg mixture are stirred in tetrahydrofuran and filtered, solid powder is dried until the solid powder flows freely, and a carrier used for preparing the low entanglement polyethylene catalyst is obtained; then, a carrier of an aluminium alkyl modified catalyst is prepared through the aluminium alkyl; and finally, a TiC14 tetrahydrofuran solution is added into the carrier of the aluminium alkyl modified catalyst, after stirring, the solid powder is washed by means of the tetrahydrofuran solution and dried until the solid powder flows freely, and the Ziegler-Natta catalyst for efficiently preparing the low entanglement polyethylene is obtained. POSS can be assembled into a microsphere with particle diameter being 20-100 nm in a pore passage of the porous carrier. The active points are divided effectively. The intervals between active centers are increased. The occurrence of chain overlapping in the polymerization process is restrained. The low entanglement polyethylene Ziegler-Natta can be prepared efficiently with the polymerizing temperature being higher than or equal to 60 DEG C.

Owner:宁波链增新材料科技有限公司

Process for preparing linear alpha olefins

InactiveUS7589245B2High yieldHigh selectivityHydrocarbons from unsaturated hydrocarbon additionCatalystsPolymer scienceIsomerization

A process for the preparation of linear alpha olefins having 2n carbon atoms from linear alpha olefins having n carbon atoms comprising the steps of (a) dimerizing a linear alpha olefin having n carbon atoms in the presence of a dimerization catalyst to produce a linear internal olefin having 2n carbon atoms; (b)(i) reacting the linear internal olefin having 2n carbon atoms produced in step (a) with a trialkylaluminium compound in the presence of a catalytic amount of an isomerization / displacement catalyst in order to cause isomerization of the linear internal olefin and to displace alkyl group(s) from said trialkylaluminium compound to form an alkyl aluminium compound wherein at least one of the alkyl groups bound to aluminium is a linear alkyl which has been derived from the isomerization of said linear internal olefin; and (b)(ii) reacting said alkyl aluminium compound with an alpha olefin optionally in the presence of a displacement catalyst so as to displace said linear alkyl from said alkyl aluminium compound to form a linear alpha olefin having 2n carbon atoms.

Owner:SHELL OIL CO

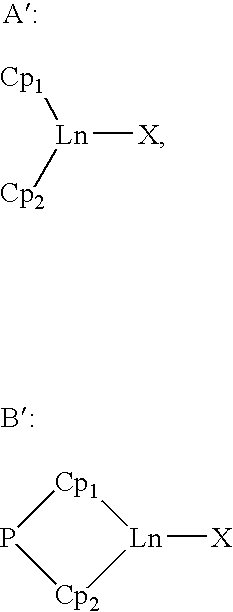

Catalytic system for obtaining conjugated diene/monoolefin copolymers and these copolymers

InactiveUS7547654B2Organic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPolymer sciencePtru catalyst

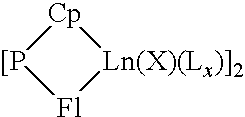

A catalytic system usable for the copolymerization of at least one conjugated diene and at least one monoolefin, a process for preparing this catalytic system, a process for preparing a copolymer of a conjugated diene and at least one monoolefin using said catalytic system, and said copolymer are described. This catalytic system includes:(i) an organometallic complex represented by the following formula:{[P(Cp)(Fl)Ln(X)(Lx)}p (1)where Ln represents a lanthanide atom to which is attached a ligand molecule comprising cyclopentadienyl Cp and fluorenyl Fl groups linked to one another by a bridge P of the formula MR1R2, M is an element from column IVa of Mendeleev's periodic table and R1 and R2 each represent alkyl groups of 1 to 20 carbon atoms or cycloalkyl or phenyl groups of 6 to 20 carbon atoms, X represents a halogen atom, L represents an optional complexing molecule, such as an ether, and optionally a substantially less complexing molecule, such as toluene, p is a natural integer greater than or equal to 1 and x is greater than or equal to 0, and(ii) a co-catalyst selected from alkylmagnesiums, alkyllithiums, alkylaluminums, Grignard reagents and mixtures of these constituents.

Owner:MICHELIN RECH & TECH SA +1

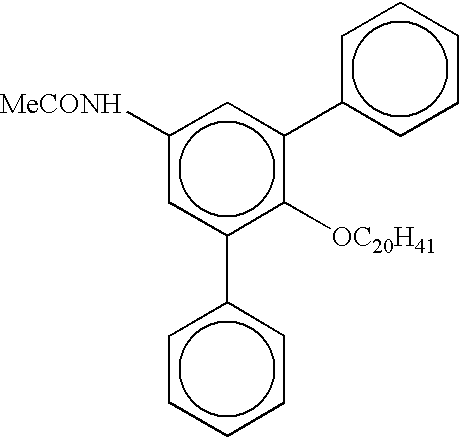

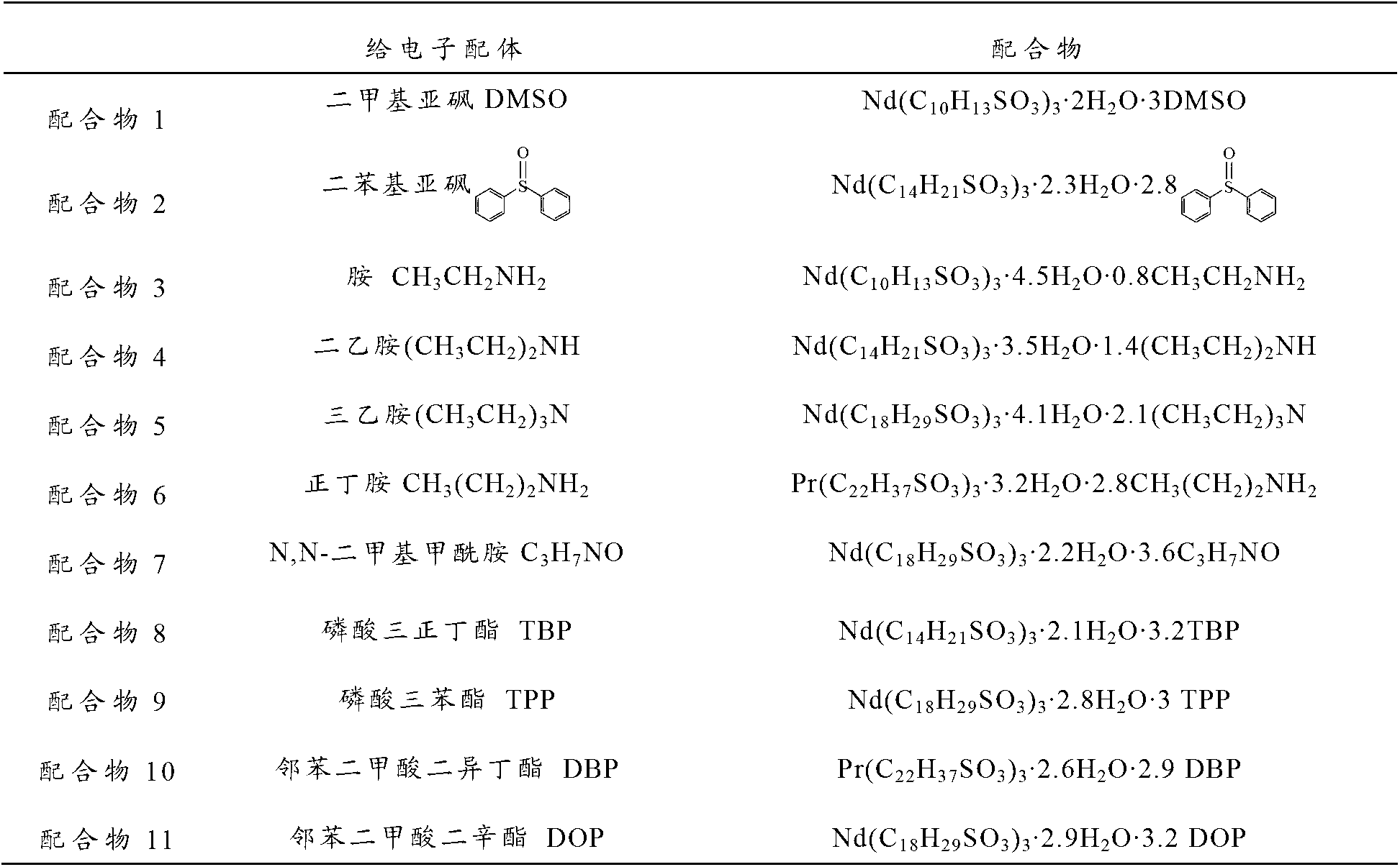

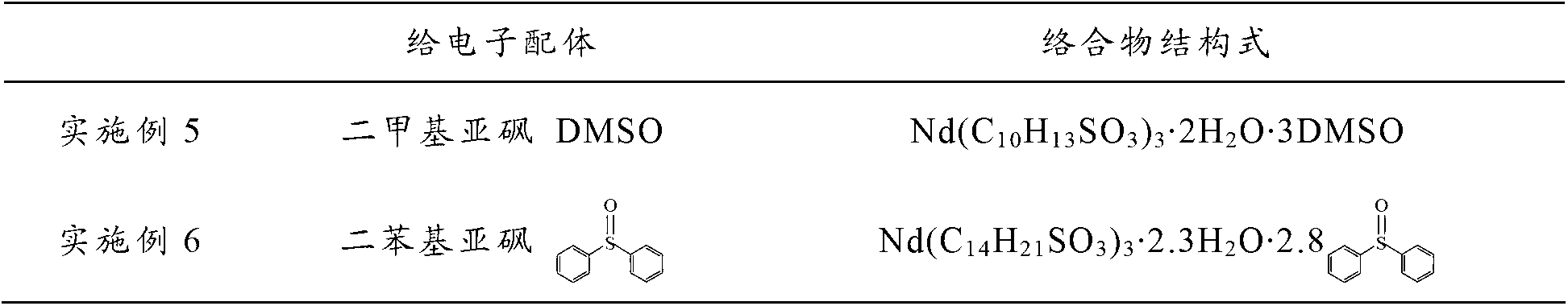

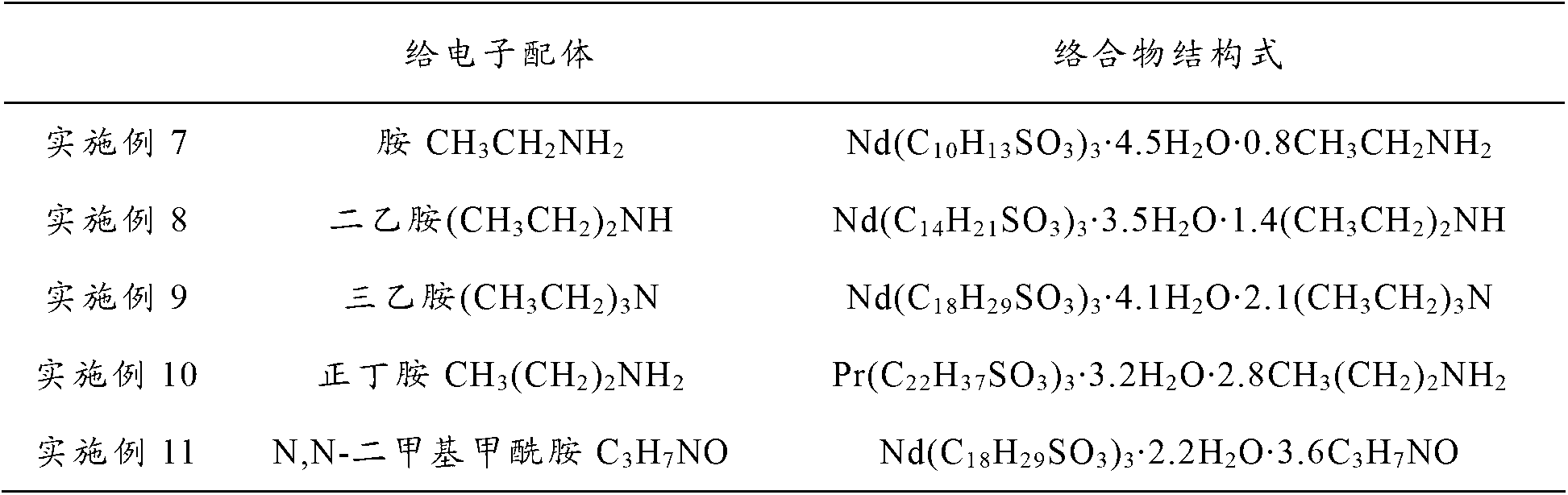

Rare earth complex and preparation method thereof, rare earth catalyst system and preparation method of butadiene-isoprene copolymer

