Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1925results about How to "Accurate evaluation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Using commercial share of wallet in private equity investments

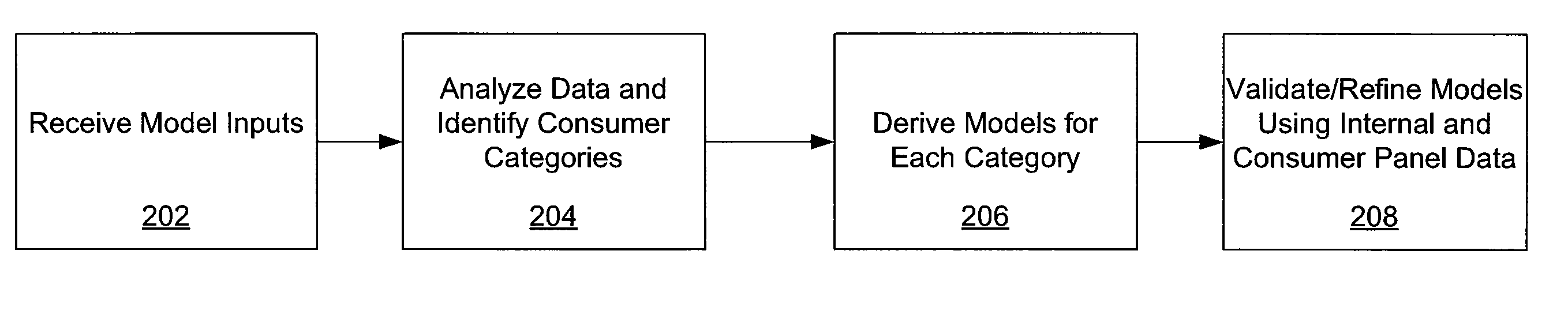

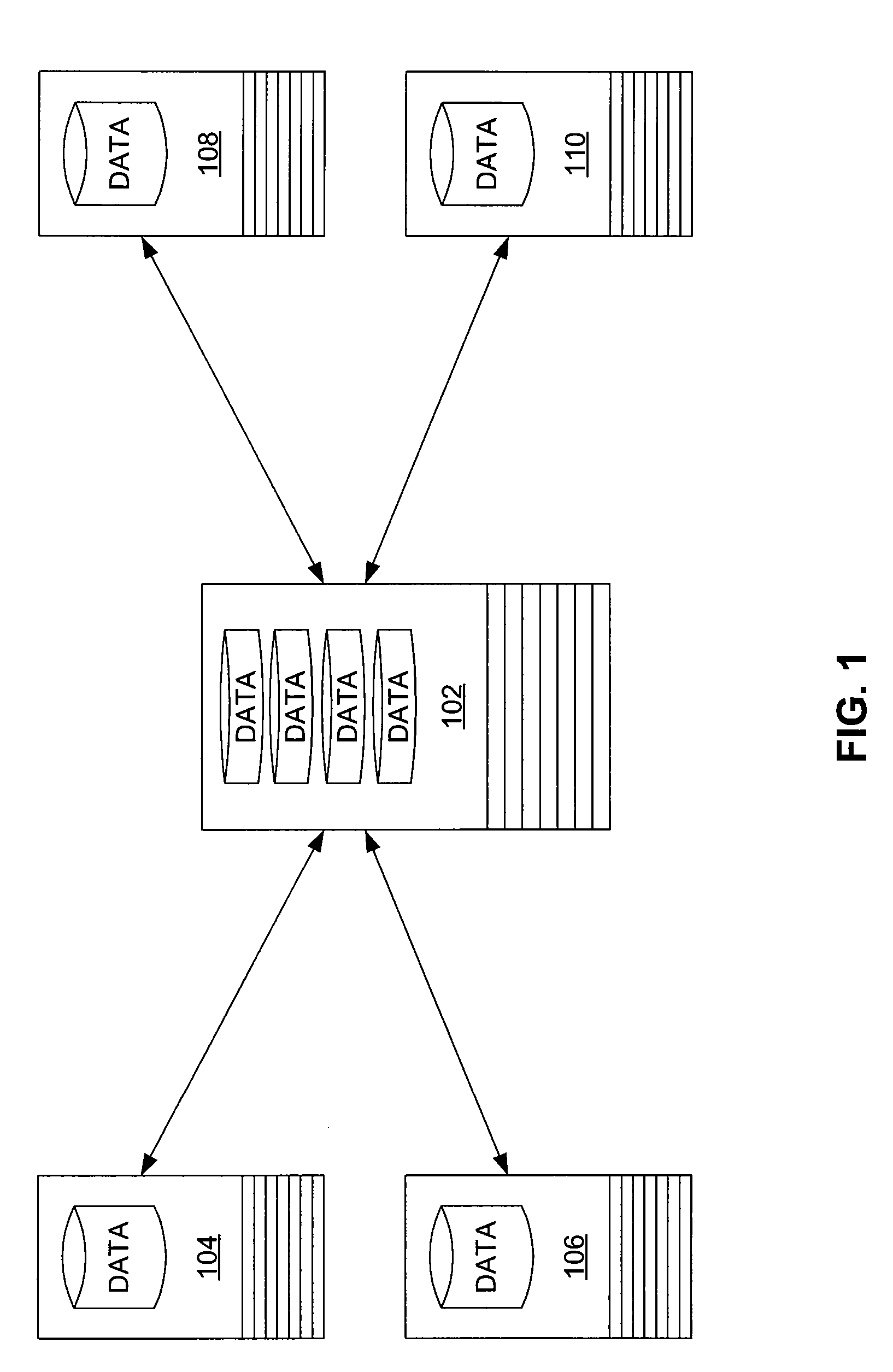

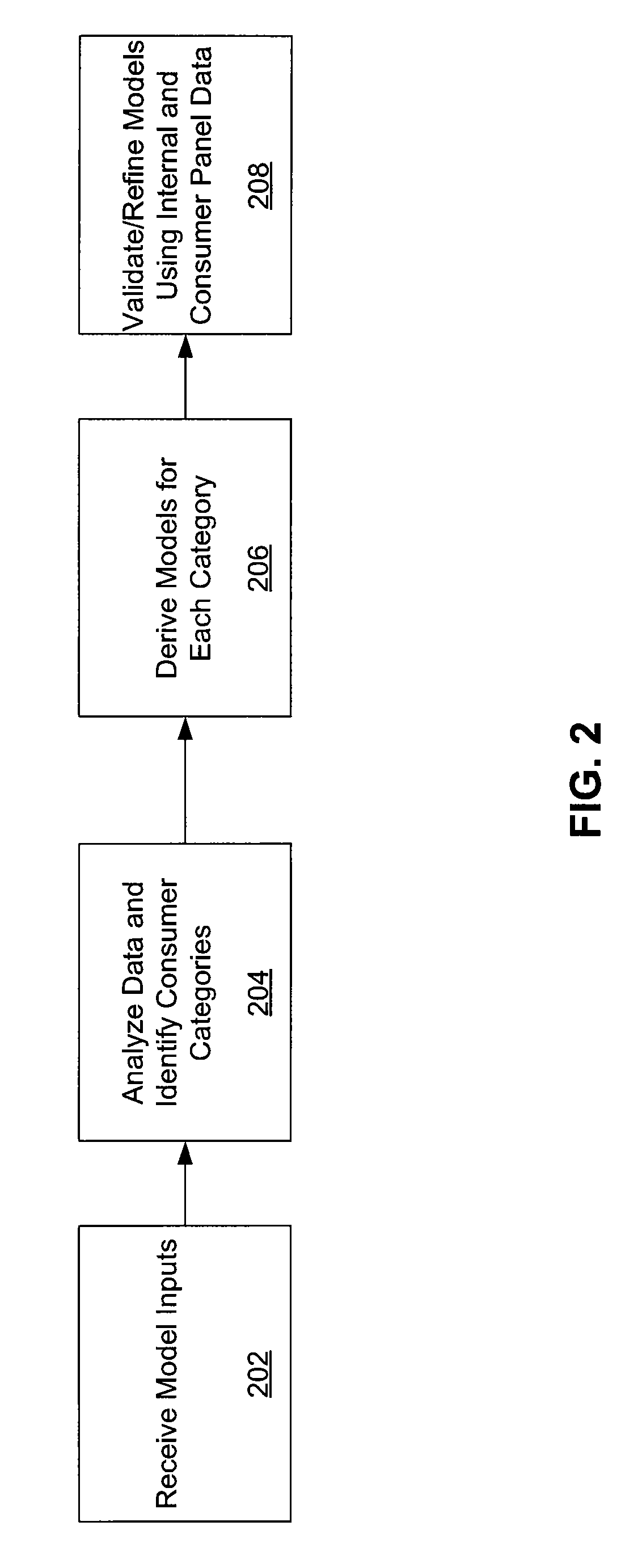

ActiveUS20070078741A1Accurate evaluationAccurate balanceFinanceMarket data gatheringData scienceModelling methods

Owner:AMERICAN EXPRESS TRAVEL RELATED SERVICES CO INC

Autonomous underwater vehicle trajectory tracking control method based on deep reinforcement learning

ActiveCN108803321AStabilize the learning processOptimal target strategyAdaptive controlSimulationIntelligent control

The invention provides an autonomous underwater vehicle (AUV) trajectory tracking control method based on deep reinforcement learning, belonging to the field of deep reinforcement learning and intelligent control. The autonomous underwater vehicle trajectory tracking control method based on deep reinforcement learning includes the steps: defining an AUV trajectory tracking control problem; establishing a Markov decision-making process model of the AUV trajectory tracking problem; constructing a hybrid policy-evaluation network which consists of multiple policy networks and evaluation networks;and finally, solving the target policy of AUV trajectory tracking control by the constructed hybrid policy-evaluation network, for the multiple evaluation networks, evaluating the performance of eachevaluation network by defining an expected Bellman absolute error and updating only one evaluation network with the lowest performance at each time step, and for the multiple policy networks, randomly selecting one policy network at each time step and using a deterministic policy gradient to update, so that the finally learned policy is the mean value of all the policy networks. The autonomous underwater vehicle trajectory tracking control method based on deep reinforcement learning is not easy to be influenced by the bad AUV historical tracking trajectory, and has high precision.

