Production method of microalloyed tin bronze alloy

A micro-alloying and tin-bronze technology, which is applied in the field of preparation of micro-alloying tin-bronze alloys, can solve problems such as inapplicability, and achieve the effects of saving energy, reducing the degree of segregation, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Micro-alloyed tin-bronze alloy preparation method of the present invention, concrete steps are:

[0032] 1. Alloy melting: non-vacuum induction furnace is used for melting. Put the electrolytic copper into the smelting furnace, heat until the melt is completely melted, add a covering agent to keep it warm, after degassing and impurity removal, cover with burning charcoal, add the dried Cu-P master alloy and Sn, and stir well After standing;

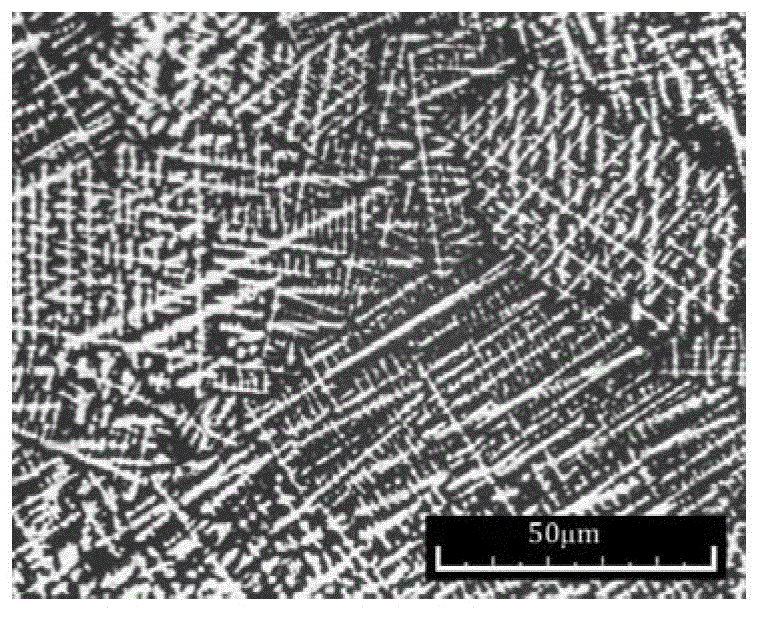

[0033] 2. Microalloying treatment: add 0.2% cobalt refiner to the refined melt, and perform microalloying treatment at a high temperature of 1240-1300 ° C; The smelting temperature is consistent, and the microalloying treatment temperature refers to the temperature used in the existing alloy smelting;

[0034] 3. Alloy casting: Ingot casting of microalloying melt, the casting temperature is 1150-1250°C slightly lower than the temperature used in the above microalloying treatment, under the action of cooling conditions and refiner...

Embodiment 2

[0038] Micro-alloyed tin-bronze alloy preparation method of the present invention, concrete steps are:

[0039] 1. Alloy melting: non-vacuum induction furnace is used for melting. Put the electrolytic copper into the smelting furnace, heat until the melt is completely melted, add a covering agent to keep it warm, after degassing and impurity removal, cover with burning charcoal, add the dried Cu-P master alloy and Sn, and stir well After standing;