ActiveCN103059053ANot corrosiveEnvironmentally friendlyGroup 3/13 element organic compoundsBenzeneHalogen

The invention provides a rare earth complex shown in formula (I) and a preparation method thereof and a rare earth catalyst system. The invention further provides a preparation method of butadiene-isoprene copolymer. The rare earth catalyst system is used for preparing the butadiene-isoprene copolymer. The rare earth catalyst system comprises alkyl benzene sulfonic acid rare earth complex and aluminum alkyl, so that the catalyst system does not contain halogen and does not have a corrosion action, and is environment friendly during the process of preparing the butadiene-isoprene copolymer. Experimental results show that the content of cis-1,4 in butadiene and isoprene of the butadiene-isoprene copolymer prepared by the rare earth catalyst system is larger than 95%.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

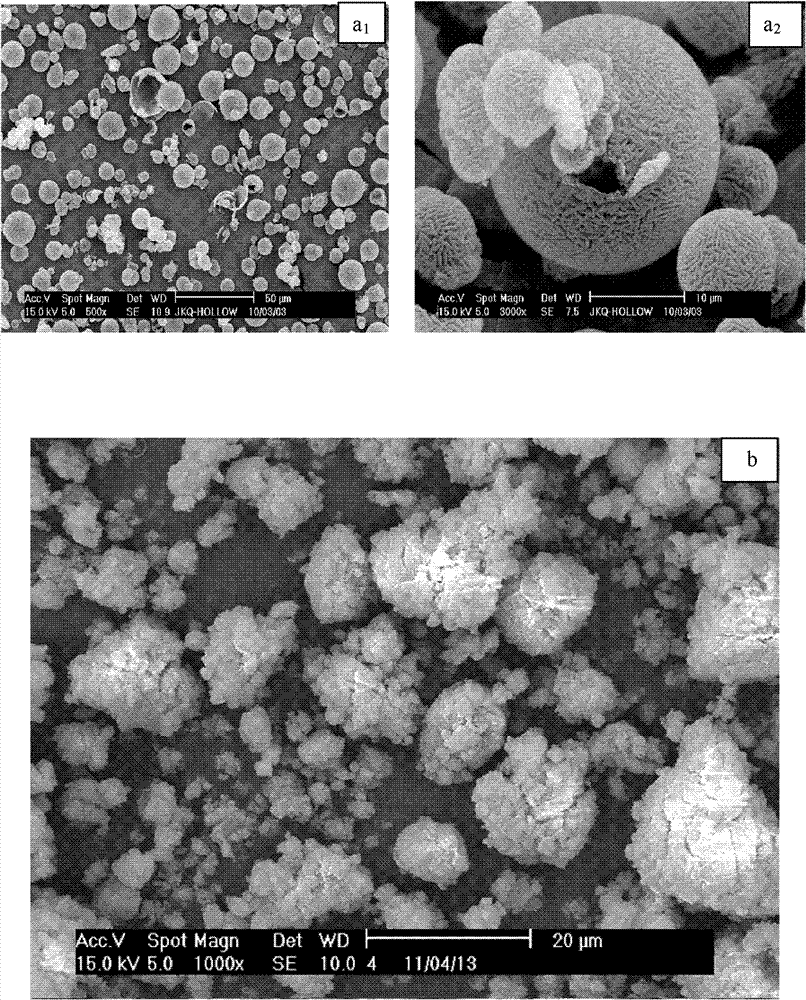

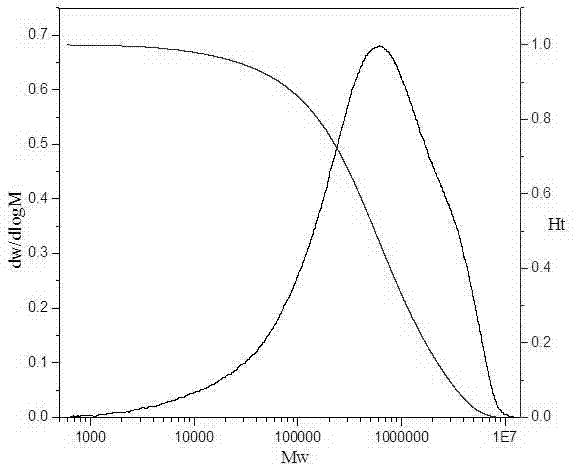

Supported metallocene catalyst and preparation method and application thereof

The invention provides a supported metallocene catalyst which comprises a carrier, and an alkylaluminoxane / magnesium chloride complex and a metallocene compound which are supported on the carrier; the carrier is spherical mesoporous silica, wherein the carrier has an average particle diameter of 20-80 microns, a specific surface area of 550-650 square meter / g, a pore volume of 0.4-1.2 ml / g, and a most probable pore size of 1-7 nanometers; the metallocene compound has a structure as shown in formula 1. When the supported metallocene catalyst of the invention is used for catalyzing olefin polymerization, the catalytic efficiency for homopolymerization at 70 DEG C is up to 2.3*10<8> gPE / (mol Zr.h), and the catalytic efficiency for copolymerization at 70 DEG C is up to 2.2*10<8> gPE / (mol Zr.h); the supported metallocene catalyst overcomes the defect of kettle adhesion, has a low polymerization temperature, and thus reduces the energy consumption to some extent.

Owner:CHINA PETROLEUM & CHEM CORP +1

Propylene polymerized catalyst system, preparationmethod and usage

A catalyst system for the polymerization of propylene is composed of primary catalyst and secondary catalyst which is alkyl aluminium compound. Said primary catalyst is prepared through reaction between microspheric magnesium chloride-alcohol addition, titanium halide solution and 1,3-diether, filtering, washing and drying. Its advantages are high activity and high stereostructure regularity.