Owner:TSINGHUA UNIV

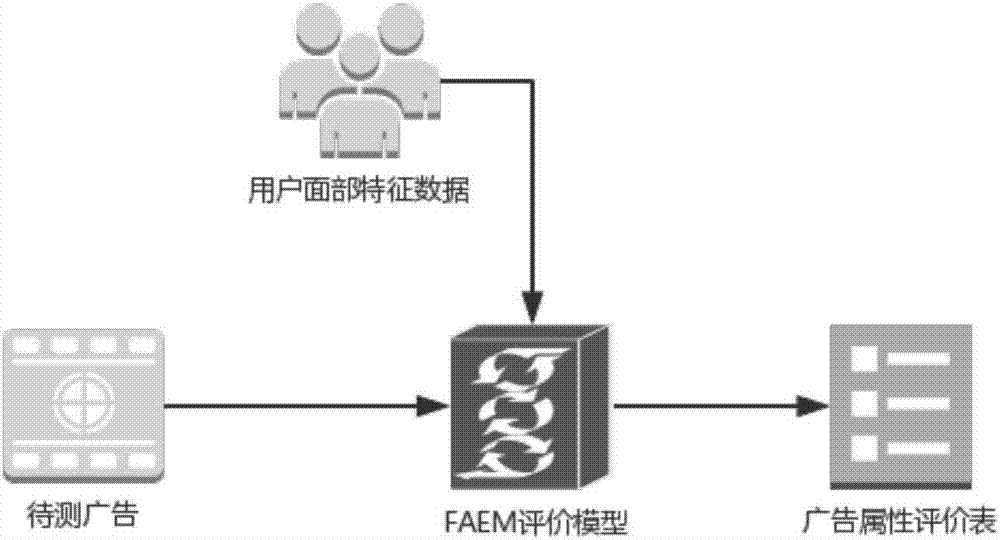

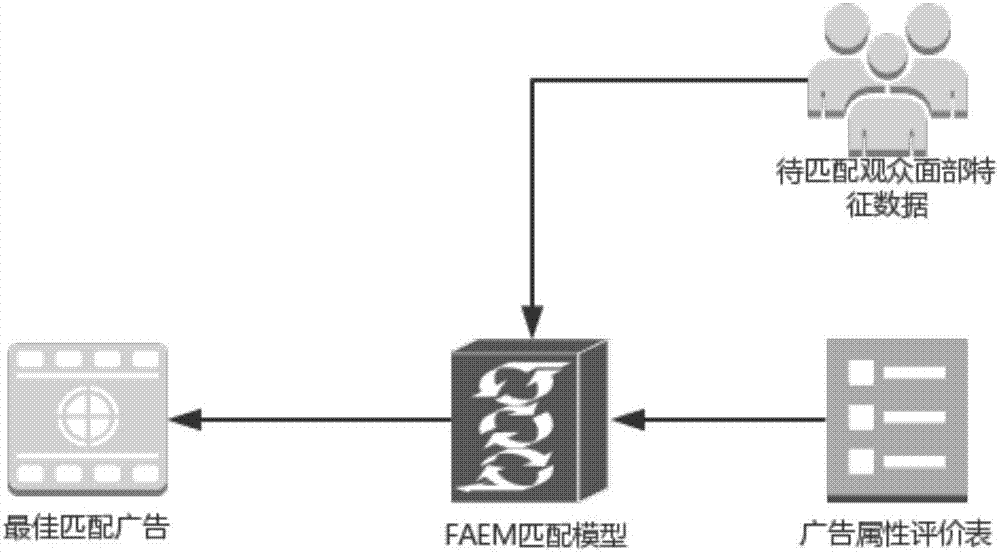

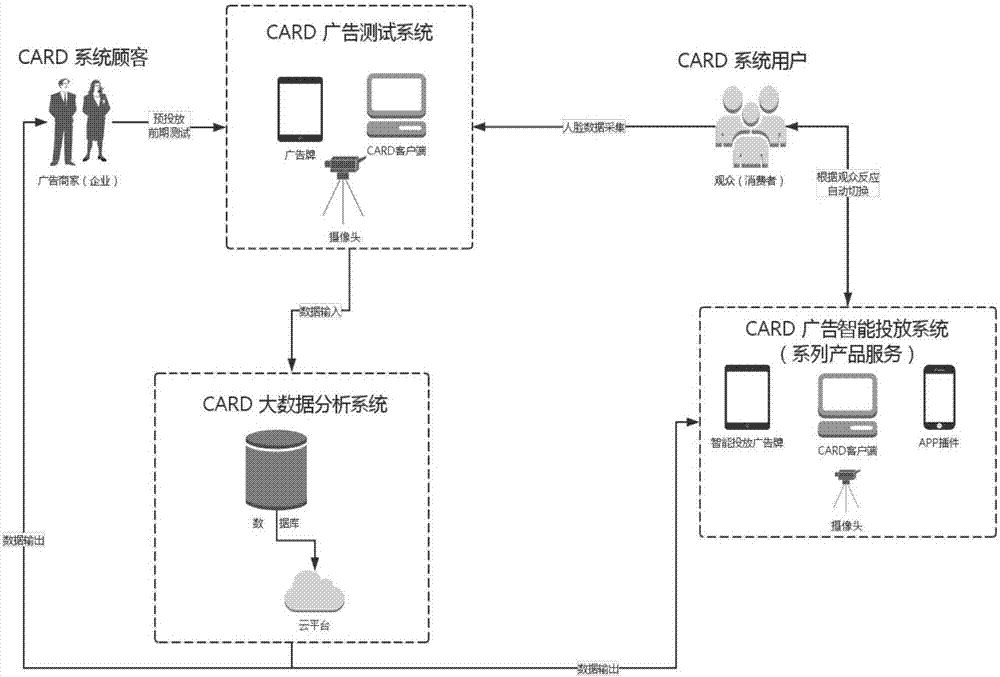

Advertisement injecting effect evaluation and intelligent push decision method based on face identification and big data analysis

The invention discloses an advertisement injecting effect evaluation and intelligent push decision method based on face identification and big data analysis. The advertisement injecting effect evaluation and intelligent push decision method comprises a face identification technology is employed to obtain face feature data of the audience group, and the data is introduced into an advertisement injecting effect evaluation module as parameters, and is used for quantifying the advertisement injecting effect; furthermore, historical data is stored in a database, a data analysis system can carry out further analysis, the analysis result can be provided for the advertiser as an injecting decision reference, and can also be provided for the advertising agency who can carry out reasonable bidding and charging on the advertising position. At the same time, an FAEM matching algorithm is employed to match the advertisement played at present with audience face feature data at present, and advertisement push is carried out in dependence on the matching result. According to the invention, accurate evaluation of the advertisement injecting effect can be given out scientifically and objectively, and advertisements can be injected selectively and intelligently in dependence on audiences of the advertisements.

