Olefin polymerizing catalyst, preparation and use thereof

A technology for olefin polymerization and catalyst, which is applied in the field of olefin polymerization catalyst and its preparation and application, and can solve problems such as poor stereo orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

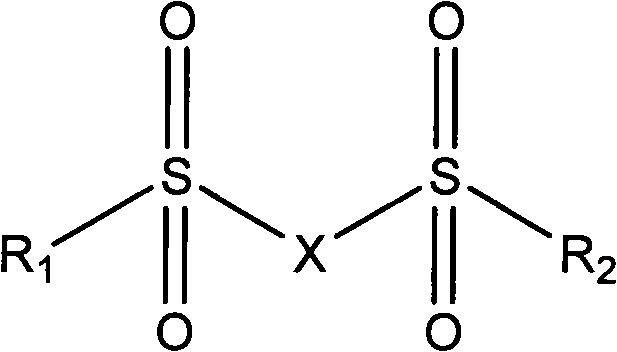

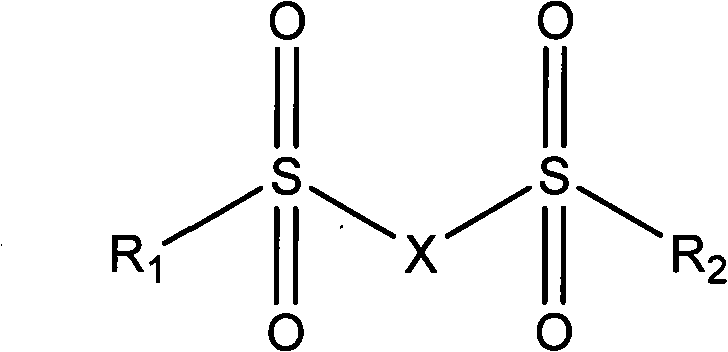

Method used

Image

Examples

Embodiment 1

[0156] Add 45mL of anhydrous hexane and 15g of anhydrous MgCl to a 250mL three-necked flask in sequence 2 , 144mL of anhydrous n-butanol, hexane was distilled off, and the temperature was lowered to ambient temperature (about 10°C) to obtain a uniform colorless and transparent solution. The prepared MgCl 2 - Add the n-butanol solution to a 500 mL three-neck flask containing 100 mL of paraffin oil and 0.32 g of sorbitan trioleate, and stir at a speed of 1000 rpm for 30 minutes to obtain a stable white emulsion. The temperature is controlled at about 35°C, and 26mL of 5M SiCl is slowly added dropwise over 40 minutes 4 - Solution in hexane, heated to 50°C for 1 hour. Cool, settle, and filter out the paraffin oil in the upper layer. Wash with a total of about 100 mL of anhydrous hexane three times, and drain to obtain 6.3 g of magnesium chloride alcoholate carrier.

[0157] 1.3 g of solid alcoholate carrier and 30 mL of anhydrous heptane were added to a 250 mL three-necked fla...

Embodiment 2

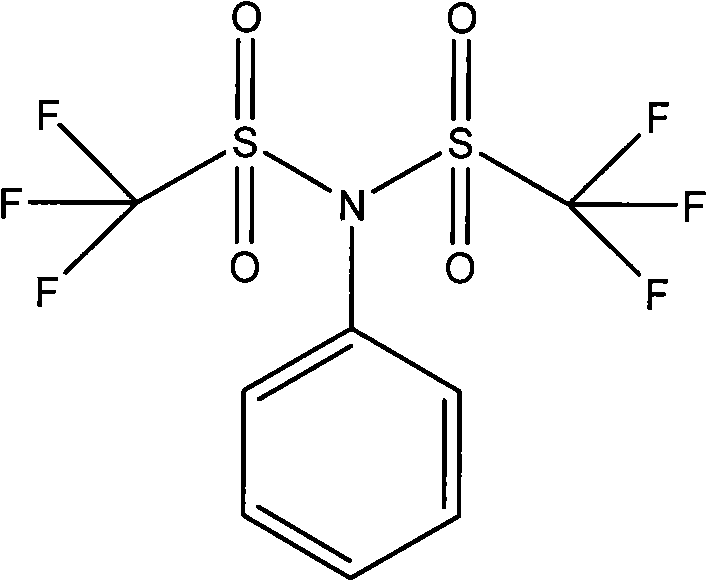

[0160] The method is the same as in Example 1, except that N-methoxyphenyl-bis(trifluoromethanesulfonyl)imide is used as the electron donor to obtain 0.65 g of a solid catalyst with a titanium content of 3.86%. Catalyst activity of 5518 g polymer / g (Ti) hour -1 , Isotacticity 93%.

Embodiment 3

[0162] The method is the same as in Example 1, except that N-phenyl-bis(trifluoromethanesulfonyl)imide is used as the electron donor to obtain 0.49 g of a solid catalyst with a titanium content of 3.95%. Catalyst activity of 11797 g polymer / g (Ti) hour -1 , Isotacticity 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com