Owner:INST OF CHEM CHINESE ACAD OF SCI

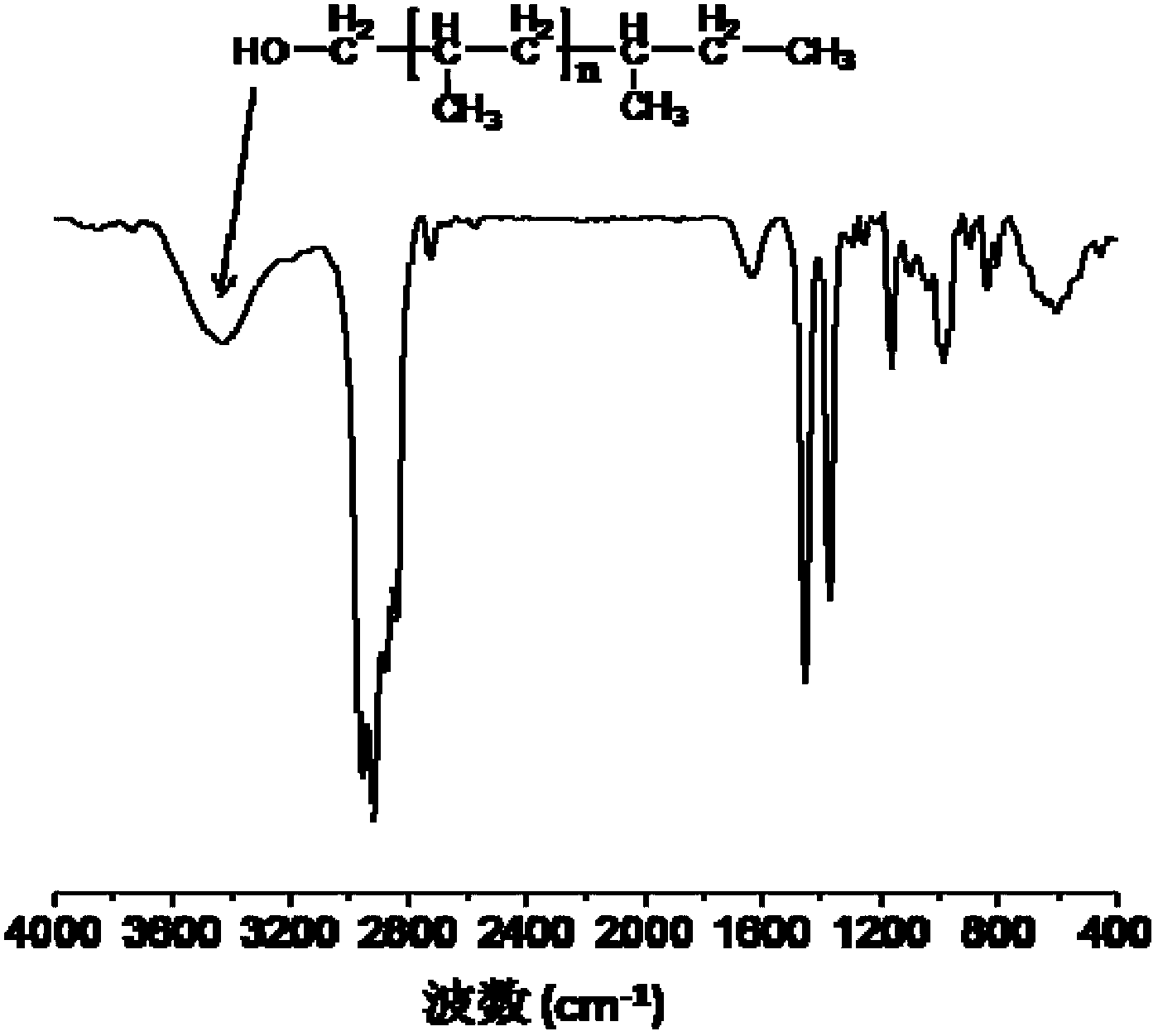

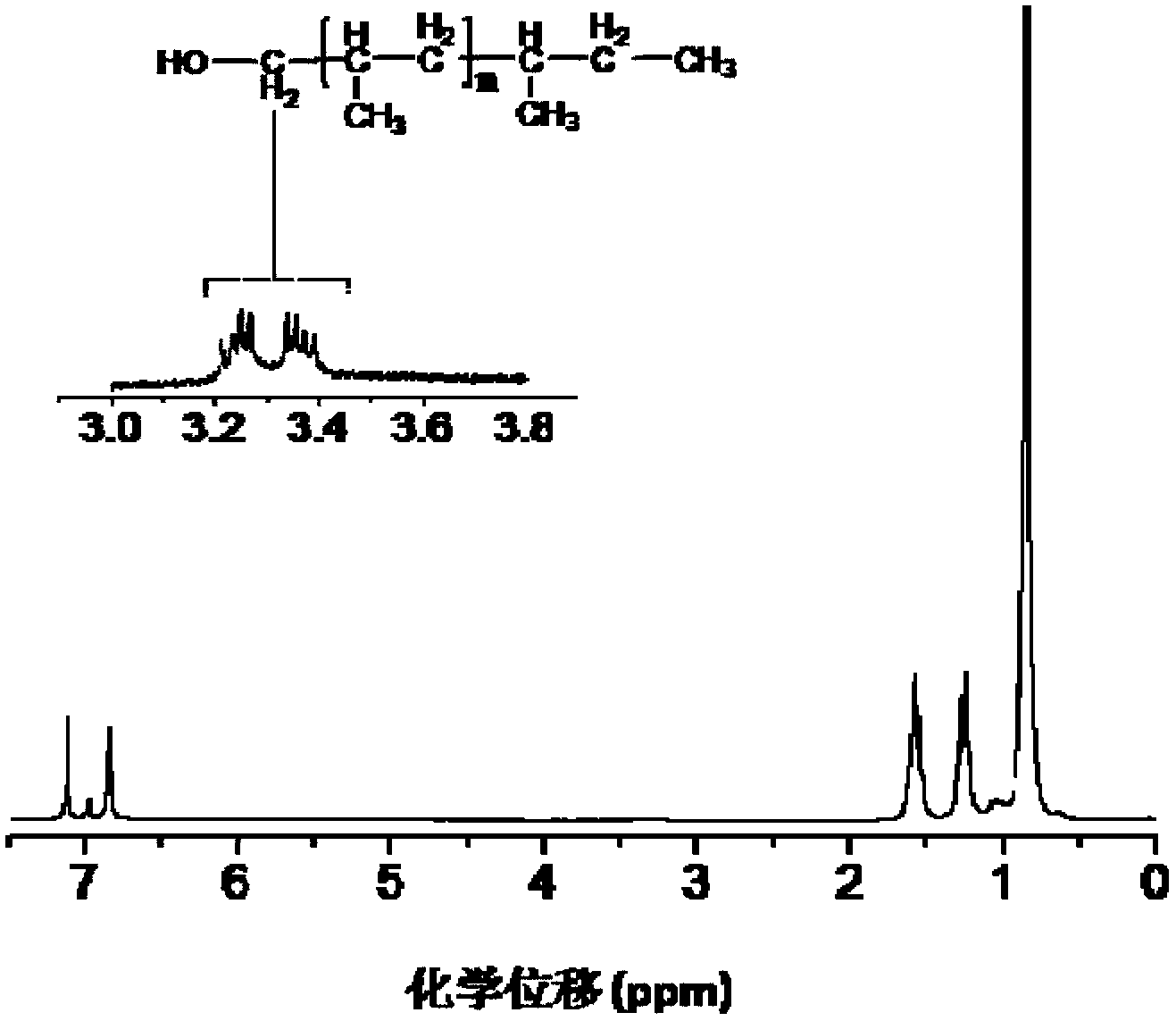

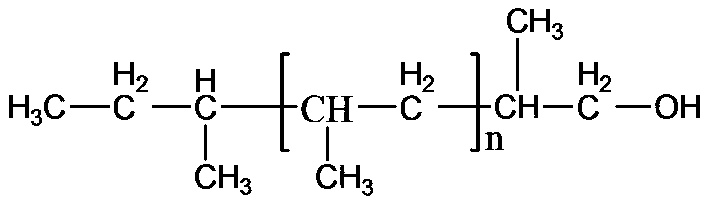

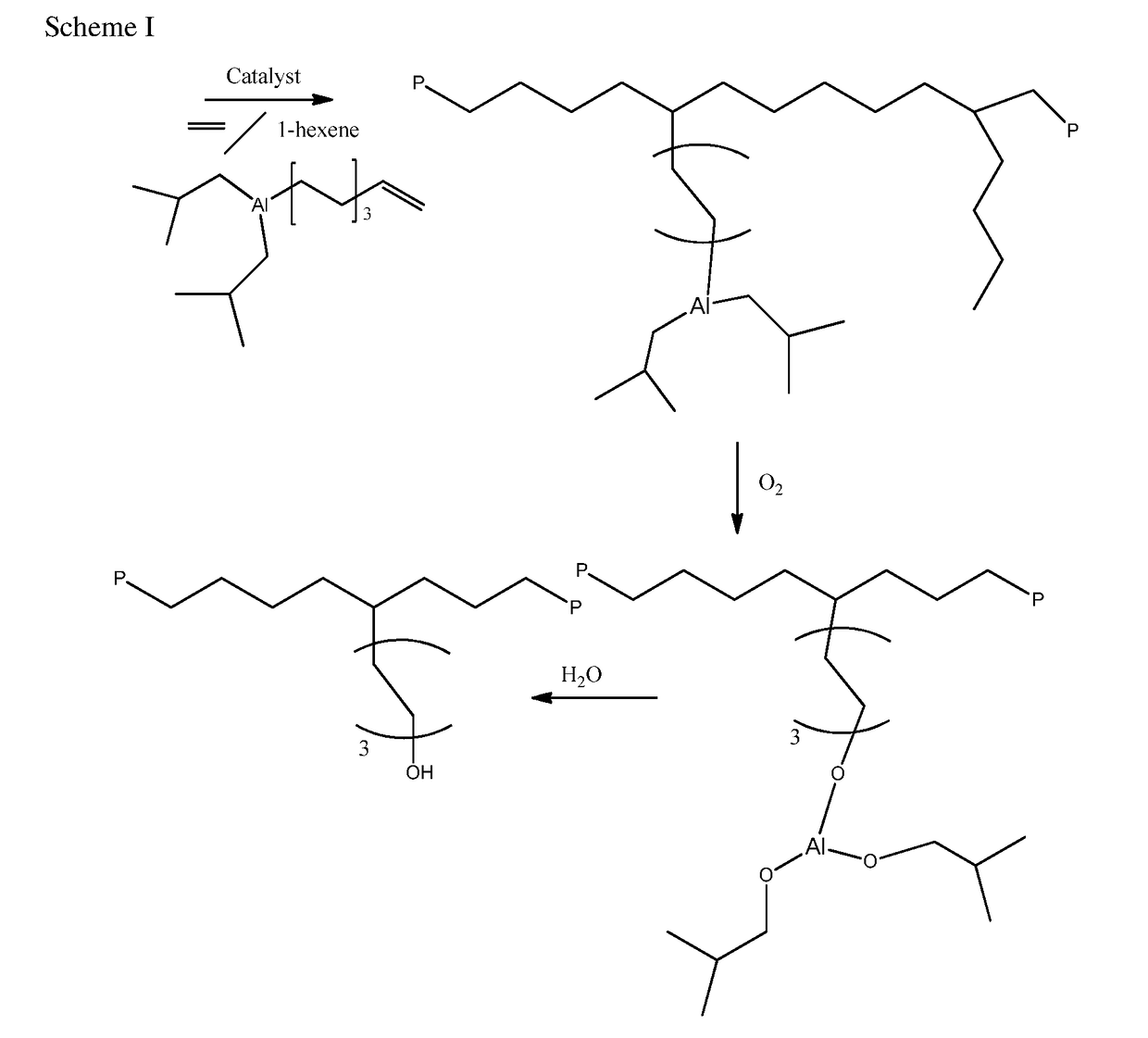

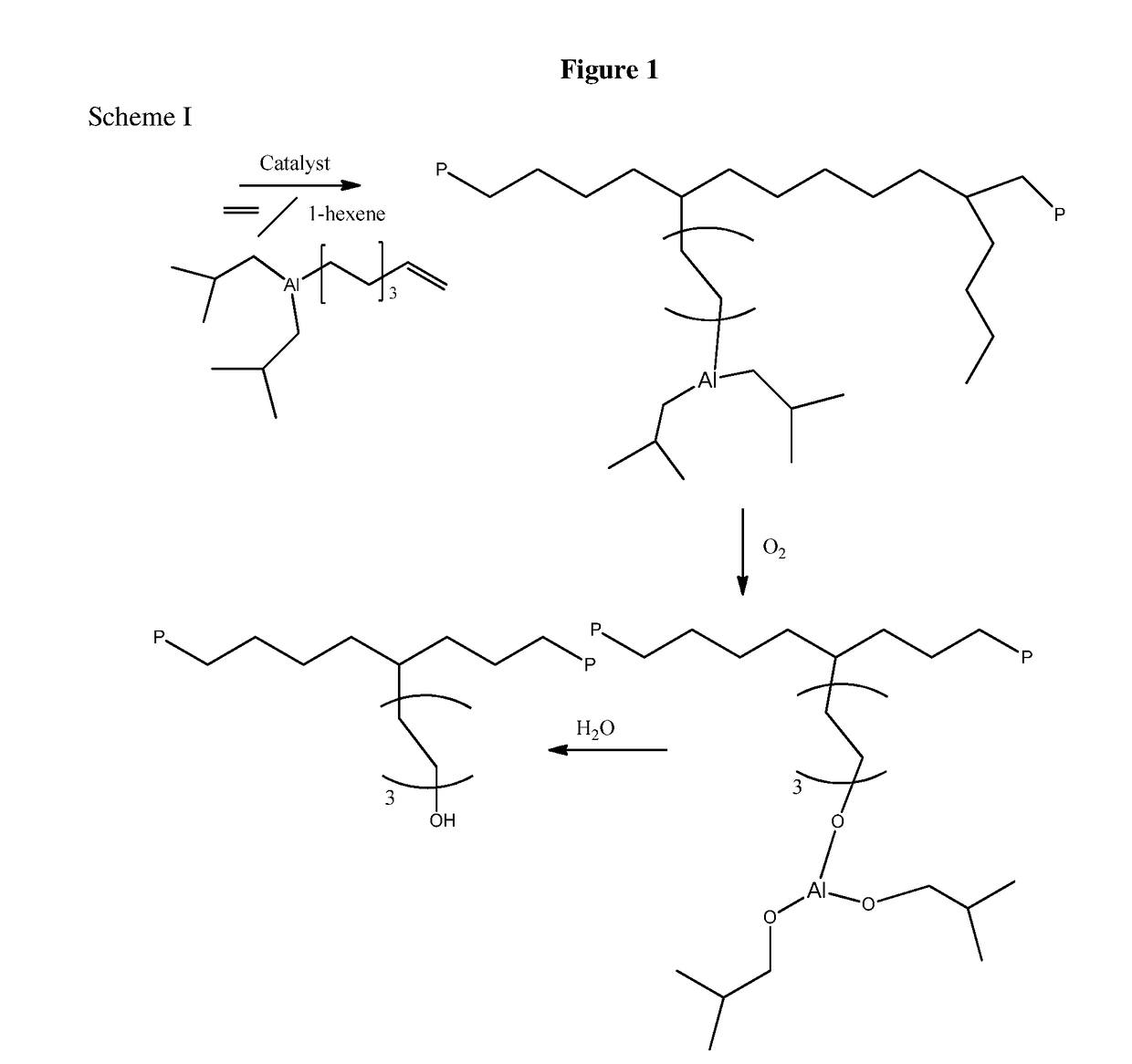

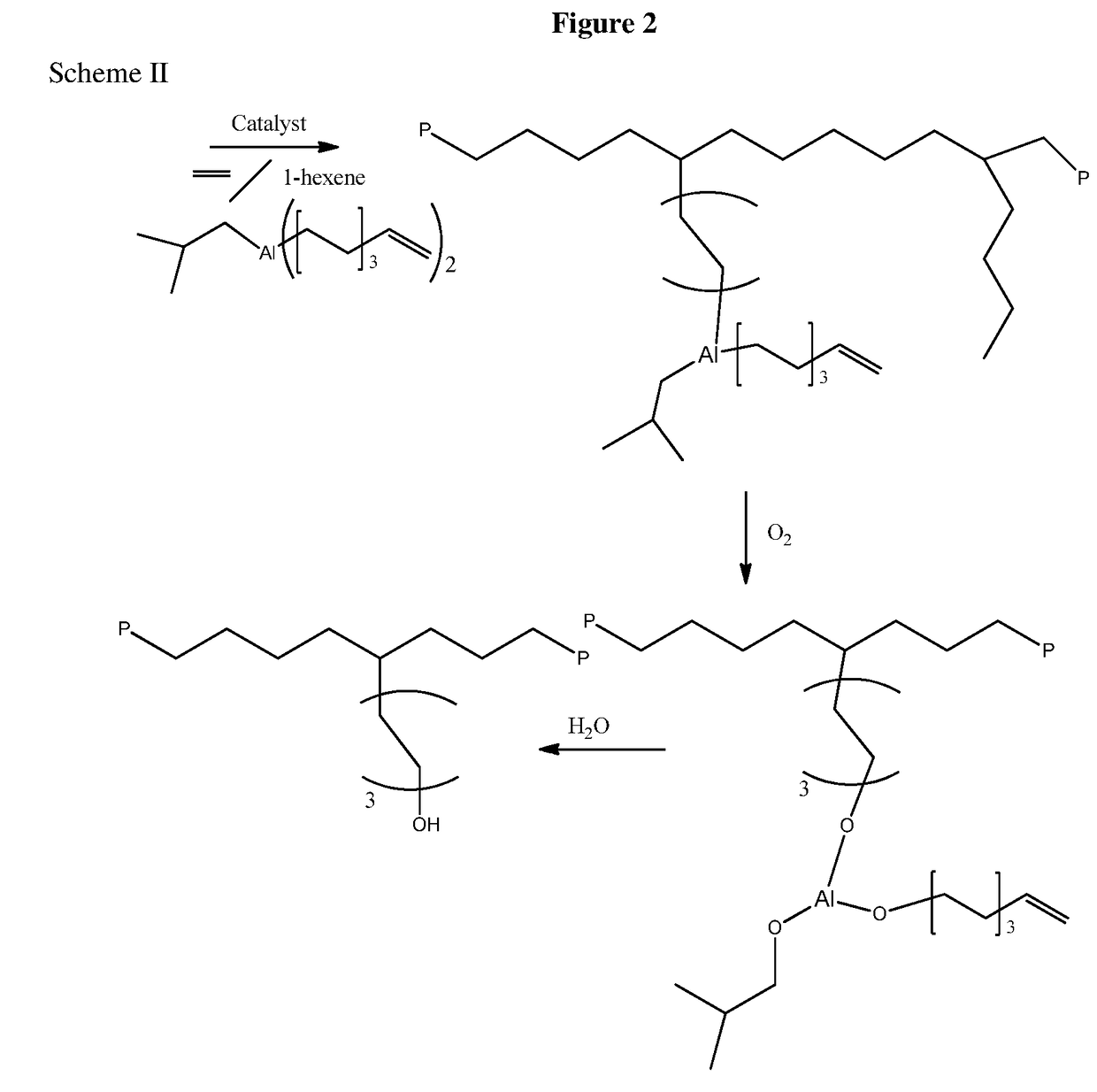

Isotatic polypropylene with functionalized terminal hydroxyl group and preparation method of isotatic polypropylene

InactiveCN103214605AEasy to prepareSimple manufacturing methodBulk chemical productionElectron donorAluminium alkyl

The invention relates to isotactic polypropylene and aims at providing the isotatic polypropylene with a functionalized terminal hydroxyl group and a preparation method of isotatic polypropylene. The preparation method comprises the following steps of: adding an organic solvent, aluminium alkyl serving as a promoter, an alkane external electron donor and an alkyl metal chain transfer agent to a Schlenk bottle under anhydrous and oxygen-free conditions, finally adding 40mg of main catalyst TiCl4 / MgCl2, and feeding propylene; oxidizing a polymerization product by dry oxygen, quenching by a hydrochloric acid aqueous solution to inactivate the catalyst, stirring for 5 minutes, standing and skimming by a separating funnel, and removing upper-layer clear liquid and middle-layer clear liquid; and removing the solvent in a solid product, repeatedly washing by distilled water and the organic solvent and carrying out vacuum drying, thus obtaining the isotactic polypropylene, one end of which is the hydroxyl group. The chain transfer agent used in the invention does not need to be specially synthesized and can be added together with the main catalyst, and the polymerization activity of the main catalyst is not reduced; and the main catalyst is the industrially common TiCl4 / MgC12 catalyst rather than metallocene, and industrialization is easy to realize.

Owner:ZHEJIANG UNIV

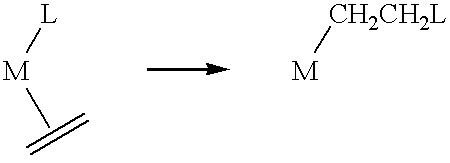

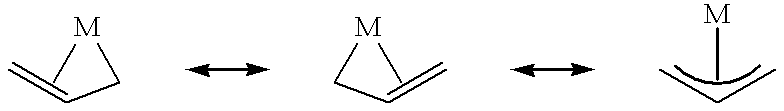

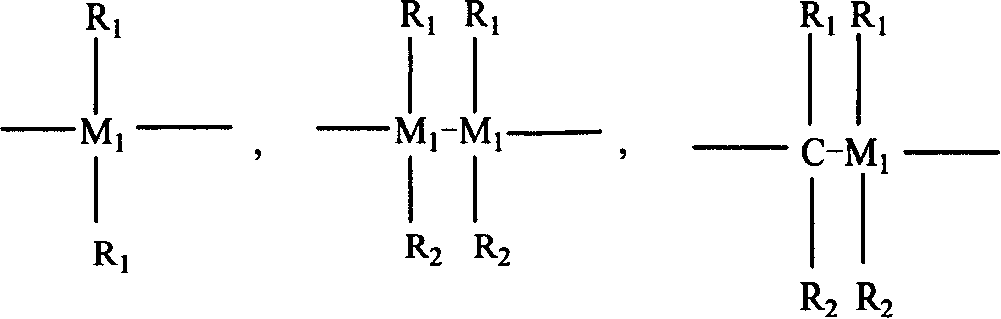

Aluminum Alkyls with Pendant Olefins for Polyolefin Reactions

