Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

124 results about "Brittle crack" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High strength and low yield ratio steel for structure having excellent low temperature toughness

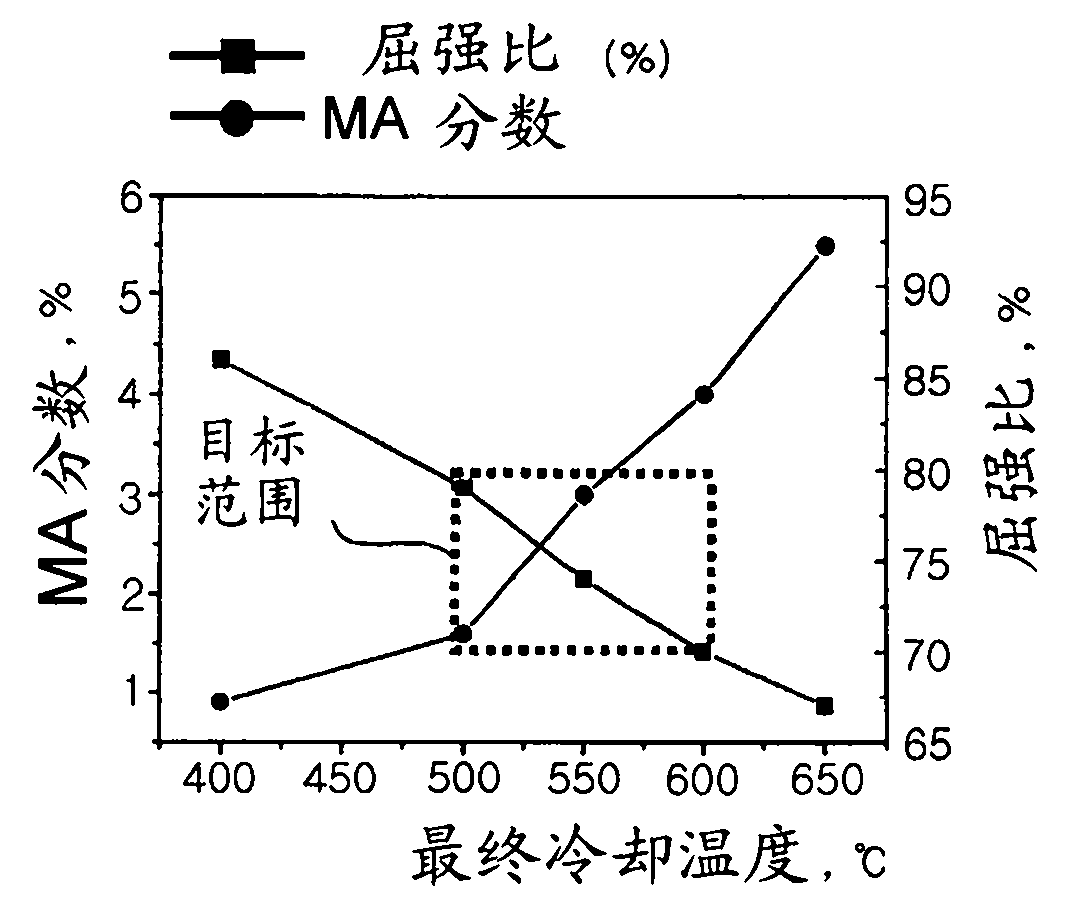

There is provided a high strength and low yield ratio steel for structure that is used as steel for structures of buildings and has excellent characteristics such as low temperature toughness, a tensile strength of approximately 600 MPa or more and a low yield ratio of 80% or less. The high strength and low yield ratio steel includes, by weight percent: C: 0.02 to 0.12%, Si: 0.01 to 0.8%, Mn: 0.3 to 2.5%, P: 0.02% or less, S: 0.01% or less, Al: 0.005 to 0.5%, Nb: 0.005 to 0.10%, B: 3 to 50 ppm, Ti: 0.005 to 0.1%, N: 15 to 150 ppm, Ca: 60 ppm or less, and the balance of Fe and inevitable impurities, and further includes at least one component selected from the group consisting of, by weight percent: Cr: 0.05 to 1.0%, Mo: 0.01 to 1.0%, Ni: 0.01 to 2.0%, Cu: 0.01 to 1.0% and V: 0.005 to 0.3%, wherein a finish cooling temperature is limited to 500 to 600 DEG C after the finish-rolling process. The high strength and low yield ratio steel satisfying characteristics such as low temperature toughness, brittle crack arrestabi lity and low yield ratio, and the manufacturing method thereof may be provided.

Owner:浦项股份有限公司

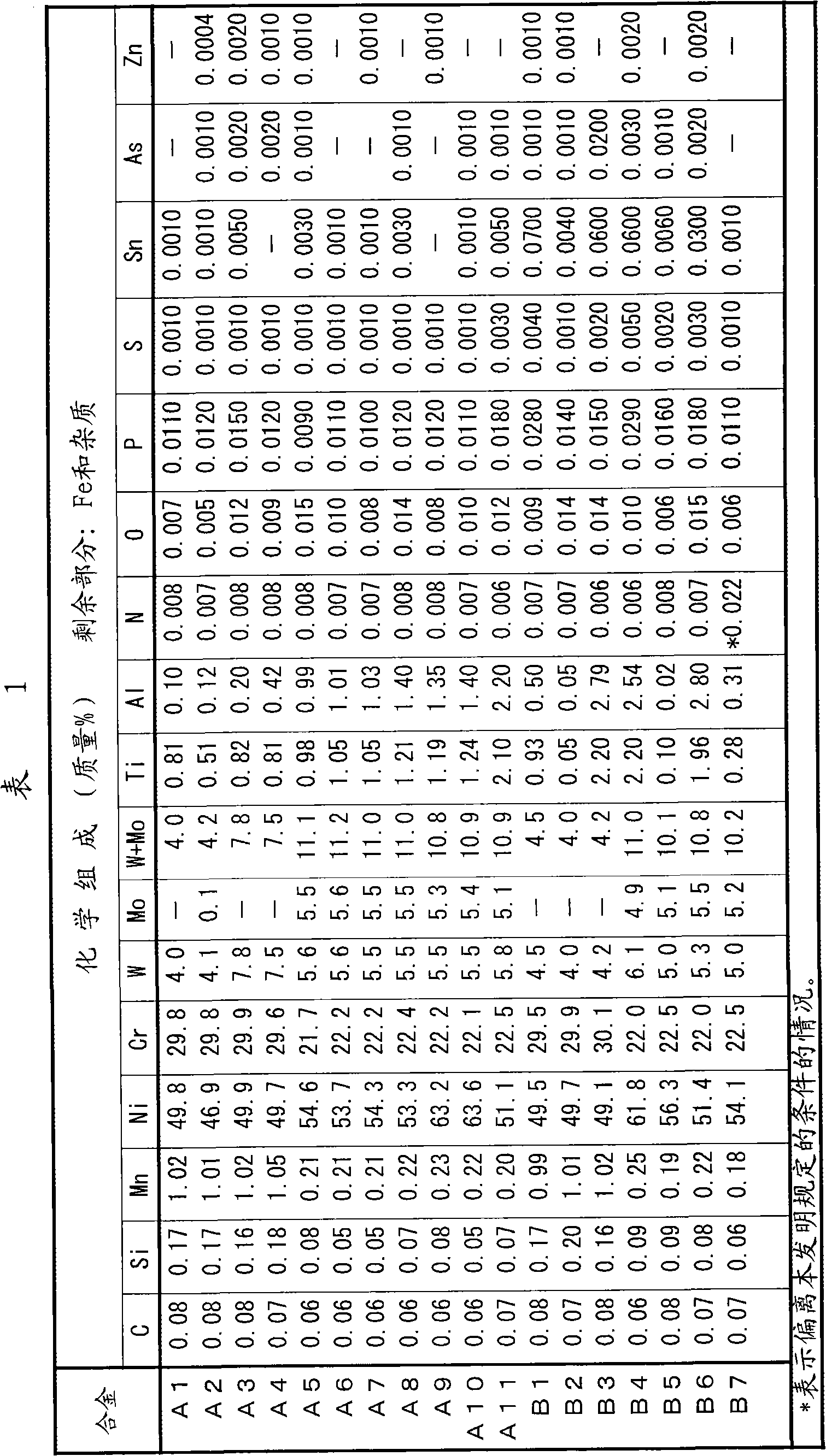

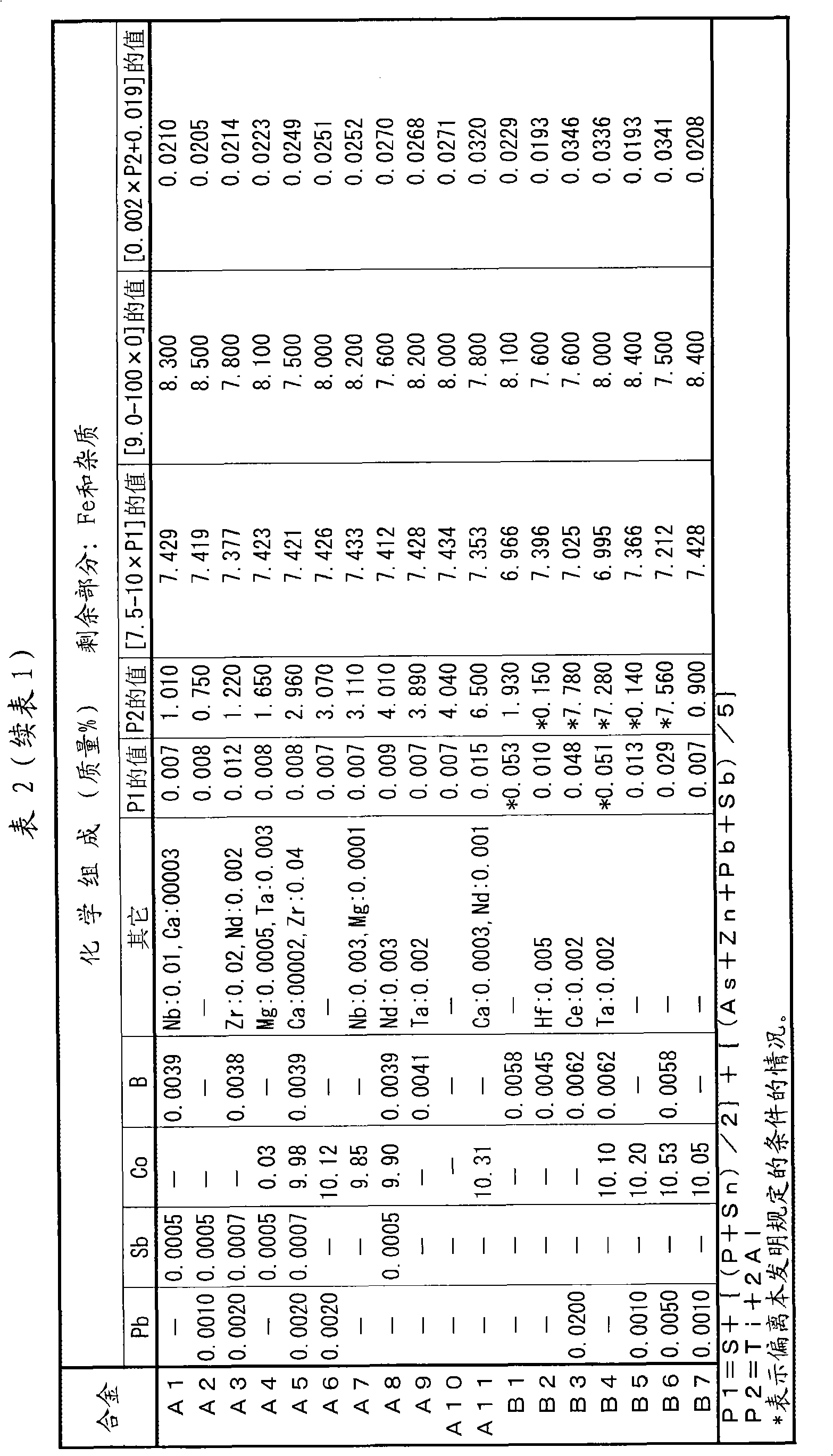

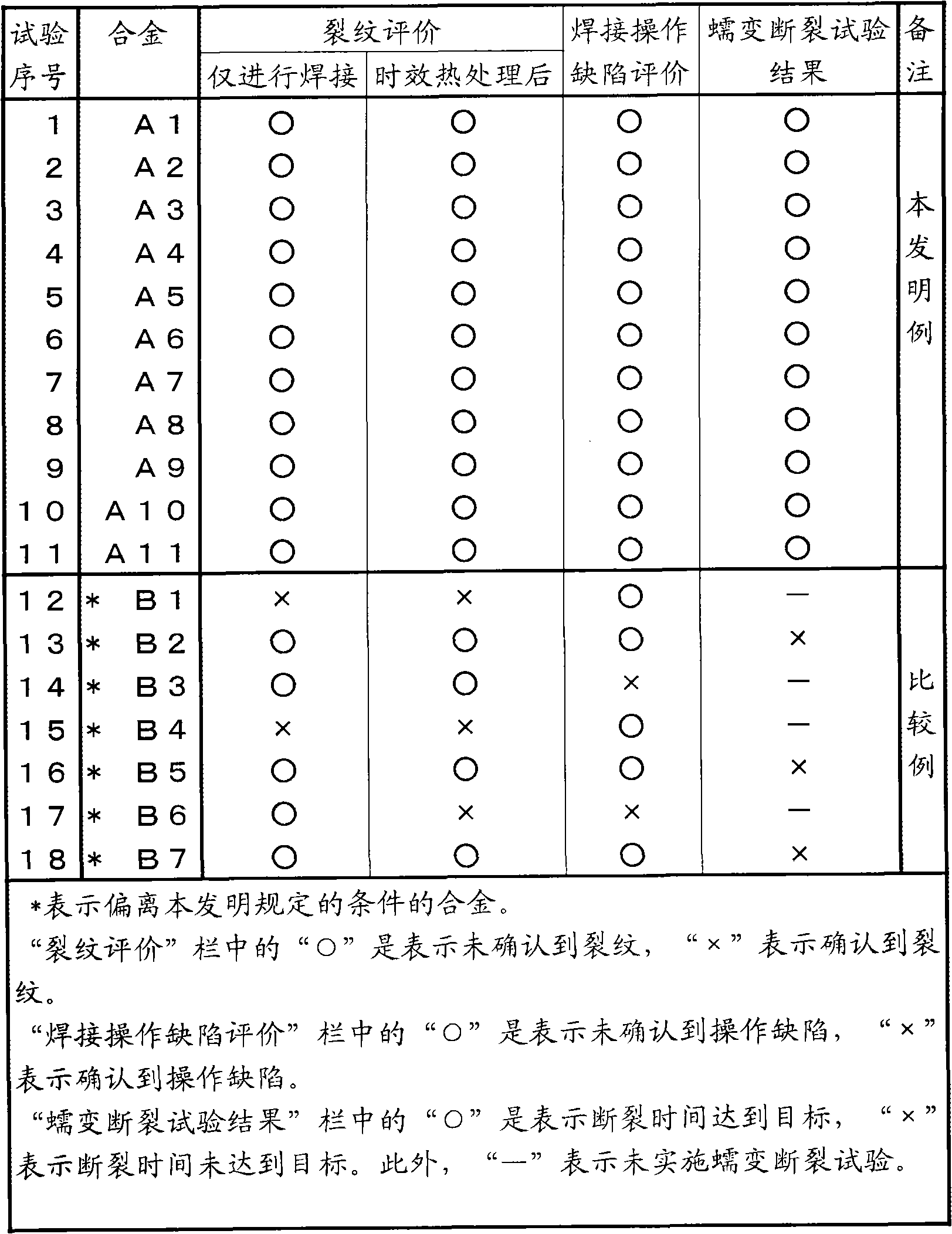

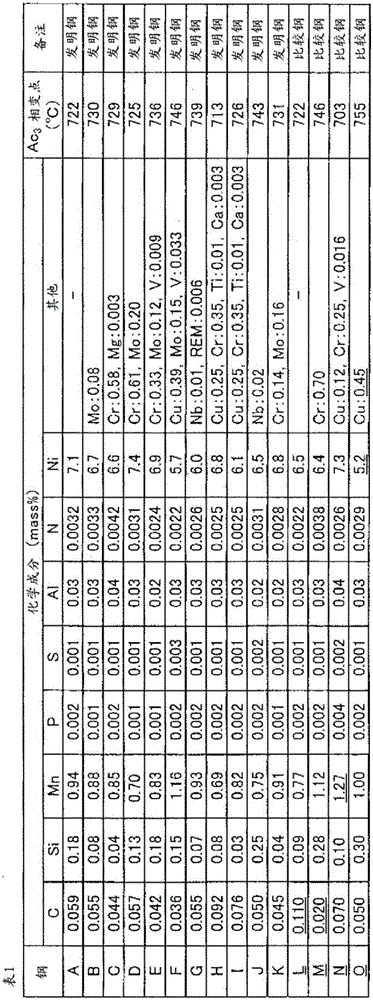

Austenitic heat resistant alloy

InactiveCN101864531APrevent liquefaction cracksPrevent embrittlement cracksSteam boilersSteam boilers componentsLiquationUltimate tensile strength

An austenitic heat resistant alloy, which comprises, by mass percent, C<=0.15%, Si<=2%, Mn<=3%, Ni: 40 to 80%, Cr: 15 to 40%, W and Mo: 1 to 15% in total content, Ti<=3%, Al<=3%, N<=0.03%, O<=0.03%, with the balance being Fe and impurities, and among the impurities P<=0.04%, S<=0.03%, Sn<=0.1%, As<=0.01%, Zn<=0.01%, Pb<=0.01% and Sb<=0.01%, and satisfies the conditions [P1=S+{(P+Sn) / 2}+{(As+Zn+Pb+Sb) / 5}<=0.050], [0.2<=P2=Ti+2Al<=7.5-10P1], [P2<=9.0-100O] and [N<=0.002P2+0.019] can prevent both the liquation crack in the HAZ and the brittle crack in the HAZ and also can prevent defects due to welding fabricability, which occur during welding fabrication, and moreover has excellent creep strength at high temperatures.

Owner:NIPPON STEEL CORP

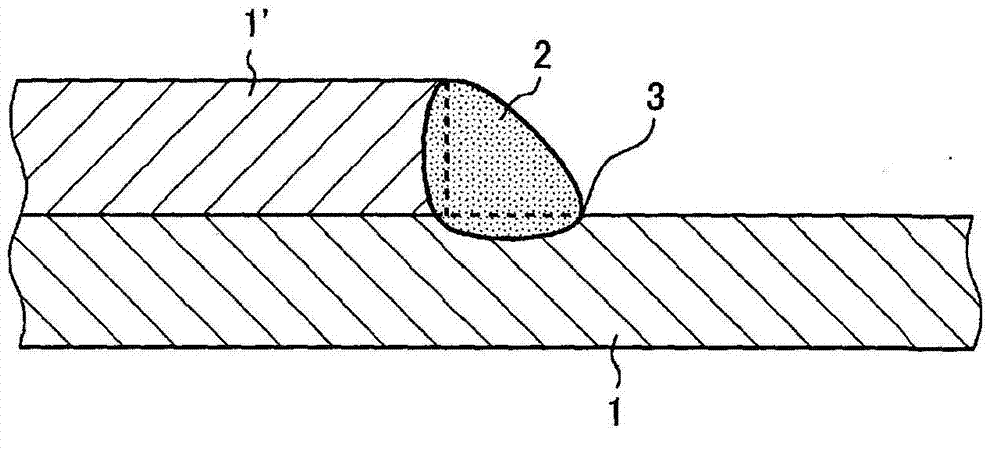

Weld structure having excellent brittle crack propagation resistance and method of welding the weld structure

This present invention relates to a welding method for manufacturing welded structures having excellent properties to prevent the propagation of brittle fracture occurring in welded joints, characterized by the step of forming a repair weld having a greater toughness than that of a butt weld and an outer edge whose angle with respect to the longitudinal direction of the butt weld is not less than 10 degrees and not more than 60 degrees, by applying repair welding to a region to arrest a brittle crack in a butt-welded joint where a brittle crack is likely to propagate after removing part of the butt-welded joint, in said region, by gouging or machining.