Owner:杨伊迪

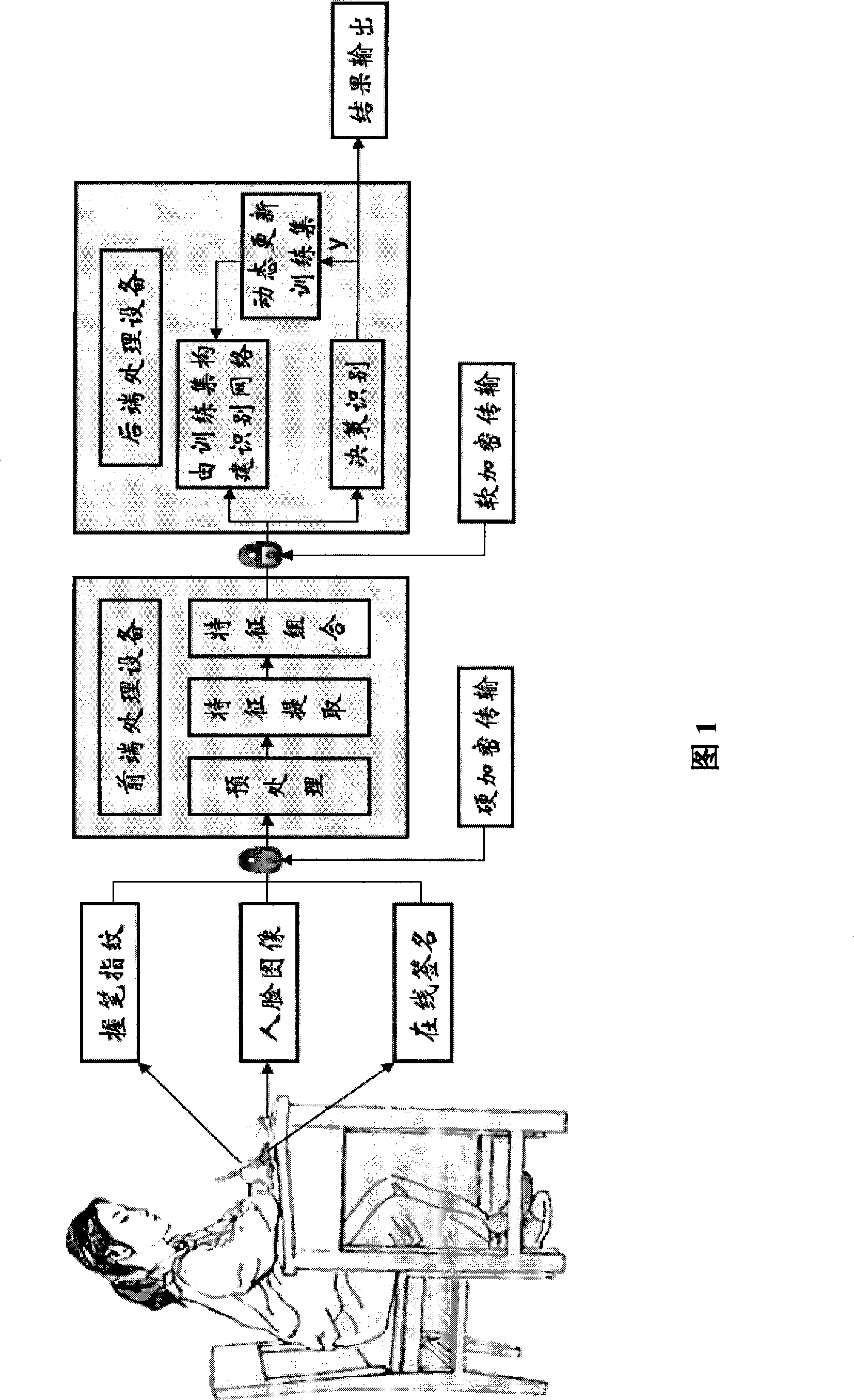

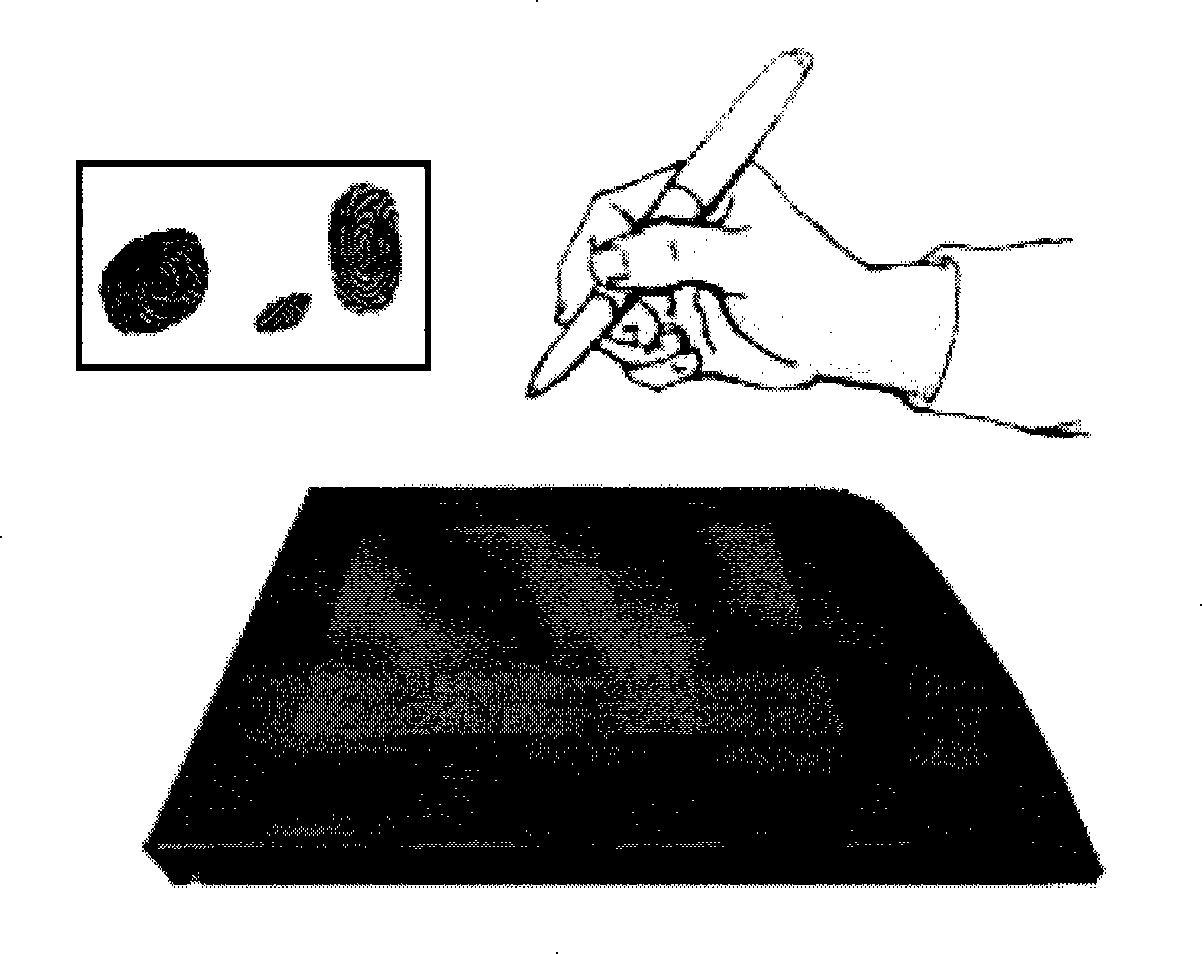

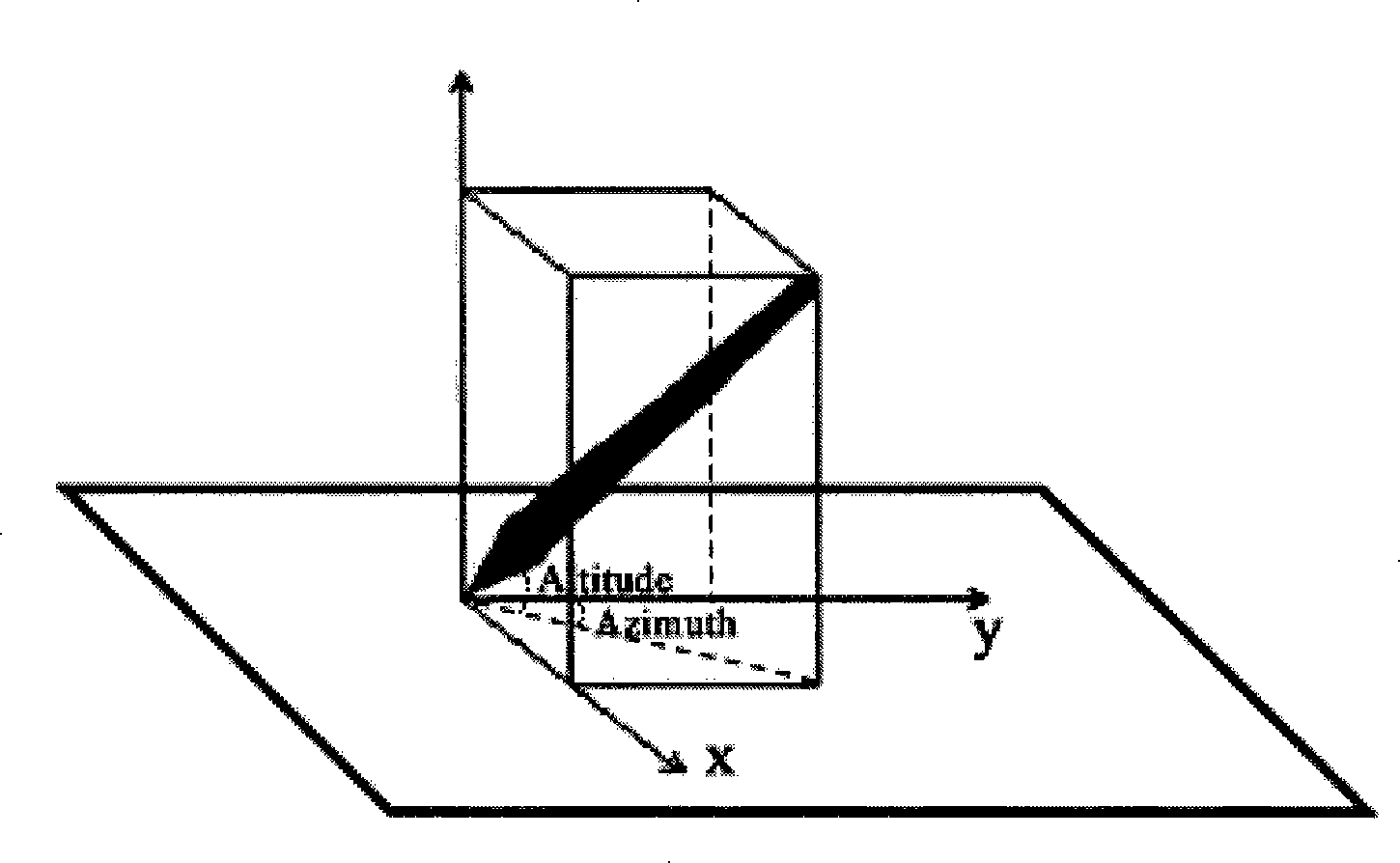

Examiner identity appraising system based on bionic and biological characteristic recognition

InactiveCN101246543AProtect personal information securityProprietaryCharacter and pattern recognitionHigh dimensionalityObservation point

The invention discloses an examiner identification system based on bionic and biometric identification, using synthetically various biometric identification methods based on high-dimension space geometric shape adaptive coverage theory to achieve identification of examiner identity. First of all, through an acquisition equipment, gripping-pen fingerprint is obtained, on-line signature and facial image, and then the data is mapped into high-dimension space observation point after feature extraction, last according to similar sample point continuity in the high-dimension space, through the relation between the observation point and sample set coverage area to obtain different biological characteristic network match degree, then through match degree fusion decision algorithm to identify identity of the examiner, and through automatic addition of new verification data to achieve sample set dynamic updating and trend forecast. Identification of the invention is fast, result is accurate, and the invention is not only suitable for examiner identification in existing examination mode, but also has broader application in the future machine- examination mode.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Method for hybrid rasterization and raytracing with consistent programmable shading

ActiveUS20070035545A1Consistent imageAccurate evaluationImage data processing detailsSpecial data processing applicationsComputer imageVirtual camera

A method of generating a computer image wherein secondary raytrace vectors are calculated for the image after the image is rendered using rasterization. The secondary raytrace vectors are based on virtual camera angles that are stored during the rasterization process. The raytrace vectors can be calculated using the same processor as the rasterization, thereby providing greater consistency in the image. A metaprogrammed shader can also be applied to the generated image, wherein the shader uses the same processor as the raytrace and rasterization steps. The metaprogrammed shader allows the shader algorithm to be segmented for streamlined processing by the processor.