This invention relates to organoaluminum compounds, organoaluminum activator systems, preferably supported, to polymerization catalyst systems containing these activator systems and to polymerization processes utilizing the same. In particular, this invention relates to catalyst systems comprising a support, an organoaluminum compound and a metallocene.

Owner:EXXONMOBIL CHEM PAT INC

Polymerization catalyst activators, method of preparing, and their use in polymerization processes

InactiveUS6858689B2Organic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationAluminoxaneAluminum alkyl

New polymerization catalyst activators are disclosed which include a heterocyclic compound, which may or may not be substituted, and an aluminum alkyl or an aluminoxane. Supported activators of the invention include the heterocyclic compound, combined with an alkylaluminum or aluminoxane, and a support material, preferably a silica support material. Also disclosed are methods for preparing these catalyst activators and polymerization processes utilizing same.

Owner:UNIVATION TECH LLC

Aluminide coating of turbine engine component

A method for forming an aluminide coating on a turbine engine component having an external surface and an internal cavity defined by an internal surface that is connected to the external surface by at least one hole. The method is conducted in a vapor coating container having a hollow interior coating chamber, and includes the steps of loading the coating chamber with the component to be coated; flowing a tri-alkyl aluminum coating gas into the loaded coating chamber at a specified temperature, pressure, and time to deposit an aluminum coating on the external and internal surfaces of the component; and heating the component in a nonoxidizing atmosphere at a specified temperature and time to form an aluminide coating on the external and internal surfaces. The coated component is typically then maintained at an elevated temperature in the presence of oxygen to form an oxide coating on the external and internal surfaces of the component. In one embodiment, the turbine engine component is a turbine engine blade having an external surface and an internal cooling cavity having an internal surface that is connected to the external surface by cooling holes.