Owner:NIPPON STEEL CORP

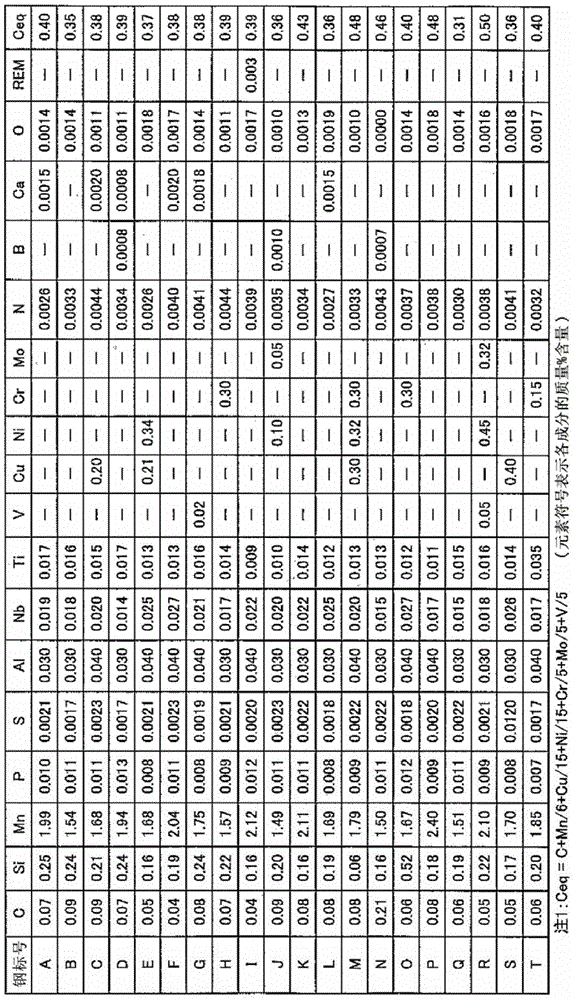

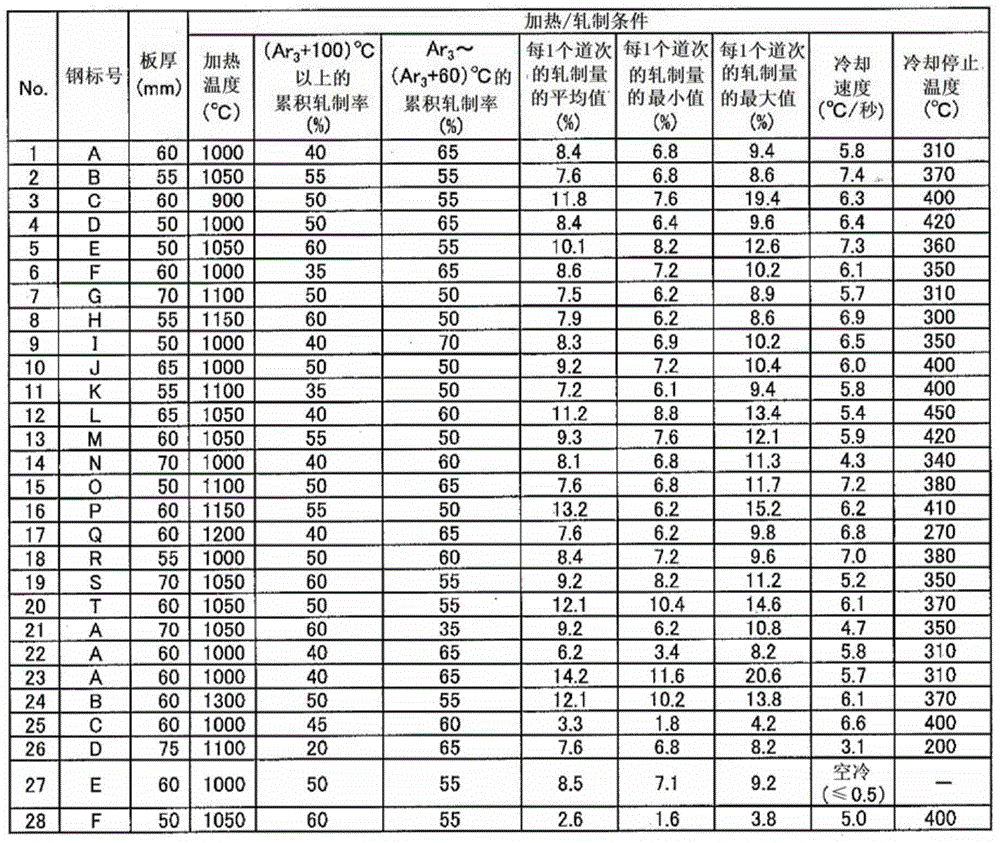

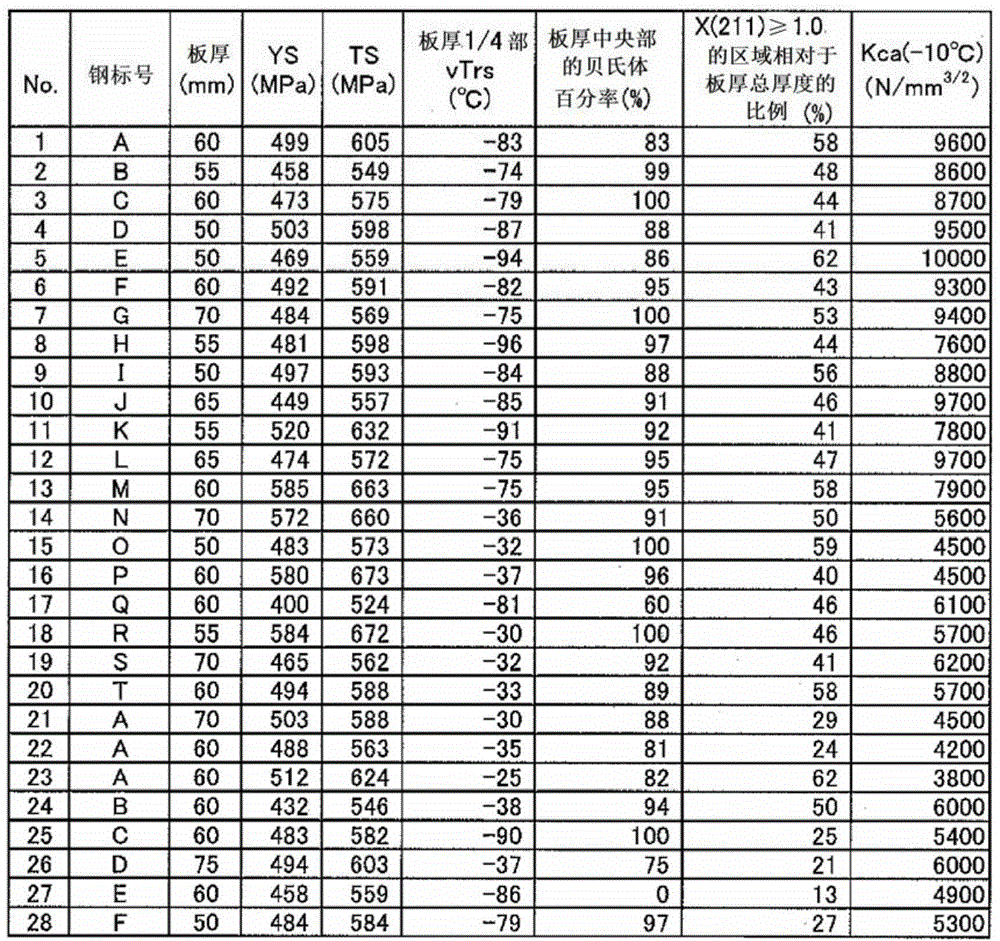

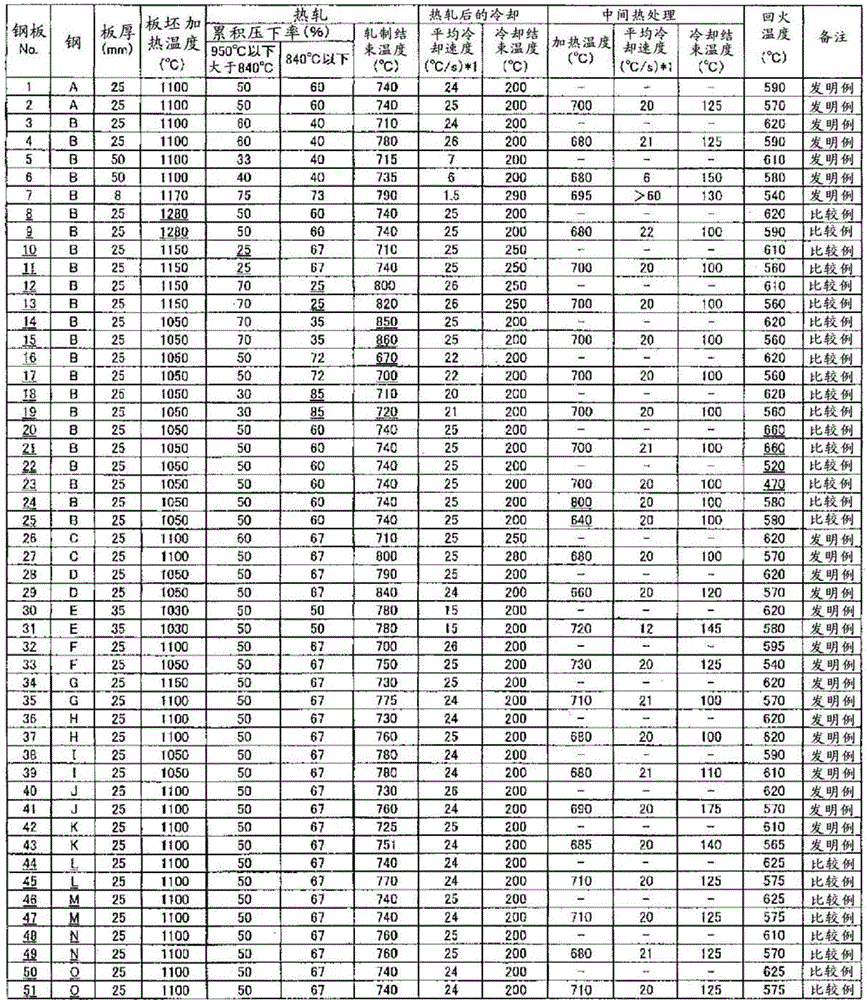

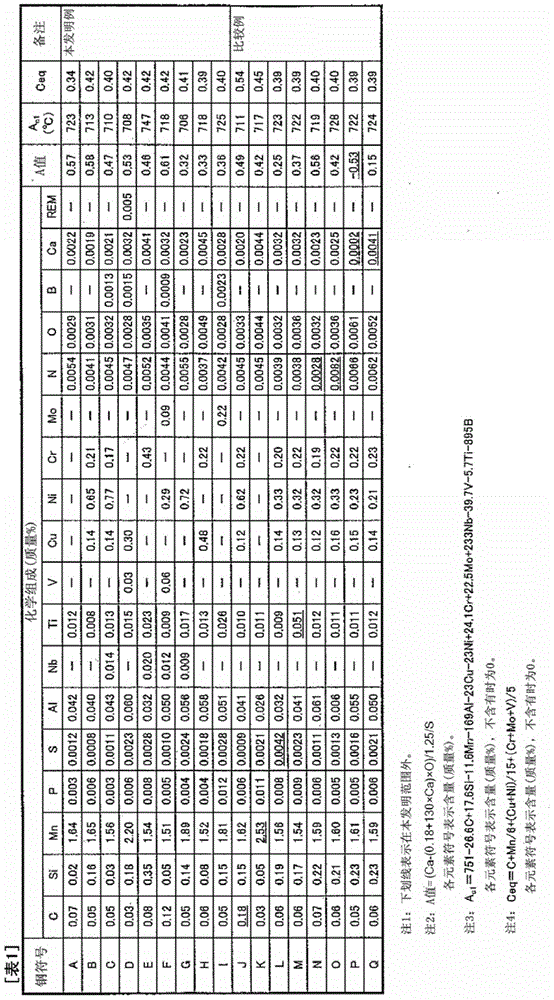

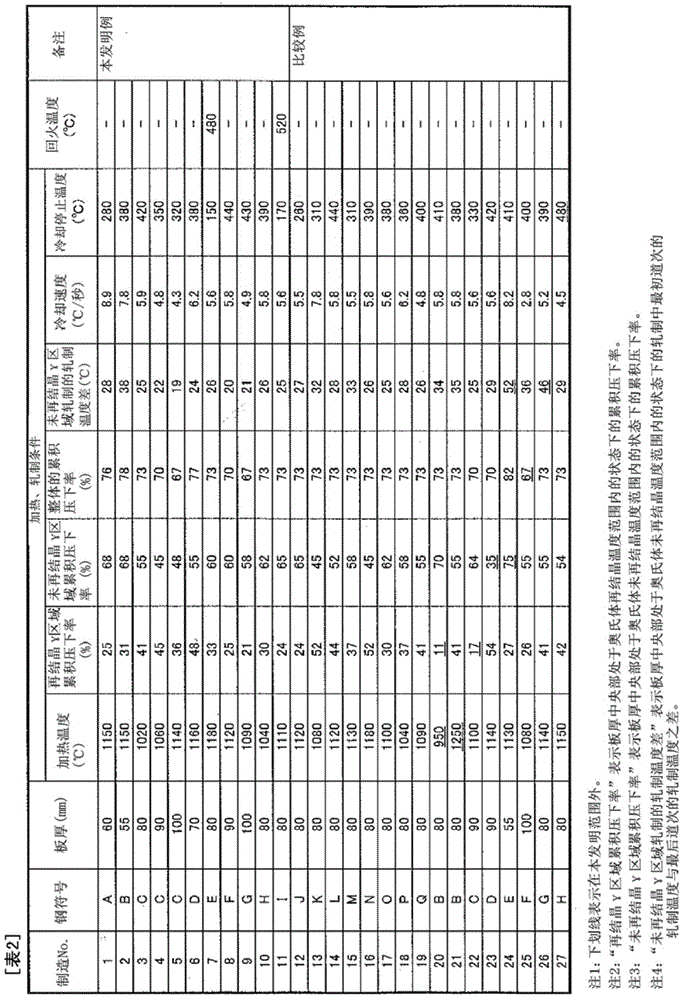

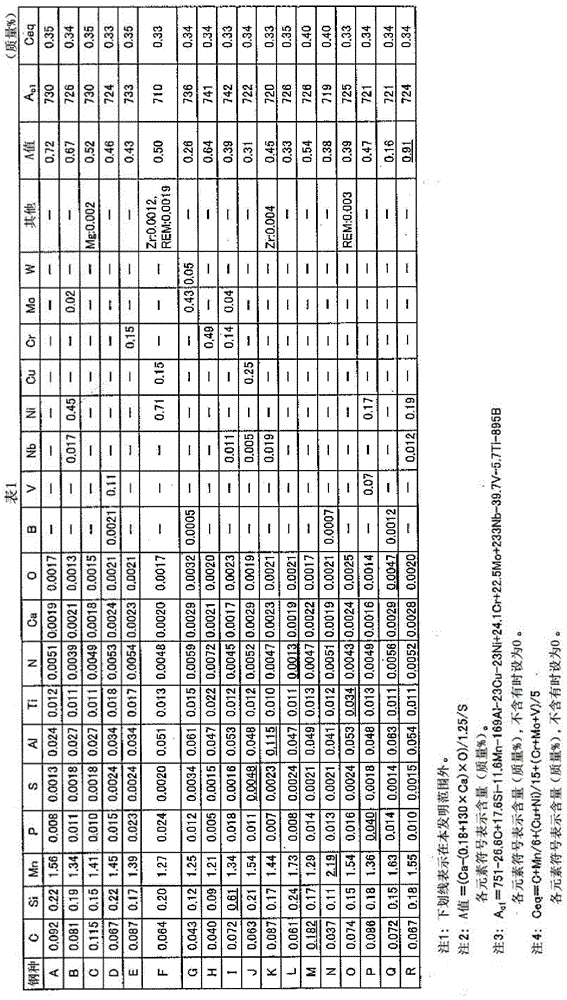

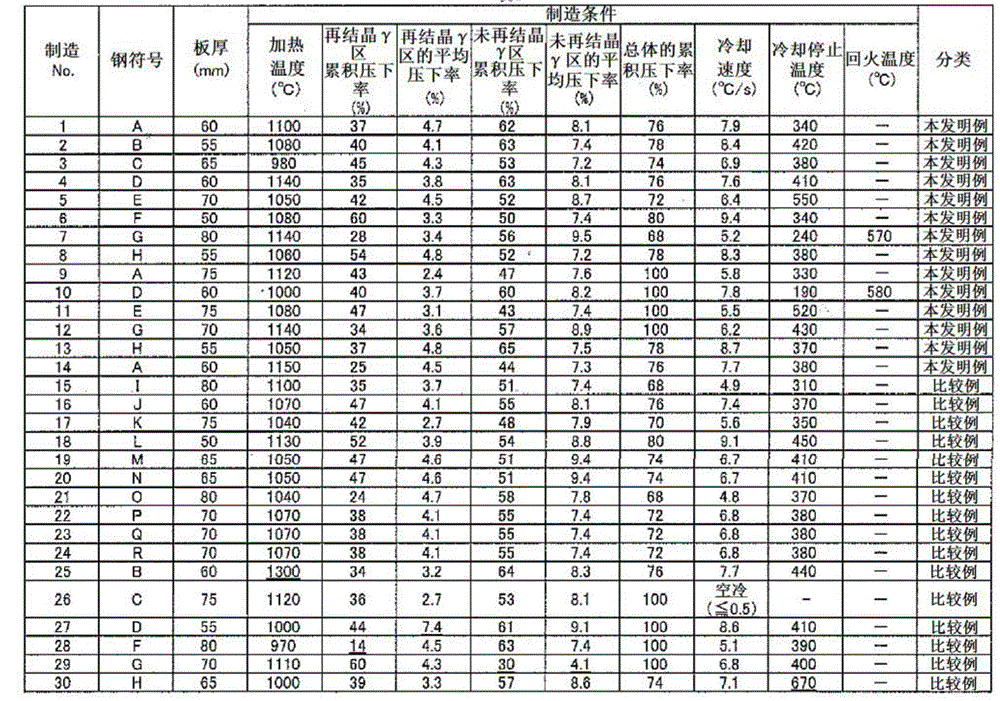

High strength steel plate having excellent brittle crack arrestability and method for manufacturing same

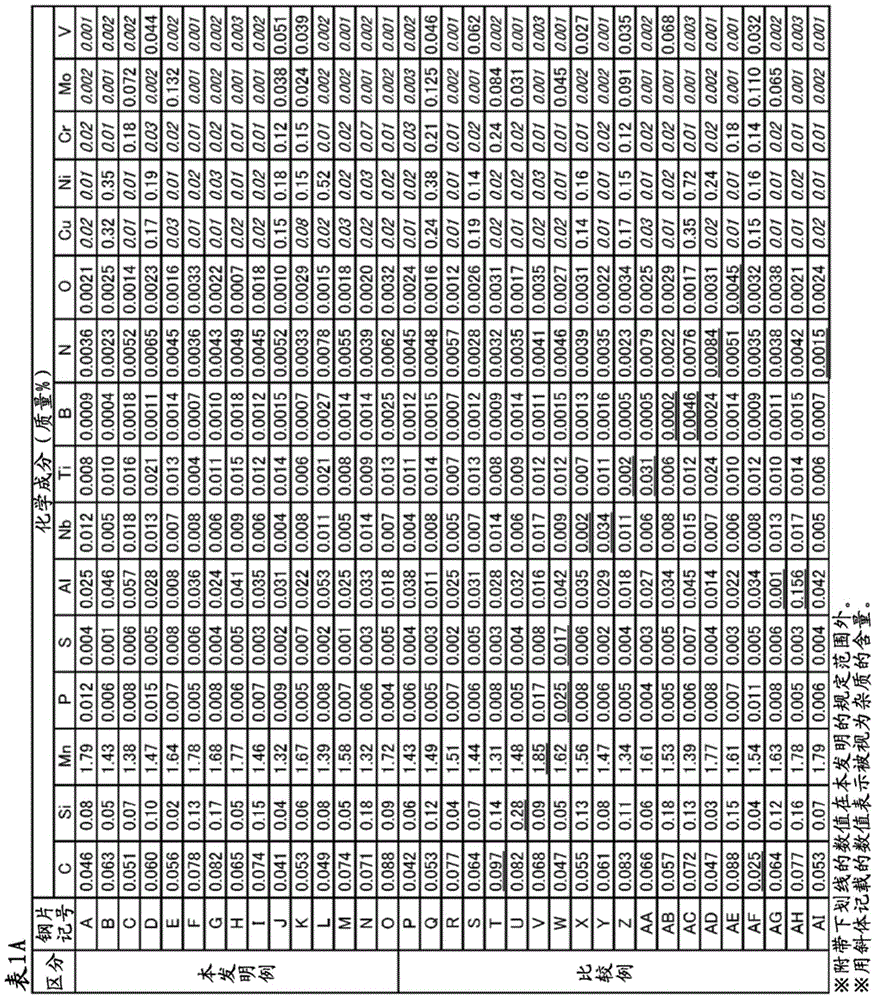

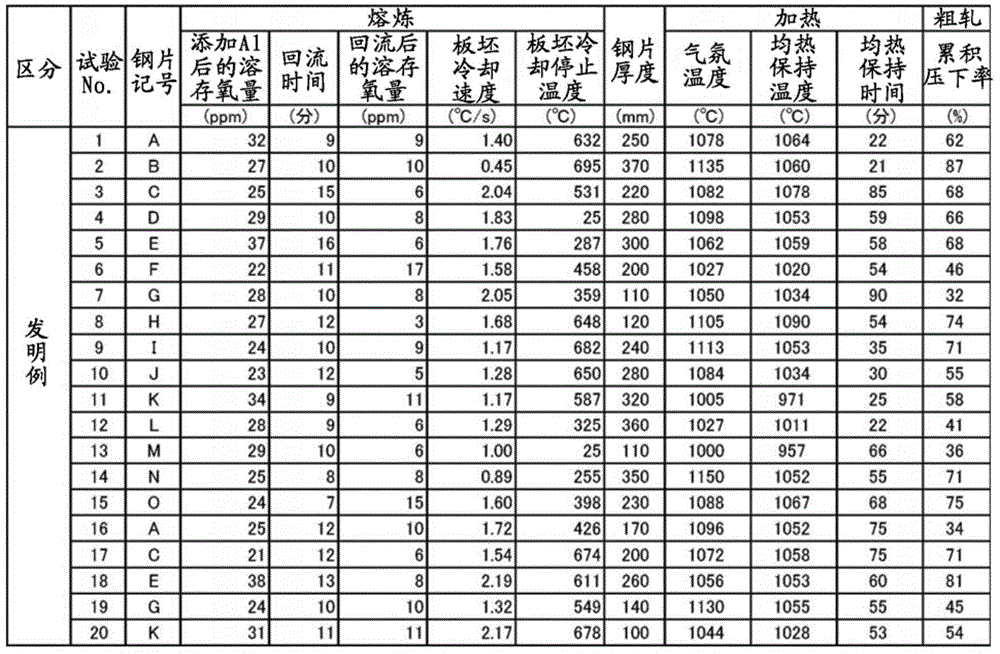

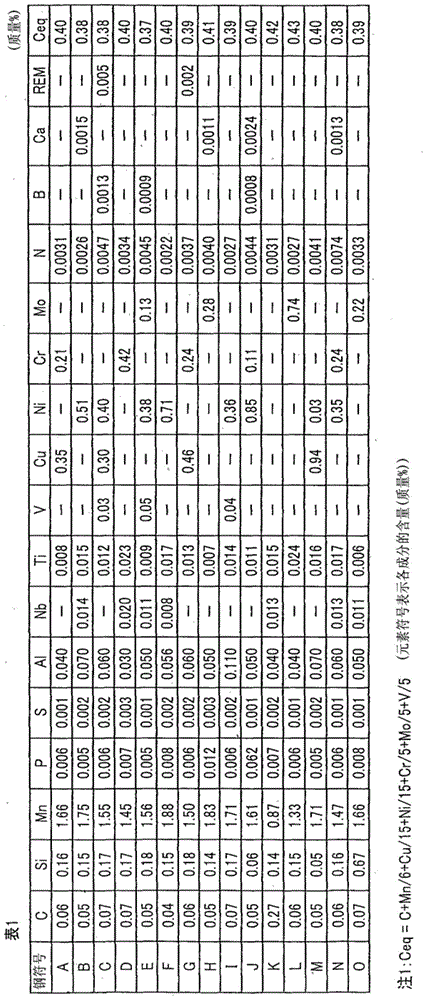

Provided are a high strength steel plate having excellent brittle crack arrestability and a method for manufacturing the same. A steel plate, which contains C, Si, Mn, Al, P, S and N each in a definite amount, satisfies the requirement Ceq (=C+Mn / 6+(Cu+Ni) / 15+(V+Mo+Cr) / 5) being 0.34-0.49% inclusive, and may further contain, if required, one or more members selected from among Nb, Ti, Cu, Ni, Cr, Mo, V, Ca, B and REM, wherein a region with an aggregate tissue, said region having an X-ray diffraction intensity ratio according to plane (211) in a plane parallel to the surface of the steel plate of 1.0 or greater, is disposed within at least 1 / 3 of the sheet thickness including the central part of the sheet thickness, the bainite fraction at the central part of the sheet thickness is 80% or greater, and the Charpy fracture transition temperature at a position of 1 / 4 of the sheet thickness is -40 DEG C or lower. The method according to the present invention comprises hot rolling a steel material in such a manner that the cumulative rolling reduction ratio is at least 50% within a temperature range at the central part of the sheet thickness from (Ar3+60) DEG C to Ar3 inclusive, and then cooling to 450 DEG C or lower at a cooling speed of 4.0 DEG C / s or higher.

Owner:JFE STEEL CORP

Steel sheet

The invention provides a steel sheet which has the characteristics of low manufacturing cost, high production efficiency, base metal brittle crack propagation stop performance and excellent tenacity of a welding heat affected zone in high heat input welding. The steel sheet has prescribed chemical components: 0.30-0.40 mass% of a carbon equivalent, and -0.0015-+0.0015 mass% of SOLB. At 1 / 2 part of a sheet thickness, the weighted average DAVE of a grain size of a grain is 3.0-17.0 [mu] m; at 1 / 2 part of a sheet thickness, the weighted average DAVE of a grain size of a grain is 3.0-17.0 [mu] m; the area percentage of a surface (100) forming a angle within 15 DEG relative to a surface in a rolling direction is 2.0-20.0%; at 1 / 4 part of a sheet thickness, the total number density of circle diameter TiN particles, MnS particles and composite particles with 0.5-2.0 [mu] m equivalents is 20-200 / mm2; at 1 / 4 part of a sheet thickness, the number density of circle diameter oxide particle with 1-10 [mu] m equivalents is 20-200 / mm2, the sheet thickness being 10-35mm, and the yield stress being 300-500 MPa.

Owner:NIPPON STEEL CORP

Steel sheet for use at lower temperatures, and method for producing same

Provided are: a steel sheet for use at lower temperatures, which has high strength, excellent toughness at lower temperatures and excellent brittle crack propagation arrest properties; and a method for producing the steel sheet. A steel sheet for use at lower temperatures, which has tensile strength of 700 MPa or more, excellent toughness at lower temperatures and excellent brittle crack propagation arrest properties, has a structure which has a specified chemical composition, and which is composed of tempered martensite having retained austenite dispersed therein, and which has such properties that the amount of the retained austenite is 2.2 to 14% by volume inclusive at a position located at a thickness of (1 / 4)t, the average grain diameter of prior austenite grains is 10 to 60 mum inclusive and the average aspect ratio of the prior austenite grains is 4.0 or less in a cross section that is parallel to the rolling direction at a position located at a thickness of (1 / 4)t, the degree of accumulation of {110} plane that is parallel to the surface of the sheet is 1.3 or more and the degree of accumulation of {100} plane that is parallel to the surface of the sheet is 0.90 or less at a position located at a thickness of 1 mm in the thickness direction from the surface of the steel sheet, and the degree of accumulation of {111} plane that is parallel to the surface of the sheet is 1.2 to 2.5 inclusive at a position located at a thickness of (1 / 2)t in the steel sheet.

Owner:JFE STEEL CORP

Production method of microalloyed tin bronze alloy

The invention discloses a production method of microalloyed tin bronze alloy. The production method of the microalloyed tin bronze alloy includes the steps of firstly, subjecting alloy to smelting, thermal insulation, degassing, deslagging and refining in a smelting furnace; secondly, adding refiner to refined melt for microalloying; thirdly, performing alloy casting, namely subjecting the microalloyed melt to ingot casting; and fourthly, performing cold rolling and cogging, namely subjecting the alloy subjected to alloy casting to cold rolling so as to obtain deformed tin bronze alloy. Casting grain of the microalloyed tin bronze alloy produced by the production method is small in size, segregation degree of Sn in the alloy can be lowered, brittle cracking in rolling can be eliminated, and the alloy is highly plastic. Especially, the microalloyed castings can be directly subjected to cold rolling, and accordingly a homogenizing step in the existing production method is omitted, energy resources are economized, process flow is shortened, production efficiency is improved, and production cost is reduced.

Owner:JIANGXI UNIV OF SCI & TECH

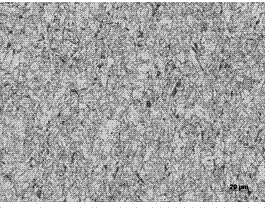

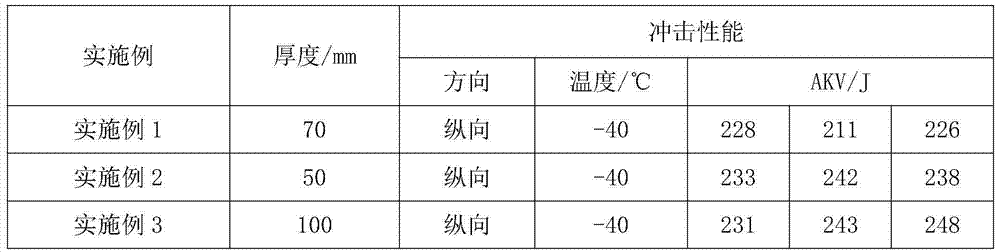

Super-thick steel plate for container ships and preparation method of super-thick steel plate

The invention discloses a super-thick steel plate for container ships, which comprises the following components in percentage by weight: 0.04-0.12% of C, 0.25-0.50% of Si, 1.00-1.65% of Mn, less than or equal to 0.010% of P, less than or equal to 0.0020% of S, 0.20-1.0% of Ni, 0.020-0.040% of Nb, 0.020-0.060% of V, 0.015-0.025% of Ti, 0.020-0.050% of Alt, and the balance of Fe and unavoidable impurities. The super-thick steel plate is prepared through the following production steps of molten iron pretreatment, BOF (basic oxygen furnace) steelmaking, LF (ladle refining) refining, RH (ruhrstahl heraeus) vacuum treatment, continuous casting, and TMCP (thermal mechanical control processing), the structure of an obtained super-thick steel plate for container ships comprises acicular ferrites, granular bainites and a small amount of pearlites, and the structure is uniform and small. The super-thick steel plate disclosed by the invention is simple in production process and low in cost, and has good lamellar tearing resistance, brittle crack preventing properties, high strength and high toughness.