Owner:DASSAULT SYST 3DEXCITE +1

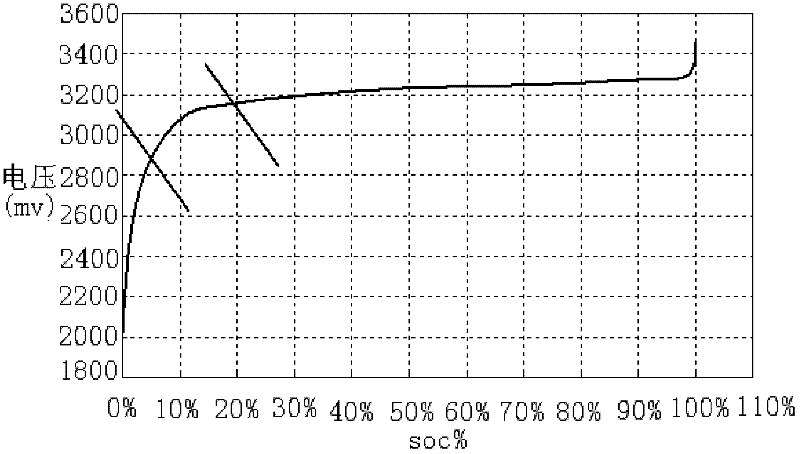

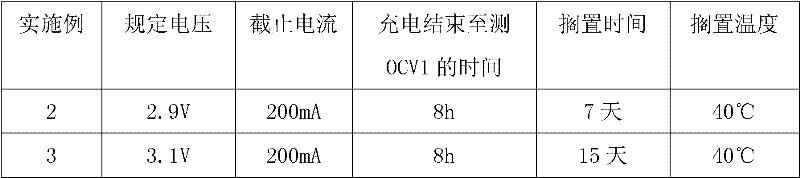

Method for evaluating self-discharge consistency of lithium iron phosphate battery

ActiveCN102508165AGood voltage consistencyImprove self-discharge rateElectrical testingLithium iron phosphateElectrical battery

The invention discloses a method for evaluating self-discharge consistency of a lithium iron phosphate battery. The method mainly comprises the following steps of: measuring open circuit voltage after the battery is charged and open circuit voltage after the battery is laid at high temperature under the conditions of constant voltage and constant current; calculating the voltage drop of the battery, a mean value and a standard difference; and determining the upper control limit of the voltage drop to determine that the battery has high self-discharge consistency under the condition that the voltage drop does not surpass an upper specification limit. By the method for evaluating the self-discharge consistency of the lithium iron phosphate battery, evaluation accuracy, high production operability and obvious practical meaning are achieved, and the grouping consistency of the lithium iron phosphate battery is effectively improved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