Owner:GENERAL ELECTRIC CO

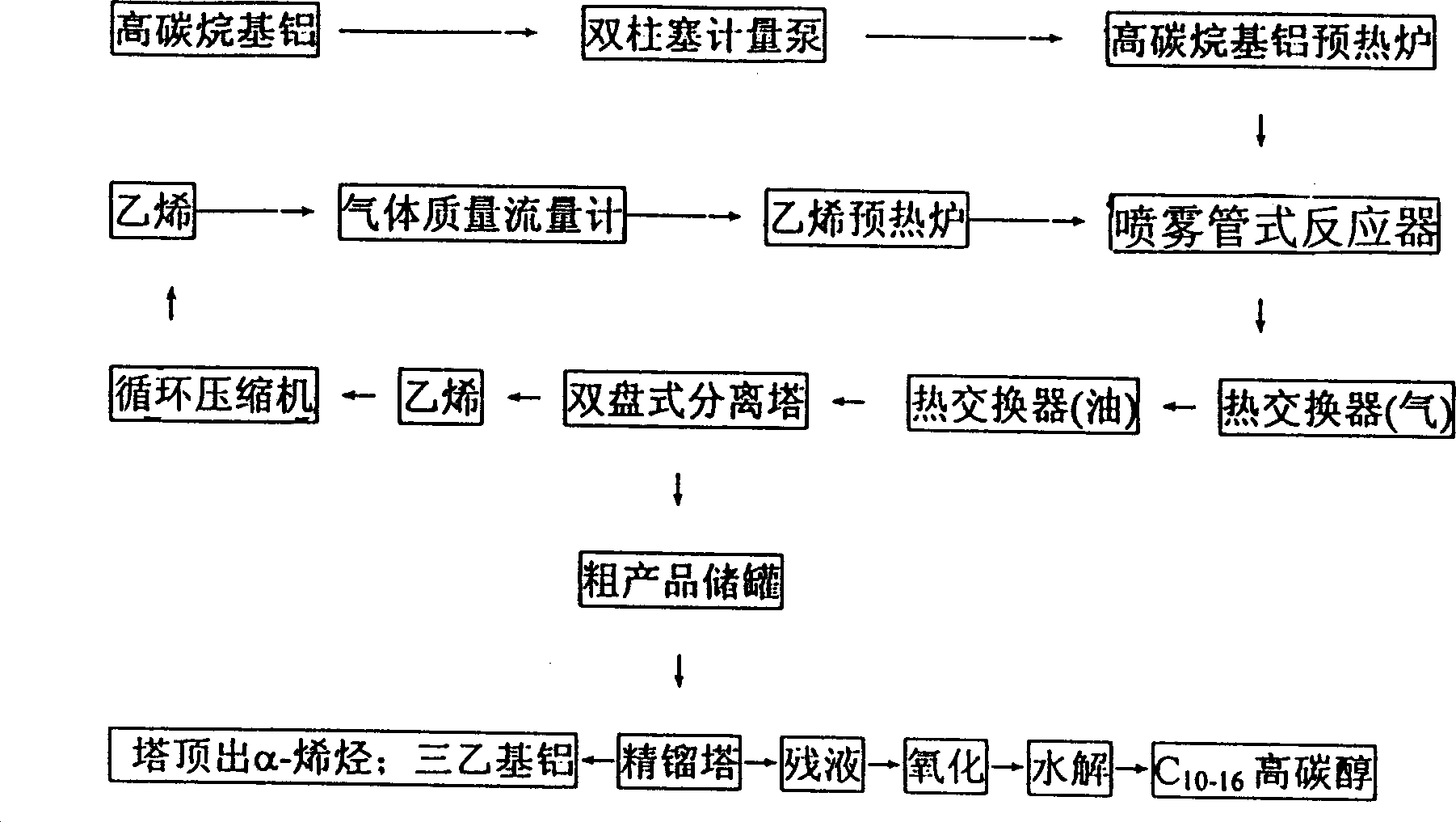

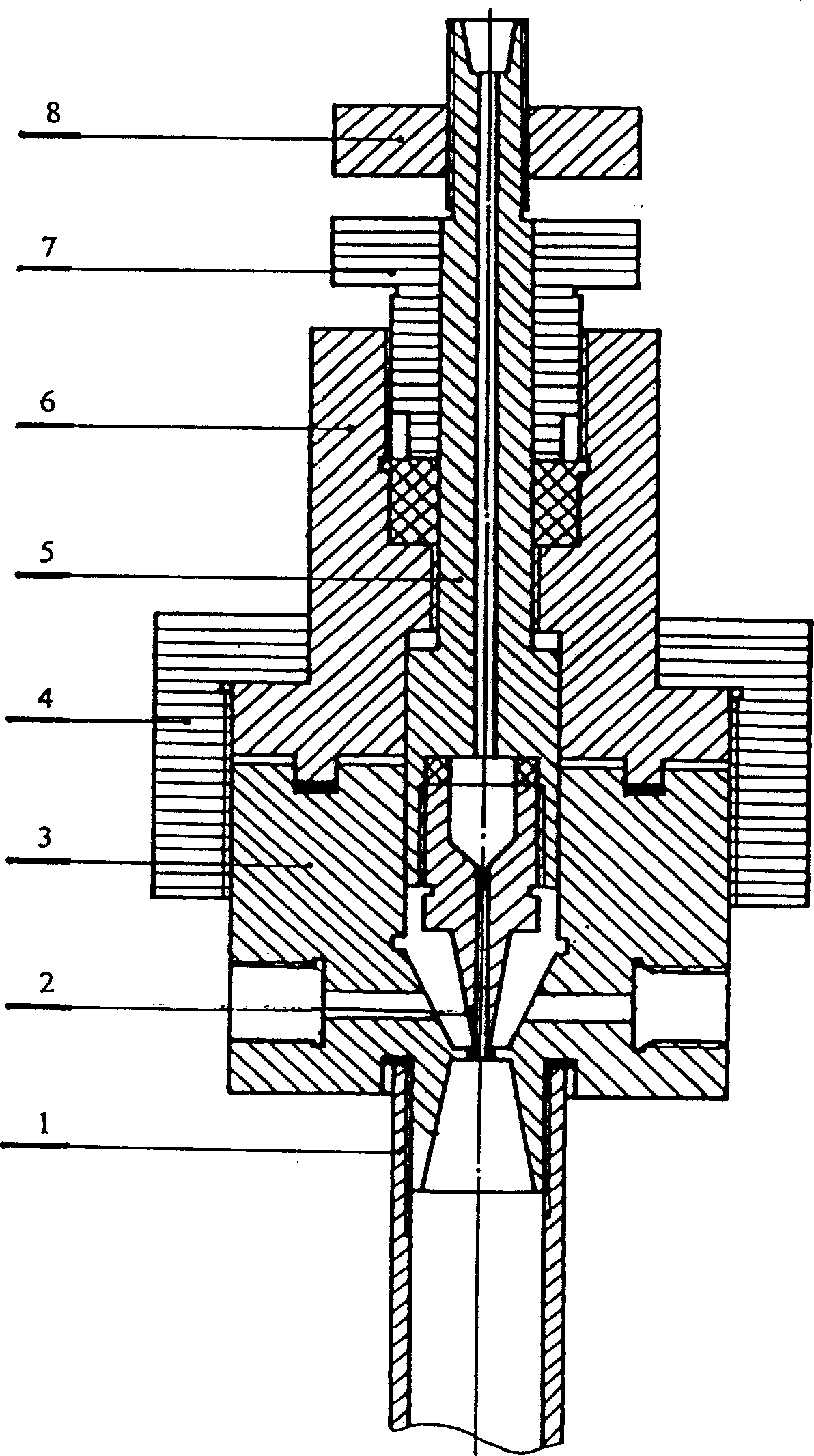

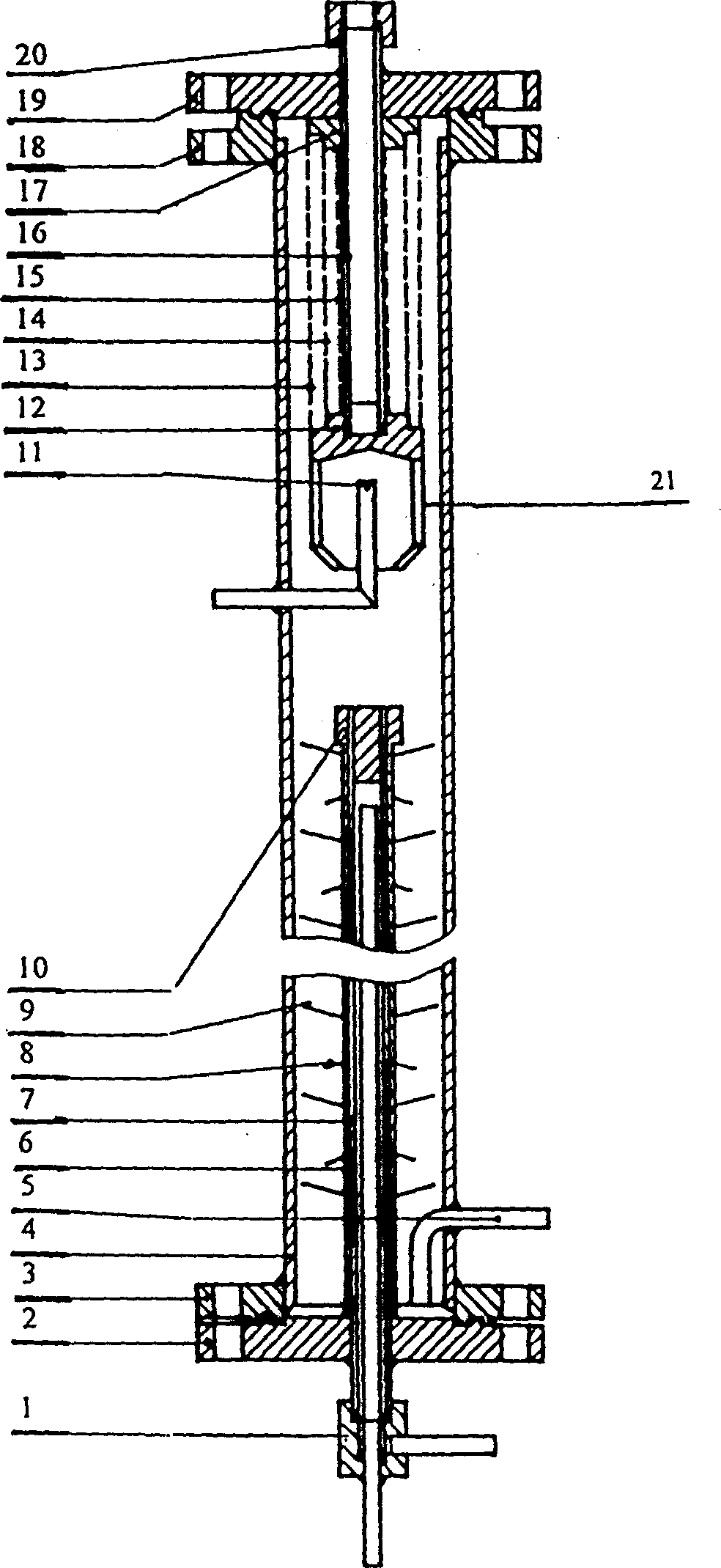

High-carbon alpha-olefine preparing process and apparatus

The present invention is the preparation process and apparatus for substituting alkyl group in high-carbon aluminium alkyl with ethylene to prepare straight-chain C4-26 alpha-olefine. High-carbon aluminum alkyl after being preheated to 120-180 deg.c is made to enter into a single-stage spraying tubular reactor at a linear speed of 150-300 m / s while ethylene after being preheated to 280-300 deg.c is made to enter into a reactor in tangent direction, so that replacement reaction is performed at 230-300 deg.c and 0.5-1.8 MPa. The atomizing reaction product is cooled to 20-60 deg.c and then, the emulsion is made to enter into the buffering tank in a double-disc separating tower for filming and separating while the gaseous phase is separated in the tower top for reuse. The coarse high-carbon alpha-olefine is fractionationed to obtain the destination product.

Owner:DALIAN UNIV OF TECH +1

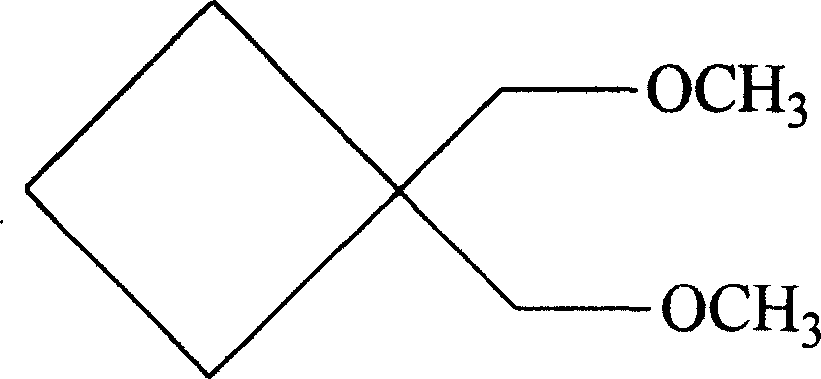

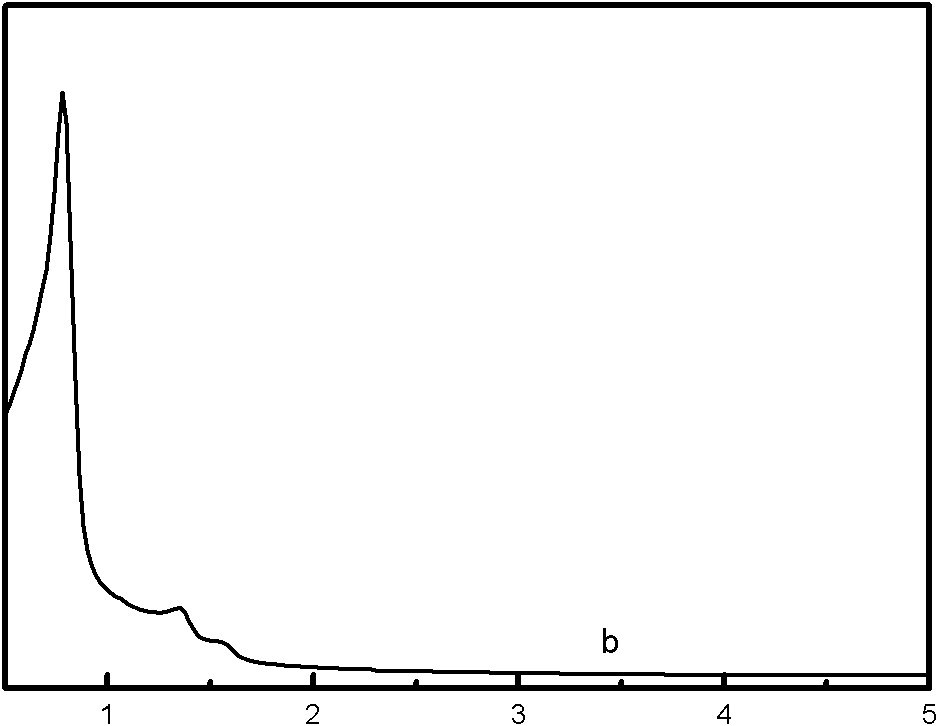

Load-type metallocene catalyst, preparation method thereof and application thereof

The invention provides a load-type metallocene catalyst which comprises a carrier and an alkyl aluminoxane / magnesium chloride complex and a metallocene compound loaded on the carrier. The hollow ball mesoporous silica carrier has an average particle diameter of 3 to 20 micrometers, a specific surface area of 200 to 300 square meter per gram, a pore volume of 0.5 to 1.5 milliliter per gram, a most probable pore size of 3 to 20 nanometers and an average pore wall thickness of 1 to 2.9 micrometers. The metallocene compound has a structure as shown in formula 1. The load-type metallocene catalyst provided by the invention has a catalytic efficiency up to 3.8 * 10<8> gPE / (mol Zr * h) while homopolymerization and a catalytic efficiency up to 3.7 * 10<8> gPE / (mol Zr * h) while copolymerization under 70 DEG C, overcomes defects of sticking to kettles, is low in a polymerization temperature, and reduces energy consumption to some extent.