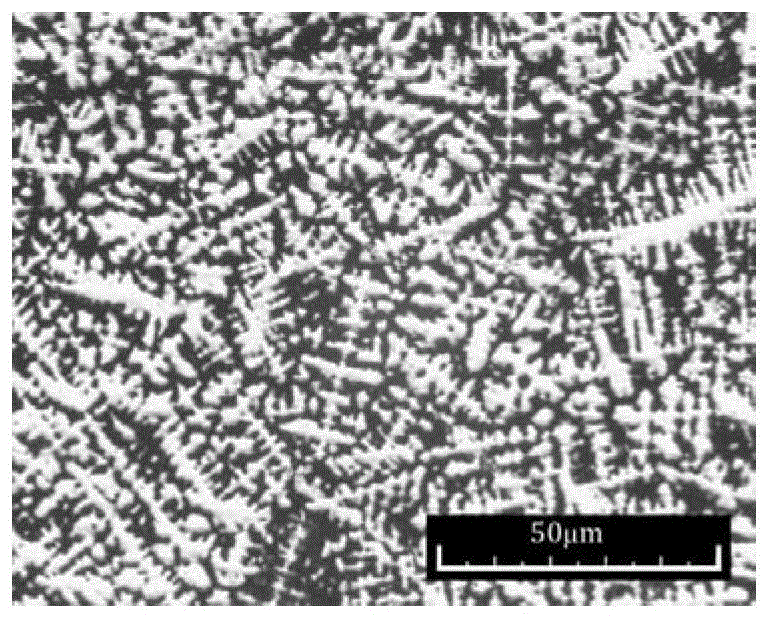

[0040] 2. Microalloying treatment: add 0.6% cobalt refiner to the refined melt, and perform microalloying treatment at a high temperature of 1240-1300 ° C; The temperature is consistent, and the microalloying treatment temperature refers to the temperature used in the existing alloy melting;

[0041] 3. Alloy casting: Ingot casting of microalloying melt, the casting temperature is 1150-1250°C slightly lower than the temperature used in the above microalloying treatment, under the action of cooling conditions and refiner cobalt, f...

Embodiment 3

[0045] Micro-alloyed tin-bronze alloy preparation method of the present invention, concrete steps are:

[0046] 1. Alloy melting: non-vacuum induction furnace is used for melting. Put the electrolytic copper into the smelting furnace, heat until the melt is completely melted, add a covering agent to keep it warm, after degassing and impurity removal, cover with burning charcoal, add the dried Cu-P master alloy and Sn, and stir well After standing;

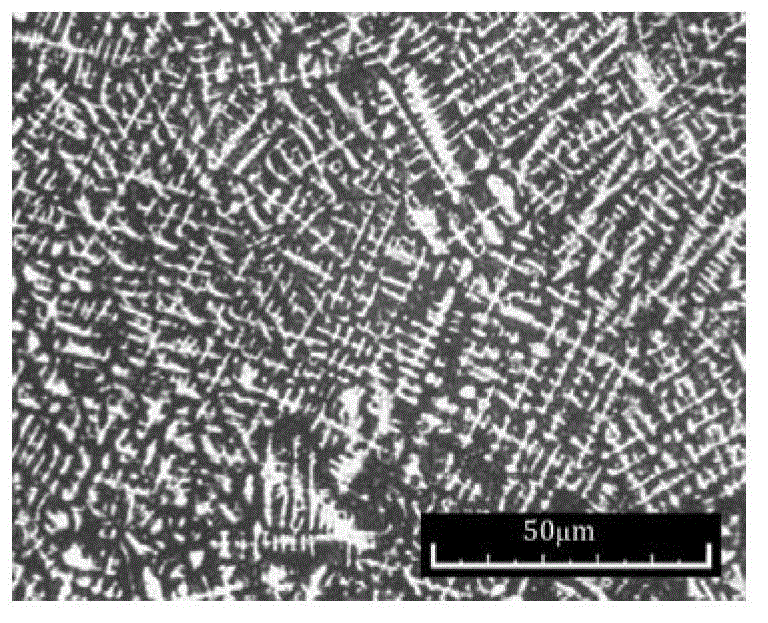

[0047] 2. Microalloying treatment: add 1.0% cobalt refiner to the refined melt, and perform microalloying treatment at a high temperature of 1240-1300 ° C; The temperature is consistent, and the microalloying treatment temperature refers to the temperature used in the existing alloy melting;

[0048] 3. Alloy casting: Ingot casting of microalloying melt, the casting temperature is 1150-1250°C slightly lower than the temperature used in the above microalloying treatment, under the action of cooling conditions and refiner cobalt, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com