Owner:NANJING IRON & STEEL CO LTD

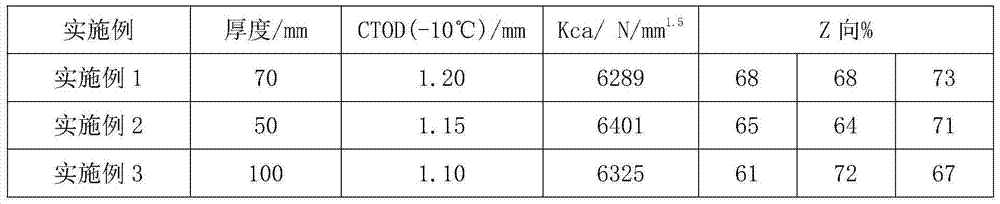

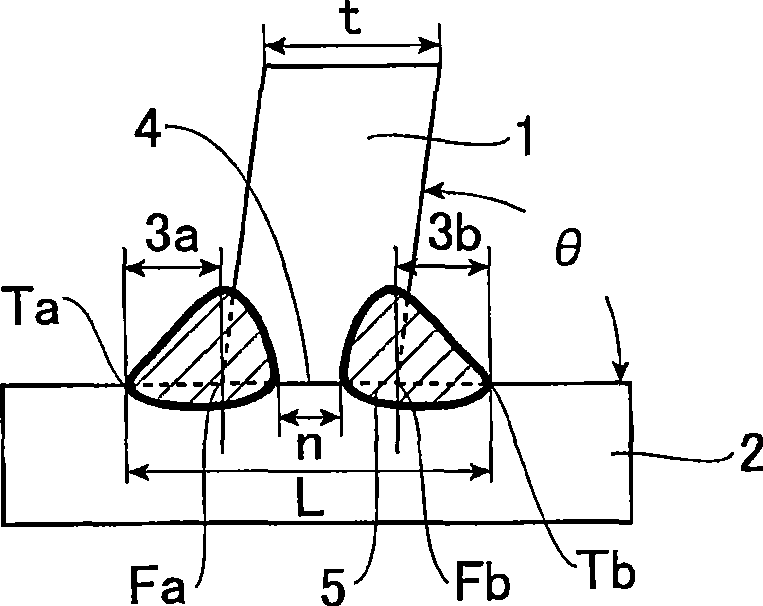

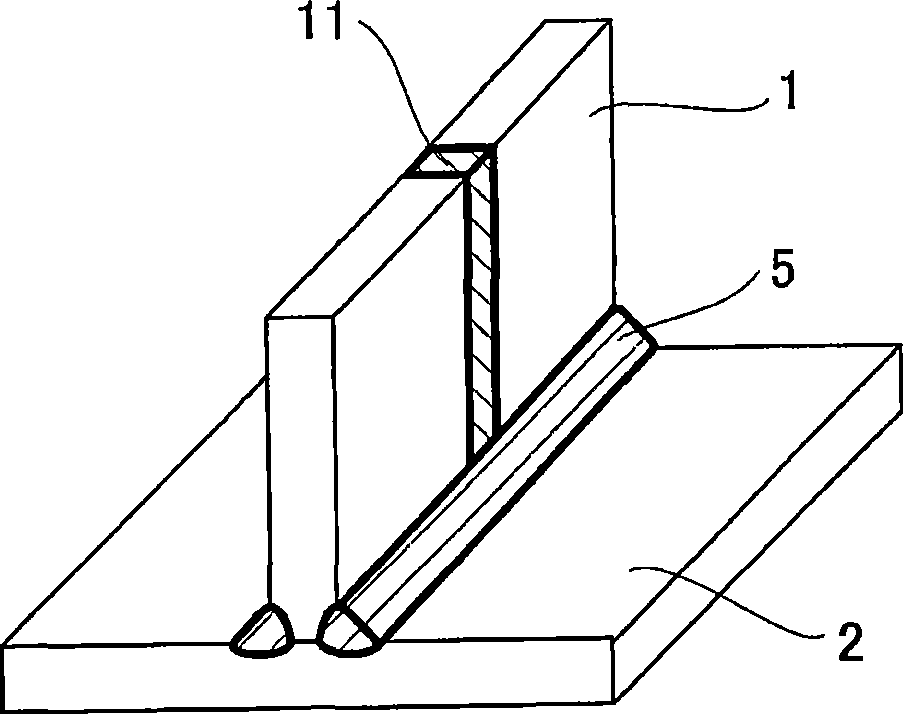

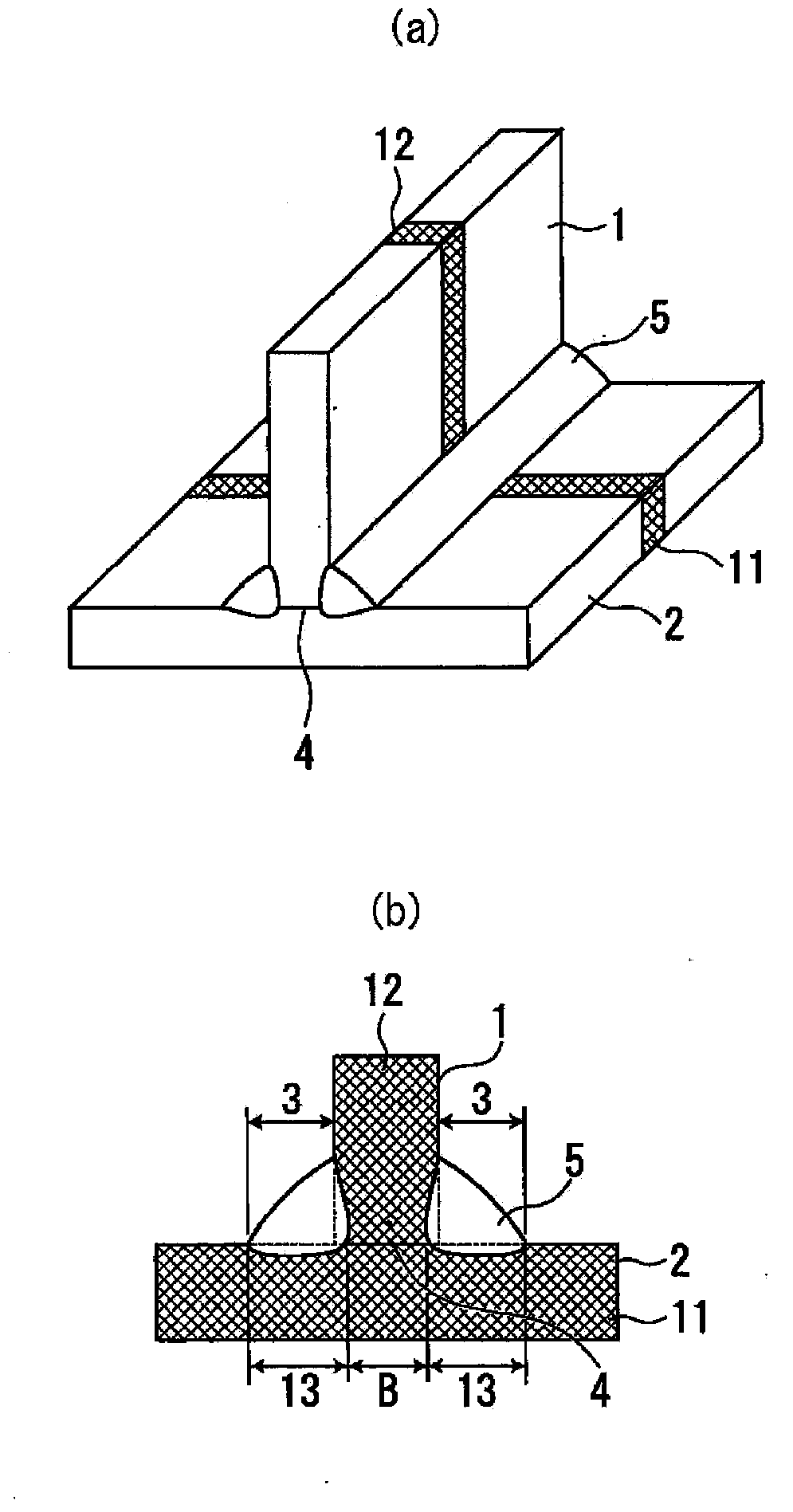

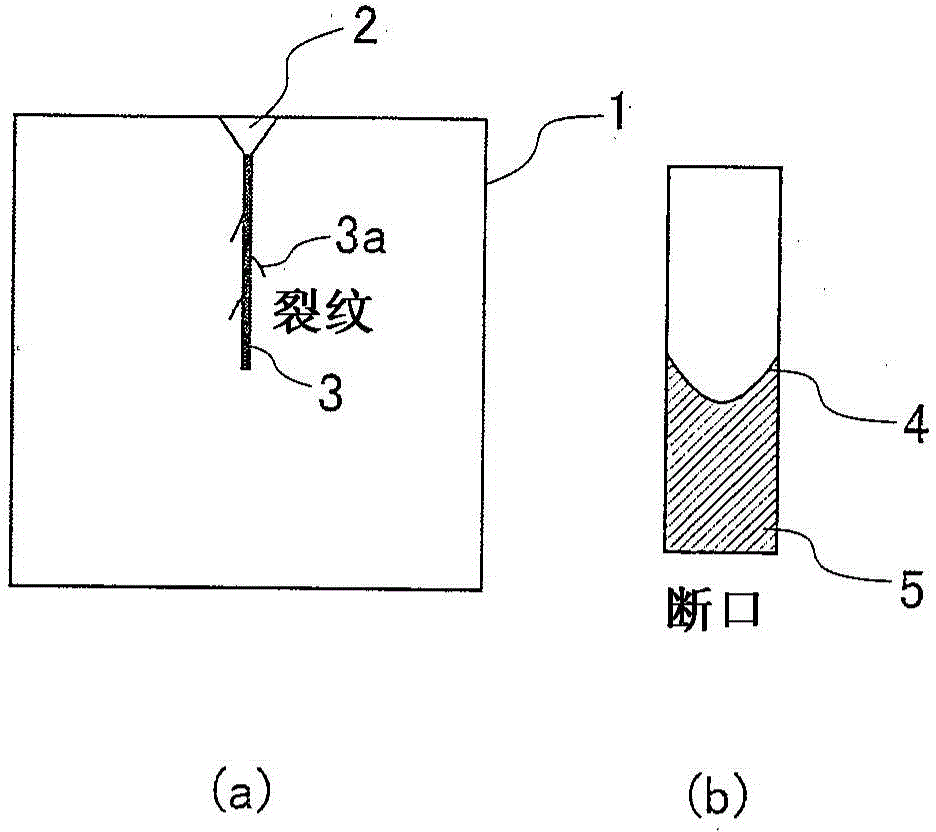

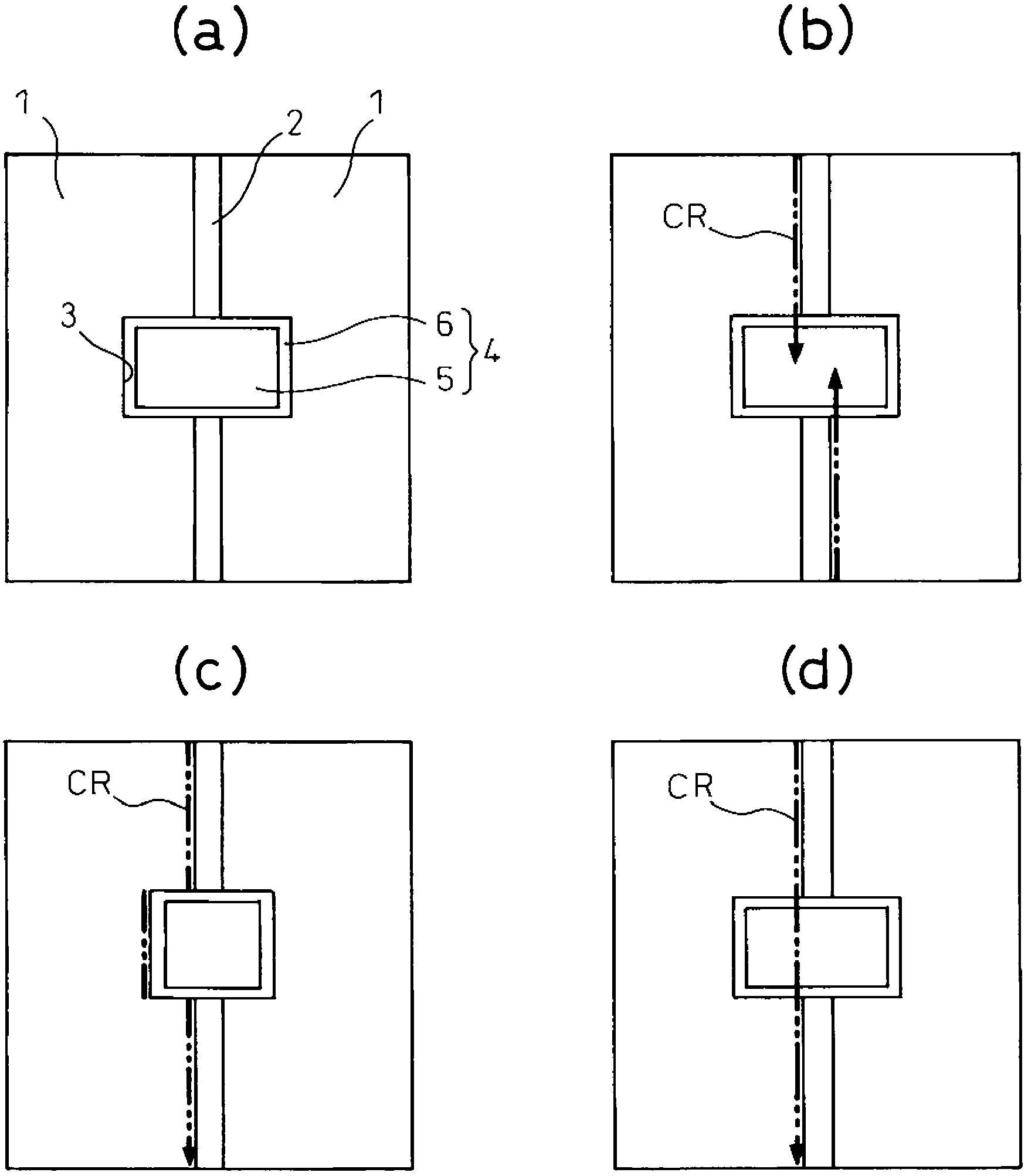

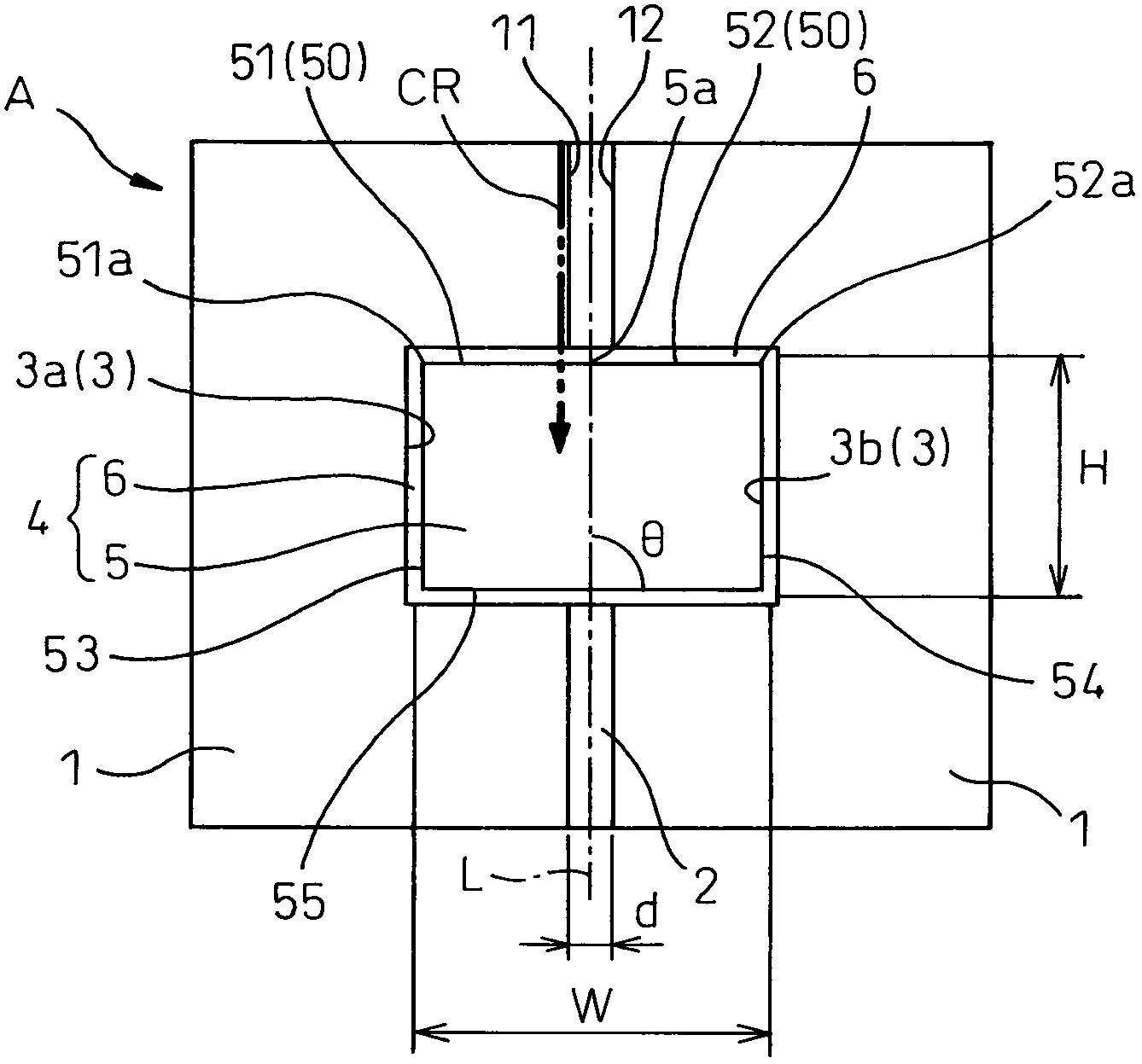

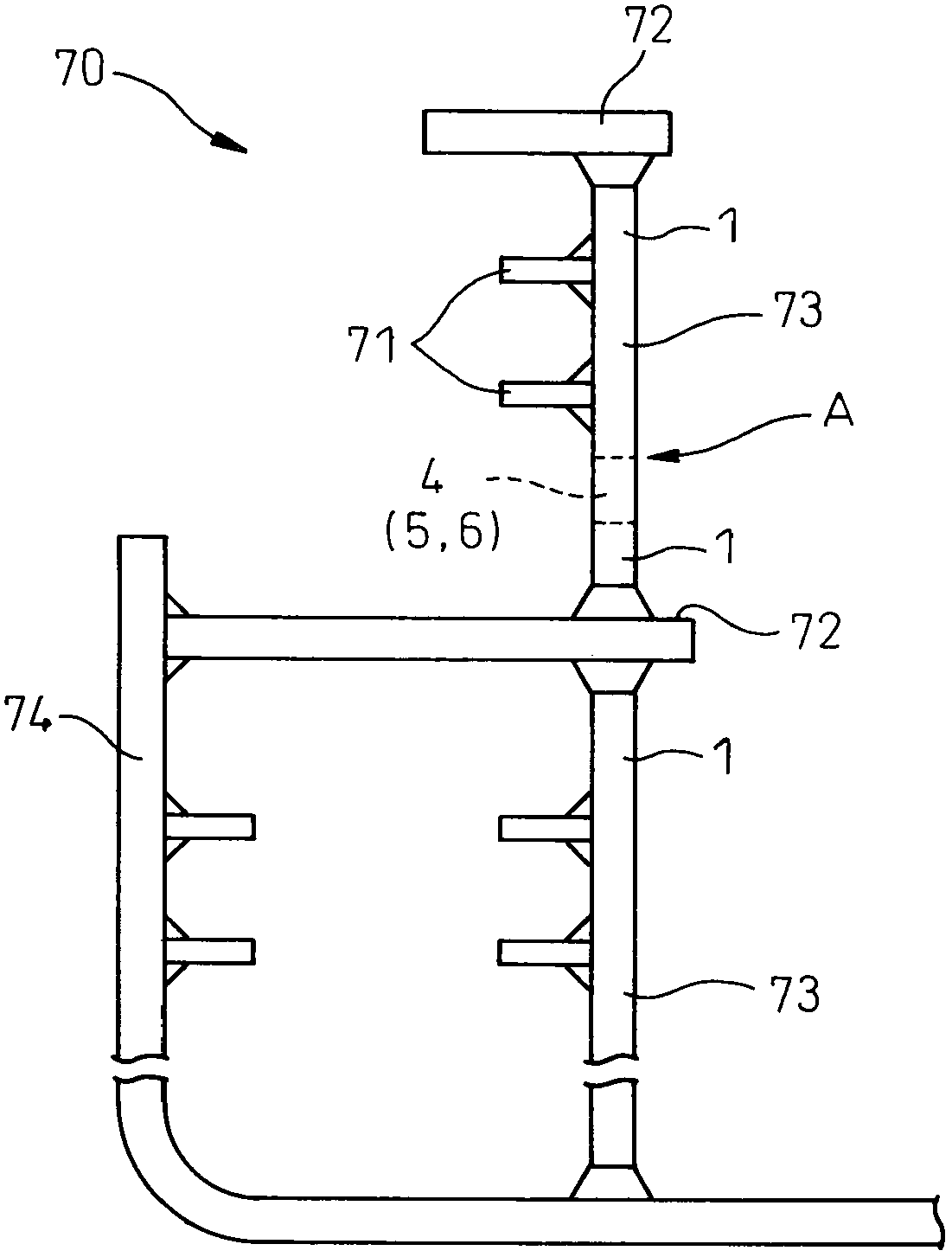

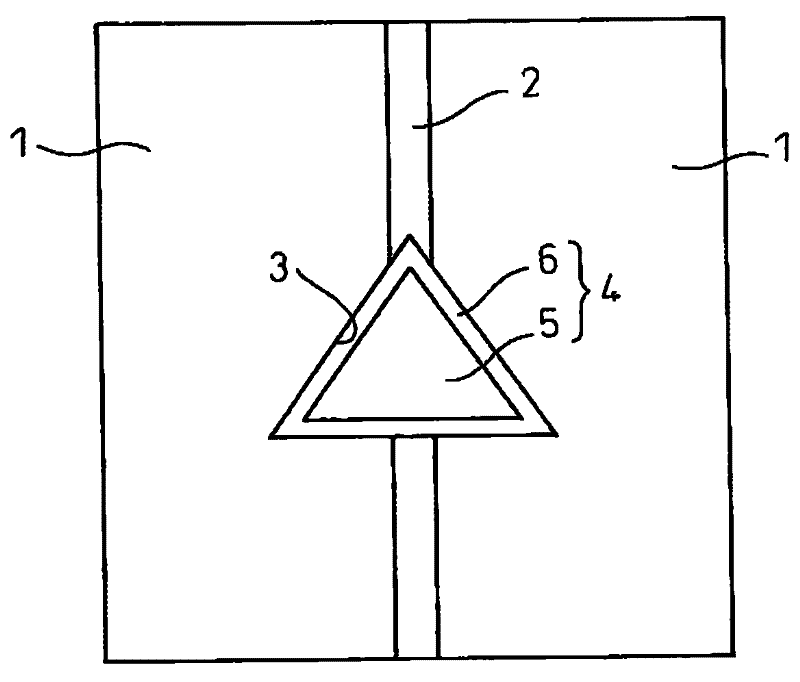

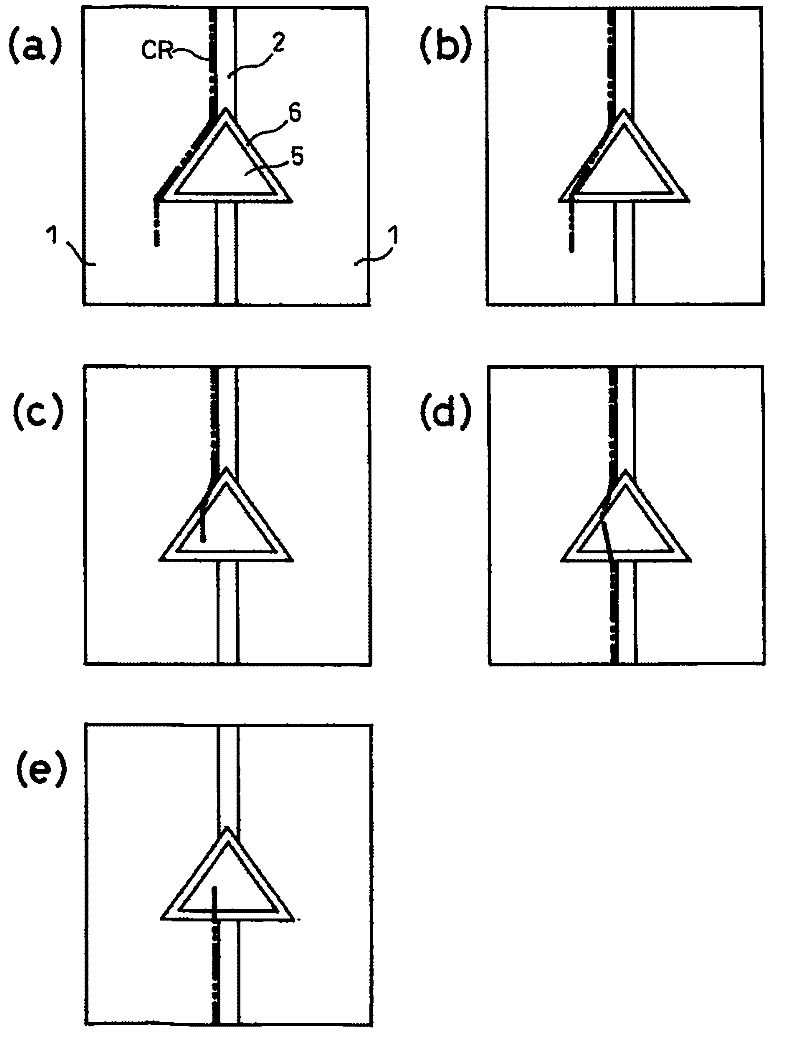

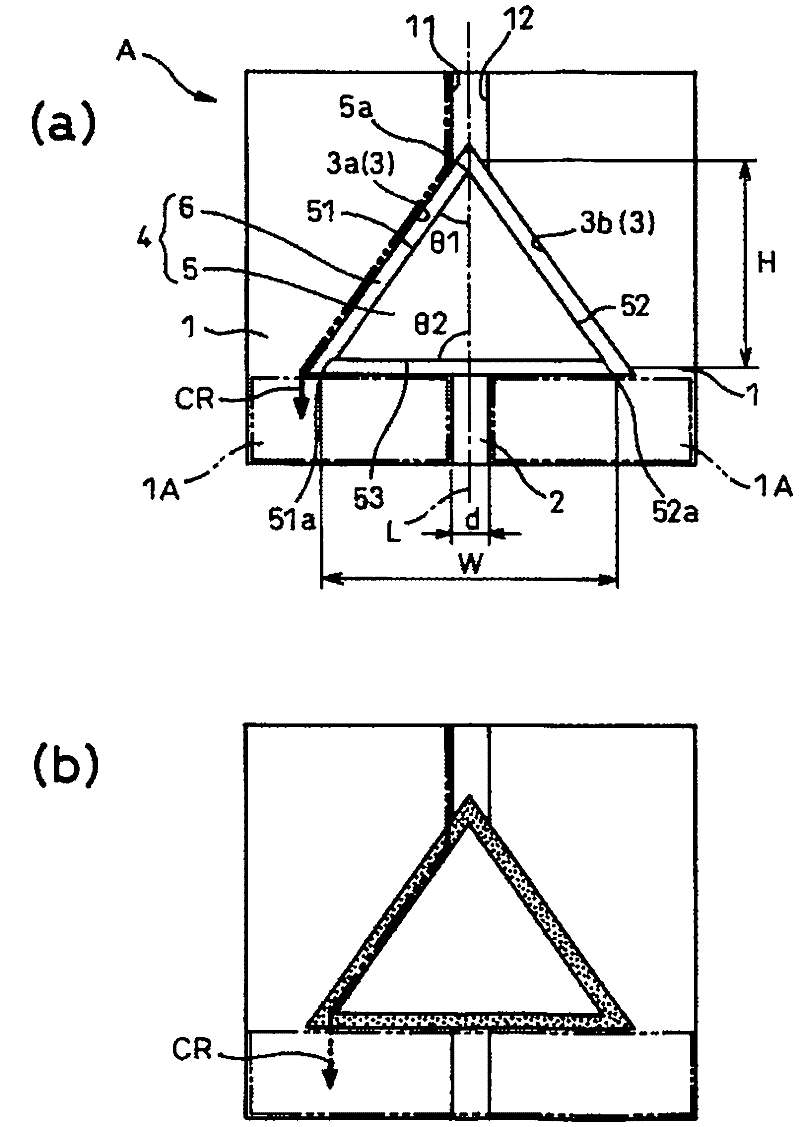

Welded structure excellent in brittle-cracking propagation stopping characteristics

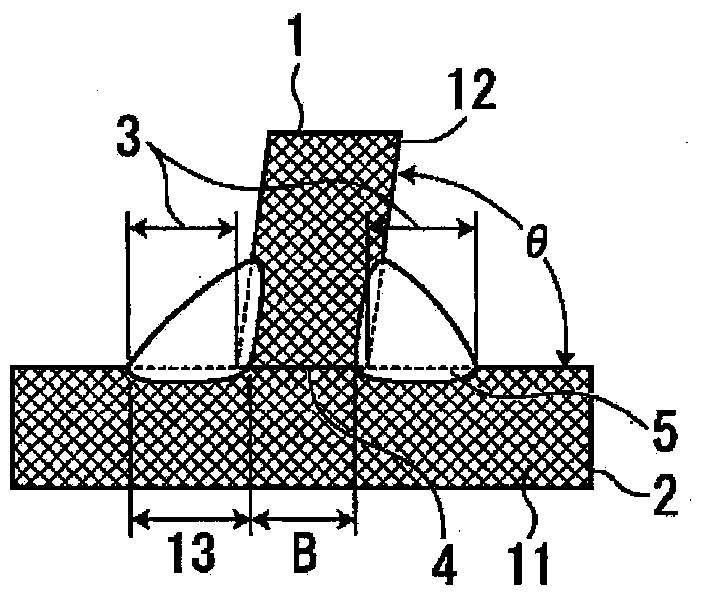

ActiveCN101443150ATransmission stoppedEnsure safetyArc welding apparatusPipe protection against damage/wearFillet weldHull structure

Provided is a welded structure suitable for a hull structure and excellent in brittle-cracking propagation stopping characteristics. The welded structure is provided with a fillet welded joint having an unwelded portion (4) left on the abutting face of a web (1) against a flange (2). A percentage (X) (= 100 / L) (%) to the sum (L) of the width (n) of the unwelded portion (4) and the leg length (3 (3a and 3b)) of the left and right fillet welded joints in the joint section of the fillet welded joint, and the brittle-cracking propagation stopping toughness (Kca (N / mm3 / 2)) at the using temperature of the flange satisfy X (%) >= {5900 - Kca(N / mm3 / 2 / 85. The unwelded portion (4) in the fillet-welded joints is given a width of 15 to 90 % of the sum of the thickness (t) of the web (1) and the leg length (3 (3a and 3b)) of the left and right fillet welded joints. In case the web has the butt-welded joint portion of the thickness (t), the percentage (X) (%) and the brittle-cracking propagation stopping toughness (Kca)(N / mm3 / 2) satisfy the aforementioned formula.

Owner:JFE STEEL CORP +1

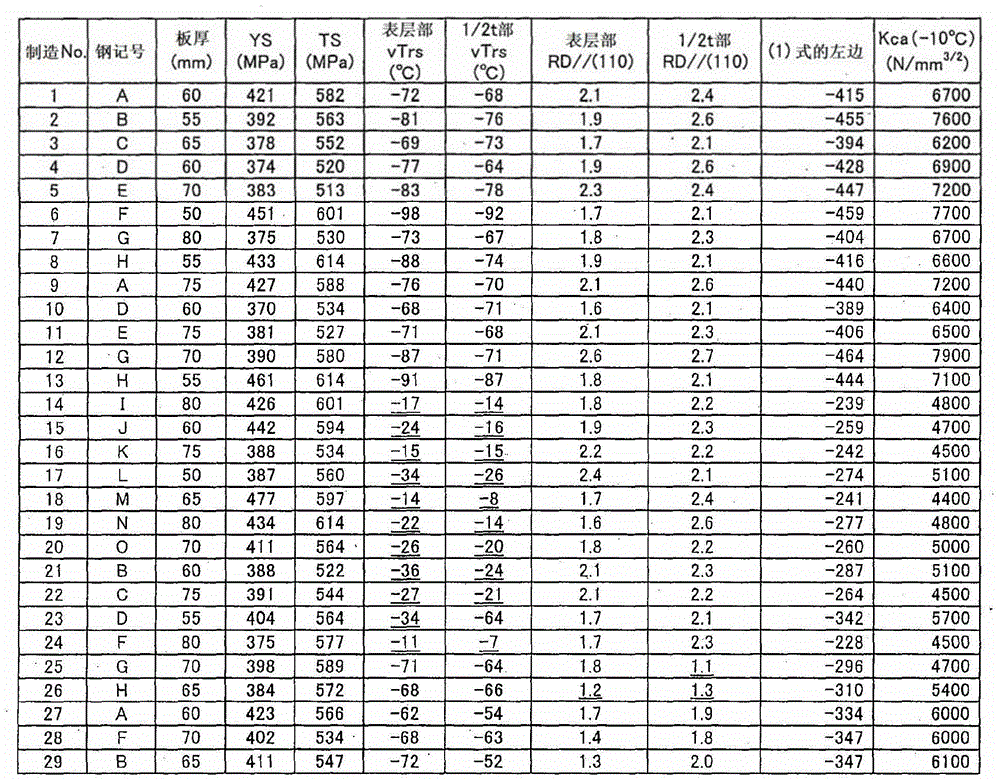

Method for determination of brittle crack propagation stopping performance in high-intensity thick steel plate

ActiveCN102472699AEvaluation omittedAccurate evaluationMaterial strength using single impulsive forceDrop weightSurface layer

Disclosed is a method for determining the brittle crack propagation stopping performance of a high-intensity thick steel plate, comprising: a step of performing a large test and a compound small test using standard steel; a step of calculating a correlation model between the results of the large test and the results of the compound small test using the standard steel; a step of performing the compound small test using sample steel; and a step of estimating the brittle crack propagation stopping performance of the sample steel by substituting the results of the compound small test using the sample steel into the correlation model, wherein the compound small test includes (a) a step of obtaining a surface layer small test piece which includes a portion of the steel plate surface layer; (b) a step of obtaining an inner small test piece respectively from one or no less than two inner regions which do not include the portion of the steel surface layer; (c) a step of performing a drop weight test using the surface layer small test piece; and (d) a step of performing a small test for measuring the percent brittle fracture or the absorption energy using the inner small test piece; and thecompound small test is performed in different fashions for the surface layer small test piece and the inner small test piece respectively.