Owner:CHINA PETROLEUM & CHEM CORP +1

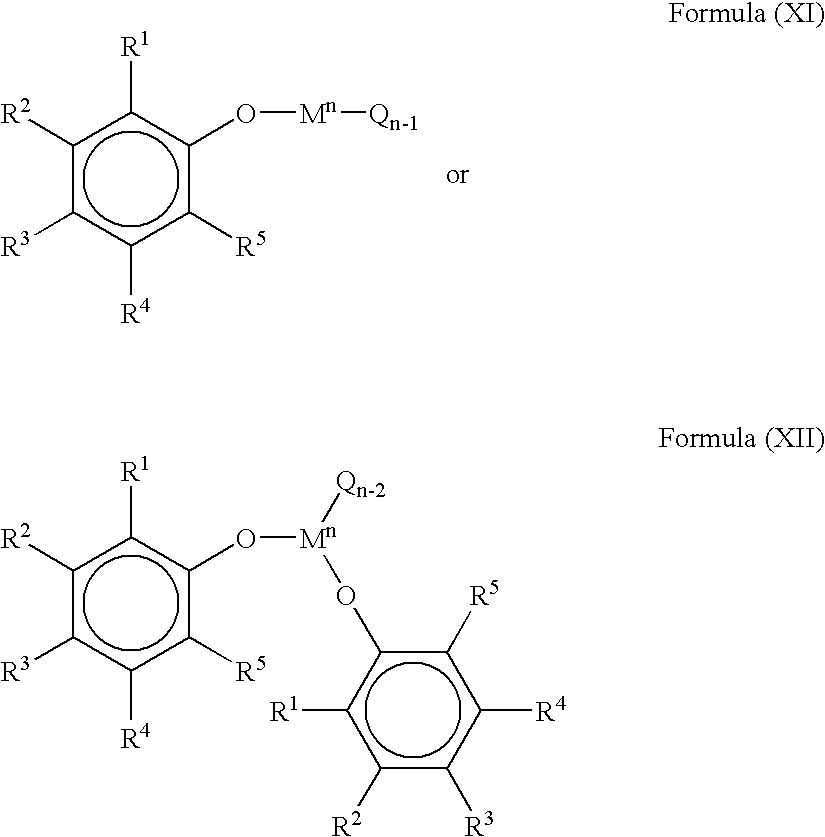

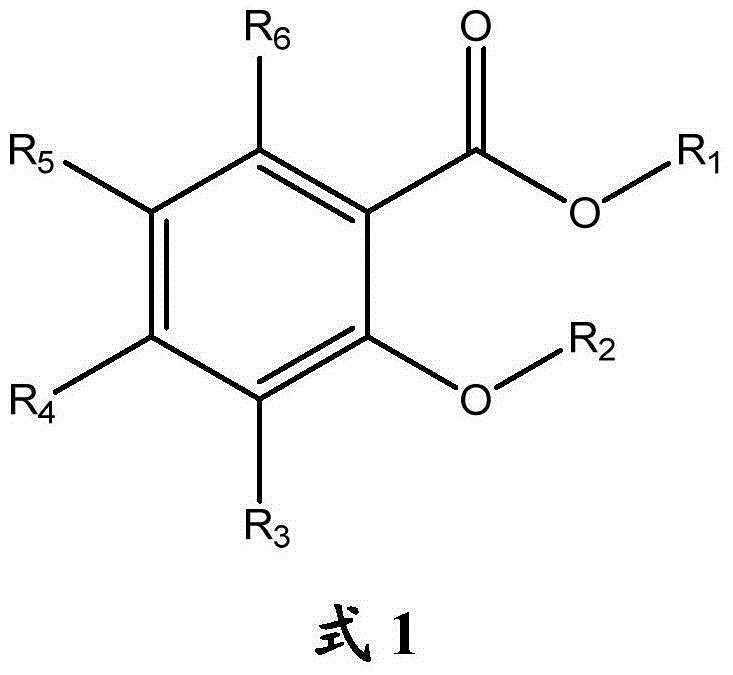

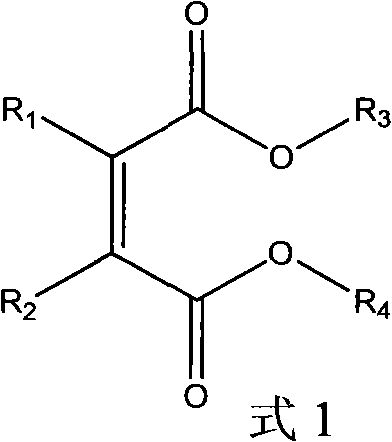

Solid catalyst component for olefin polymerization, and preparation method and application thereof

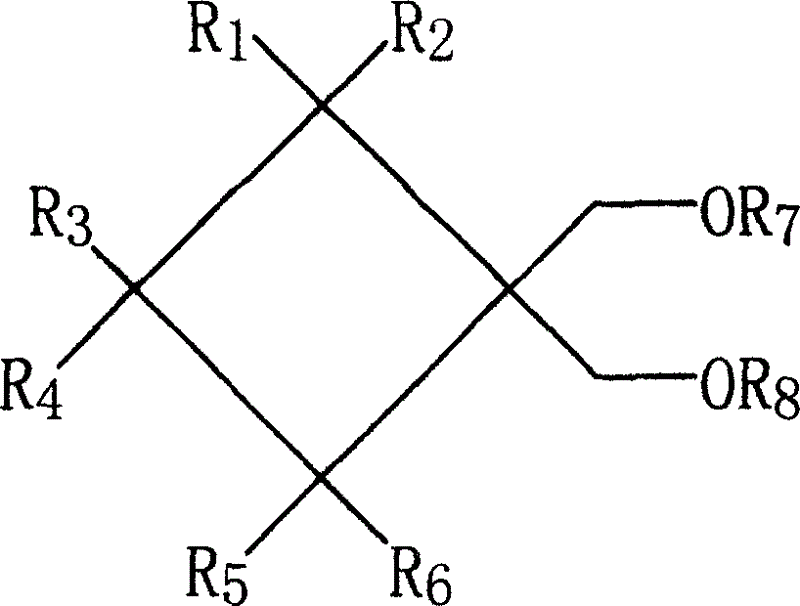

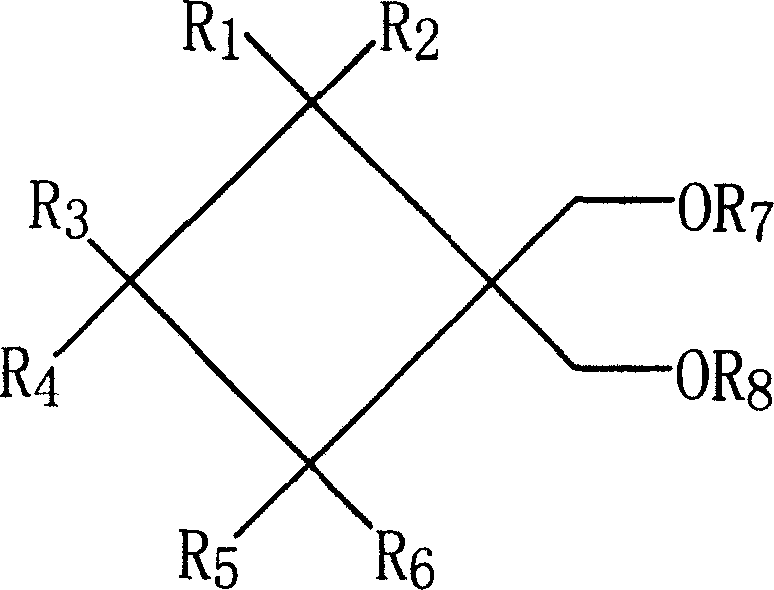

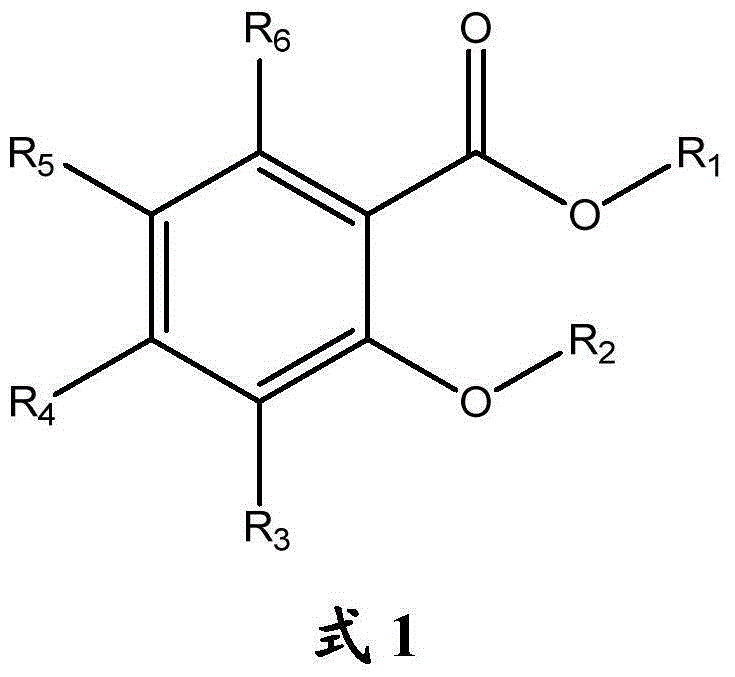

The invention discloses a solid catalyst component for olefin polymerization. The solid catalyst component comprises magnesium halide (1), a titanium active component (2) and a 2-alkoxy benzoate compound (3); the structural general formula of the 2-alkoxy benzoate compound is represented by the formula 1; in the formula 1, R1 and R2 are same or different and are independently selected from alkyl containing 1-12 carbon atoms and naphthenic base, aryl or aralkyl containing 3-8 carbon atoms; and R3, R4, R5 and R6 are same or different and are independently selected from hydrogen, alkyl containing 1-8 carbon atoms and naphthenic base, aryl or aralkyl containing 3-8 carbon atoms. The solid catalyst component, aluminium alkyl and a silane compound form a catalyst for olefin polymerization (copolymerization) so as to obtain a polymer having high activity and high isotacticity.

Owner:INST OF CHEM CHINESE ACAD OF SCI

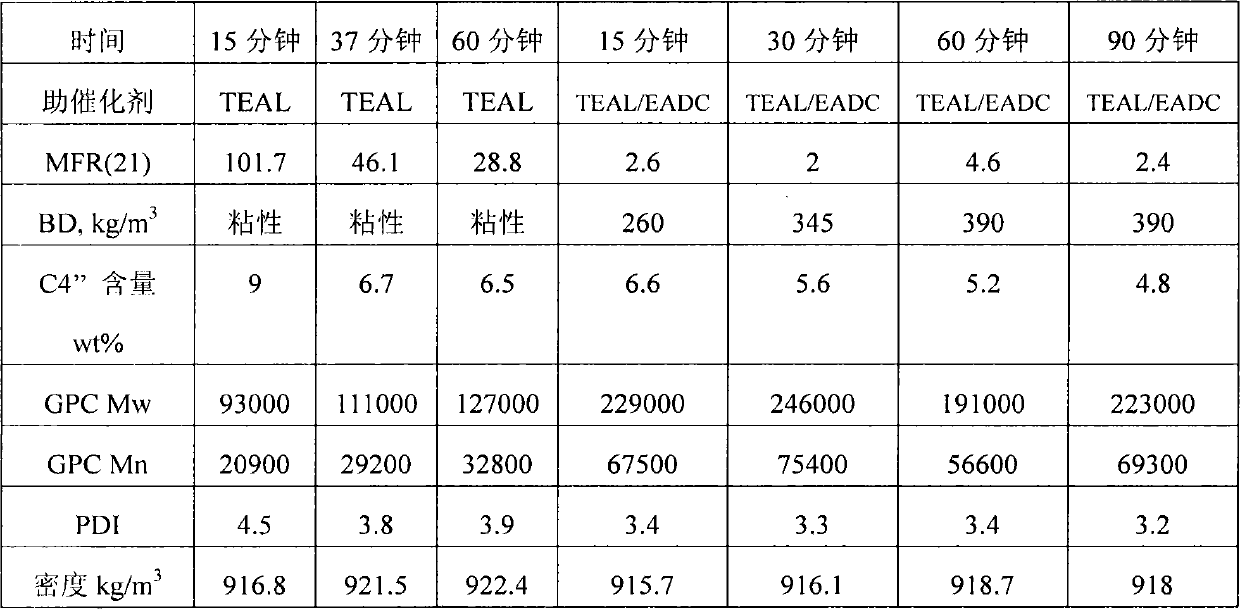

Improved ethylene polymerization catalyst composition

Ziegler-Natta catalyst composition capable of producing ethylene / alpha-olefins copolymers, particularly linear low density polyethylene; the composition having an improved stability of its behaviour during polymerization in respect to time. The Ziegler-Natta catalyst composition comprises: 1. Ziegler-Natta catalyst composition for the production of ethylene copolymers comprising A) a procatalyst, which procatalyst comprises a) an Al compound having the formula Al(alkyl)xCl3-x (I), where alkyl is an alkyl group with 1 to 12 and 0 = x = 3, b) a magnesium hydrocarbyloxy compound of formula Mg(OR1)2-n(R2)n (II), wherein each R1 and R2 is independently a C1-20 hydrocarbon residue which may optionally be substituted with halogen and 0 = n yTi(OR3)4-y (III), wherein R3 is a C2-20 hydrocarbon residue and y is 1, 2, 3 or 4, with compounds a), b) and c); being supported on a particulate inorganic carrier and B) a halogenated aluminium alkyl cocatalyst of the formula (IV) (C1-C4-alkyl)m-Al-X3-m, wherein X is chlorine, bromine, iodine or fluorine and m is 1 or 2.