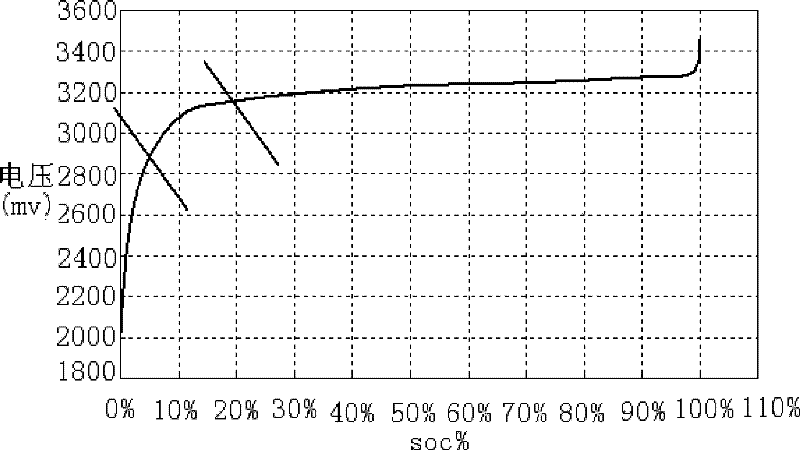

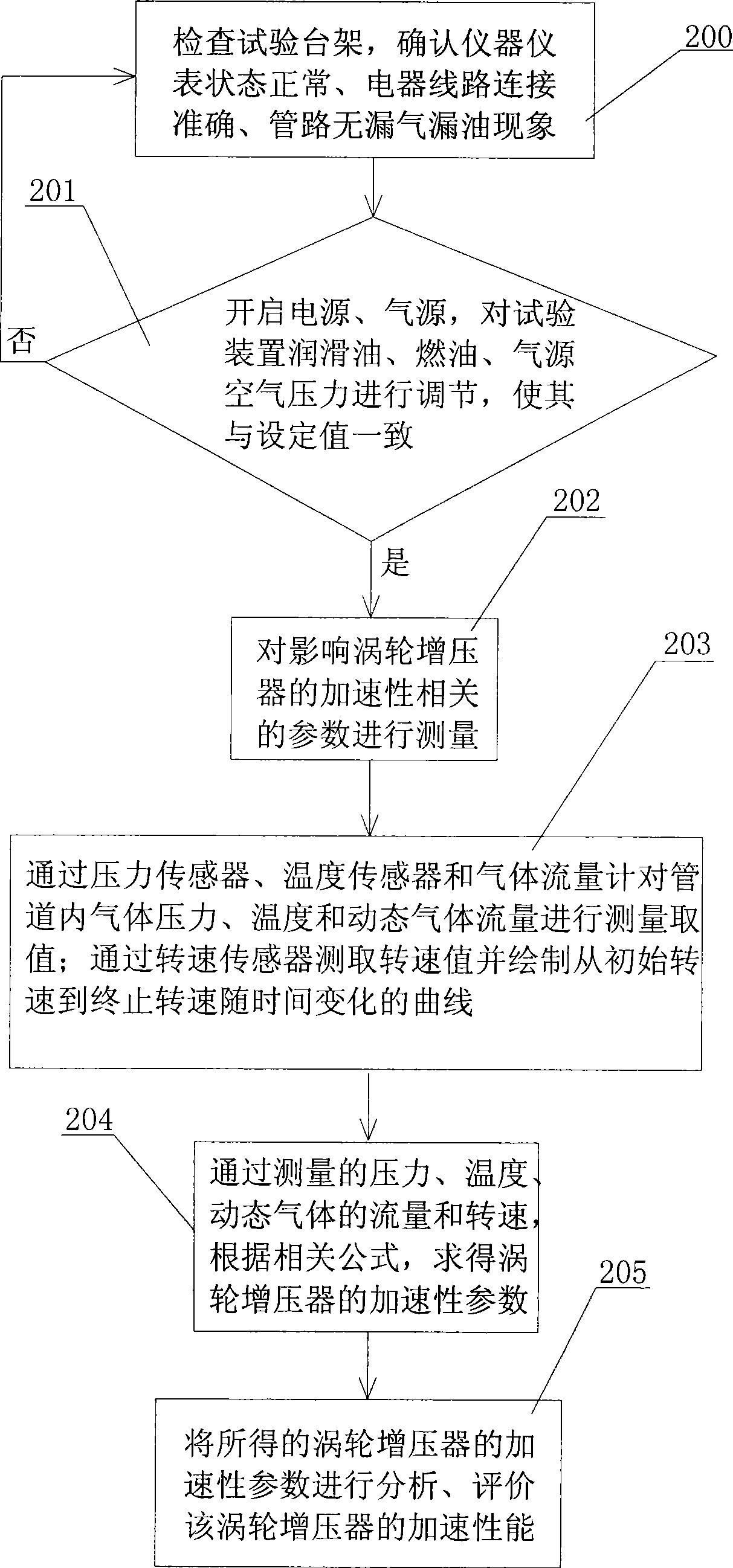

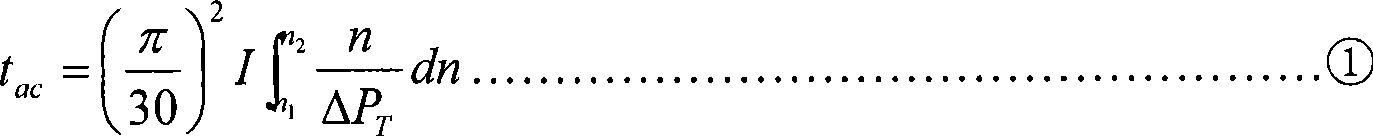

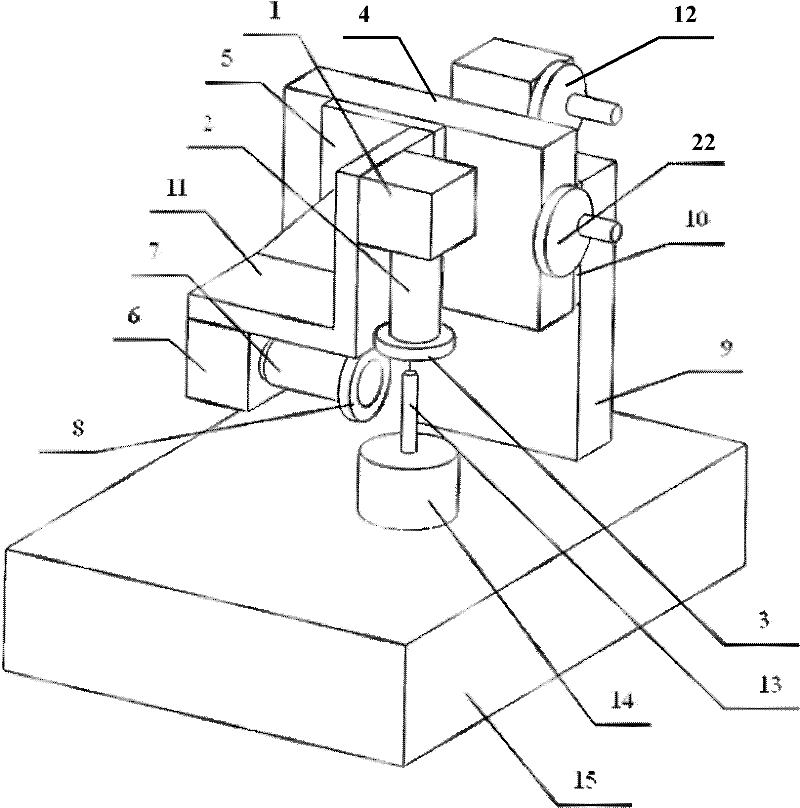

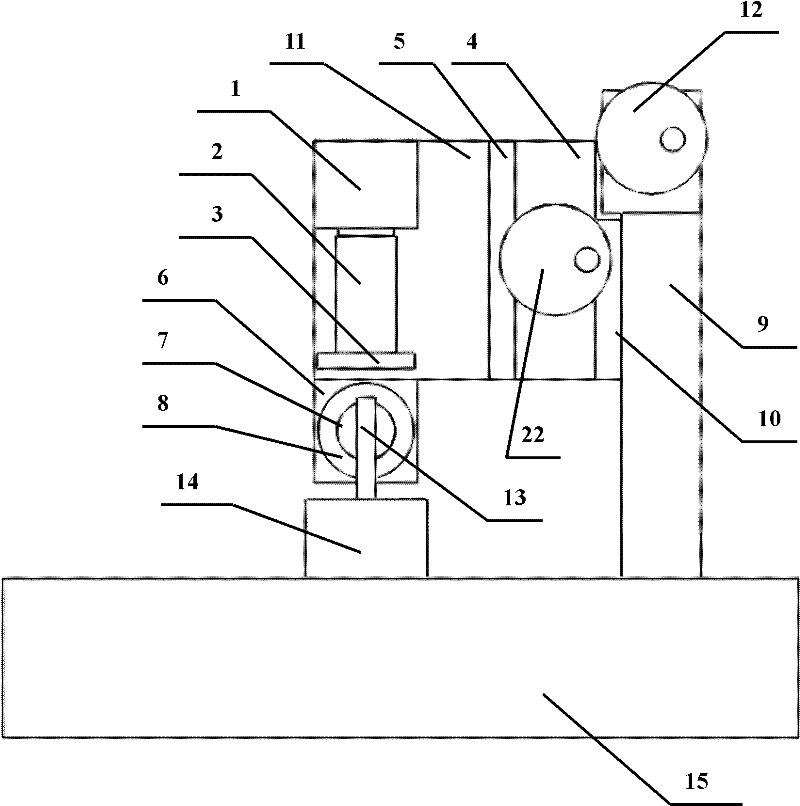

Acceleration performance evaluation test method and test apparatus of turbo-charger

InactiveCN101532910AImprove acceleration performanceAccurate evaluationMachine part testingInternal-combustion engine testingImpellerTurbocharger

The invention discloses an acceleration performance evaluation test method and a test apparatus of a turbo-charger. The acceleration performance evaluation parameters of the turbo-charger are obtained according to formula computing by measuring the parameters of the turbo-charger such as pressure, temperature, flow rate and rotate speed. The invention has the following advantages: the acceleration performance of the turbo-charger is accurately and conveniently evaluated by measuring and computationally analyzing acceleration parameter Acnp, and provides measuring means and judgment basis for improving and optimally designing the turbo-charger, compressor impeller and rotor system and improving the acceleration performance of supercharger.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Orthogonal vision detection system for detecting wear condition of end mill

ActiveCN102564314AClear and bright field of viewHigh precisionUsing optical meansCcd cameraLight source

The invention relates to an orthogonal vision detection system for detecting the wear condition of an end mill and belongs to the technical field of optical measurement and mechanical engineering. The orthogonal vision detection system comprises top surface and lateral surface CCD (Charge Coupled Device) cameras, top surface and lateral surface lenses, top surface and lateral surface ring-shaped light sources, an X-directional guide rail, a Z-directional guide rail, an X-directional sliding block, a Z-directional sliding block, a bracket, handwheels, a rotating table, a marble base, an image acquisition card and a computer. According to the invention, the double CCD cameras which are arranged in the orthogonal directions are adopted, an image analog signal of a wear region is acquired by the image acquisition card and is converted into a digital signal, computer-vision software is applied, the digital signal is processed by the computer and the width and the area of a wear zone of a rear tool face of the end mill are accurately measured, so that the detection of the wear condition of the end mill is implemented. The orthogonal vision detection system has the characteristics of non contact, high resolution, high automation degree and high speed. The fault-free operating time of machine tool equipment an be effectively prolonged and the product quality is improved. The orthogonal vision detection system has very important significance and practical value in application of an automatic machine tool.