Owner:NIPPON STEEL CORP

Brittle fracture crack transmission resisting T-shaped welding joint construction with excellent crack arrest characteristic

The invention provides a T shape welded joint structure which is formed by jointing a vertical component and a horizontal component, the vertical component is formed by butt welding with high strength steel plate and the horizontal component is formed by butt welding with high strength steel plate. The structure is charactered in that position of a welding line of the vertical component on the T shape welded joint structure extended direction is inconsistent with position of a welding line of the horizontal component on the T shape welded joint structure extended direction, and the high strength steel plate constituting the horizontal component satisfies (1) Kca value for representing fracture-arrest characteristic that is more than 7000N / mm<3 / 2> at -10 DEG C., (2) average pendulum absorbing energy value is more than 70J at -100 DEG C. in plate thickness direction 1 / 2. Brittle crack transmission can be prevented efficiently by using the structure, even if brittle failure generates on large heat quality importing welding part.

Owner:KOBE STEEL LTD

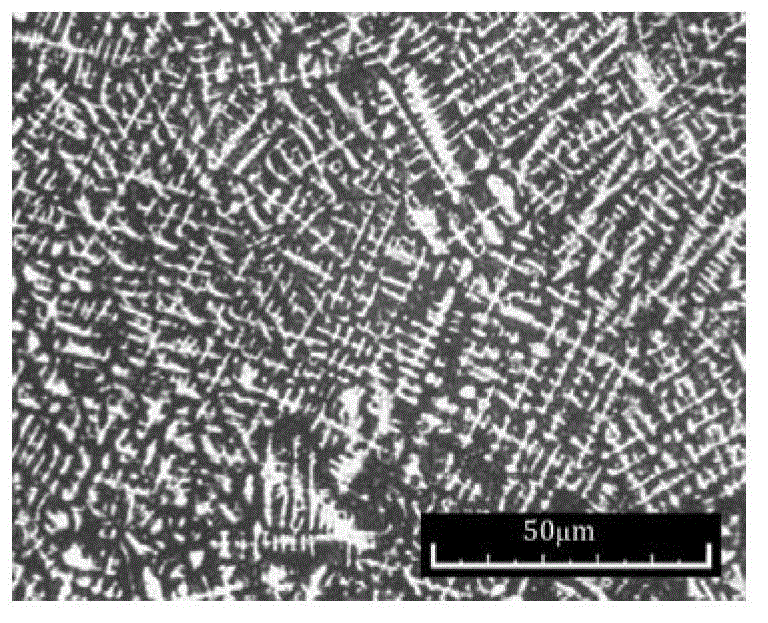

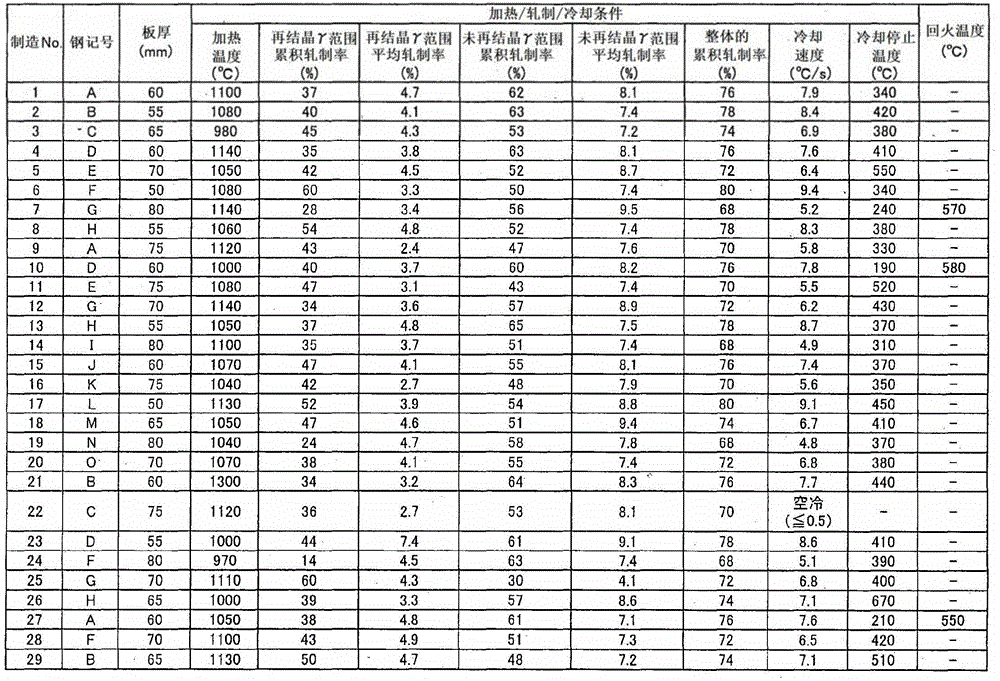

High strength thick steel plate for high heat input welding with excellent brittle crack arrestability and manufacturing method therefor

Provided are a high strength thick steel plate for high heat input welding, the plate of a preferred plate thickness of at least 50 mm being used for ships and having excellent brittle crack arrestability, and a manufacturing method therefor. A thick steel plate having a specific component composition, the main constituent of the metal structure being bainite, the thick steel plate having a texture in which the density in the RD / / (110) plane at the plate thickness center is 1.5-4.0, and the Charpy fracture appearance transition temperature (vTrs) at the surface layer and the plate thickness center being no more than -40°C; and a manufacturing method therefor.

Owner:JFE STEEL CORP

Welded structure

ActiveCN104271301AImprove securityEnsure safetyArc welding apparatusWelding/soldering/cutting articlesFillet weldLeg length

The present invention pertains to a welding structure provided with a fillet welded joint obtained by bringing the weld end surface of a joining member into contact with the weld surface of a butt weld joint of a joined member, both members having a plate thickness of at least 50 mm, and joining the joining member and the joined member by fillet welding. The weld leg length and / or the welding width of the fillet welded joint are 16 mm or less. The welding metal in the butt weld joint of the joining member and / or the joined member is set at -65 °C at vTrs-W (°C), and / or a toughness of at least 140 J is set at vE-20-W (J). A non-welded section exists on the surface where the joining member and joined member are brought into contact, where the cross section of the butt weld joint of the fillet welded joint is no less than 95% of the plate thickness (tw) of the joining member. By satisfying a predetermined relationship between vTrs (°C) and / or vE-20 (J) of the fillet welded metal, and the plate thickness (tf) of the joined member, the propagation of brittle cracks is prevented before said cracks lead to large-scale destruction.

Owner:JFE STEEL CORP

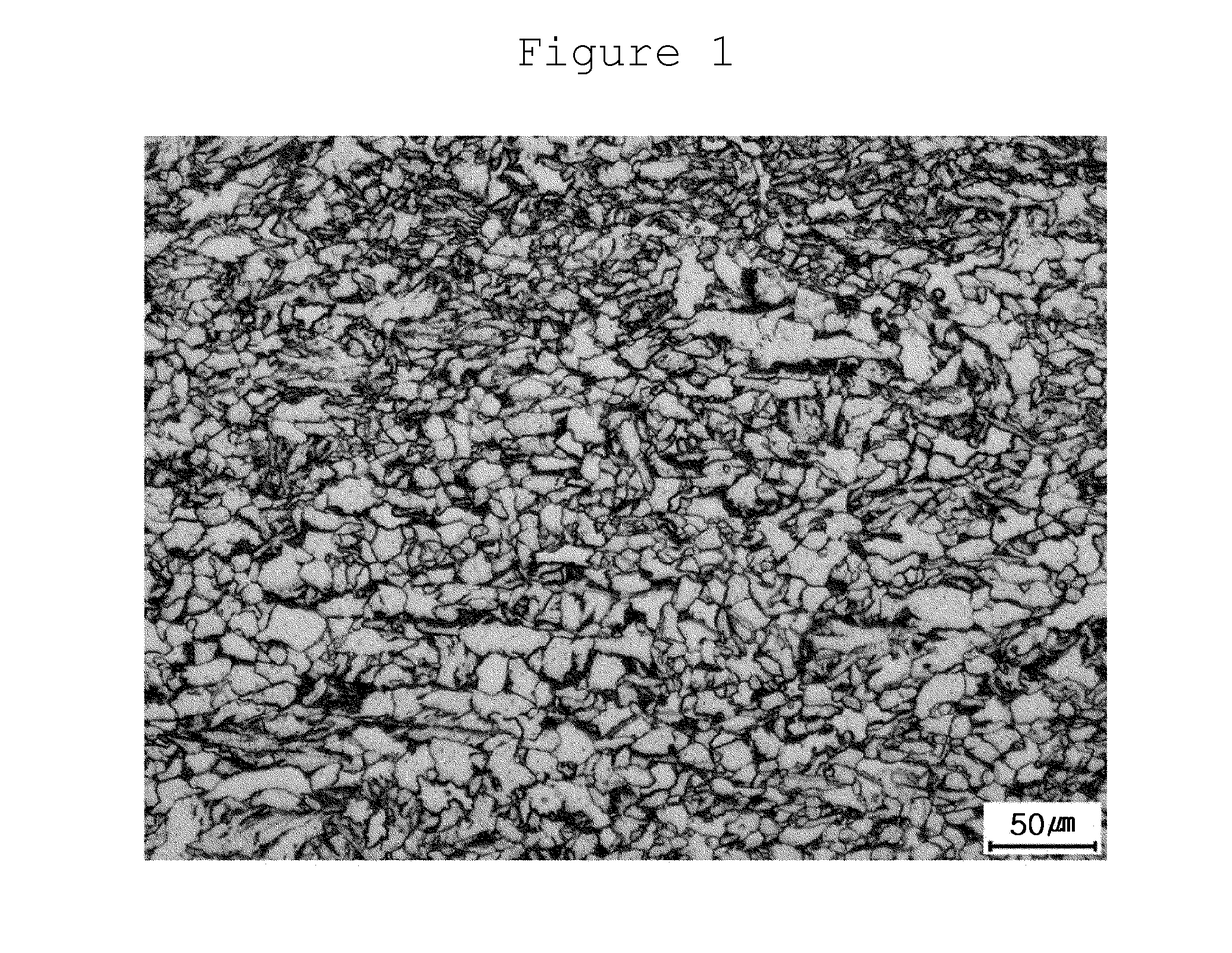

High-strength thick steel plate for construction having excellent characteristics for preventing diffusion of brittle cracks, and production method therefor

ActiveCN104011250AExcellent brittle crack propagation stop characteristicImprove securityMetal sheetTransition temperature

Provided are: a high-strength thick steel plate for construction having excellent characteristics for preventing the diffusion of brittle cracks, said plate being used for ships and having a preferred plate thickness of at least 50 mm; and a method for producing the thick steel plate. The thick steel plate has excellent characteristics for preventing the diffusion of brittle cracks, characterized in that: the thick steel sheet has a specific component composition; the main constituent of the metal structure is a ferrite phase; the thick metal sheet has an aggregate structure in which the density (I) in the RD / / (110) plane at the plate thickness surface is at least 1.3, and the density (I) in the RD / / (110) plane at the plate thickness center is at least 1.8; the Charpy fracture appearance transition temperature (vTrs) at the surface is not more than -60 DEG C, and the Charpy fracture appearance transition temperature (vTrs) at the plate thickness center is not more than -50 DEG C.

Owner:JFE STEEL CORP

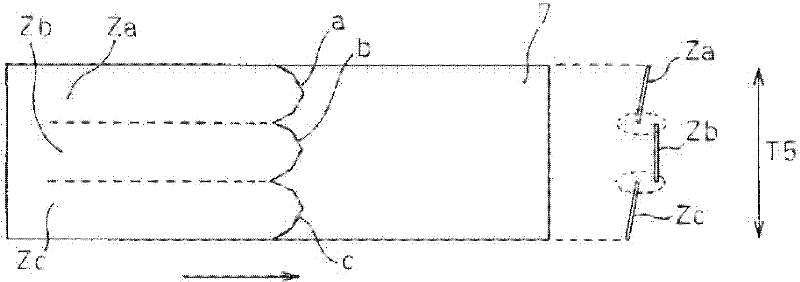

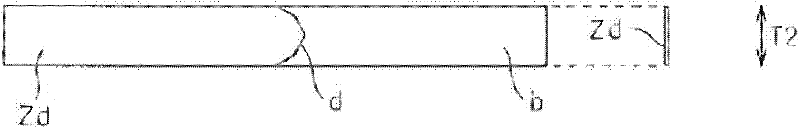

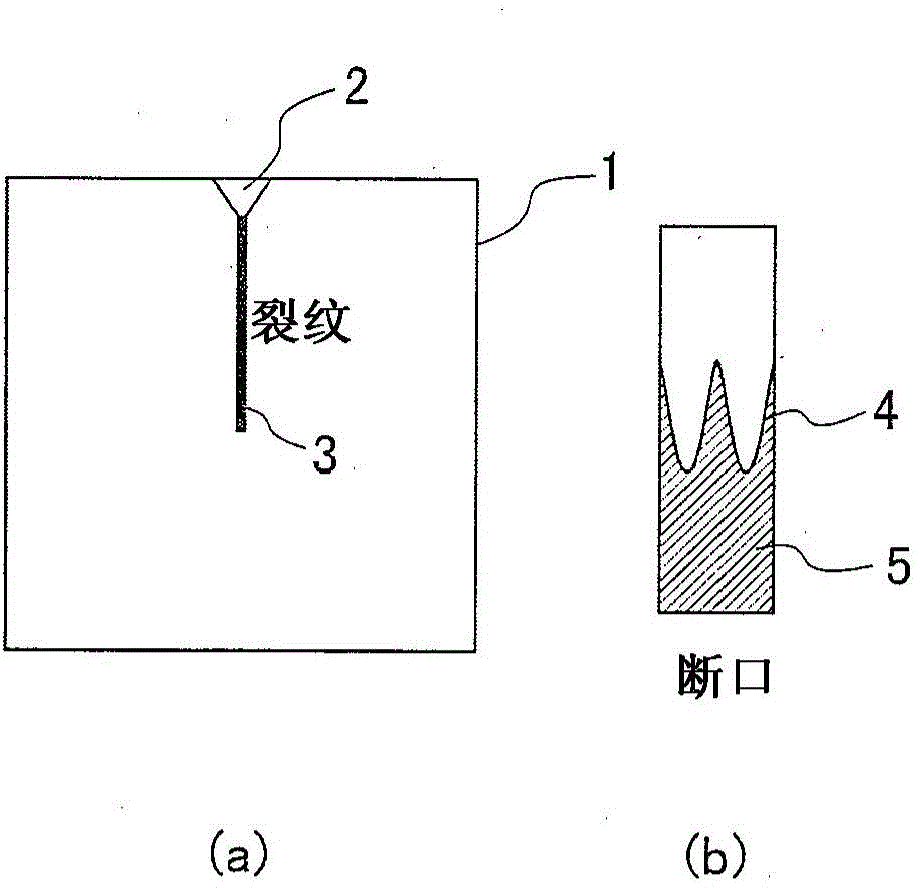

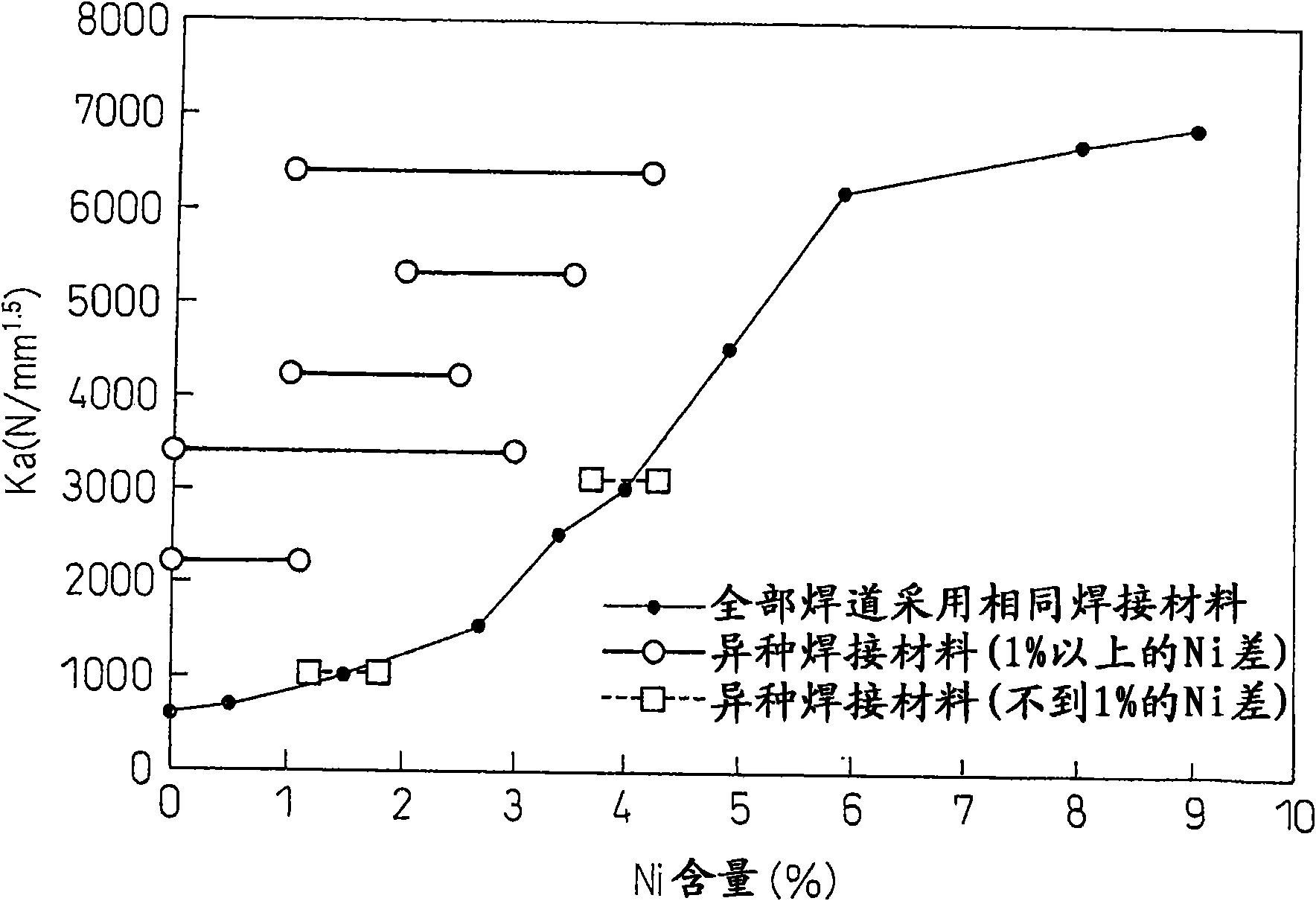

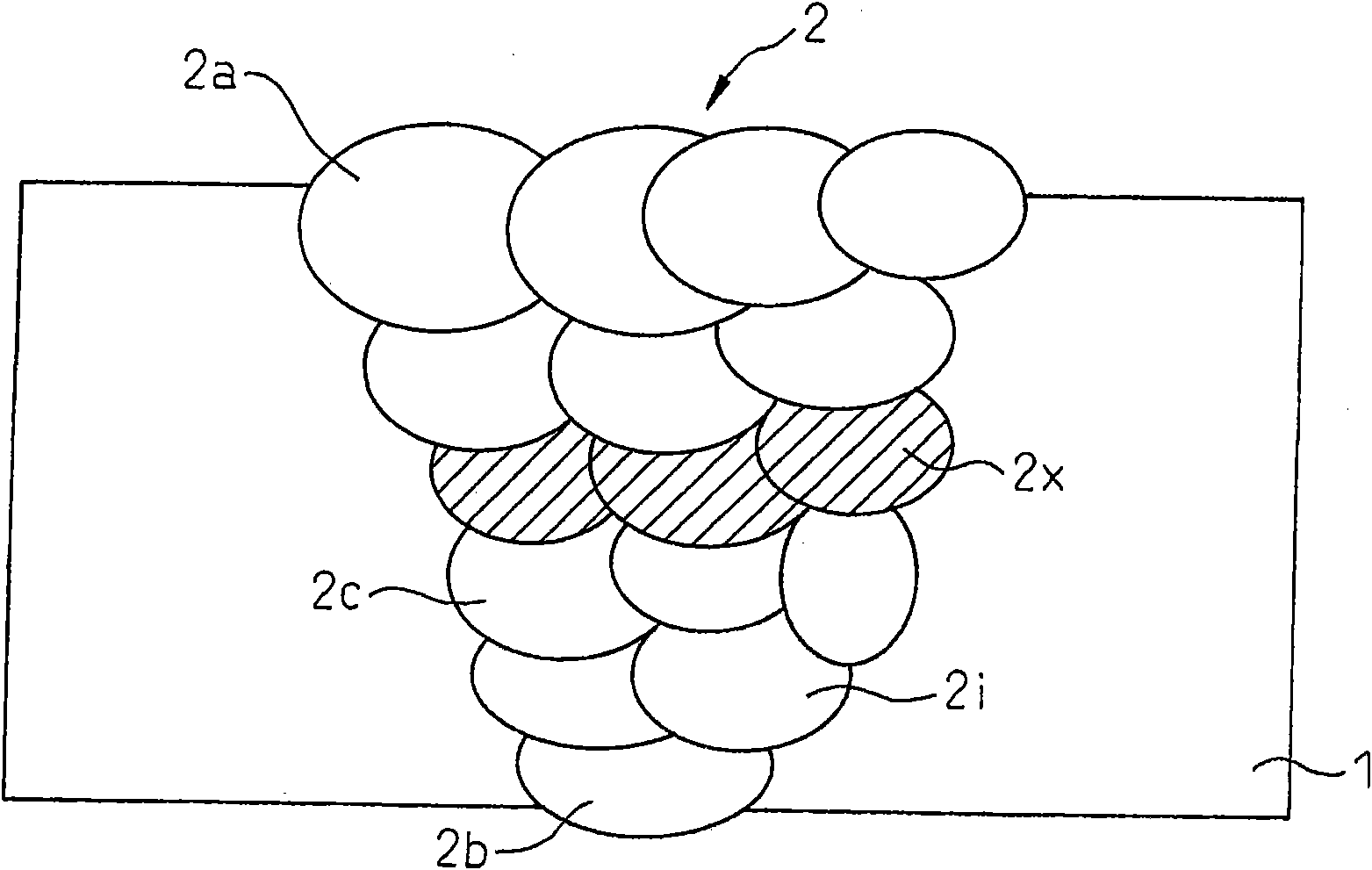

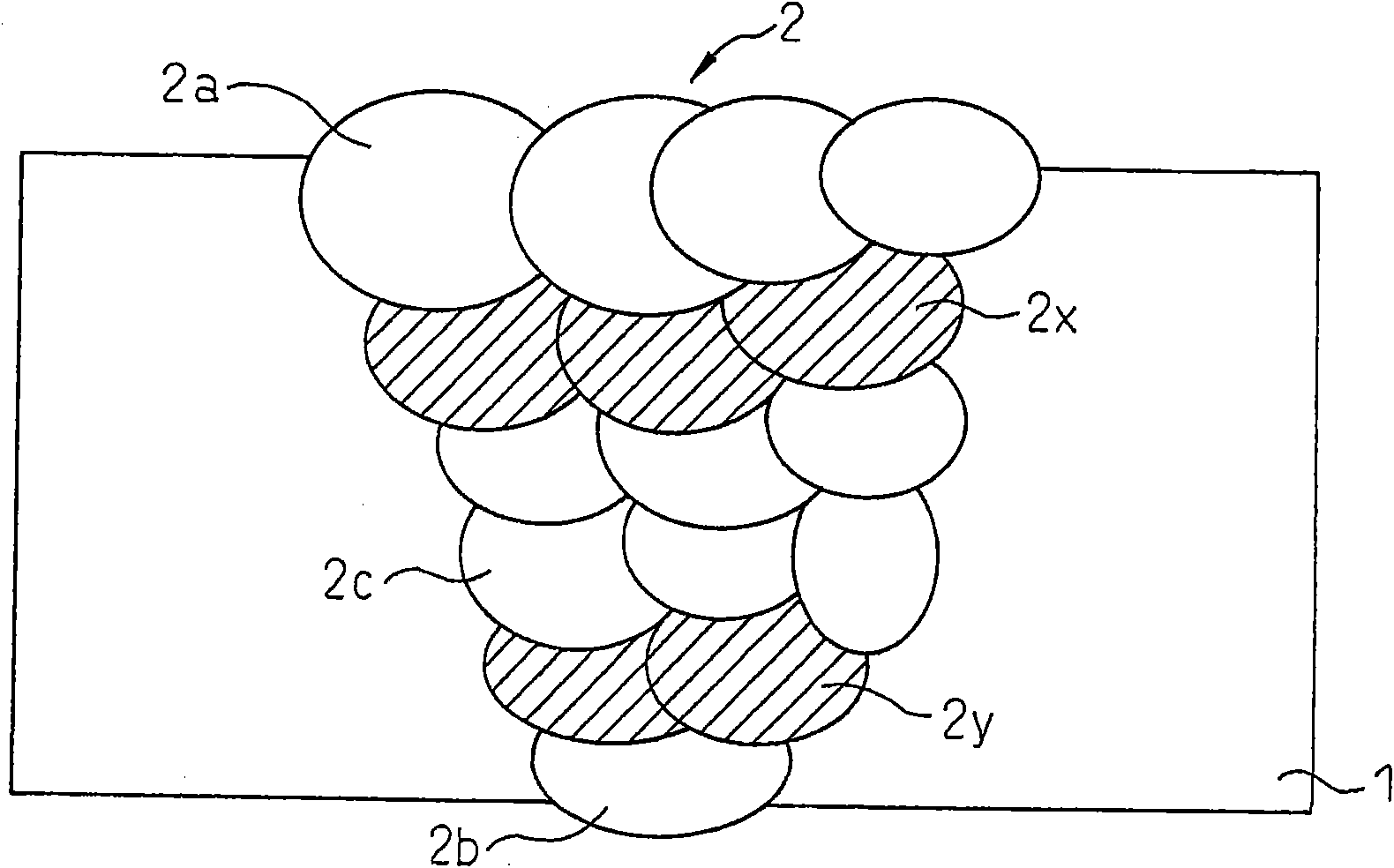

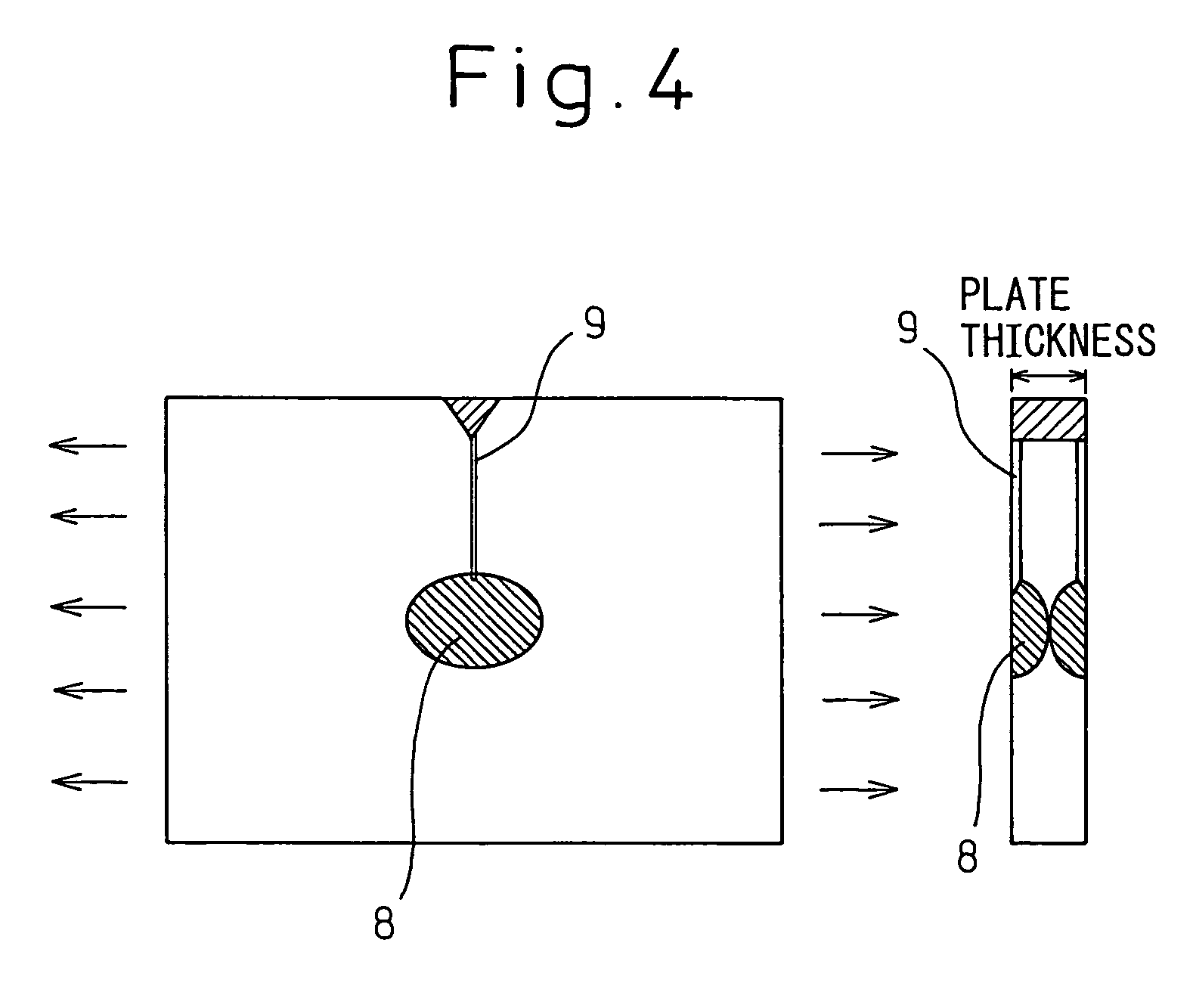

Multipass butt-welded joint having excellent brittle crack propagation resistance, and welded structure

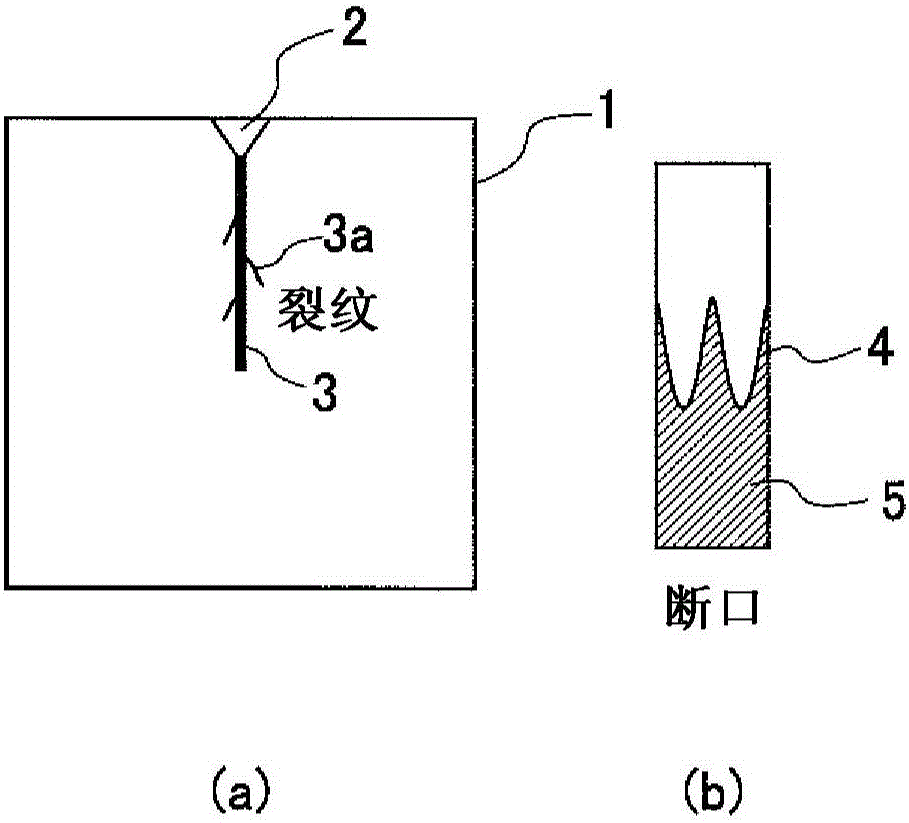

InactiveCN101578154AExcellent resistance to brittle crack growthArc welding apparatusWelding/cutting media/materialsSheet steelCrazing

Disclosed is a multipass butt-welded joint of a steel sheet, which has excellent brittle crack propagation resistance. In the joint, one or more weld layers or welding passes are arranged between a front welding layer and a rear welding layer in a separately spaced state from each other, wherein each of the weld layers or the welding passes has different properties from those of the surrounding materials and can inhibit and terminate the propagation of a brittle crack.