Owner:BOREALIS AG

Propylene polymer and preparation method thereof

The present invention provides a propylene polymer and a preparation method thereof, the number average molecular weight of the propylene polymer is 3 *10<4> to 5 * 10<4>, the molecular weight distribution index is 3-8, and the isotactic index is 70-95%. The preparation method of the propylene polymer is as follows: under olefin polymerization conditions, in the presence of a catalyst, propylene or a mixture of propylene and ethylene and / or an alpha olefin selected from C4-C8 are polymerized, the catalyst comprises a solid component, an alkyl aluminum compound and an optional external electron donor compound, the solid component comprises the following reaction product components: (i) a magnesium compound shown as a formula (1) or (2); (ii) at least one titanium compound; (iii) at least one internal electron donor; and (iv) an oxirane compound shown as a formula (3). The preparation method can be used for preparing polypropylene with low isotactic index and high molecular weight.

Owner:CHINA PETROLEUM & CHEM CORP +1

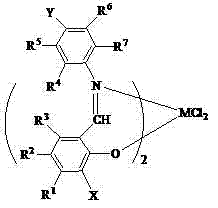

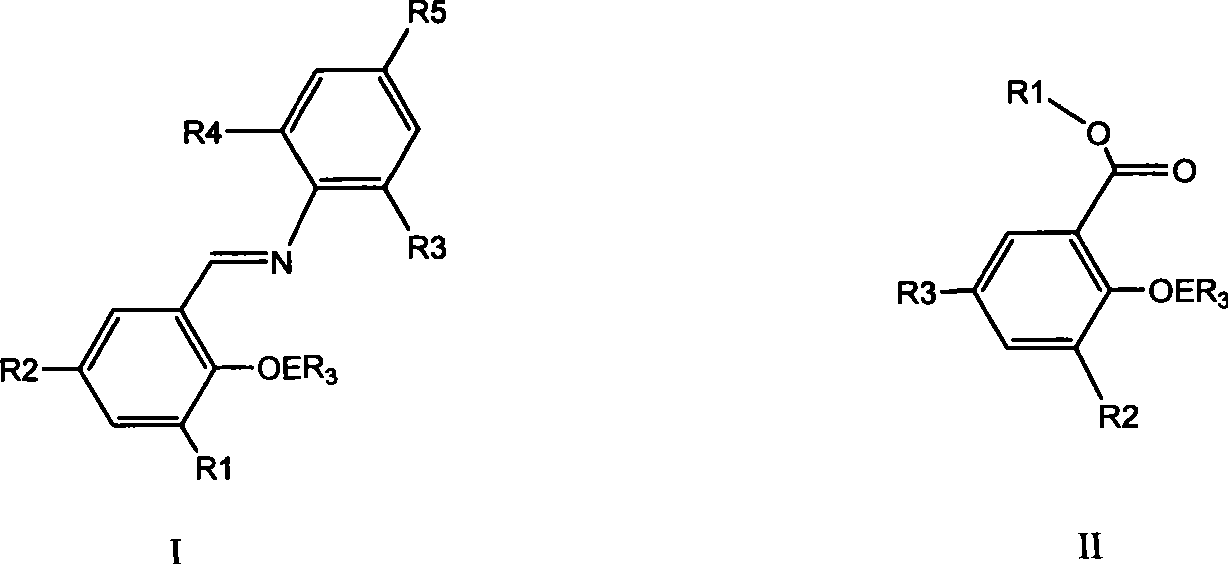

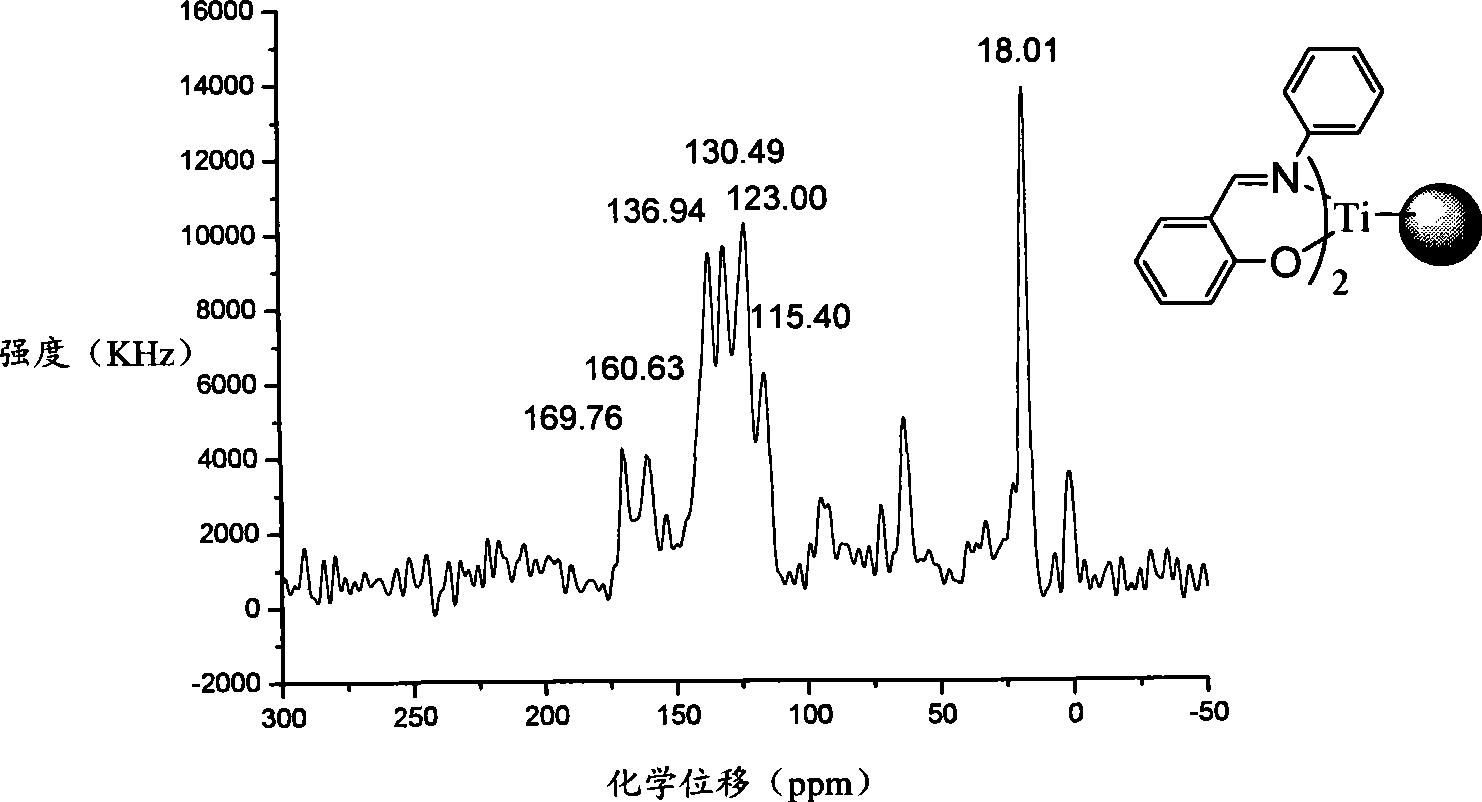

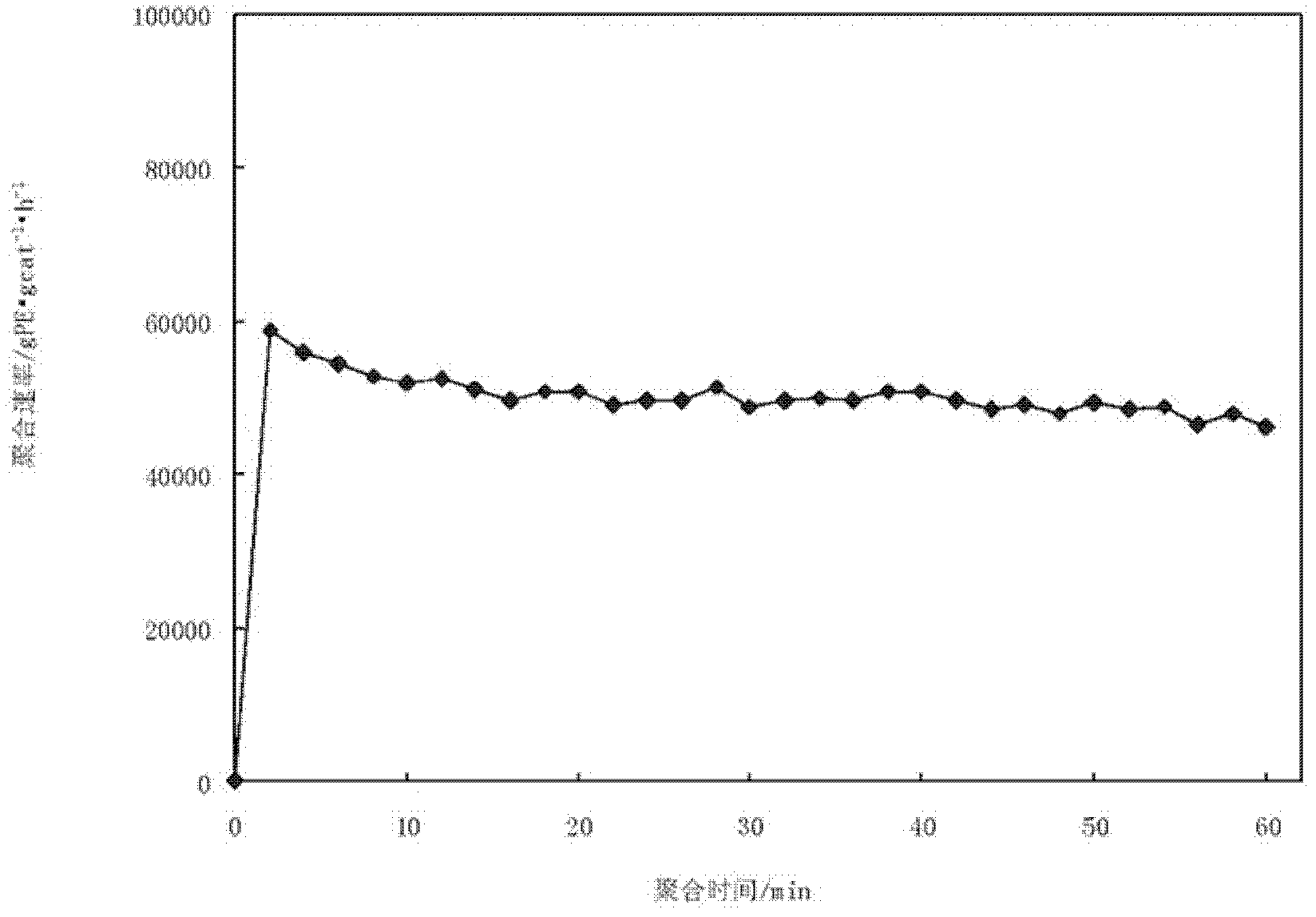

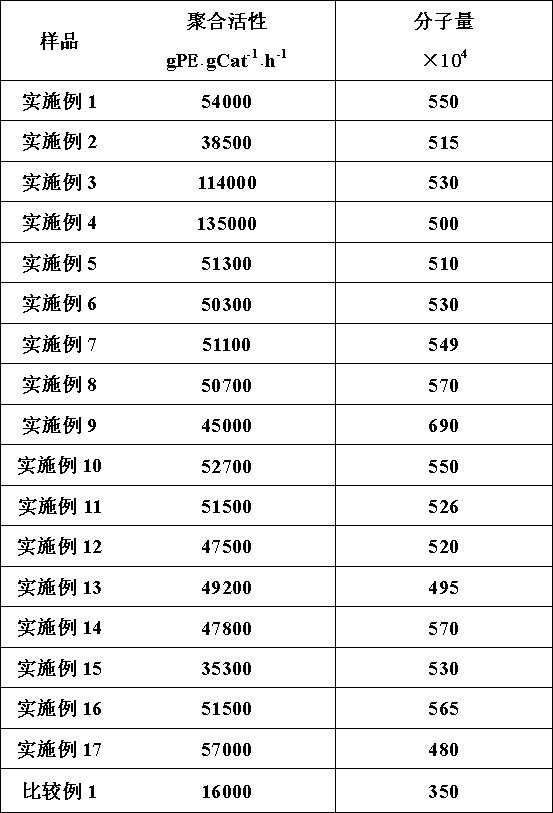

Schiff base transition metal complex containing alkoxy groups, and preparation method and application thereof

