Method for preparing high-fluidity wide-distribution polypropylene and product thereof

A polypropylene and wide-distribution technology, applied in the field of high-flow and wide-distribution polypropylene, can solve the problems of troublesome and inconvenient feeding of electrons, and can not be used to prepare high-flow and wide-distribution, etc., to achieve excellent mechanical properties, high flow, wide spread effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

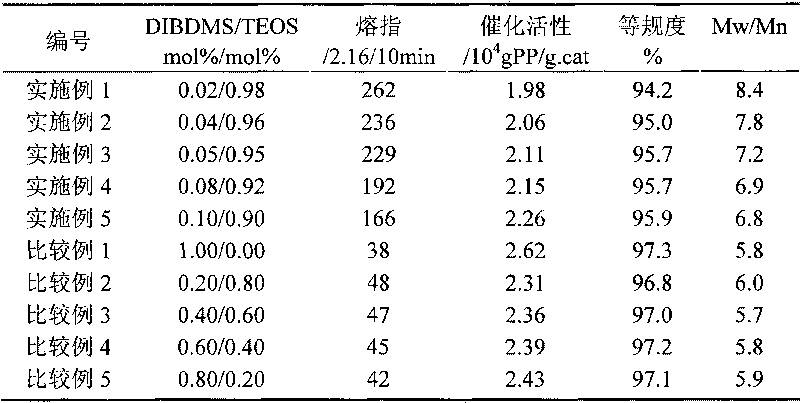

[0042] According to the aforementioned polymerization experiment, the selected component C is a compound system of TEOS and DIBDMS, and the compound ratio of the two is M(DIBDMS) / [M(TEOS)+M(DIBDMS)]=2%. The Al / Si / Ti ratio of the active components of components A, B, and C is 100:10:1, and the polymerization results are shown in Table 1.

Embodiment 2

[0044] The same implementation process as in implementation 1, except that the compounding ratio of TEOS and DIBDMS is adjusted to M(DIBDMS) / [M(TEOS)+M(DIBDMS)]=4%. The aggregation results are shown in Table 1.

Embodiment 3

[0046] The same implementation process as in implementation 1, except that the compounding ratio of TEOS and DIBDMS is adjusted to M(DIBDMS) / [M(TEOS)+M(DIBDMS)]=5%. The aggregation results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com