Owner:常州飞石机器人系统有限公司

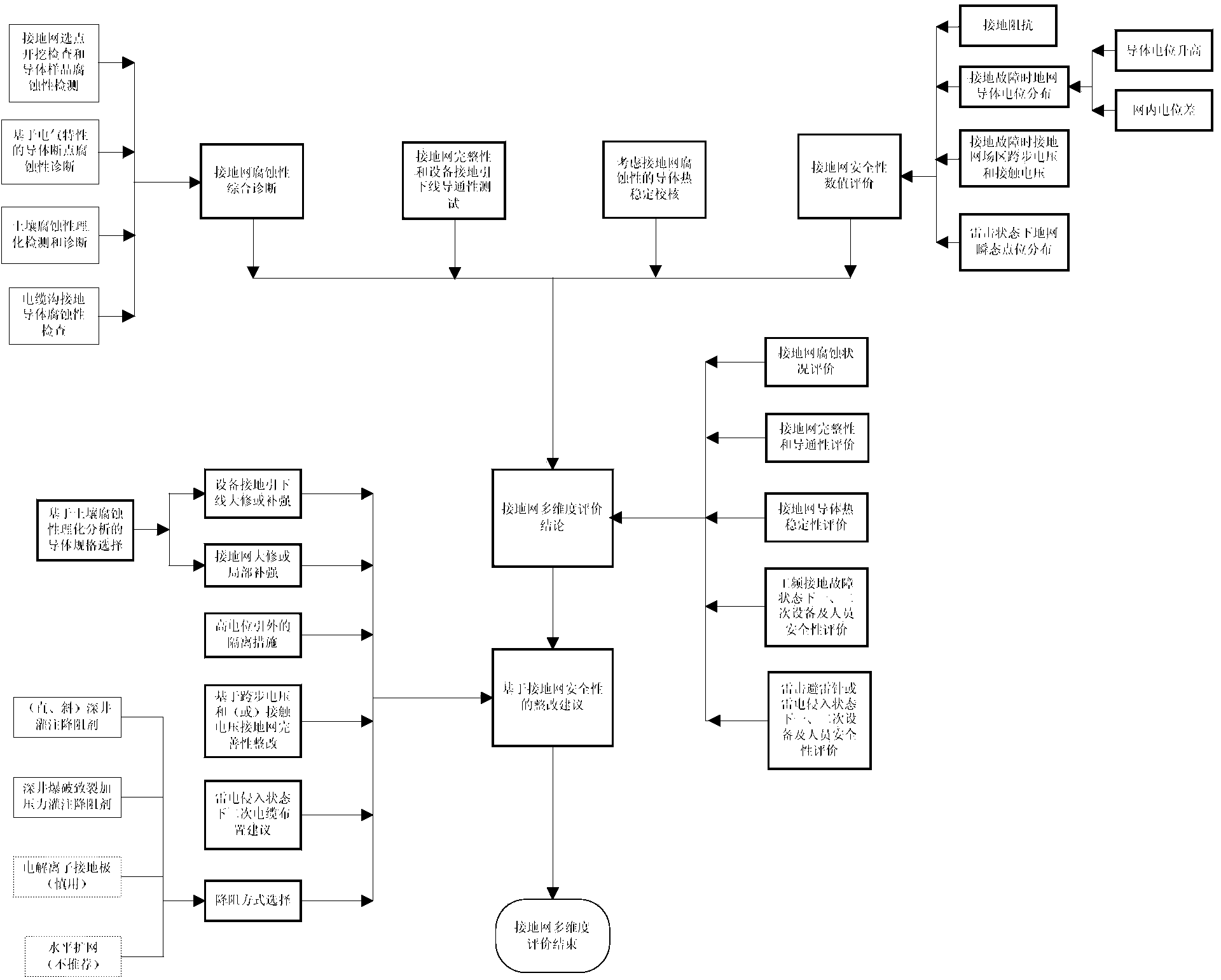

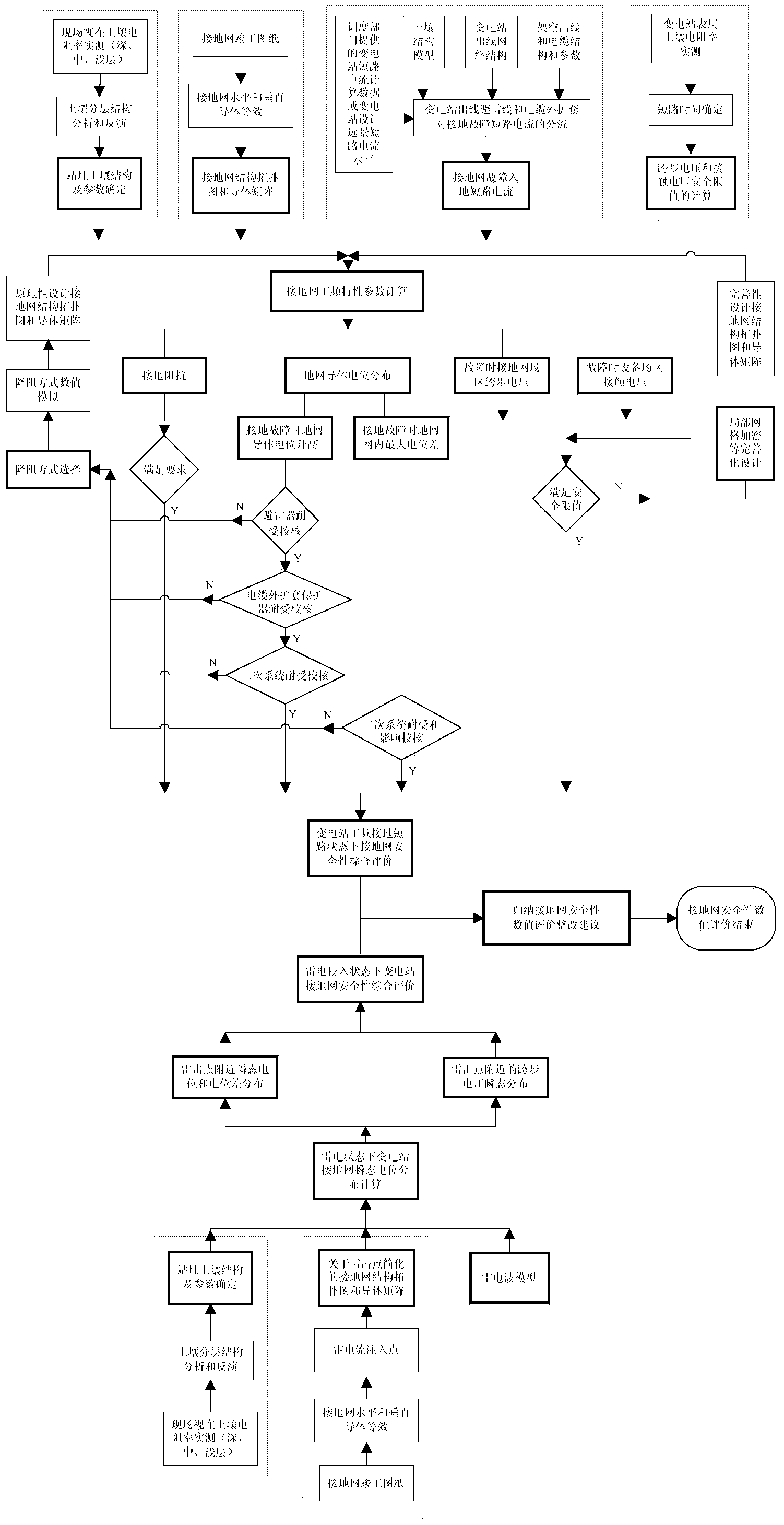

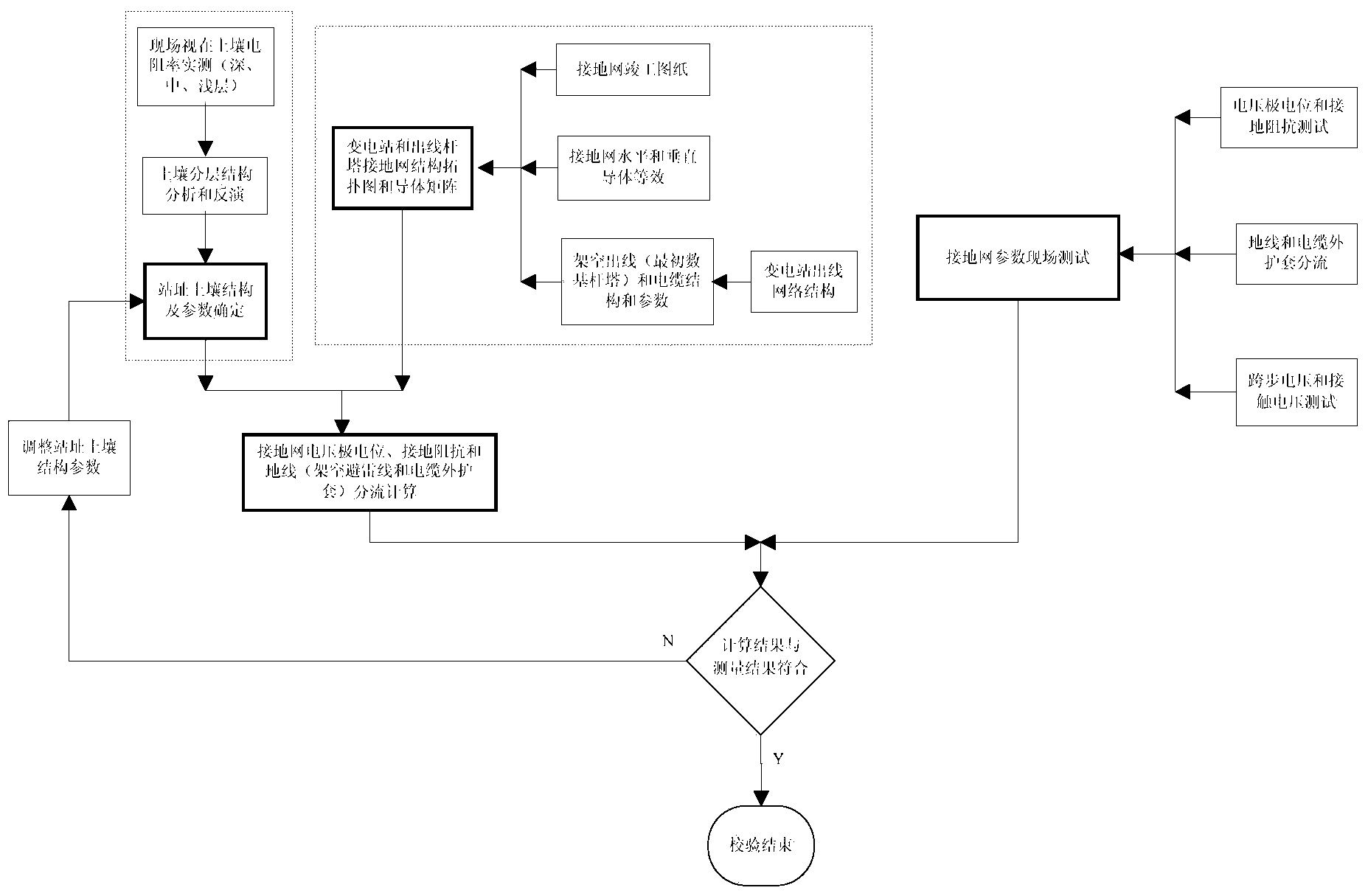

Multidimensional evaluation method for large-scale grounding grid

InactiveCN103616582AAccurate evaluationSolve evaluation problemsElectrical testingGrounding gridLightning strokes

A multidimensional evaluation method for a large-scale grounding grid includes the following steps of on-site testing, numerical calculation based on the electromagnetic field principle and multidimensional evaluation on the grounding grid. The foothold of the multidimensional evaluation method for the grounding grid is based on basic functions of the grounding grid, the basic functions are stream breaking and potential holding safety performance under power frequency grounding faults and lightning stroke faults, and the evaluation problems of characteristic parameters reflecting the safety performance of the grounding grid under the power frequency grounding faults and in the state of lightning stroke are mainly solved, wherein the characteristic parameters relate to grounding grid potential rising, potential difference in the grid, a step voltage, a contact voltage and the like. The multidimensional evaluation on the grounding grid is achieved from the aspects of the characteristic parameters of the grounding grid, integrity of the grounding grid, corrosion evaluation, thermal stability check and the like, safety of the grounding grid is expressed more scientifically, the evaluation on the state of the grounding grid is more accurate, and the safety problem and the defects of the grounding grid are rectified more effectively in a more pertinent mode.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

Method for hybrid rasterization and raytracing with consistent programmable shading

ActiveUS20080211804A1Consistent imageAccurate evaluationImage data processing detailsSpecial data processing applicationsVirtual cameraComputer image

A method of generating a computer image wherein secondary raytrace vectors are calculated for the image after the image is rendered using rasterization. The secondary raytrace vectors are based on virtual camera angles that are stored during the rasterization process. The raytrace vectors can be calculated using the same processor as the rasterization, thereby providing greater consistency in the image. A metaprogrammed shader can also be applied to the generated image, wherein the shader uses the same processor as the raytrace and rasterization steps. The metaprogrammed shader allows the shader algorithm to be segmented for streamlined processing by the processor.