InactiveCN102516291AHigh activityEasy to prepareGroup 4/14 organic compounds without C-metal linkagesTitanium organic compoundsPolymer scienceSalicylaldehyde

The invention relates to a Schiff base transition metal complex containing alkoxy groups, a preparation method thereof and application of a catalyst composition composed of the transition metal complex and aluminum alkyl in catalyzing ethene polymerization, belonging to the technical field of catalysts. The preparation method for the Schiff base transition metal complex containing alkoxy groups comprises the following steps: synthesizing Schiff base ligand through a condensation reaction between substituted salicylaldehyde and an amine compound; reacting the ligand with an alkali metal compound to obtain a ligand salt solution; and reacting the ligand salt solution with MCl4 to prepare the Schiff base transition metal complex. The preparation method is simple; and when used for ethene polymerization, the synthesized Schiff base transition metal complex containing alkoxy groups has the following advantages compared to the prior art: common aluminum alkyl is used as a cocatalyst to substitute expensive MAO during polymerization, and the catalyst composition has high activity under the condition of a small usage amount of the cocatalyst. Hexane is used as a solvent to substitute toluene during polymerization, which is favorable for industrial introduction.

Owner:SHENYANG POLYTECHNIC UNIV

Diester-maleate-containing solid catalyst component for olefin polymerization and preparation method thereof

The invention discloses a diester-maleate-containing solid catalyst component for olefin polymerization. The component comprises (1) magnesium halide, (2) a titanium active component, and (3) a diester maleate compound shown as the following formula, wherein R1 to R4 in the formula 1 can be the same or different and are selected from C1 to C8 alkyls and C1 to C8 cycloalkyls, preferentially C1 to C6 alkyls. The magnesium halide alcohol compound and the titanium compound are contacted and reacted; the diester maleate compound is added into the reaction product; and after filtering and washing, the solid catalyst component can be prepared. The solid catalyst component is combined with aluminum alkyl and a silane compound to form a catalyst, which can be applied to olefin polymerization.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Carried catalyzer for olefinic polymerization and preparation method

A carried metallocene catalyst or post-transition metal catalyst for the catalytic polymerization of ethylene and propylene contains Zr or Fe (0.05-1.00 wt. portions), aluminium alkylide chosen from trimethyl aluminium, triethyl aluminum and triisobutyl aluminum (1-50) and molecular sieve-like calcium silicon compound (100). Its preparing process is also disclosed. Its advantages are high catalytic activity and no adhesion to reactor.

Owner:INST OF CHEM CHINESE ACAD OF SCI

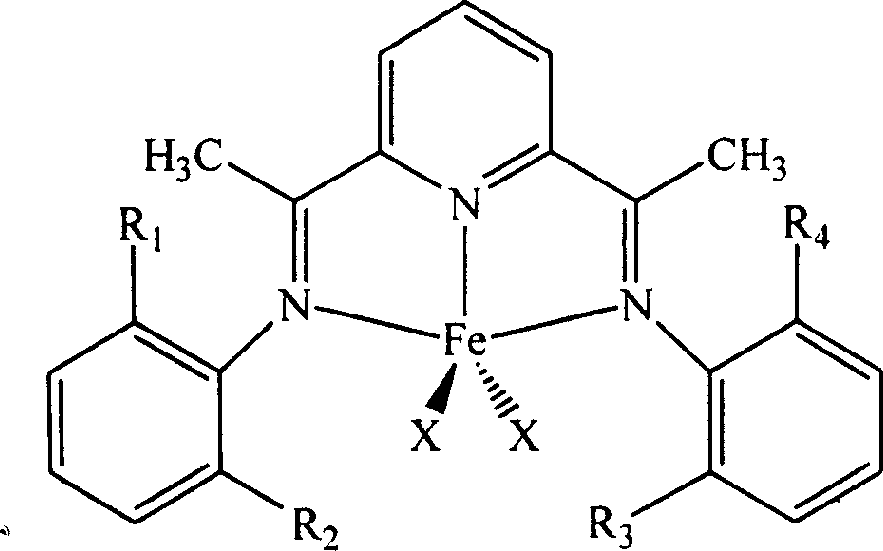

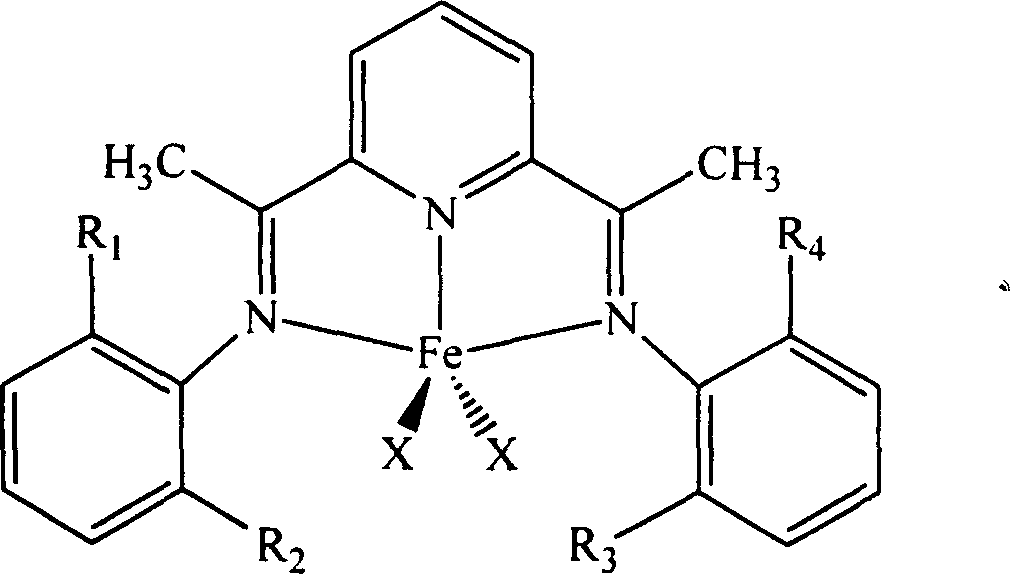

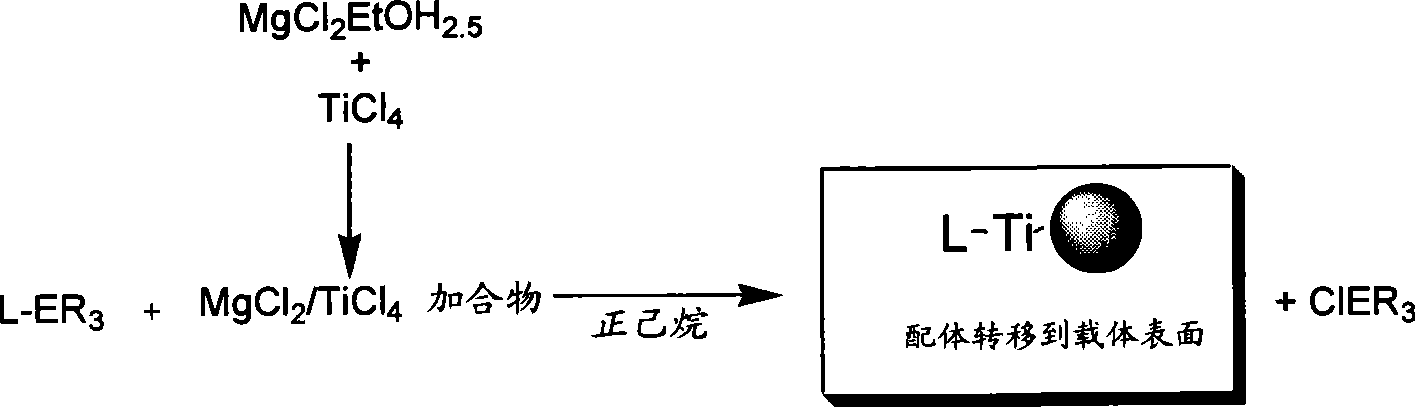

Supported catalyst for olefinic polymerization, and preparation and use thereof

The invention relates to a preparation method of an olefin polymerization catalyst, components thereof and an application thereof used in olefin polymerization. The bulk phase components of a loading catalyst used for olefin polymerization comprise: 1 percent to 10 percent of Ti, 5 percent to 30 percent of Mg, 45 percent to 85 percent of Cl, 5 percent to 45 percent of C, 1 percent to 10 percent of H and 0 percent to 5 percent of N; and surface atom components comprise 5 percent to 40 percent of O, 1 percent to 8 percent of Ti, 0 percent to 4 percent of N, 50 percent to 90 percent of C and 0.5 percent to 10 percent of Mg. The olefin polymerization catalyst is prepared by the following steps: a. MgCl2 / TiCl4 adduct is prepared; b. the MgCl2 / TiCl4 adduct is used for carrying out solid-state-reaction with anion organic ligand L-ER3, the anion organic ligand L-ER3 dissolved in an organic solvent is mixed with an organic solvent suspension of the MgCl2 / TiCl4 adduct, heated, deposited after reaction, filtered to get rid of upper liquid, washed and dried so as to obtain the polymerization catalyst applied to the olefin polymerization. The catalyst prepared by the method shows very high activity to the olefin polymerization under the activation of aluminum alkyl.

Owner:NANKAI UNIV

Ultrahigh molecular polyethylene catalyst and preparation method

The invention relates to a preparation method of an ultrahigh molecular polyethylene catalyst, which belongs to the high-molecular technical field. The method comprises the following steps: 1) under the protection of nitrogen, magnesium halide and a hydrocarbon solvent are reacted; 2) alcohol is added and forms an alcohol magnesium compound with magnesium halide; 3) halogenated alkyl aluminum and the alcohol magnesium compound form an intermediate product; 4) a supersonic wave device is switched on for performing ultrasonic treatment; 5) titanium tetrachloride is added and stirred for backflow under the heating condition; and 6) a standing process is carried out, the solid particles are washed and dried to obtain the ultrahigh molecular polyethylene catalyst. The obtained catalyst and cocatalyst alkyl aluminum are used together for synthesis of the ultrahigh molecular polyethylene. According to the invention, the ultrasonic treatment technology is used in the preparation process of the catalyst, the activity of the ultrahigh molecular polyethylene catalyst can be enhanced, the molecular weight of the polymerization products can be increased, the polymerization kinetics of the prepared catalyst is stable, and the polymerization technology can be easily controlled.

Owner:CHINA PETROLEUM & CHEM CORP

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com