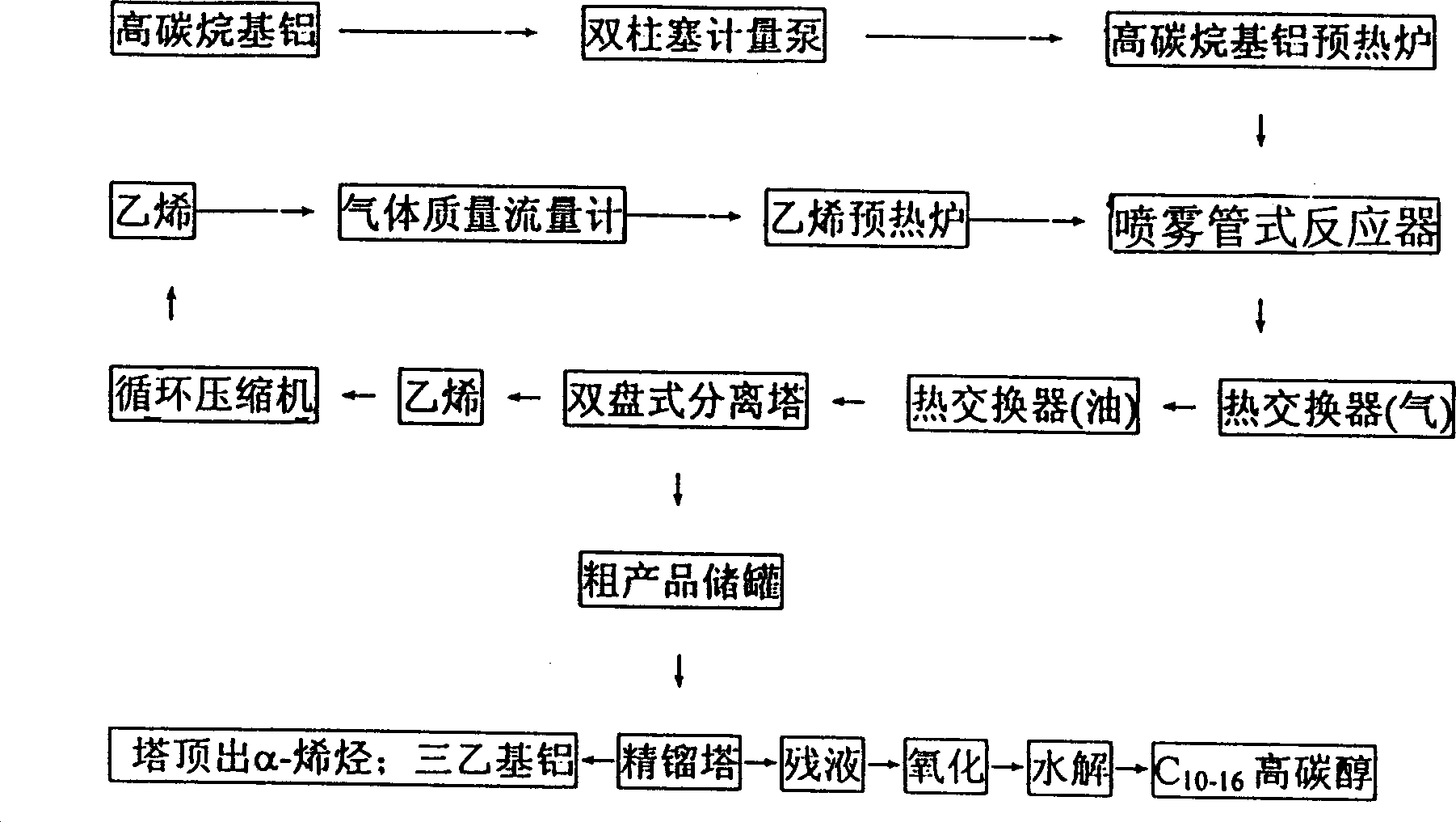

High-carbon alpha-olefine preparing process and apparatus

An olefin and high-carbon technology, applied in the field of preparation of C4-26 high-carbon α-olefins, can solve problems such as unfavorable reaction, back-mixing, and easy clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

