Supported catalyst for olefinic polymerization, and preparation and use thereof

A supported catalyst and olefin polymerization technology, which is applied in the field of preparation of olefin polymerization catalysts, can solve the problems of reduced catalyst activity, inability to effectively control polymer morphology, and poor stereoselectivity of catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

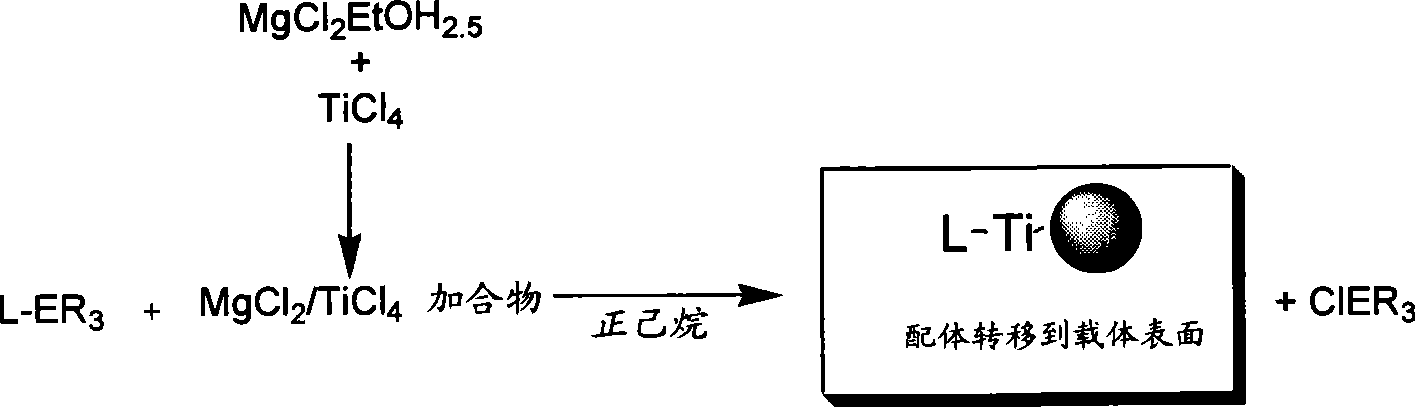

Method used

Image

Examples

Embodiment 1

[0036] Spherical carrier MgCl 2 (HOEt) 2.5 , 10g was slowly added to the 28mL TiCl 4 and 140mL hexane and pre-cooled to -25°C in a reaction flask, at this temperature, keep the temperature at °C / 5min and slowly rise to room temperature, react for 0.5 hours, filter off the liquid; add 100mL TiCl 4 Continue to heat up to 130°C, react for 2 hours, remove the upper liquid after cooling down; add 100mL TiCl 4 , heated up to 130°C, reacted for another 2h, and removed the upper liquid; washed 6 times with n-hexane at 80°C until the washing liquid was clear; the obtained solid was vacuum-dried to obtain a spherical solid, and the measured Ti% was 9.60%, thus Calculate the amount of substrate required for the stoichiometric reaction with the organic compound. Mg% is 13.94%, Cl% is 62.94%, C% is 3.50%, and H% is 2.39%.

Embodiment 2

[0038] Spherical carrier MgCl 2 (HOEt) 2.5 Slowly add 2g into 30mL hexane to form a suspension, cool down to -25°C; add 20mL hexane and 20mL TiCl dropwise 4 The mixed solution was slowly heated to room temperature, and then slowly heated to 90° C., and reacted for 2 h; washed with hexane for 3 times, and drained. The obtained solid was vacuum-dried to obtain a spherical solid, and the measured Ti% was 7.53%.

Embodiment 3

[0040] Spherical carrier MgCl 2 (HOEt) 2.5 2g was added into 30mL hexane to obtain a suspension, cooled to -25°C; 20mL hexane and 20mL TiCl were added dropwise 4 The mixture was slowly warmed up to room temperature and reacted for 2 hours. After filtration, a mixture of 20 mL of hexane and 20 mL of titanium tetrachloride was added and reacted at room temperature for 2 hours; washed 3 times with hexane and drained. The obtained solid was vacuum-dried to obtain a spherical solid, and the measured Ti% was 5.65%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com