Owner:NIPPON STEEL CORP

Process for producing arc-welded structural member

InactiveCN104334308AExcellent resistance to molten metal embrittlement crackingHot-dipping/immersion processesArc welding apparatusMetallurgyCarbon Dioxide / Helium

[Problem] To provide an arc-welded structural member which includes a Zn-Al-Mg-coated steel plate member and has excellent molten-metal brittle crack resistance, without involving a restriction on the kind of the steel of the plated base or a considerable increase in cost. [Solution] When a welded structural member is produced by bonding steel materials to each other by gas-shielded arc welding, a hot-dip Zn-Al-Mg-coated steel plate member is used as at least one of the members to be bonded and use is made of a shielding gas which comprises, as the base, Ar gas, He gas, or a gas mixture of Ar and He and which has been regulated so as to have a CO2 concentration CCO2 (vol%) that satisfies relationship (2) in accordance with the welding heat input Q (J / cm). 0<=CCO2<=2900Q-0.68 (2)

Owner:NISSHIN STEEL CO LTD

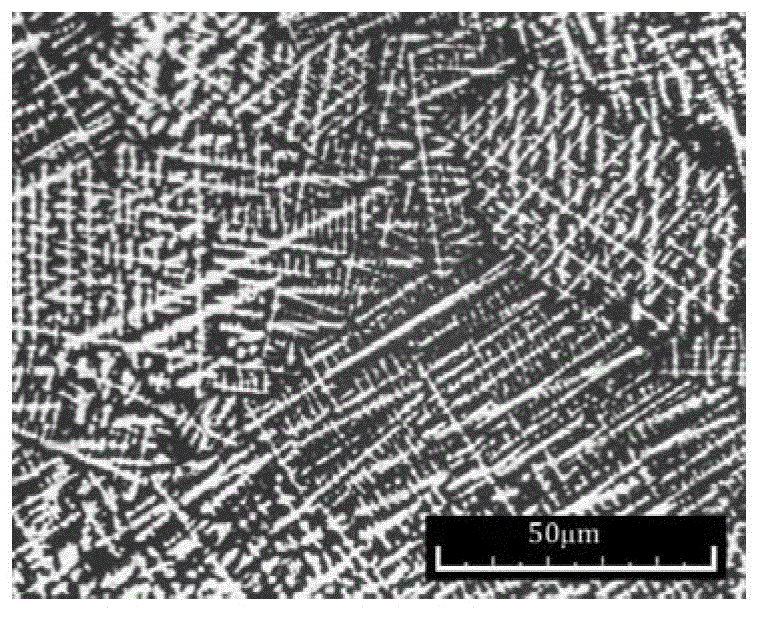

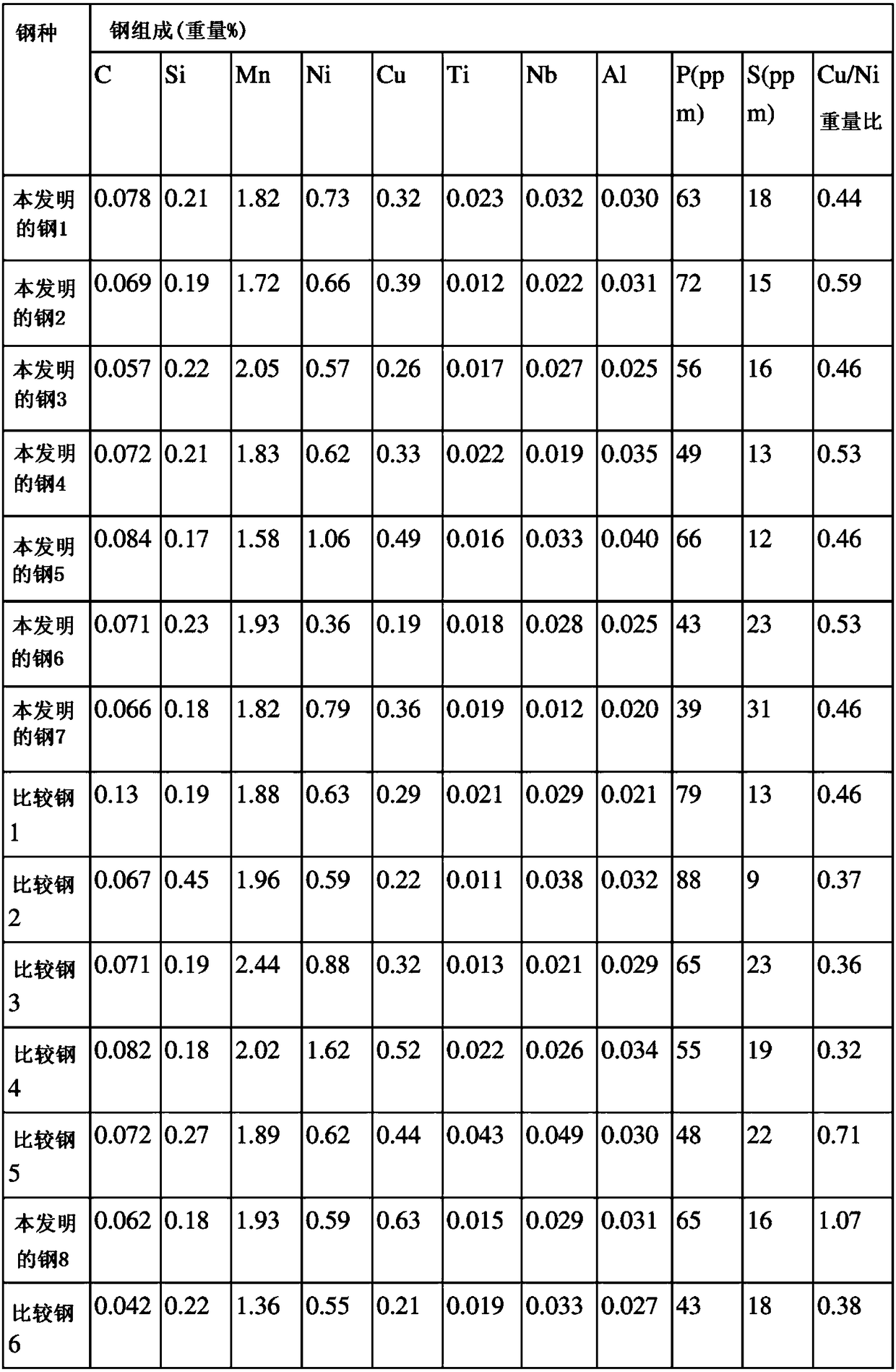

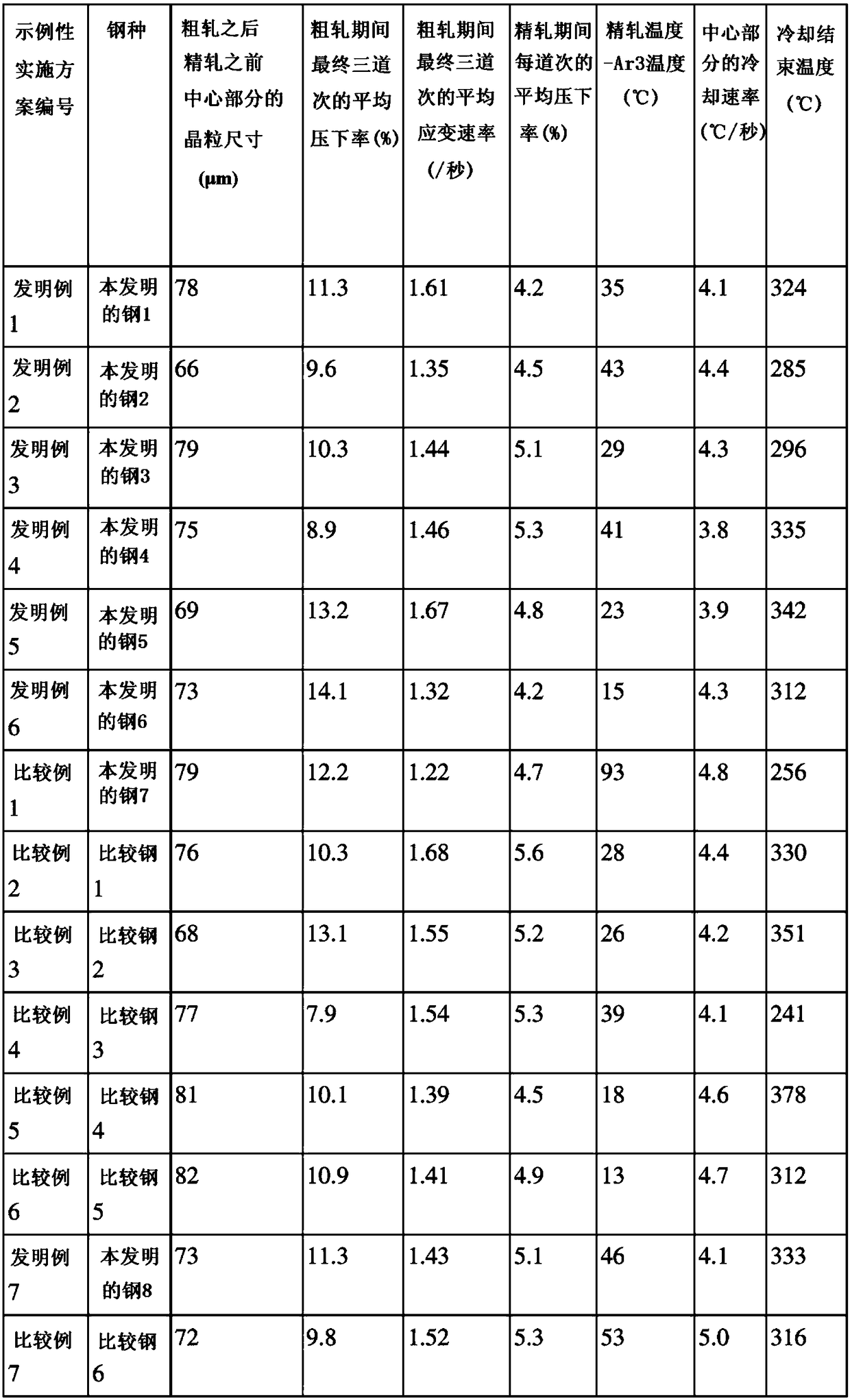

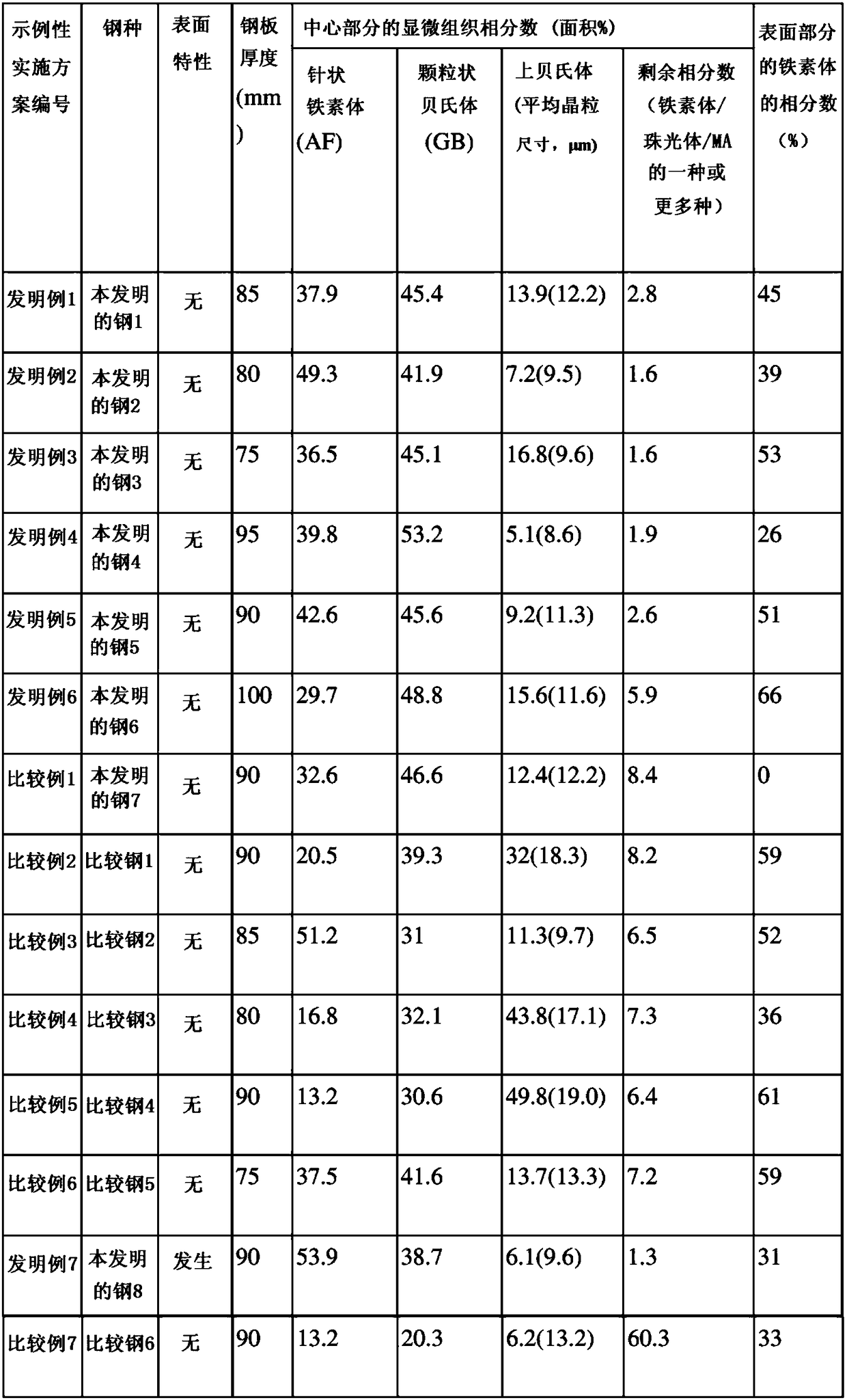

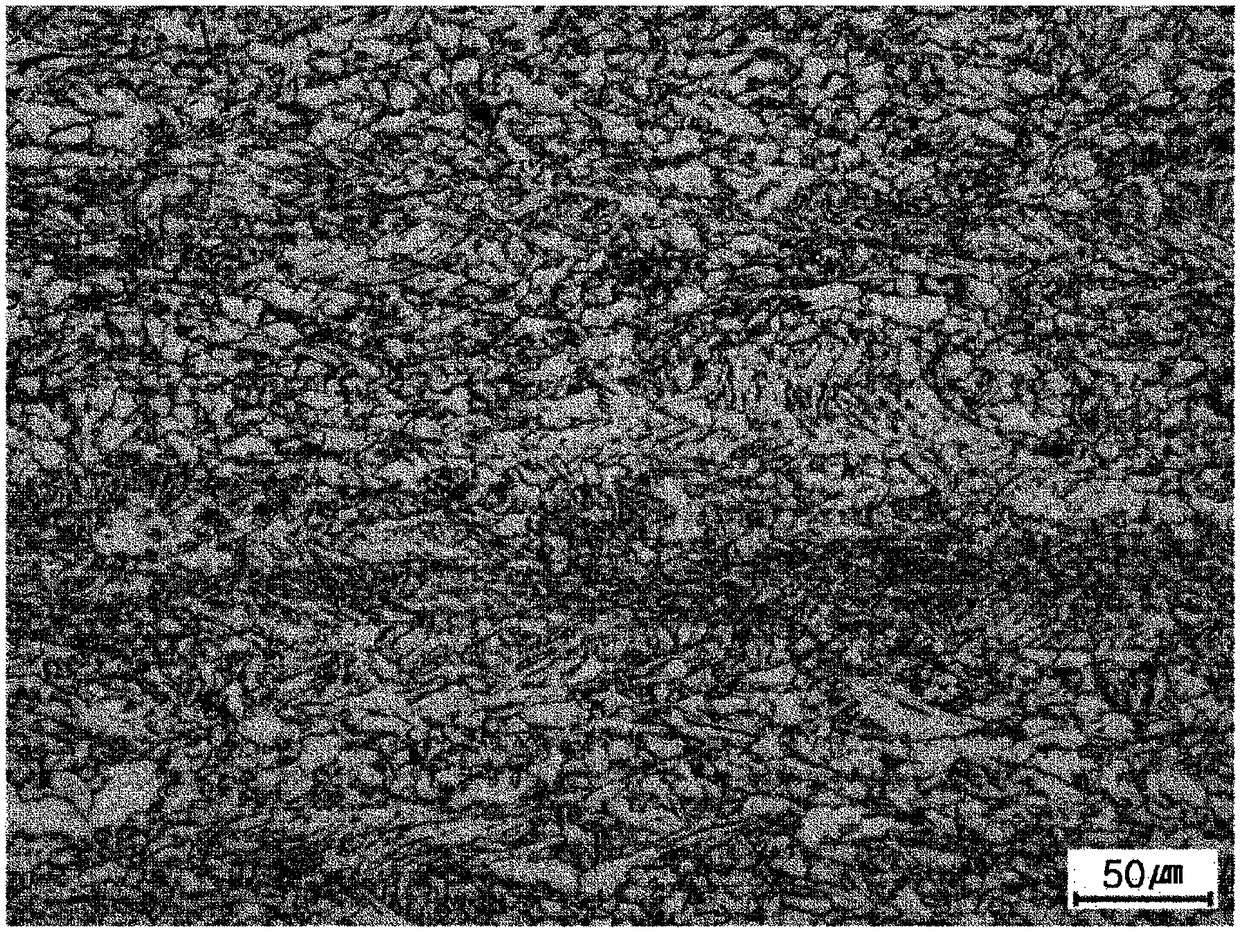

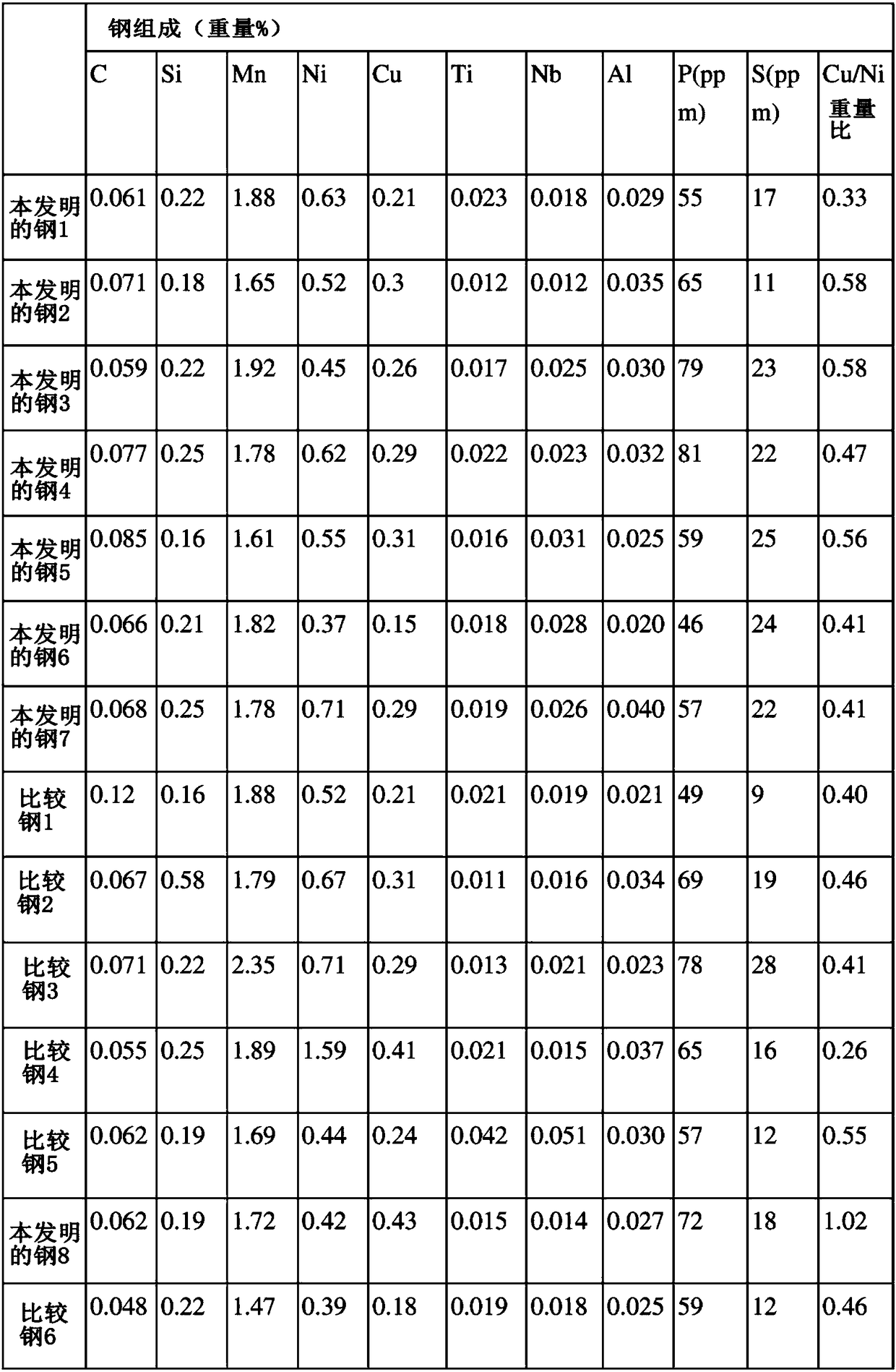

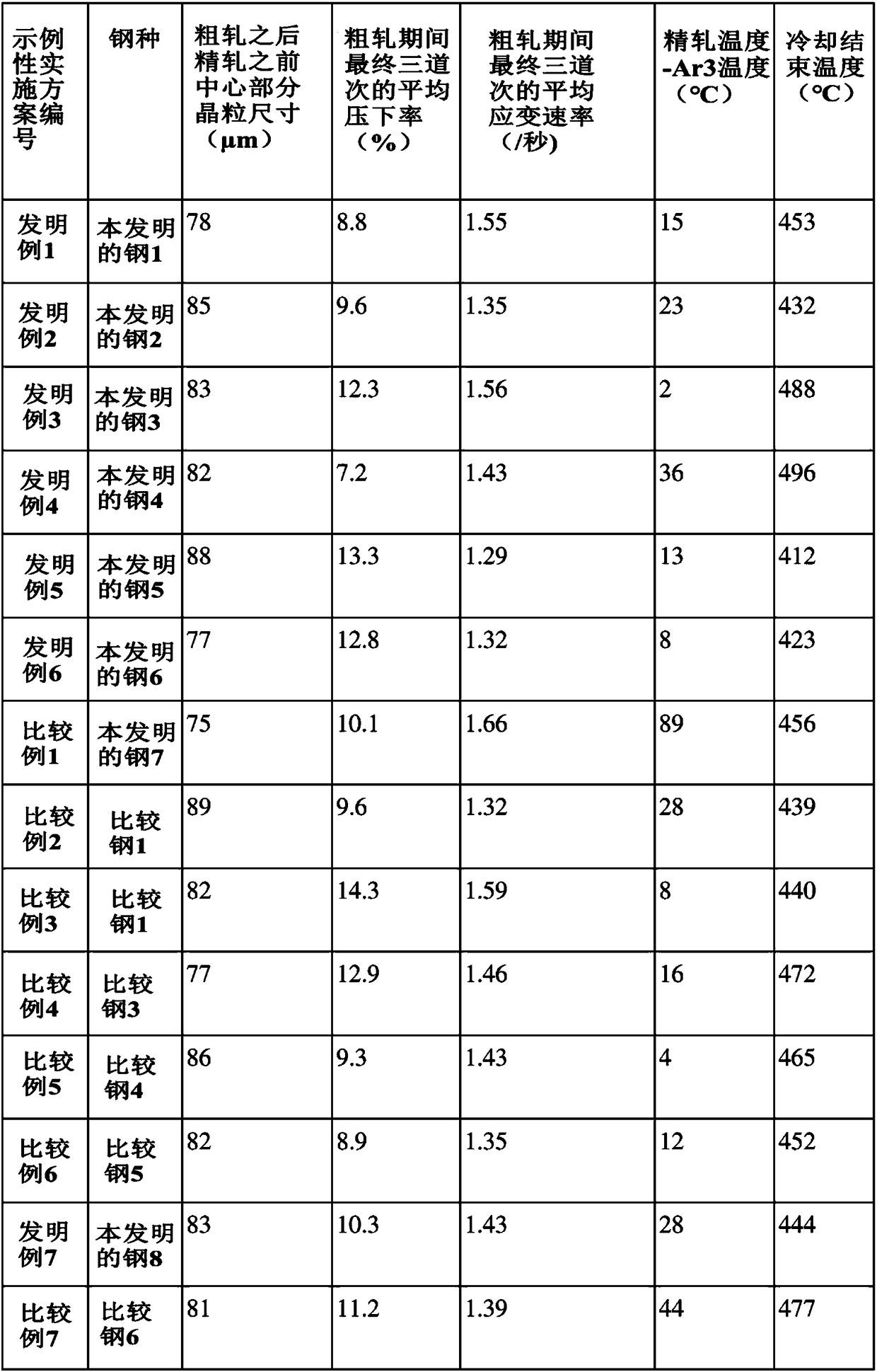

High-strength steel having excellent brittle crack arrestability and welding part brittle crack initiation resistance, and production method therefor