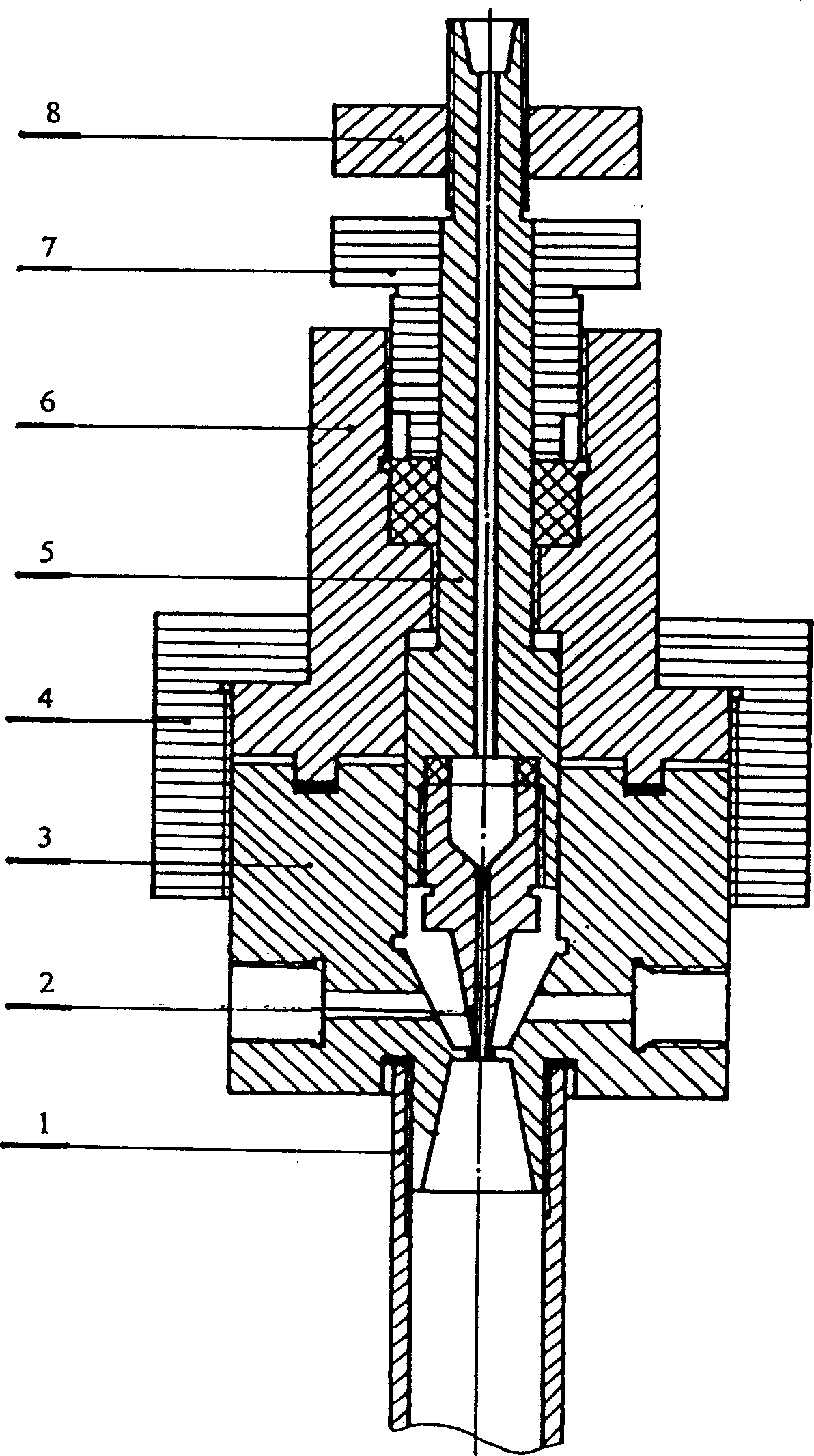

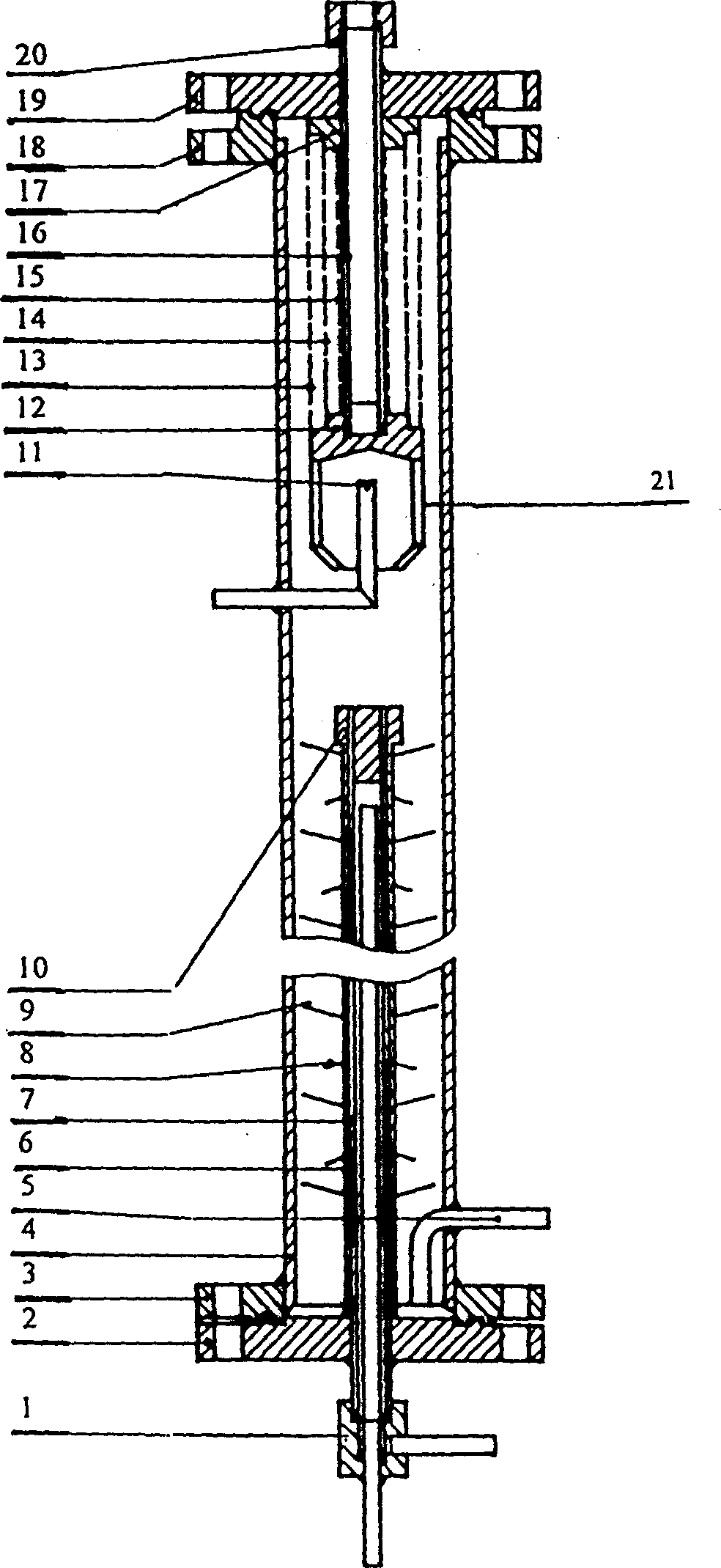

Method used

Image

Examples

Embodiment 1

[0053] The high-carbon alkyl aluminum is sent into the high-carbon alkyl aluminum preheating furnace with a flow rate of 0.25mol / h by a double plunger metering pump. The outlet temperature is 120°C, and it directly enters the displacement reactor. Ethylene is sent into the ethylene preheating furnace at a flow rate of 12.5mol / h through the gas mass flow meter, the outlet temperature is 300°C, the reaction pressure is 1Mpa, the reaction temperature is 260°C, the single-pass conversion rate of high-carbon alkyl aluminum is 84%, and the α-olefin Selectivity >99%, no product isomerization found.

Embodiment 2

[0055] The high-carbon alkyl aluminum is sent into the high-carbon alkyl aluminum preheating furnace with a flow rate of 0.25mol / h by a double plunger metering pump. The outlet temperature is 120°C, and it directly enters the displacement reactor. Ethylene is fed into the ethylene preheating furnace at a flow rate of 12.5mol / h through the gas mass flow meter, the outlet temperature is 280°C, the reaction pressure is 1Mpa, the reaction temperature is 220°C, the single-pass conversion rate of high-carbon alkyl aluminum is 39%, and the α-olefin Selectivity >99%, no product isomerization found.

Embodiment 3

[0057] Using the same method as in Example 1, the high-carbon alkylaluminum preheating temperature was increased so that the temperature of the high-carbon alkylaluminum entering the replacement reactor was 160 ° C. As a result, the high-carbon alkylaluminum single-pass conversion rate was 85.6%, and α- Olefin selectivity >99%, no product isomerization observed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com