Owner:SERIOUS HACK +1

Biological optical measurement instrument

ActiveUS20080188729A1Reduce numberAccurate evaluationElectroencephalographySensorsActive timeOptical measurements

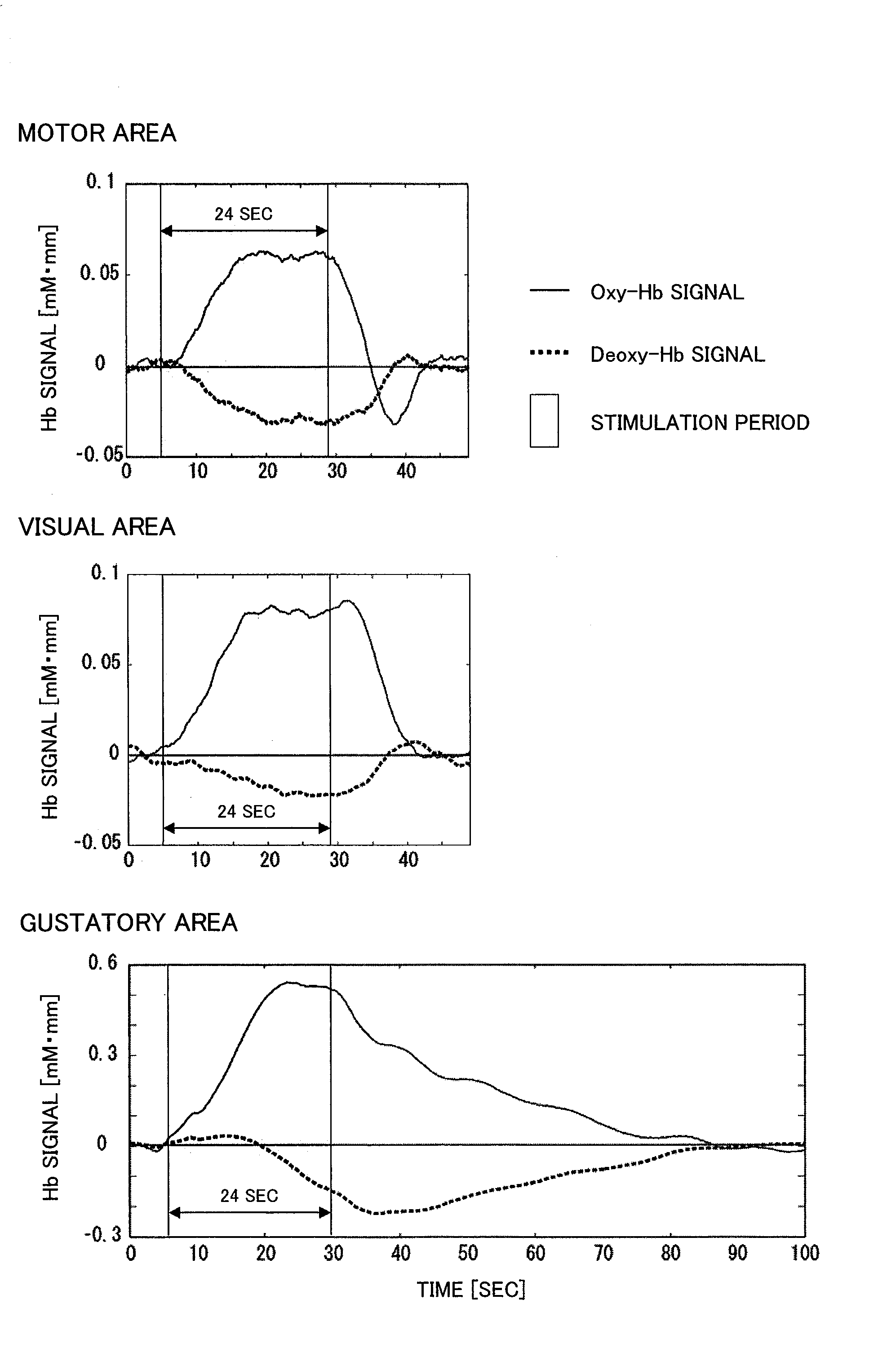

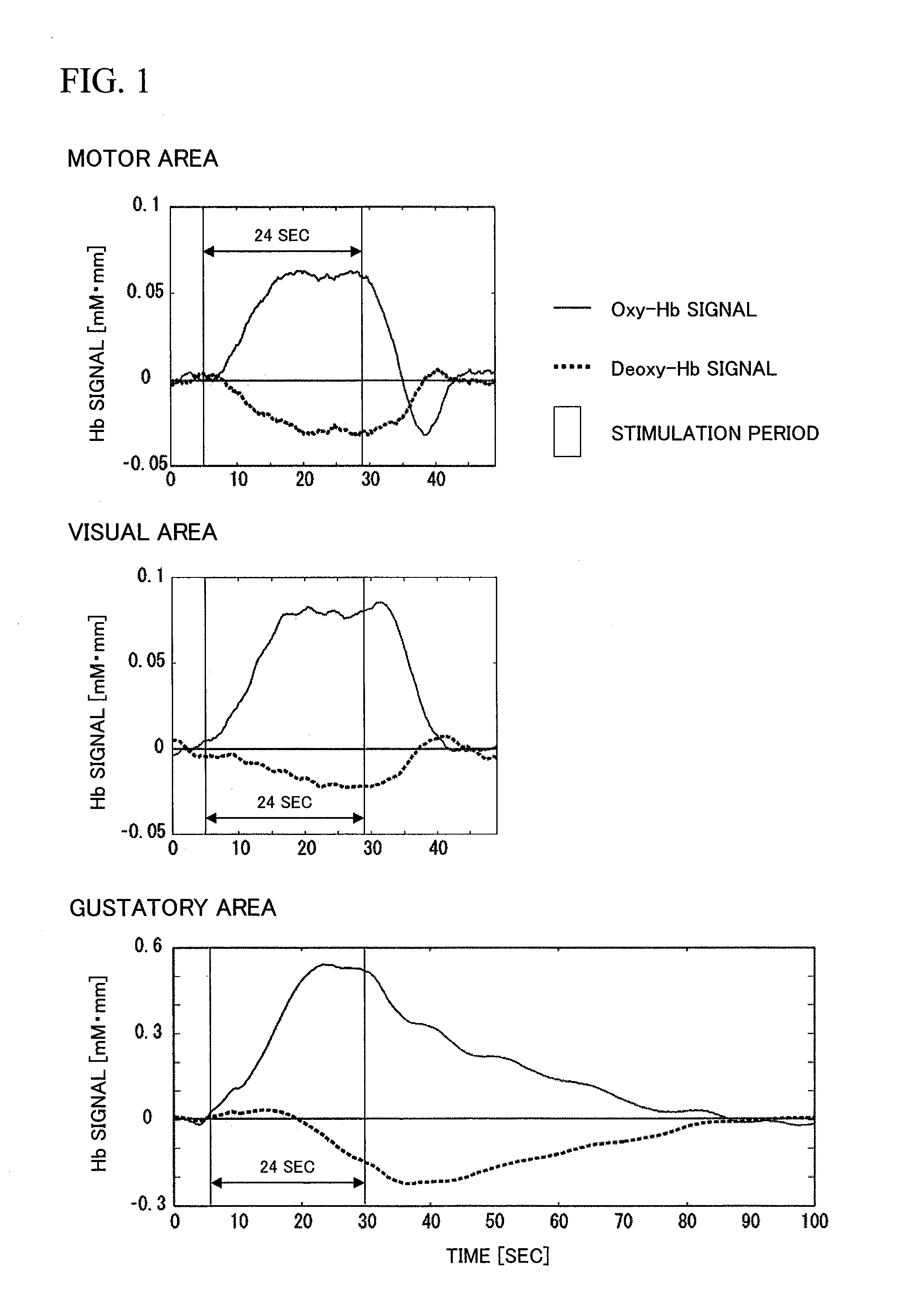

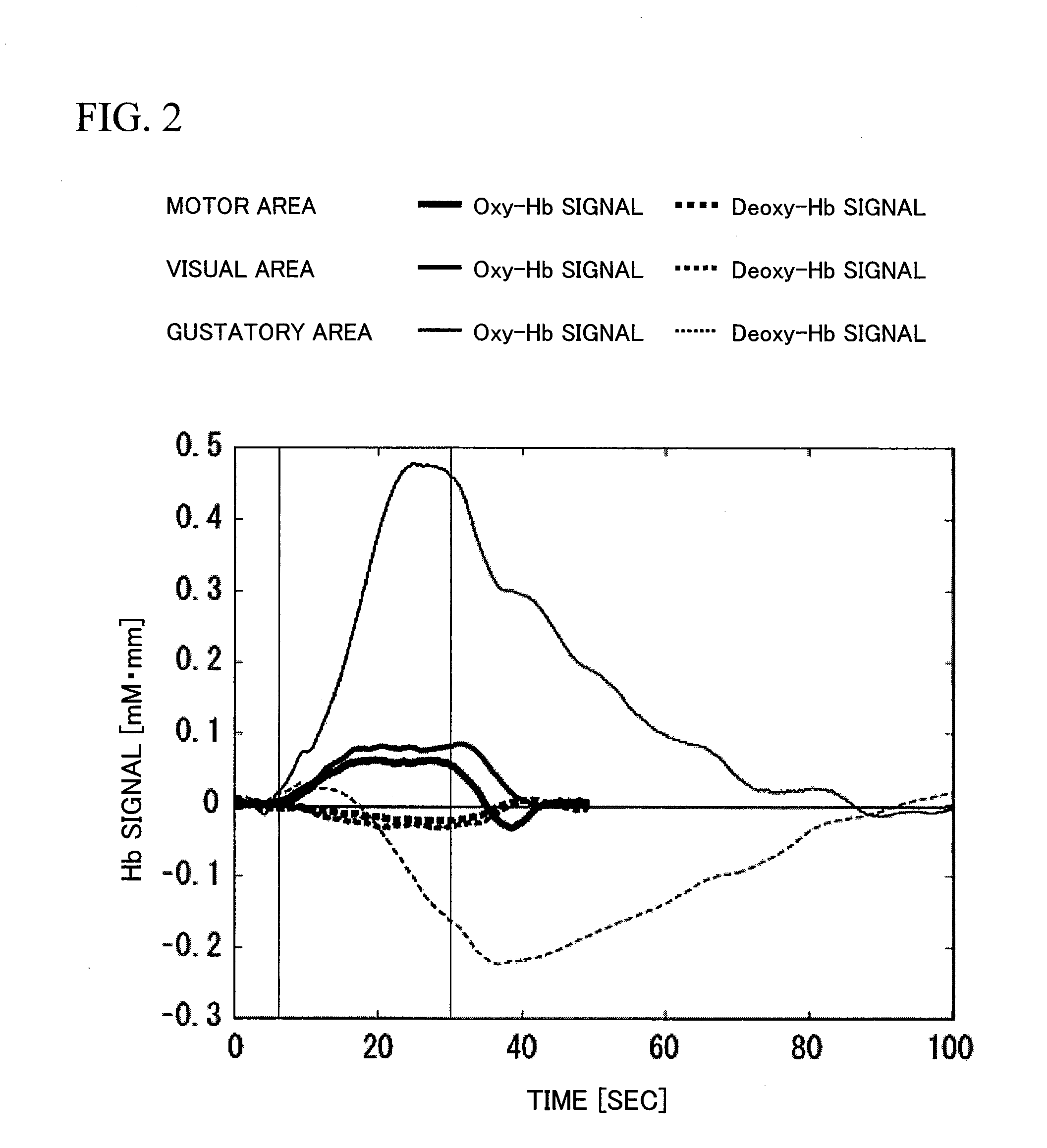

Appropriate measurement and analysis parameters are set according to cerebral function to be measured. To measure gustatory function, a time period of absence of cerebral activity to be measured is set so as not to contain a period of 60 seconds after start of stimulation, an activity period for analysis for an oxyhemoglobin concentration change