ActiveCN108368587AHigh yield strength levelRoll mill control devicesFurnace typesHeat-affected zonePearlite

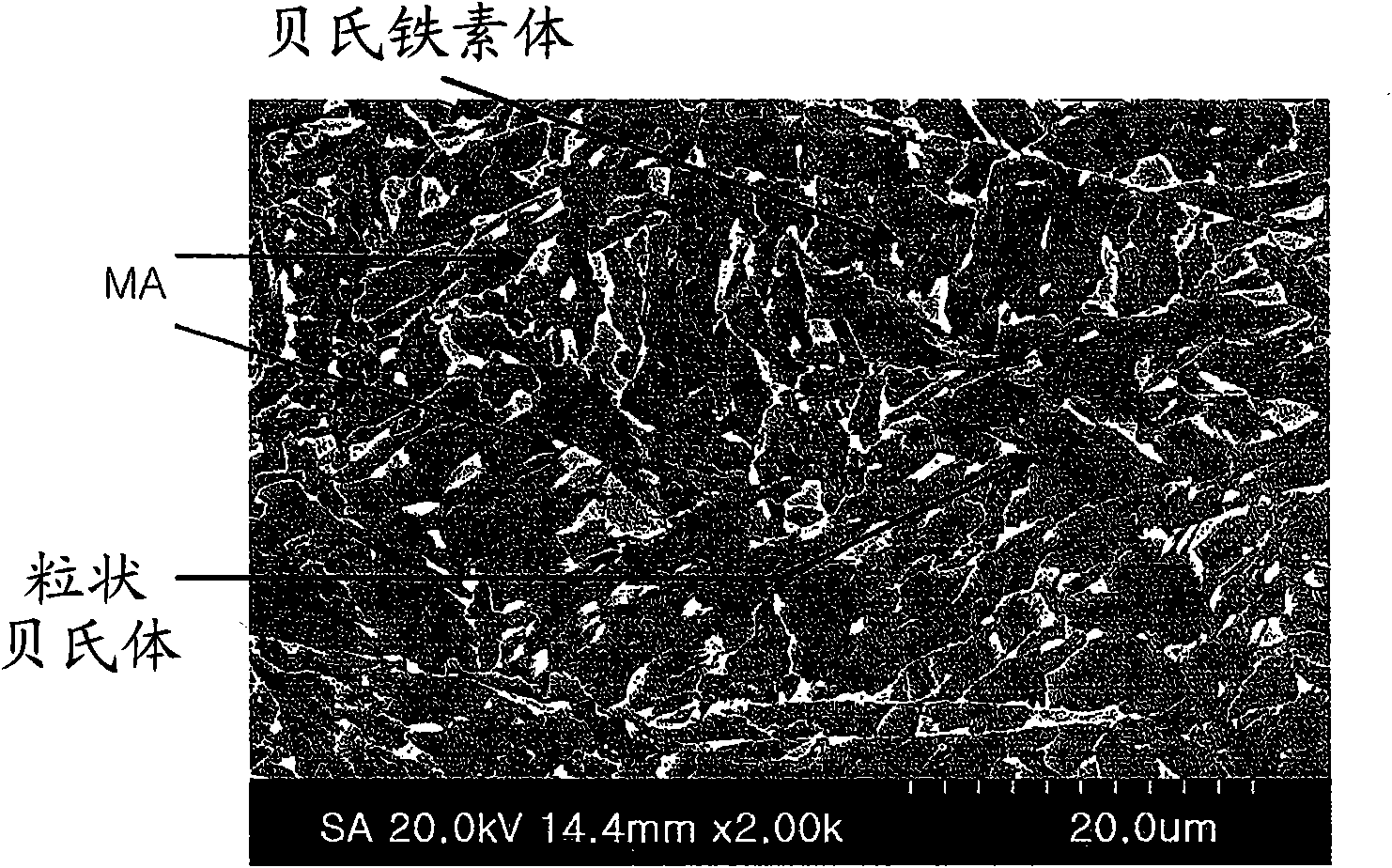

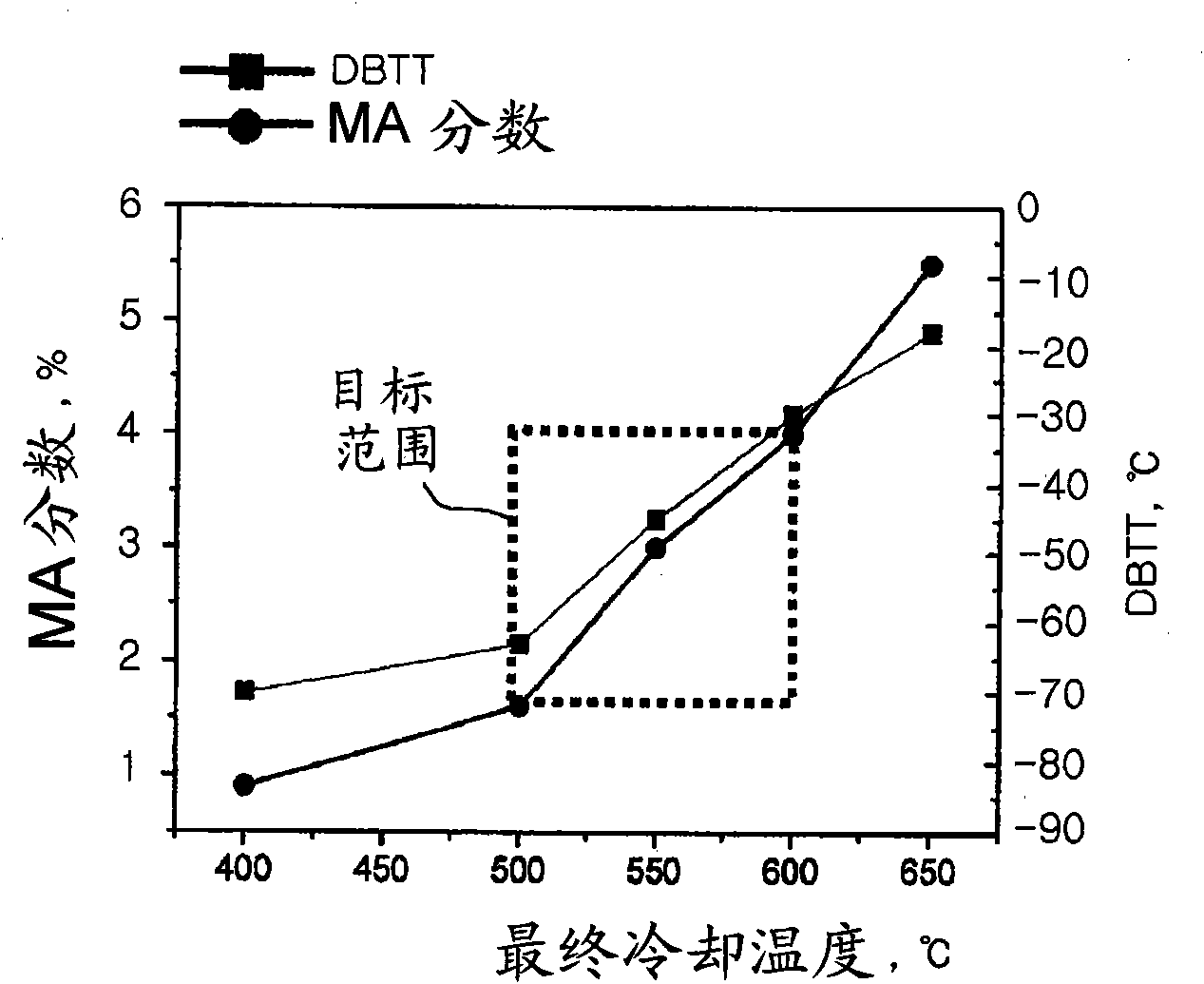

The purpose of another aspect of the present invention is to provide a high-strength steel having excellent brittle crack arrestability and welding part brittle crack initiation resistance, and a production method therefor. According to one aspect of the present invention, provided are a high-strength steel having excellent brittle crack arrestability and welding part brittle crack initiation resistance, and a production method therefor, the high-strength steel: comprising, in wt%, C: 0.05-0.09%, Mn: 1.5-2.2%, Ni: 0.3-1.2%, Nb: 0.005-0.04%, Ti: 0.005-0.04%, Cu: 0.1-0.8%, Si: 0.05-0.3%, Al: 0.005-0.05%, P: 100ppm or less, S: 40ppm or less, and a remainder made up by Fe and other inevitable impurities; having a center part microstructure comprising an acicular ferrite and granular bainite mixed-phase, upper bainite, and a remainder made up by one type or more selected from the group consisting of ferrite, pearlite, and a martensite-austenite (MA) constituent; having, in a 2mm or less subsurface region, a surface part microstructure comprising ferrite and a remainder made up by one type or more among bainite and martensite; and having a welding heat affected zone, which is formed during welding, that comprises, in area%, 5% or less of a martensite-austenite constituent. According to the present invention, high-strength steel having high yield strength, excellent brittle crack arrestability, and excellent welding part brittle crack initiation resistance may be obtained.

Owner:浦项股份有限公司

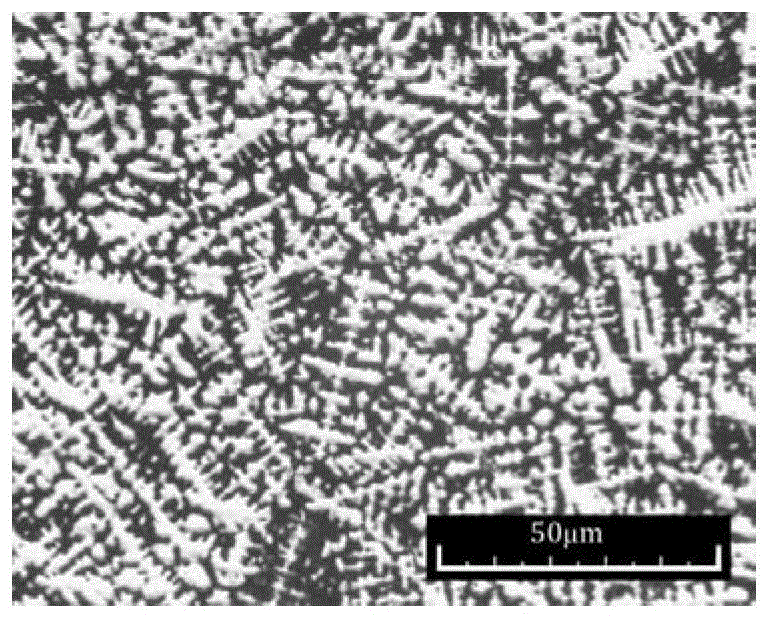

High-strength steel having excellent brittle crack arrestability and welding part brittle crack initiation resistance, and production method therefor

ActiveCN108291287AHigh yield strength levelExcellent resistance to brittle crack initiationRoll mill control devicesFurnace typesHeat-affected zonePearlite

One aspect of the present invention provides a high-strength steel having excellent brittle crack arrestability and welding part brittle crack initiation resistance, and a production method therefor.According to one aspect of the present invention, provided are a high-strength steel having excellent brittle crack arrestability and welding part brittle crack initiation resistance, and a productionmethod therefor, the high-strength steel: comprising, in wt%, C: 0.05-0.09%, Mn: 1.5-2.0%, Ni: 0.3-0.8%, Nb: 0.005-0.04%, Ti: 0.005-0.04%, Cu: 0.1-0.5%, Si: 0.05-0.3%, Al: 0.005-0.05%, P: 100ppm or less, S: 40ppm or less, and a remainder made up by Fe and other inevitable impurities; having a center part microstructure comprising, in area%, 70% or more of acicular ferrite and 10% or less of pearlite, wherein the equivalent circular diameter of the pearlite is 15um (micrometers) or less; having , in a 2mm or less subsurface region, a microstructure comprising, in area%, 30% or more of one typeor more among ferrite and a remainder made up by bainite, martensite, and pearlite; and having a welding heat affected zone, which is formed when welding , that comprises, in area%, 5% or less of a martensite-austenite constituent. According to the present invention, high-strength steel having high yield strength, excellent brittle crack arrestability, and excellent welding part brittle crack initiation resistance may be obtained.

Owner:浦项股份有限公司

High strength steel sheet having excellent brittle crack resistance and method for manufacturing same

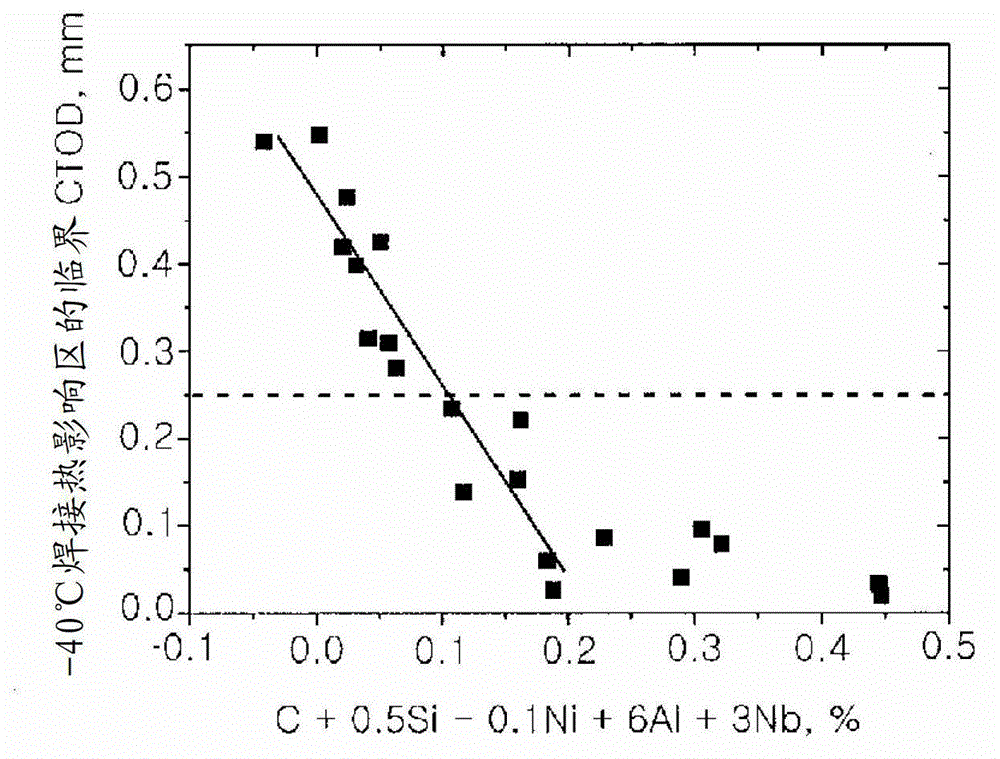

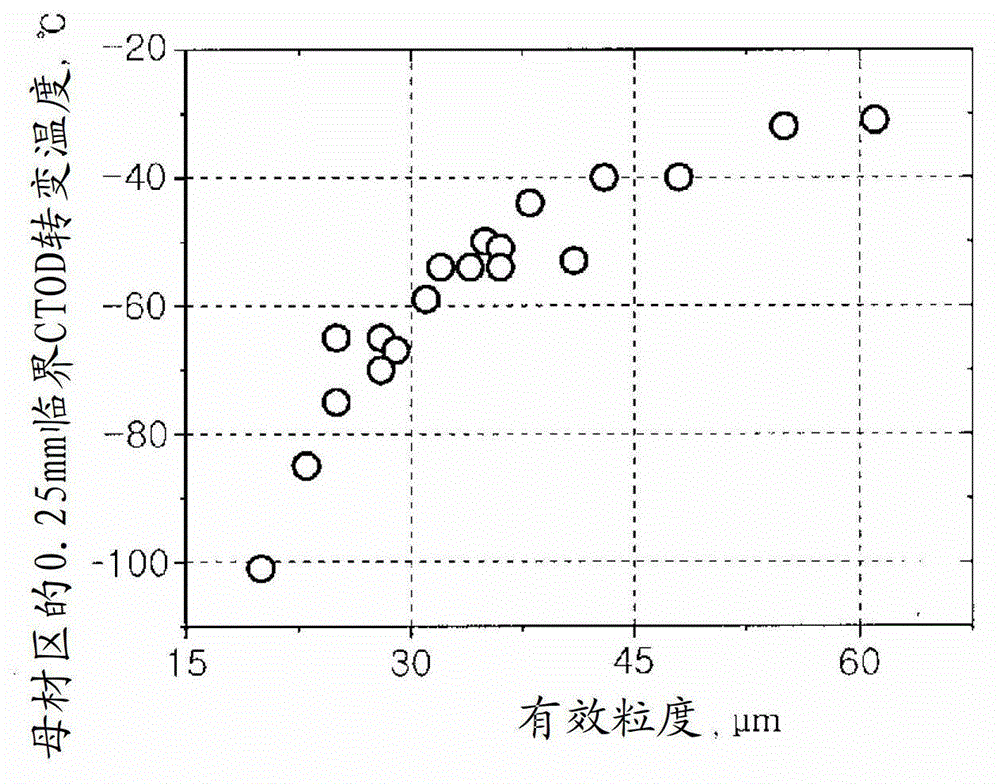

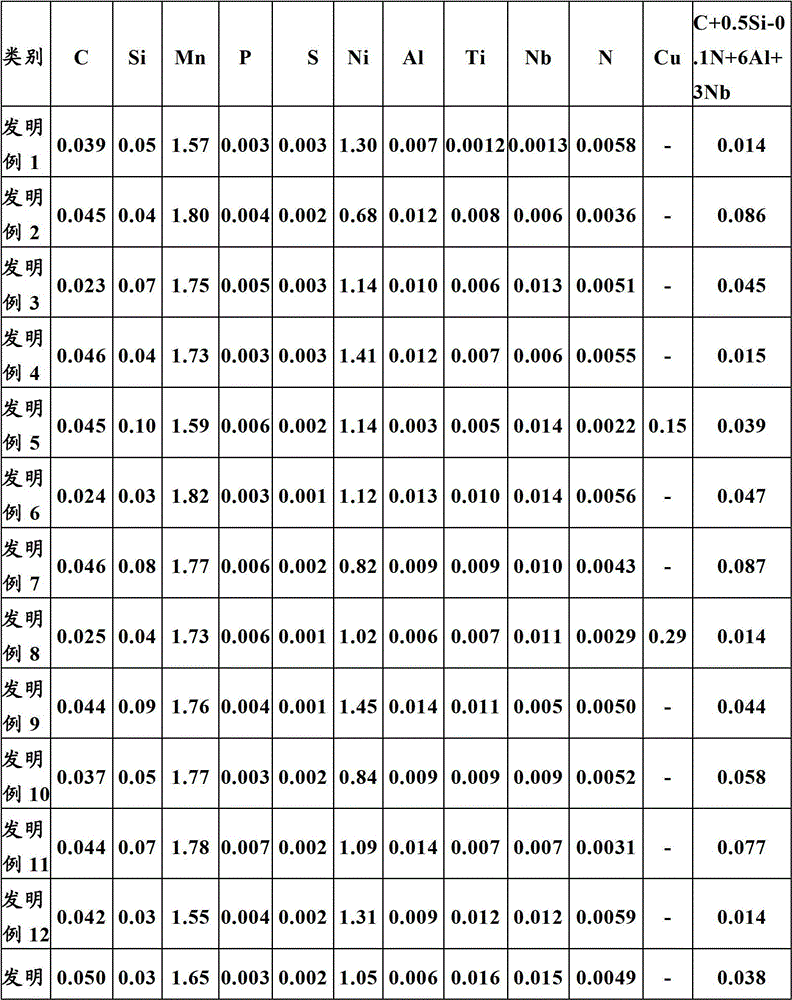

ActiveCN102753719AImprove the immunityFurnace typesMetal rolling arrangementsHeat-affected zoneNiobium

Provided is a steel plate having excellent resistance to brittle crack initiation in a parent material zone and a weld heat affected zone. More particularly, the present invention relates to a high-strength steel sheet having excellent resistance to brittle crack initiation which includes 0.02 wt% to 0.06 wt% of carbon (C), 0.1 wt% or less of silicon (Si), 1.5 wt% to 2.0 wt% of manganese (Mn), 0.012 wt% or less of phosphorous (P), 0.003 wt% or less of sulfur (S), 0.5 wt% to 1.5 wt% of nickel (Ni), 0.003 wt% to 0.015 wt% of aluminum (Al), 0.005 wt% to 0.02 wt% of titanium (Ti), 0.005 wt% to 0.015 wt% of niobium (Nb), 0.002 wt% to 0.006 wt% of nitrogen (N), and iron (Fe) as well as unavoidable impurities as a remainder, and has a value of C+0.5Si-0.1Ni+6Al+3Nb of 0.1% or less, and a method of manufacturing the high-strength steel sheet.

Owner:浦项股份有限公司

Thick steel board

The invention provides a thick steel board excellent in brittle crack propagation-arresting property without causing increase in production cost. Even if the thickness of the steel board exceeds 50mm,the board still meets the requirement of high strength (tensile strength is over 490MPa), and Kca value under the temperature of -10 DEG C. is over 3500N / mm[3 / 2]. By appropriately modulating composition of chemical components, the thick steel board has an average area ratio of the quasi-polygonal ferrite of 30-85% in the microscopic constitution at the position t / 4-t / 2 deep from the surface, wherein t represents the thickness of the board.

