Electrical telemechanical host with plant-level automatic power generation function

A technology of automatic power generation control and electric power telecontrol, which is applied in the direction of AC networks, electrical components, circuit devices, etc. with the same frequency from different sources, and can solve the problems of increasing protocol communication, increasing the complexity of system structure, etc., and achieving economical dispatching channels, improve network data security, and improve flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

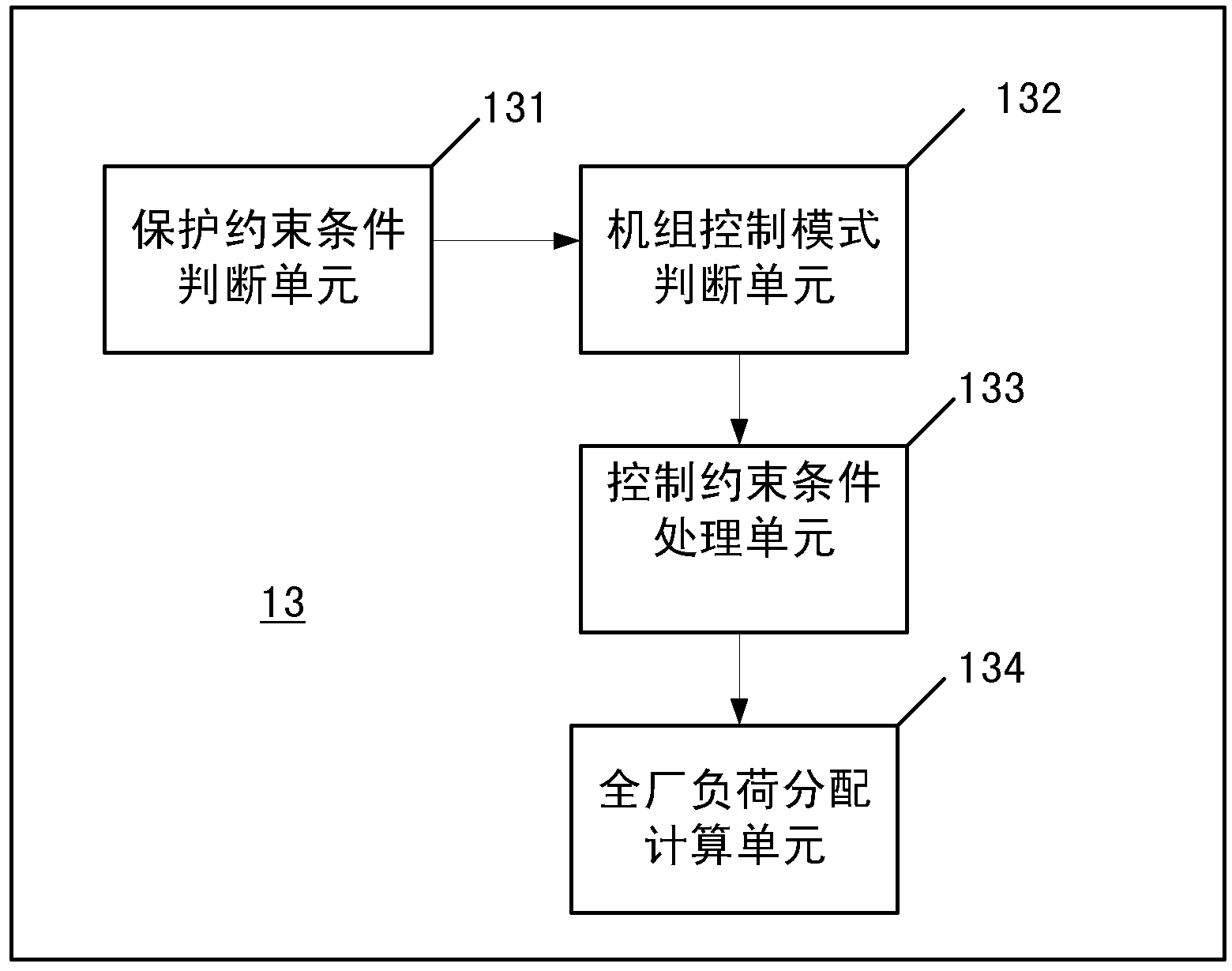

[0046] figure 1 It is a schematic diagram of the module structure of the power remote control host with plant-level automatic power generation control function according to an embodiment of the present invention. Such as figure 1As shown, the power telecontrol host 1 with factory-level automatic power generation control function is connected to the remote signaling module 2 , telemetry module 3 , remote adjustment module 4 and remote control module 5 through a bus 6 . In addition, the electric power telecontrol host 1 is also connected to the dispatching energy management system / data acquisition and monitoring system master station (abbreviated as the dispatching EMS / SCADA master station) 7 . The power telecontrol host 1 includes a communication submodule 11 , a data...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com