Propylene polymerized catalyst system, preparationmethod and usage

A technology for propylene polymerization and catalyst, applied in the field of preparation of catalytic system, can solve the problems of decreased activity, complicated polymerization process and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

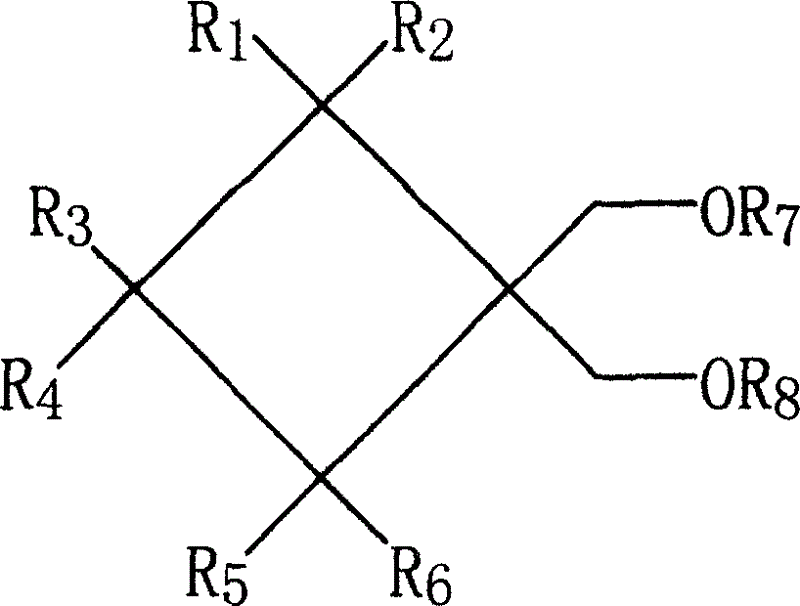

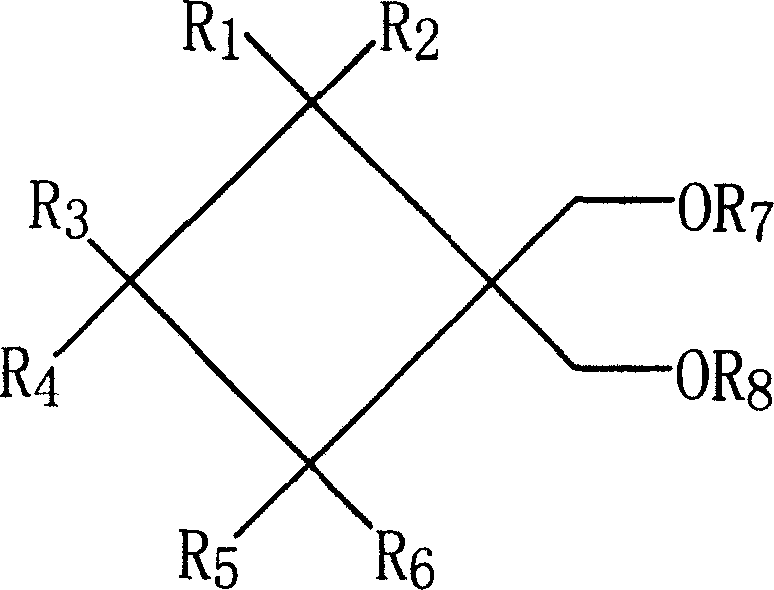

Method used

Image

Examples

Embodiment 1

[0077] Catalyst preparation

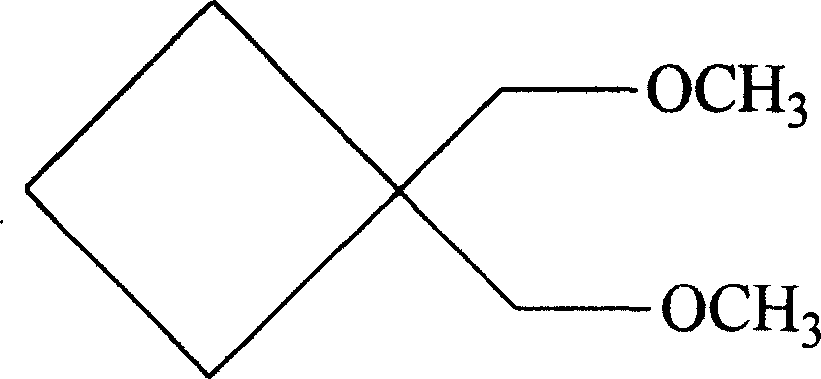

[0078] Add 4.3 grams of microspherical magnesium chloride alcoholate particles to 140 ml of titanium tetrachloride liquid at -20°C, react for 1.5 hours, slowly heat up to 40°C and add 0.5 grams of 1,1-bis(methoxymethane Base)-cyclobutane, reacted at 120°C for 2 hours, filtered, then added 140 ml of titanium tetrachloride, reacted at 120°C for 2 hours, filtered, washed five times with 100 ml of hexane at 60°C, and washed with 100 milliliters of hexane was washed once, and the magnesium chloride supported catalyst was obtained after vacuum drying. The above operations were all completed under anhydrous and oxygen-free conditions.

[0079] slurry polymerization

[0080] In 250 milliliters of vacuum-dried reaction flasks fully replaced with nitrogen and propylene gas, add 100 milliliters of anhydrous and anaerobic-treated heptane, keep the pressure in the bottle at 1 atmosphere, and keep the temperature at 40 ° C. Add the alkylaluminum solution, sti...

Embodiment 2

[0082] Except that when preparing the procatalyst, the amount of 1,1-bis(methoxymethyl)-cyclobutane was changed from 0.5 gram to 0.75 gram, others were the same as in Example 1.

[0083] The aggregated relevant data are listed in Table 1.

Embodiment 3~5

[0085] According to the polymerization method of embodiment 1, the molar ratio of the titanium in the main catalyst and the aluminum in the cocatalyst is respectively 1: 40 / 20 / 100, and other are identical with embodiment 1.

[0086] The aggregated relevant data are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com