Owner:KOBE STEEL LTD

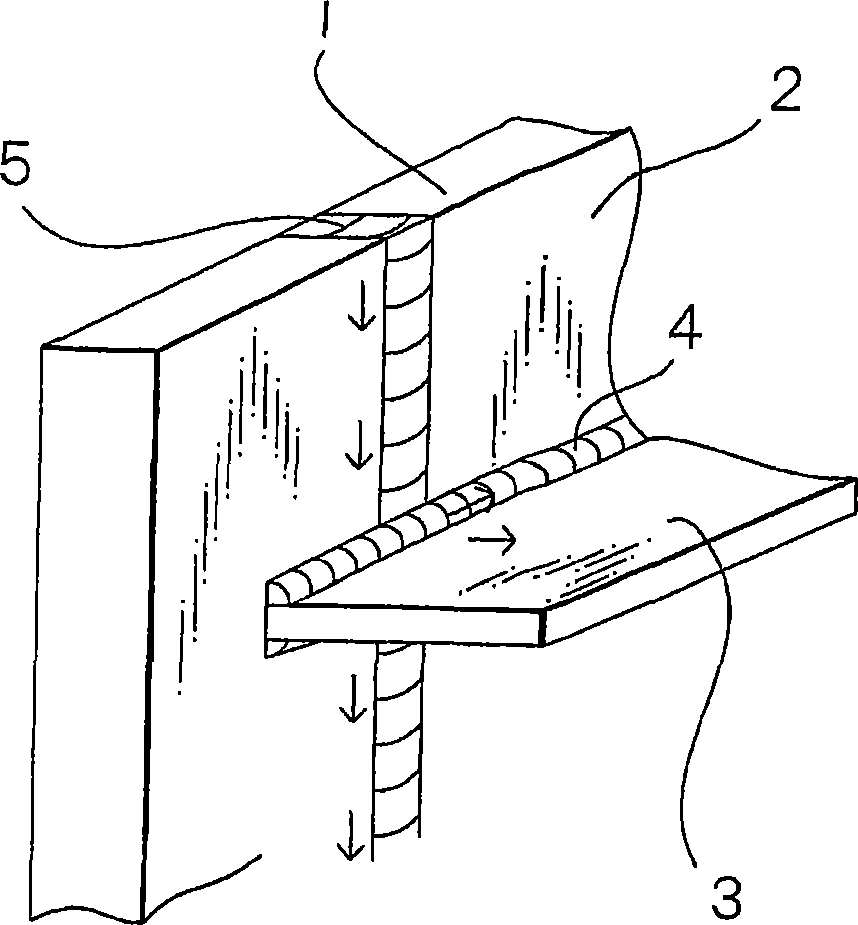

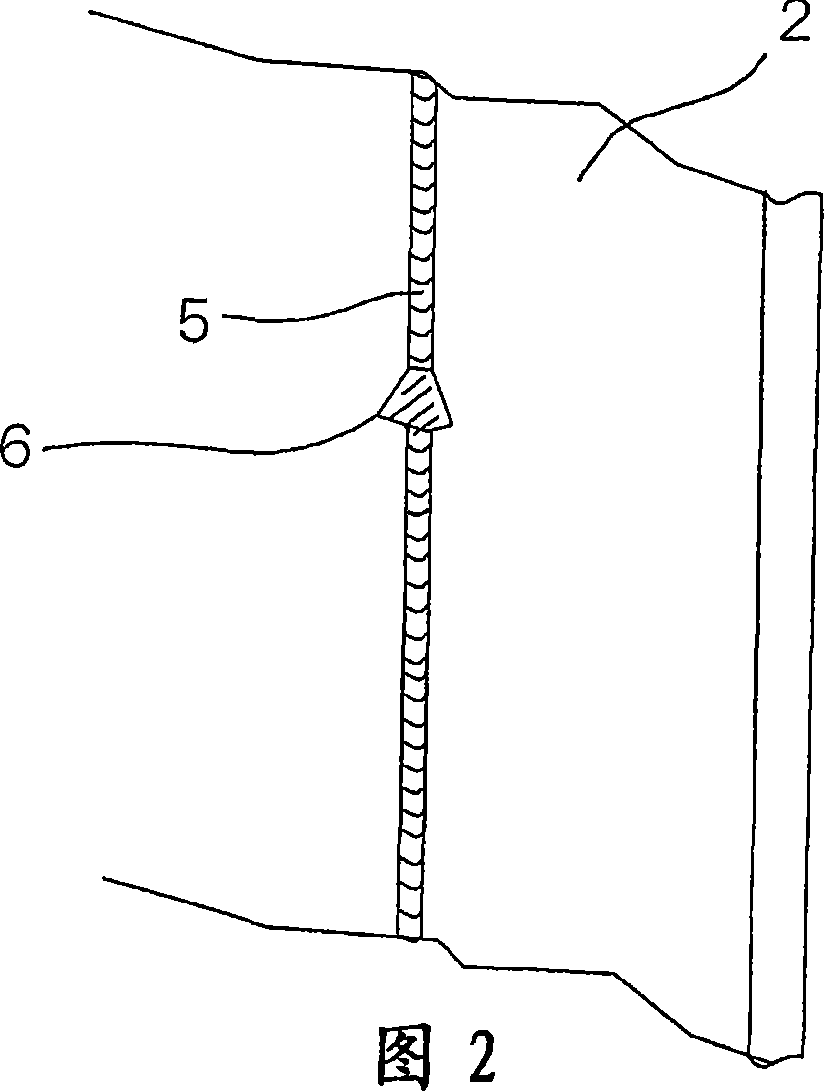

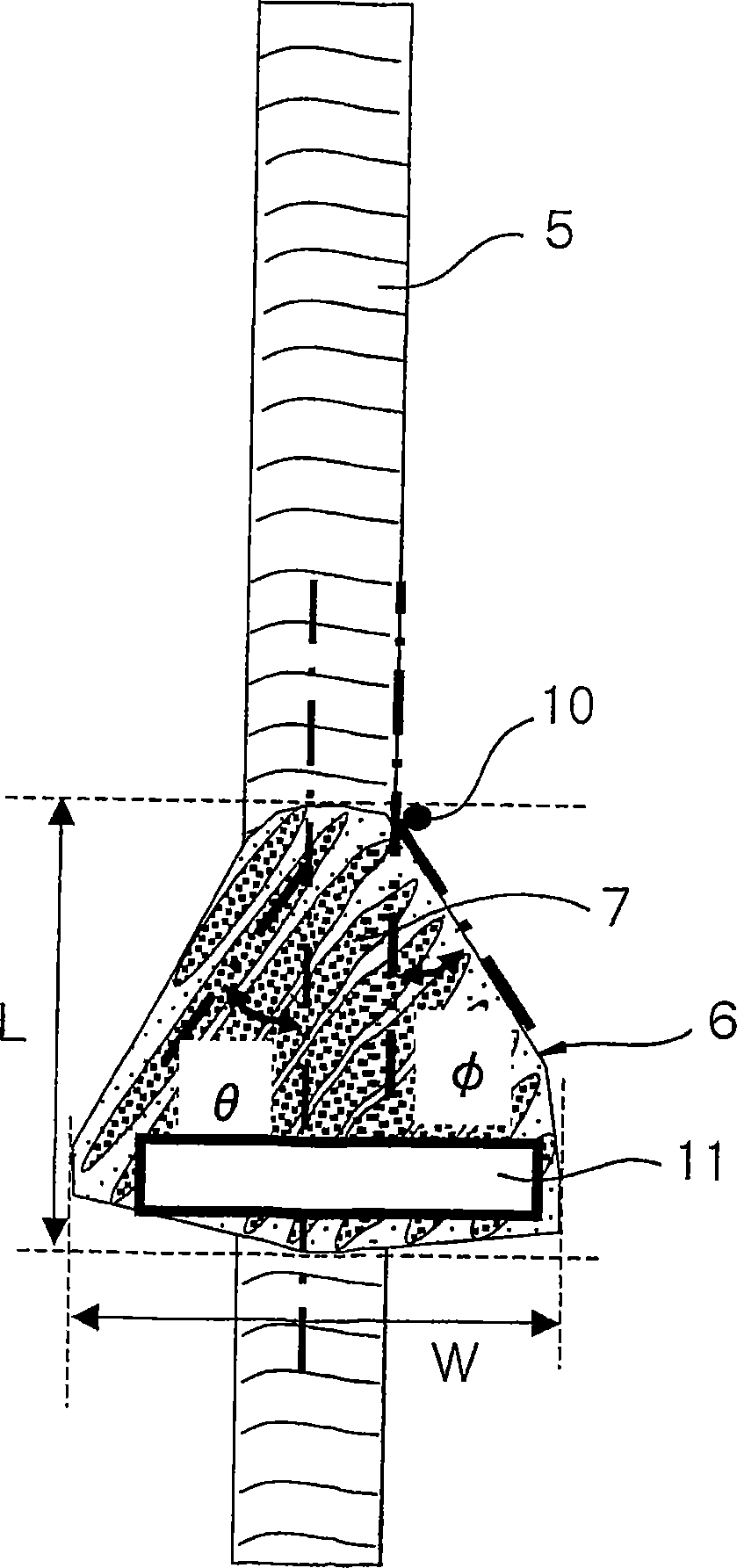

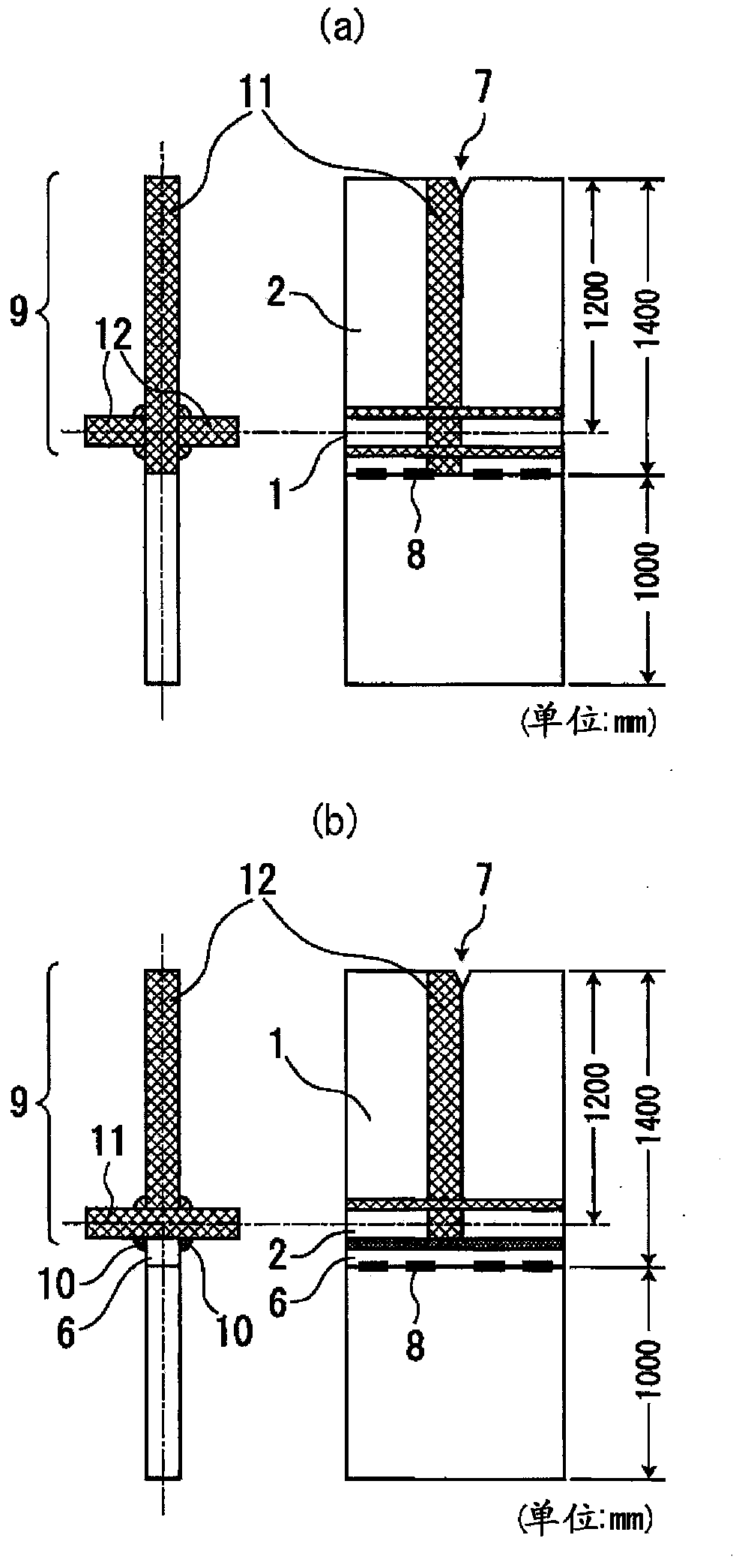

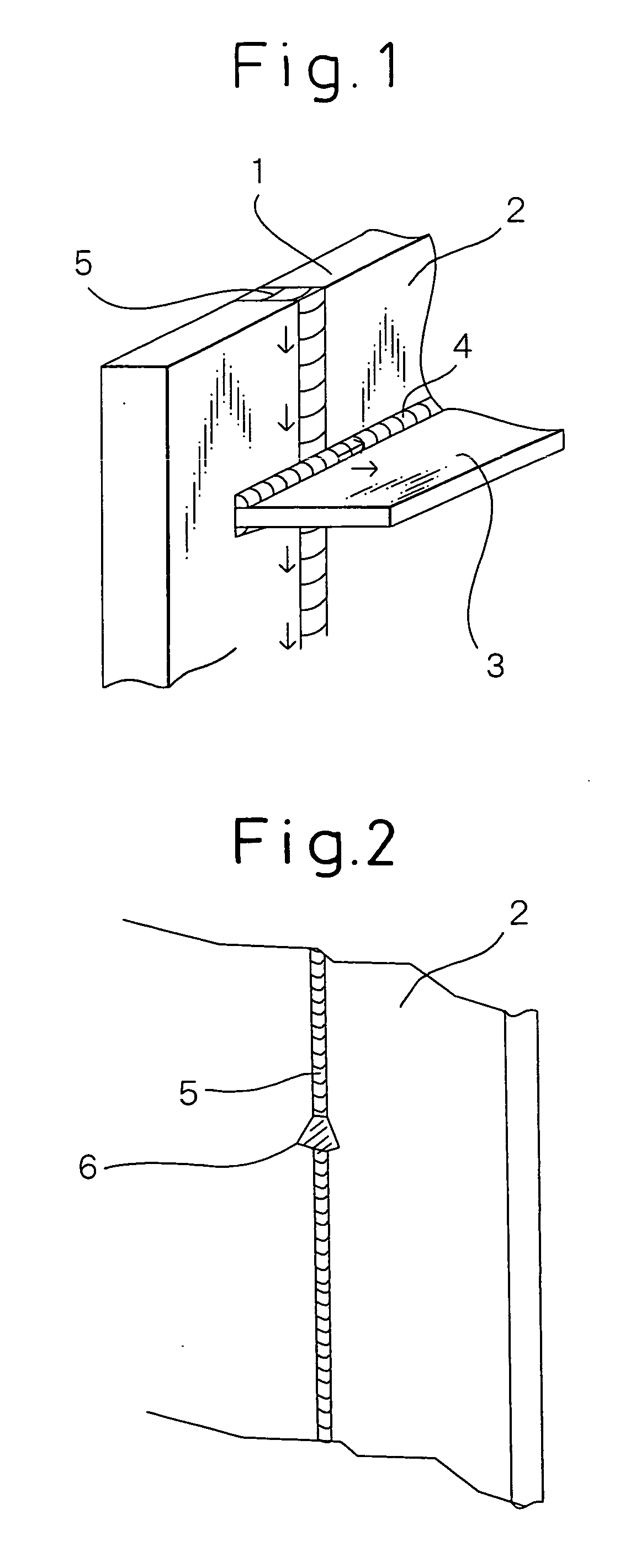

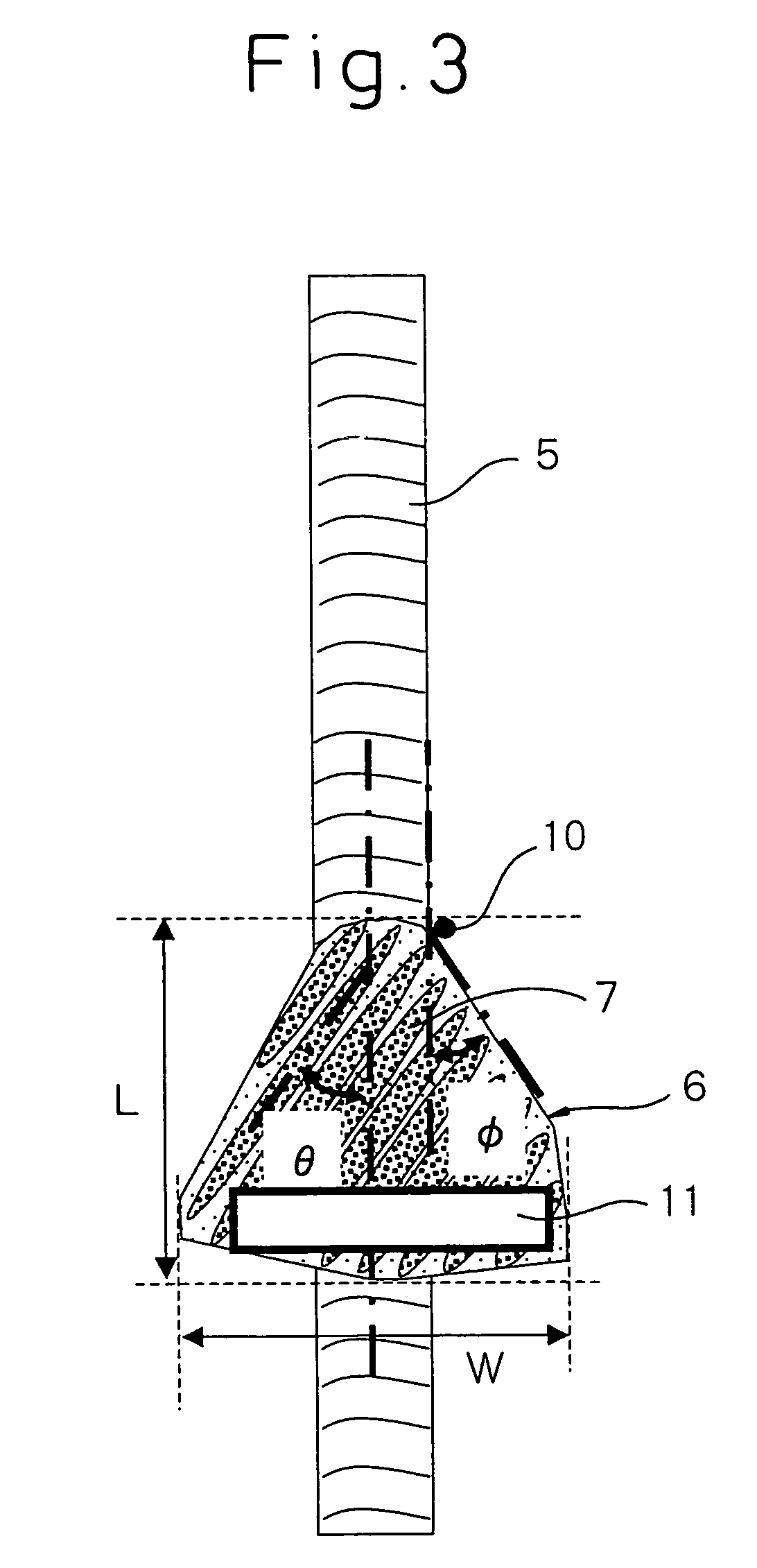

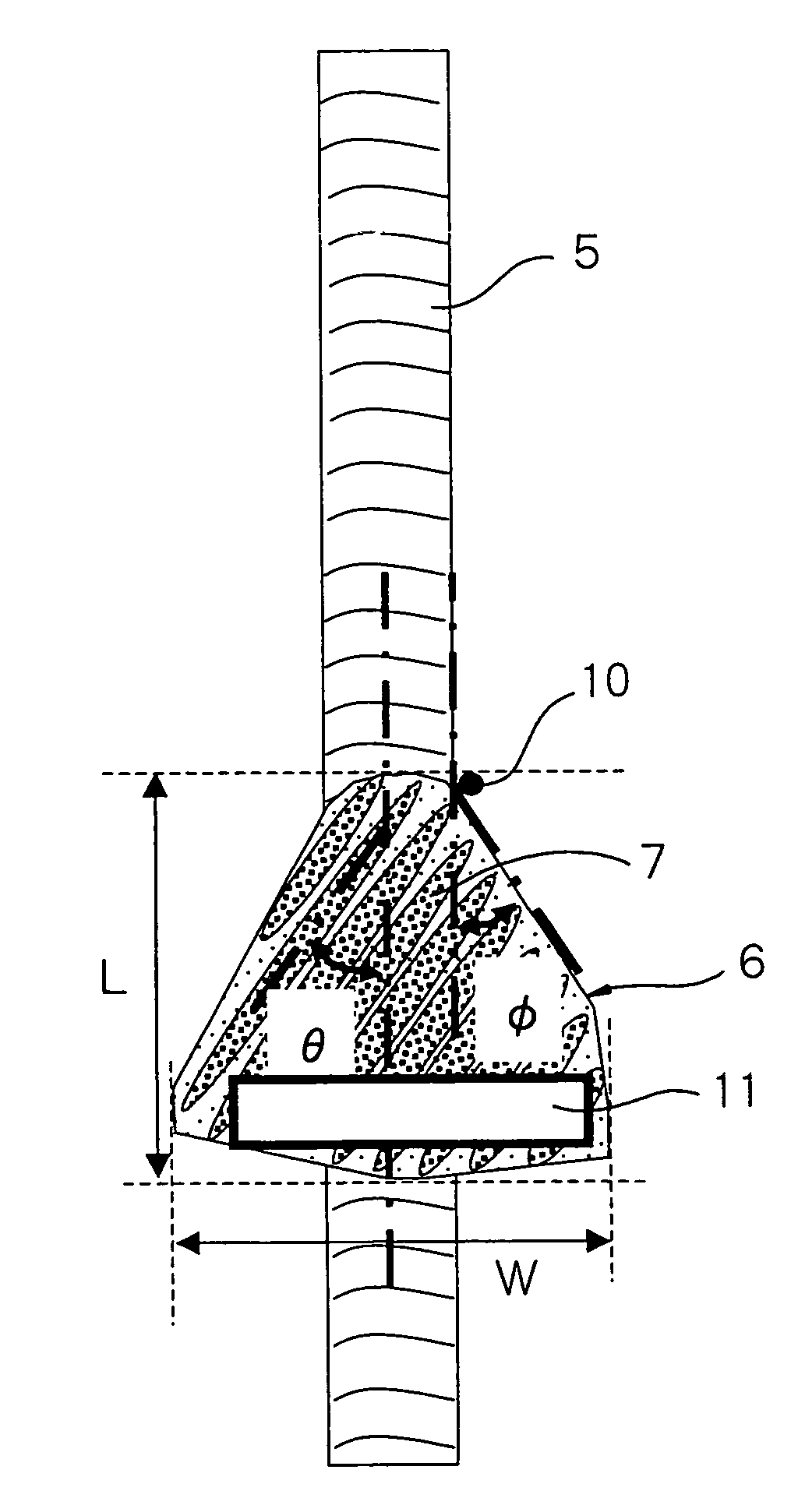

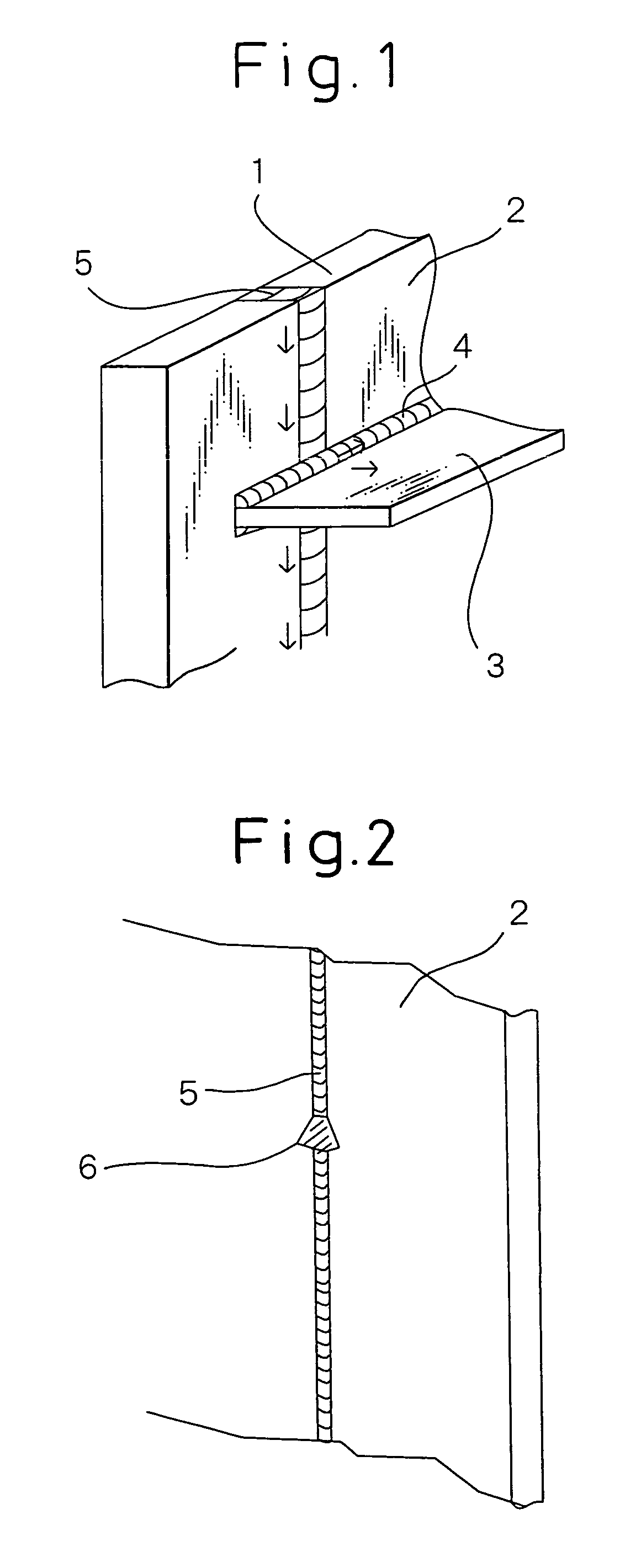

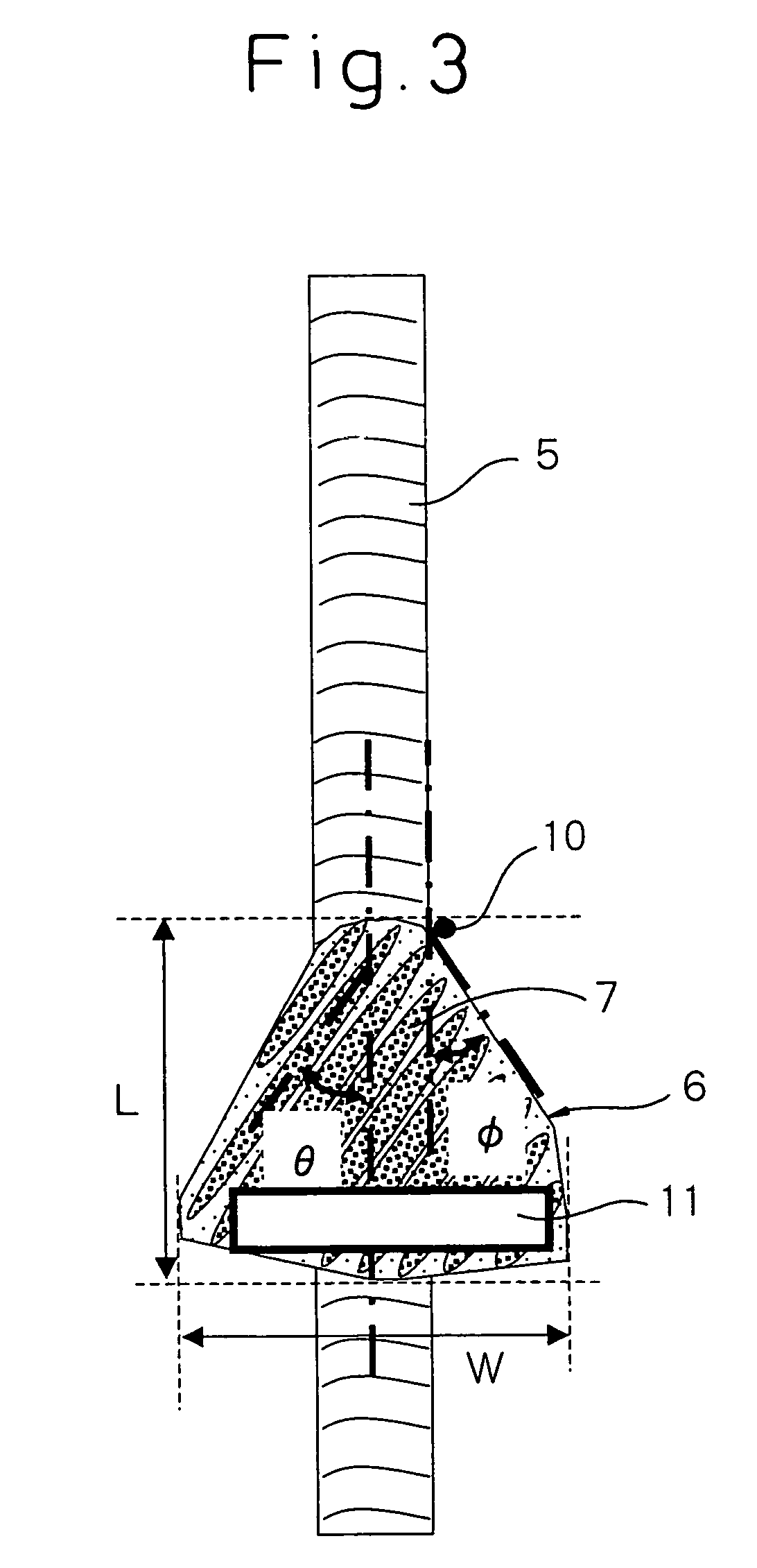

Welded structure having excellent resistance to brittle crack propagation and welding method therefor

InactiveUS20070040001A1Avoid crackingMaintain good propertiesCooking-vessel materialsArc welding apparatusCrazingToughness

A welding method for manufacturing welded structures having excellent properties to prevent the propagation of brittle fracture occurring in welded joints, characterized by the step of forming a repair weld having a greater toughness than that of a butt weld and an outer edge whose angle φ with respect to the longitudinal direction of the butt weld is not less than 10 degrees and not more than 60 degrees, by applying repair welding to a region to arrest a brittle crack in a butt-welded joint where a brittle crack is likely to propagate after removing part of the butt-welded joint, in said region, by gouging or machining.

Owner:NIPPON STEEL CORP

High-strength thick steel plate for construction having excellent characteristics for preventing diffusion of brittle cracks, and production method therefor

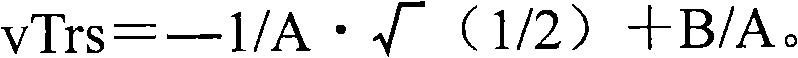

ActiveCN104024462AImprove securityExcellent brittle crack propagation stop characteristicSheet steelVolumetric Mass Density

Provided are: a high-strength thick steel plate for construction having excellent characteristics for preventing the diffusion of brittle cracks, said plate being used for ships and having a preferred plate thickness of at least 50 mm; and a method for producing the thick steel plate. The thick steel plate has excellent characteristics for preventing the diffusion of brittle cracks, characterized in that: the main constituent of the metal structure is bainite; the steel plate has an aggregate structure in which the density (I) in the RD / / (110) plane at the plate thickness center is at least 1.5; and the Charpy fracture appearance transition temperature (vTrs) at the surface and plate thickness center is not more than -40 DEG C. More preferably, the Charpy fracture appearance transition temperature (vTrs) at the plate thickness center, and the density (I) in the RD / / (110) plane satisfy formula (1). vTrs(1 / 2t) - 12 IRD / / (110)[1 / 2t] <= -70 ...(1), wherein, vTrs(1 / 2t) is the fracture appearance transition temperature at the plate thickness center ( DEG C), and IRD / / (110)[1 / 2t] is the density in the RD / / (110) plane at the plate thickness center.

Owner:JFE STEEL CORP

Welded structure having excellent resistance to brittle crack propagation and welding method therefor

InactiveUS7748596B2Maintain good propertiesImprove toughnessCooking-vessel materialsArc welding apparatusCrazingSectility

A welding method for manufacturing welded structures having excellent properties to prevent the propagation of brittle fracture occurring in welded joints, characterized by the step of forming a repair weld having a greater toughness than that of a butt weld and an outer edge whose angle φ with respect to the longitudinal direction of the butt weld is not less than 10 degrees and not more than 60 degrees, by applying repair welding to a region to arrest a brittle crack in a butt-welded joint where a brittle crack is likely to propagate after removing part of the butt-welded joint, in said region, by gouging or machining.

Owner:NIPPON STEEL CORP

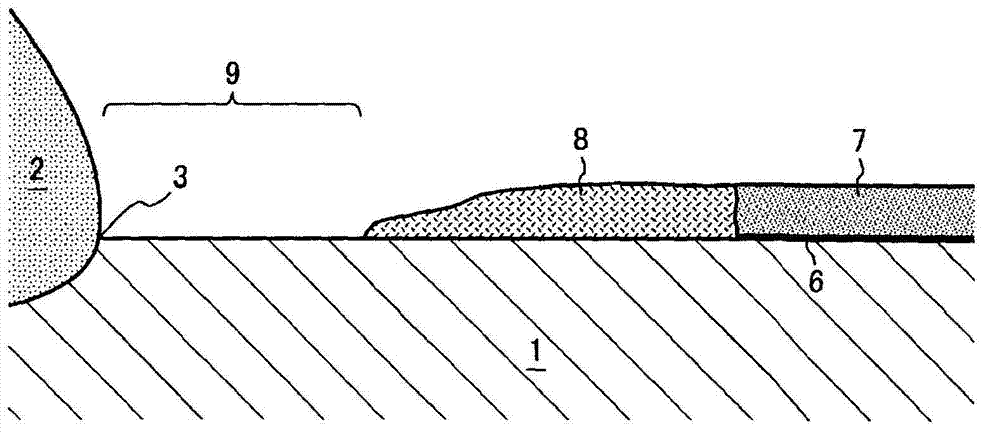

Weld structure having resistance to brittle crack propagation

InactiveCN102712063AAvoid destructionInhibit expansionArc welding apparatusFurnace typesButt weldingCrazing

Disclosed is a weld structure in which a steel plate weld joint is formed by butt-welding steel plates together, wherein: an anti-crack control section in which the propagation of brittle cracks generated in the steel plate weld joint are stopped is disposed on at least one section of the steel plate weld joint; and the outer peripheral section of an arrestor member configuring the anti-crack control section is formed on the front and rear of the steel plate weld joint in the lengthwise direction so as to intersect with the steel plate weld joint at an angle between 60 DEG to 120 DEG relative to the lengthwise direction. As a consequence, it is possible to prevent brittle cracks from propagating the weld joint or the base material even when brittle cracks form on the weld joint.

Owner:NIPPON STEEL CORP

Welded structure with excellent resistance to brittle crack propagation

InactiveCN102271861AAvoid spreadingIncrease productivityArc welding apparatusDomestic vesselsCrazingSheet steel

The present invention relates to a welded structure wherein steel plates having at least parts of the base metal with a brittle crack arrest toughness Kca of 4000 N / mm<1.5> or more are butt welded together so as to form a welded joint, wherein at least one location of the welded joint is provided with a crack control part comprising an arrester member comprising a steel material with a brittle crack arrest toughness Kca of 6000N / mm<1.5> or more and arrester welded joints (6) formed by the arrest member being butt welded to steel plates (1) and wherein outer edges of the arrester member are formed so as to slant from the weld line of the steel plate welded joint (2) by 15 DEG to 50 DEG with respect to the longitudinal direction of the welded joint.

Owner:NIPPON STEEL CORP

TA (1-18)/5 series aluminum alloy/TA (1-18) composite board and welding method

ActiveCN108857035ACompliant with industrial application standardsNon-electric welding apparatusBoundary effectsAlloy composite

In order to solve the technical problem that the aluminum alloy easily produces brittle crack or interface delamination in a single-sided or double-sided explosion welding process of the titanium andhigh-strength aluminum alloy composite board, by using the interface binding energy minimum principle, the window rule and the limit rule as the theoretical principles, the lower limit welding dynamicand static parameter windows of TA (1-18) / 5 series aluminum alloy / TA (1-18) are constructed and calculated, the sparse wave boundary effect eliminating technology, the aluminum alloy plate anti-deformation brittle crack control technology and the annealing process parameters for eliminating the explosion stress of the TA (1-18) / 5 series aluminum alloy / TA (1-18) single-sided or double-sided composite board are comprehensively used, the method for obtaining the TA (1-18) / 5 series aluminum alloy / TA (1-18) high-strength double-sided composite material with a welding rate of 100% and a complete set of welding process parameters is obtained from experiments, the onetime explosive welding of TA (1-18) / 5 series aluminum alloy composite material is achieved successfully, and the technical scheme and technological method are provided for the application of light high-strength high-corrosion-resistant composite materials.

Owner:ARMY ENG UNIV OF PLA

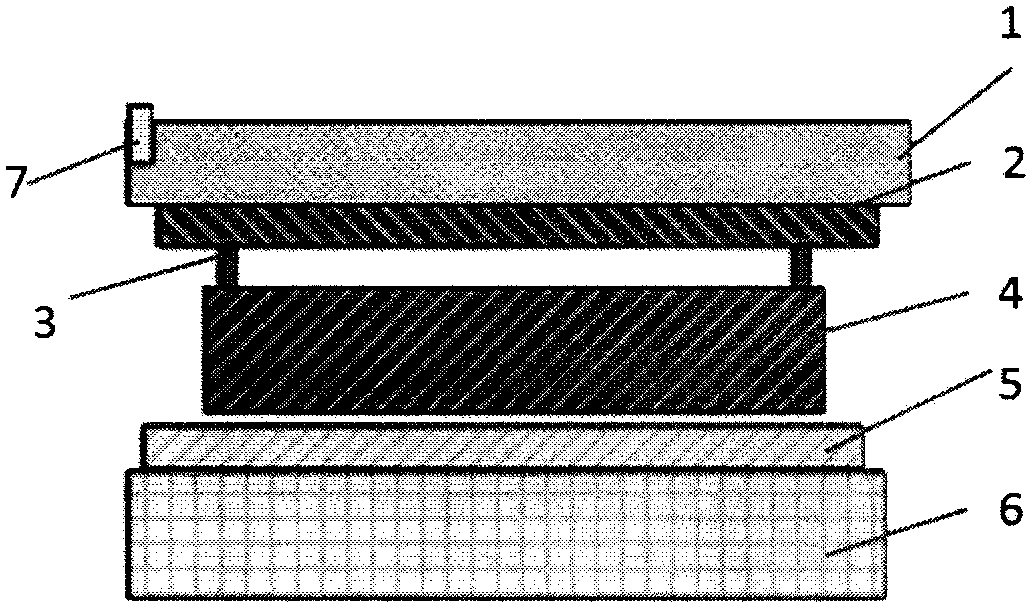

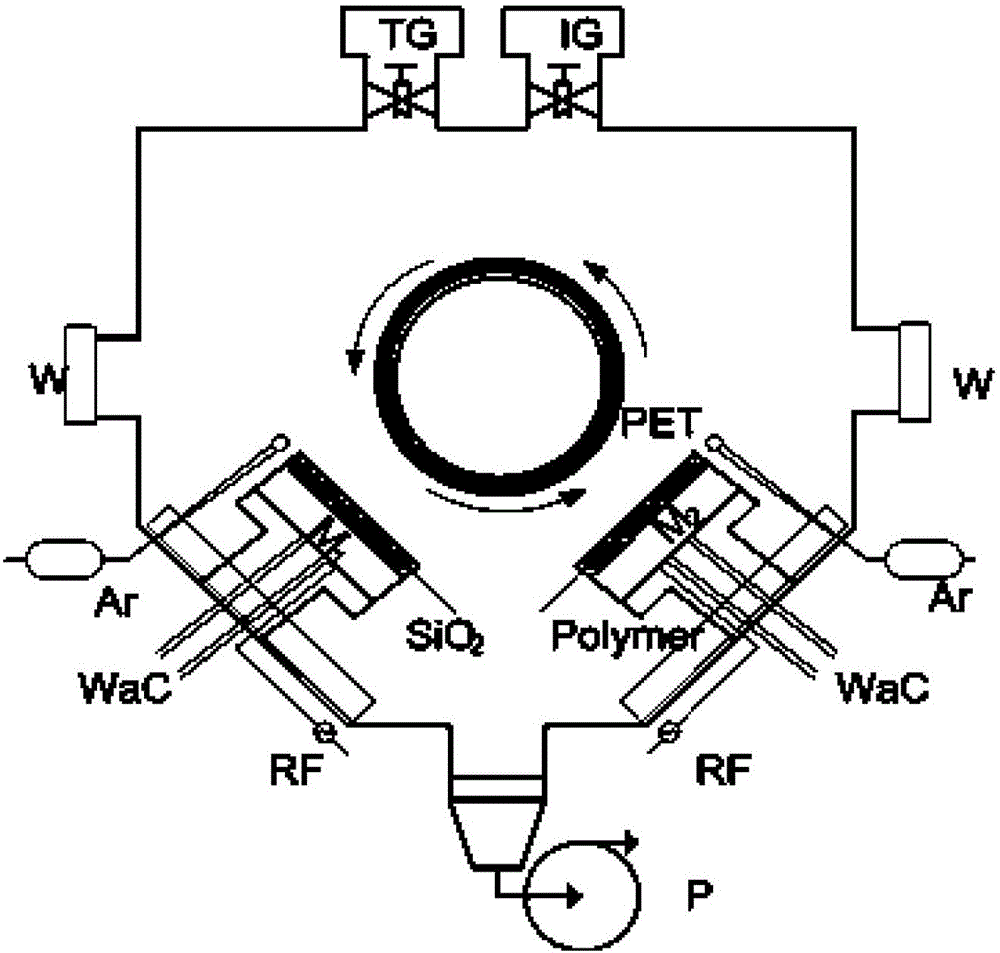

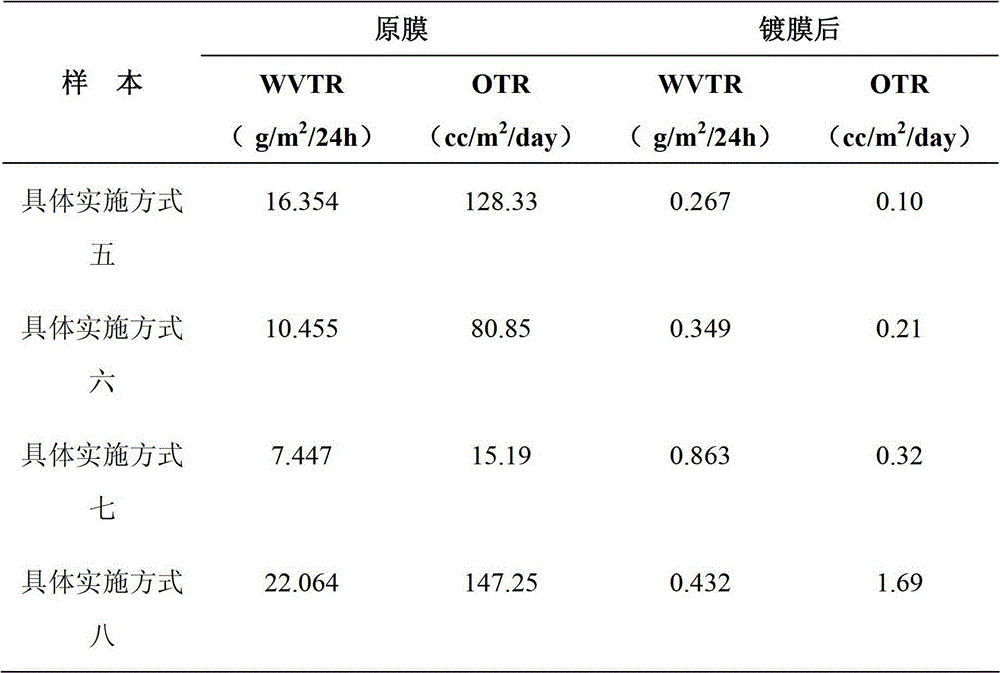

Crack-free multilayer high-barrier packaging film prepared by adopting rotary radio frequency magnetron sputtering method

InactiveCN102877036AReduce brittlenessGood flexibilityVacuum evaporation coatingSputtering coatingEpoxyRadio frequency magnetron sputtering

The invention discloses a crack-free multilayer high-barrier packaging film prepared by adopting a rotary radio frequency magnetron sputtering method, relating to a preparation method of a composite packaging film and solving the problem of poor barrier property and durability caused by brittle cracks on the traditional silicon oxide film. A preparation method of the crack-free multilayer high-barrier packaging film comprises the steps of: 1, placing a plastic substrate subjected to ultrasonic cleaning and corona treatment in a vacuum chamber; 2, winding the substrate on a roller for fixing, regulating a vacuum system; 3, introducing Ar gas, regulating a working pressure, driving the substrate to rotate by the roller; 4, starting a radio frequency power supply, firstly pre-sputtering a SiO2 porcelain target and an epoxy resin target, then opening a baffle plate, alternatively depositing an epoxy resin film layer and a SiO2 porcelain film layer, and preparing the crack-free multilayer high-barrier packaging film. The crack-free multilayer high-barrier packaging film prepared by adopting the preparation method is repeatedly folded for 100 times, and is degraded in transmission property to below 10 percent so that excellent durability and barrier property are shown. The crack-free multilayer high-barrier packaging film is mainly applied to package of foods, precision machinery parts, electronic components and medical instruments.

Owner:HARBIN UNIV OF COMMERCE

High-strength steel having superior brittle crack arrestability, and production method therefor

InactiveUS20170327922A1Excellent brittle crack arrestabilityHigh yield strengthFurnace typesHeat treatment furnacesUltimate tensile strengthImpurity

Provided are high-strength steel having superior brittle crack arrestability and a production method therefor. The high-strength steel comprises 0.05-0.1 wt % of C, 0.9-1.5 wt % of Mn, 0.8-1.5 wt % of Ni, 0.005-0.1 wt % of Nb, 0.005-0.1 wt % of Ti, 0.1-0.6 wt % of Cu, 0.1-0.4 wt % of Si, at most 100 ppm of P, and at most 40 ppm of S with the remainder being Fe and other inevitable impurities, and has microstructures including one structure selected from the group consisting of a single-phase structure of ferrite, a single-phase structure of bainite, a complex-phase structure of ferrite and bainite, a complex-phase structure of ferrite and pearlite, and a complex-phase structure of ferrite, bainite, and pearlite. The high-strength steel has high yield strength and superior brittle crack arrestability.

Owner:POHANG IRON & STEEL CO LTD

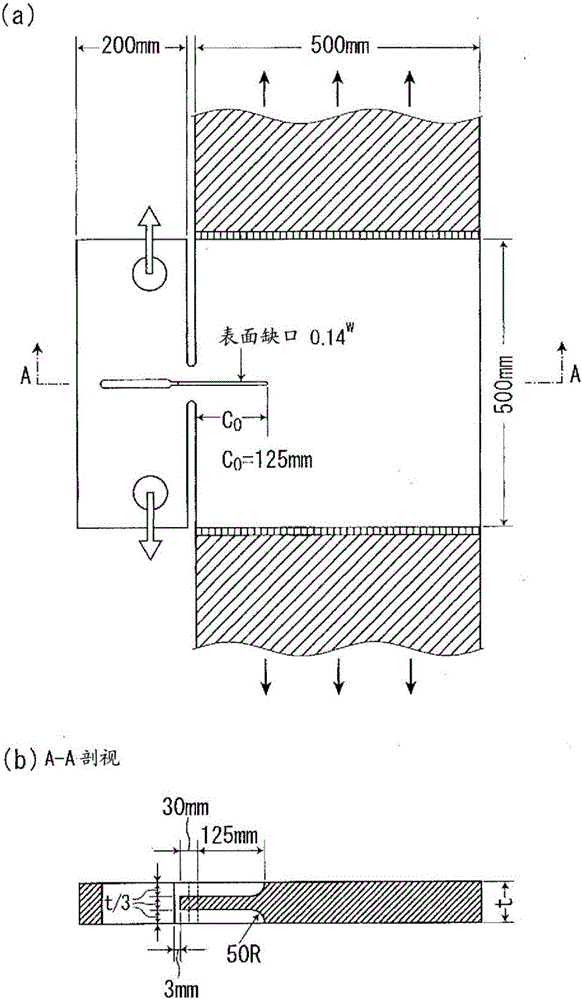

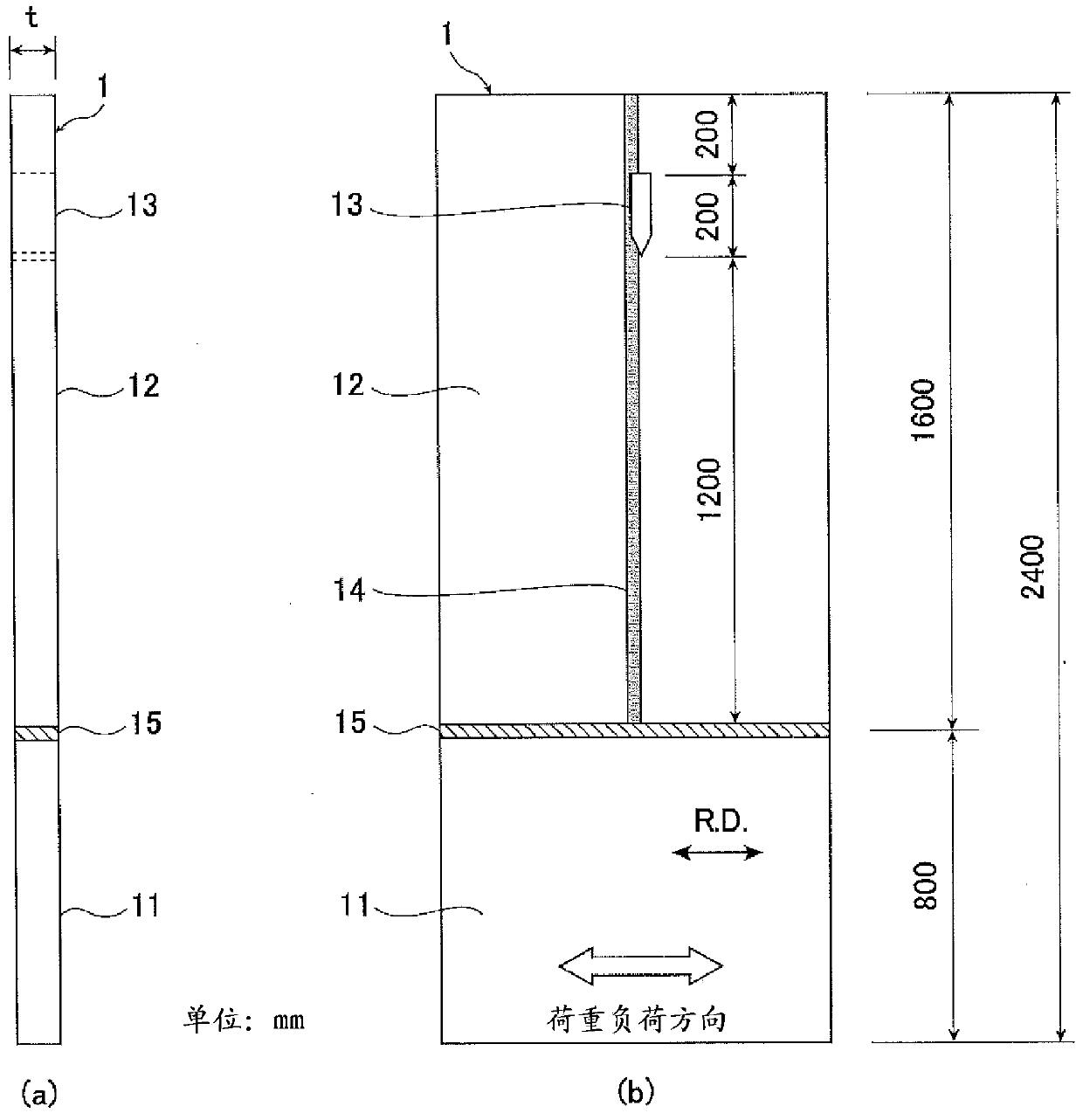

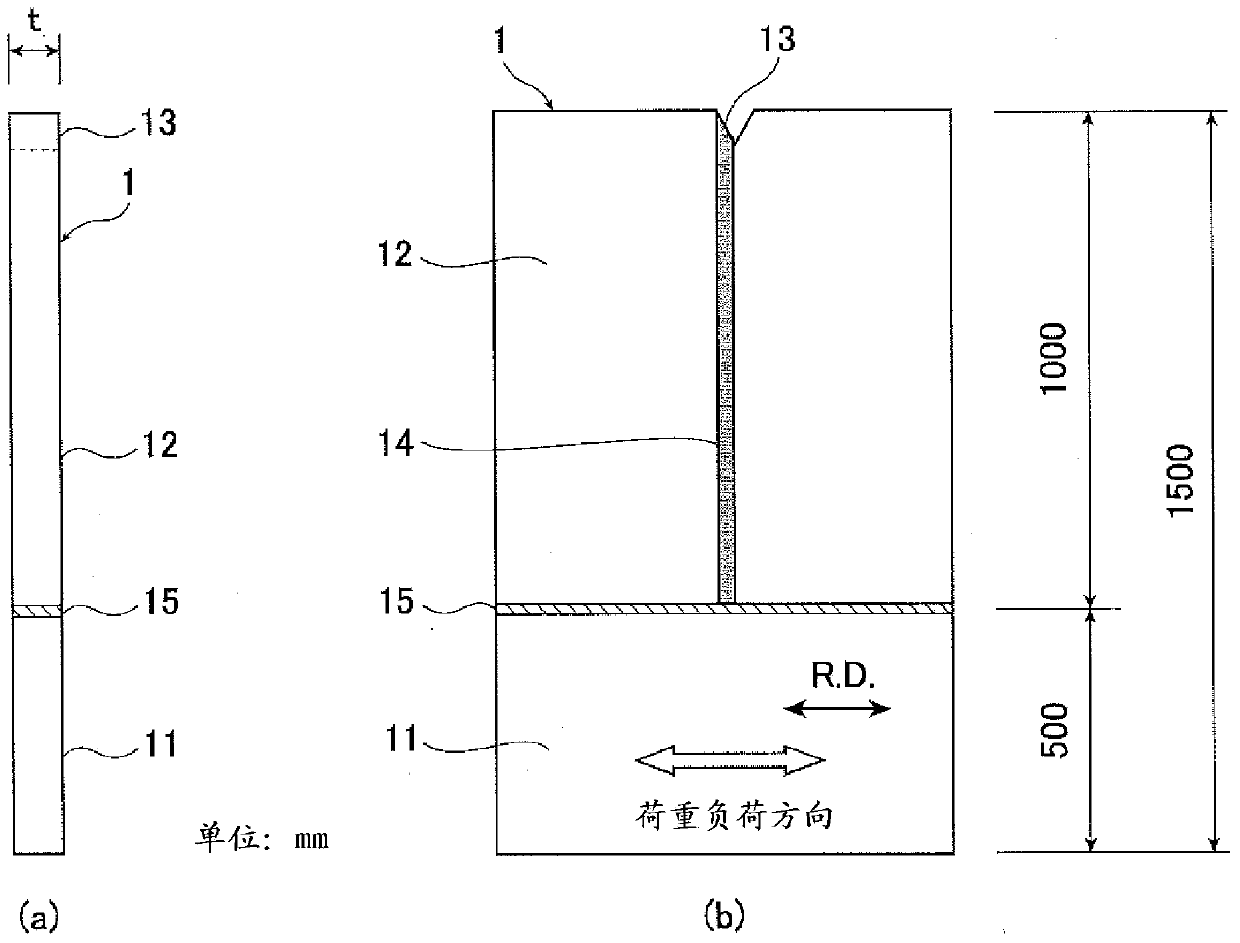

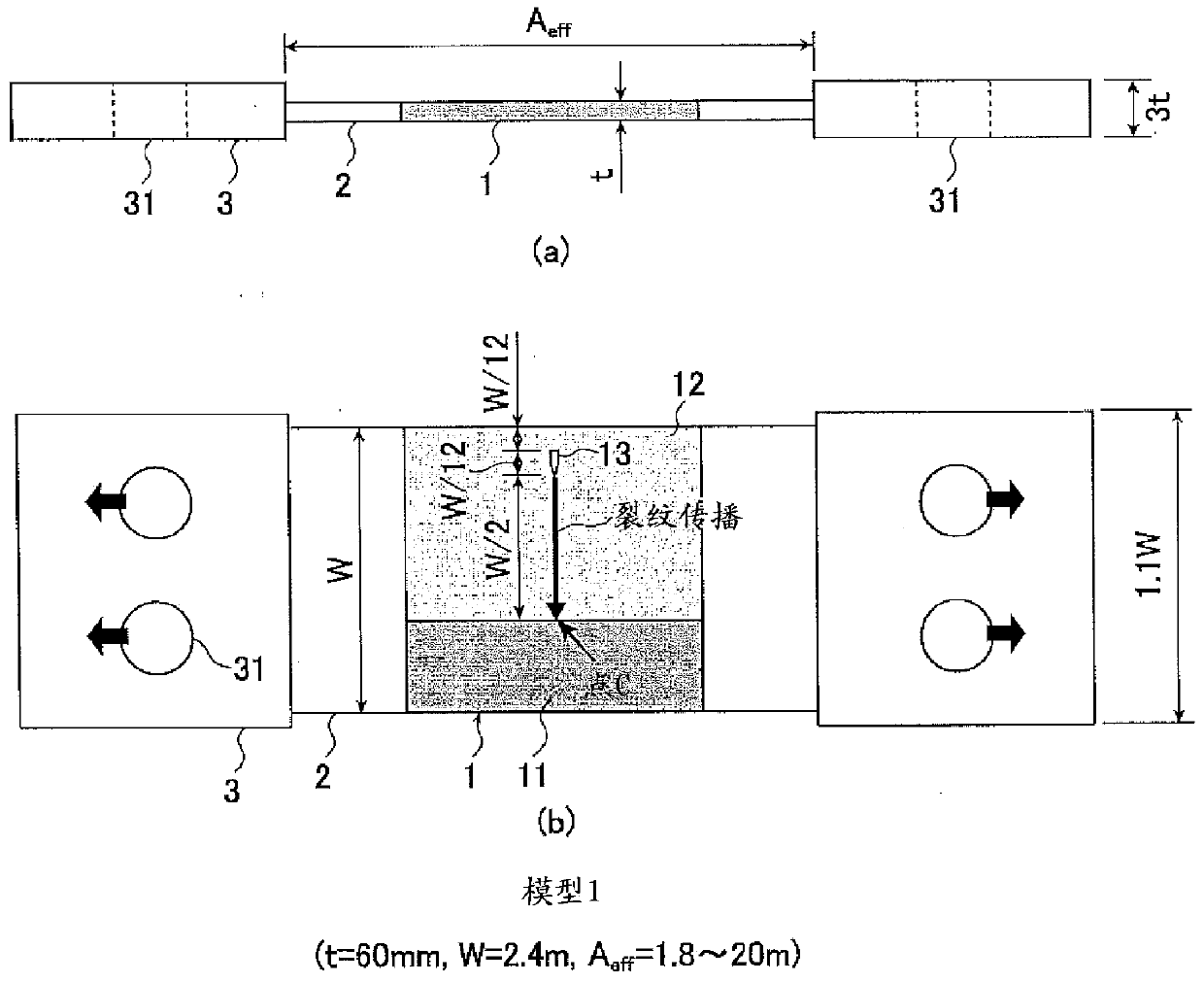

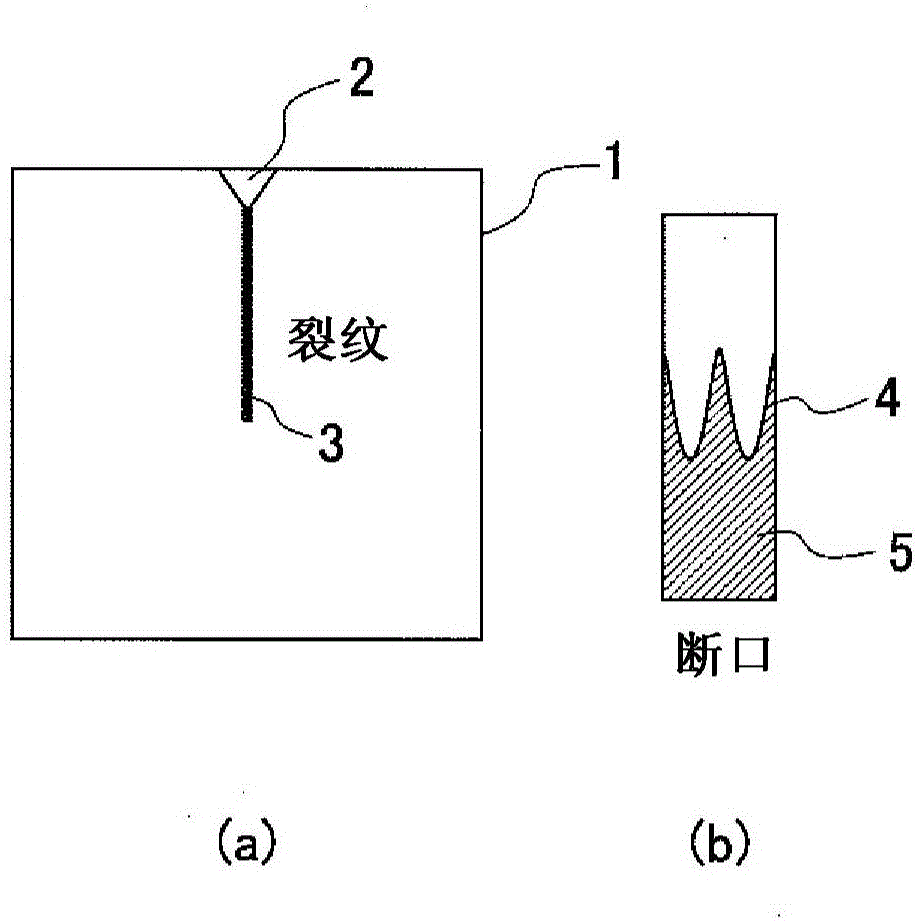

Method for evaluating long brittle crack arresting ability in thick steel plate, and testing device and method for manufacturing thick steel plate using same

InactiveCN104272084AExcellent propagation stop performanceMaterial strength using tensile/compressive forcesTest sampleTensile testing

Provided is a testing device and a method for evaluating long brittle crack arresting ability that is appropriate for an actual ship of thick steel plate (mainly thick steel plate having a thickness of at least 50 mm), the thick steel plate having excellent brittle crack arresting ability and being suitable for use in large container ships, bulk carriers, etc. When a tensile load is applied by a tensile tester in the direction perpendicular to the width of a large test sample having a width of at least 1.5 m, and long brittle crack arresting ability is evaluated for a long brittle crack of length 1 m or greater, a transmitting part for transmitting the tensile load from the tensile tester to the large test sample has thickened parts having a thickness at least 2.5 times that of the large test sample on either side of the center in the width of the large test sample spaced apart at least 2.8 times, preferably at least 4.1 times, the width of the large test sample, and the tensile load from the tensile tester is applied in positions on either side of the center of the large test sample in the direction perpendicular to the width by the thickened parts. A testing device having the transmitting part.

Owner:JFE STEEL CORP

High strength thick steel plate with superior brittle crack arrestability for high heat input welding and method for manufacturing same

ActiveCN105102651AImprove securityExcellent brittle crack propagation stop characteristicSheet steelSurface layer

Provided are a high strength thick steel plate, which has superior brittle crack arrestability for high heat input welding that has a plate thickness of 50 mm or greater and is suitably used in marine vessels, and a manufacturing method for the same. The present invention is a thick steel plate and a manufacturing method for the same, wherein the thick steel plate has: a specific component composition, a metal structure composed mainly of ferrite, and an aggregate structure in which the density at the RD / / (110) plane at the surface layer of the plate thickness is 1.3 or greater and the density at the RD / / (110) plane in the center part of the plate thickness is 1.8 or greater. Charpy fracture appearance transition temperature (vTrs) is −50°C or less at the surface layer and in the center part of the plate thickness.

Owner:JFE STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com