signal is set so as to contain a period between an instant after a lapse of 16 seconds, and an instant after a lapse of 25 seconds, after the start of the stimulation, and an activity period for analysis for a deoxyhemoglobin concentration change signal is set so as to contain a period between an instant after a lapse of 28 seconds and an instant after a lapse of 37 seconds after the start of the stimulation. Moreover, a time interval between stimulations is set to 80 seconds or more.

Owner:HITACHI LTD

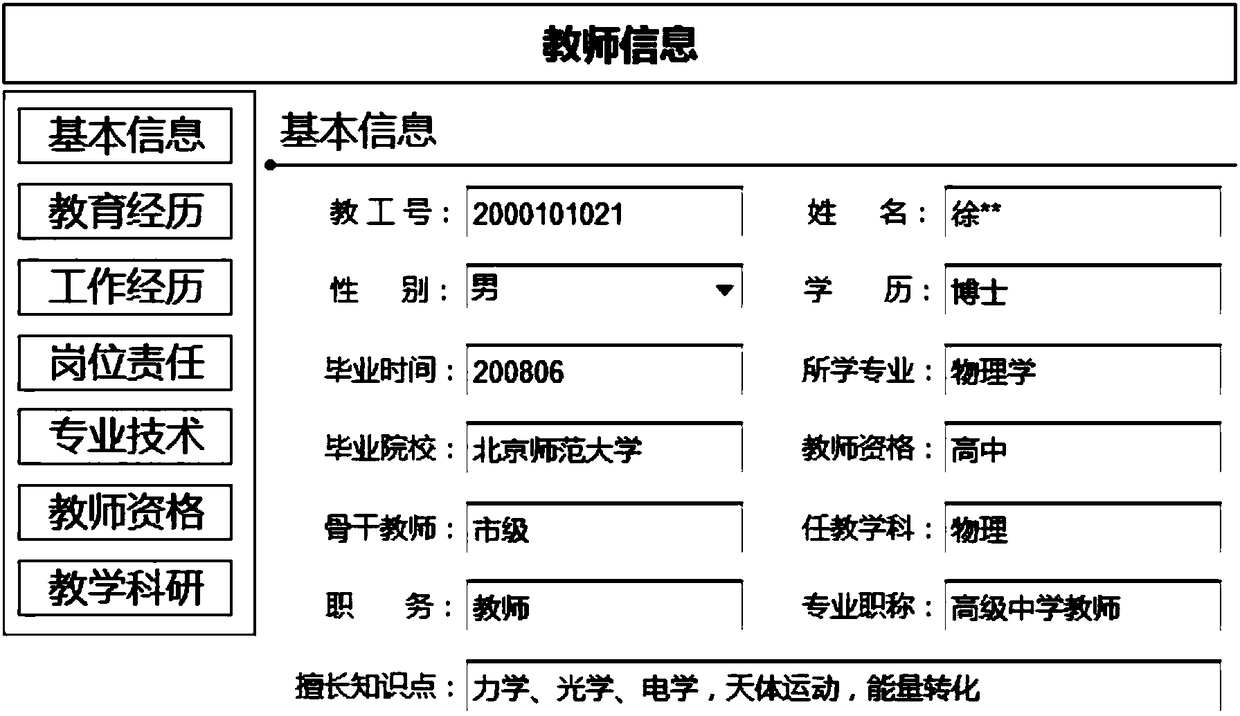

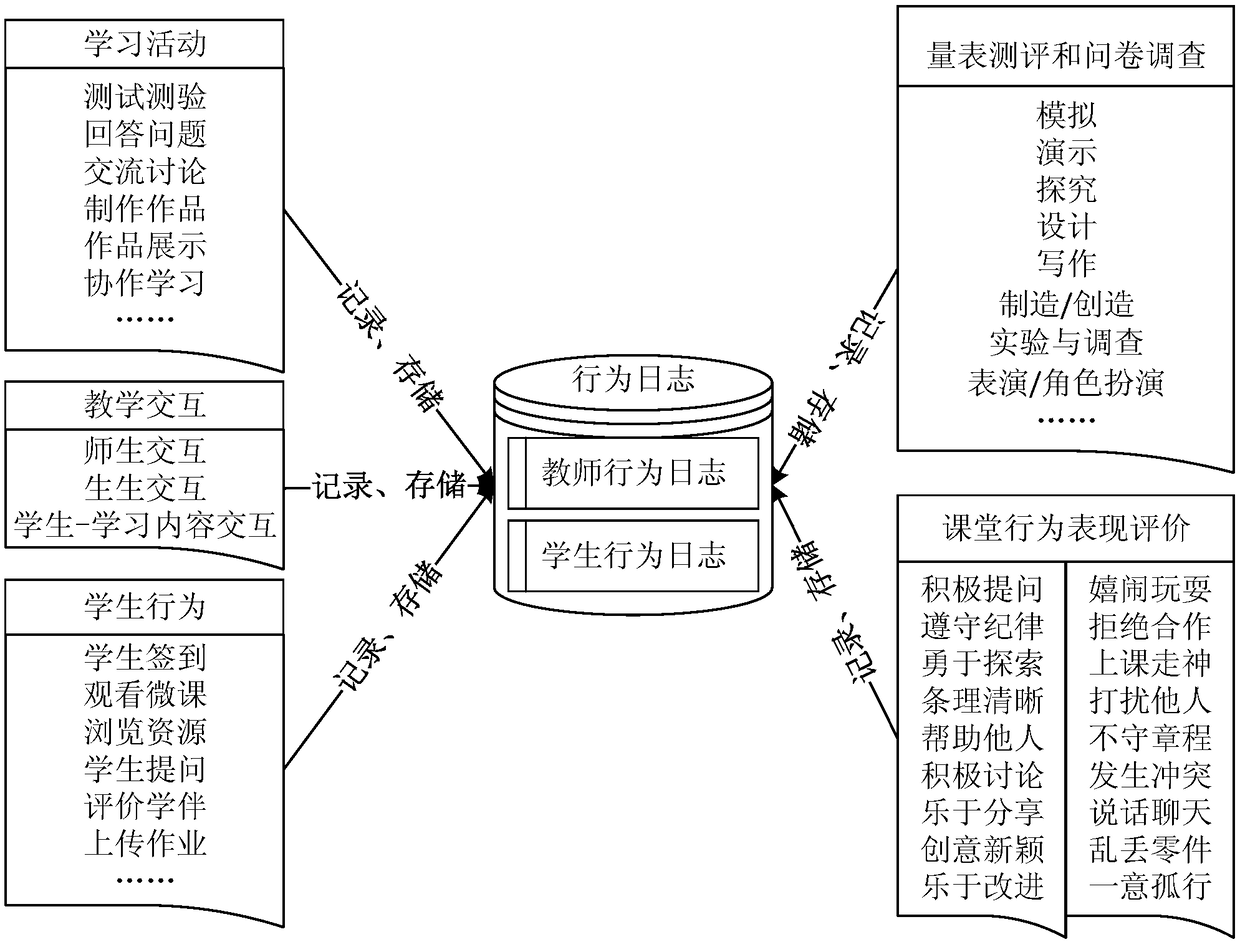

Big data-based STEM education assessment system and method

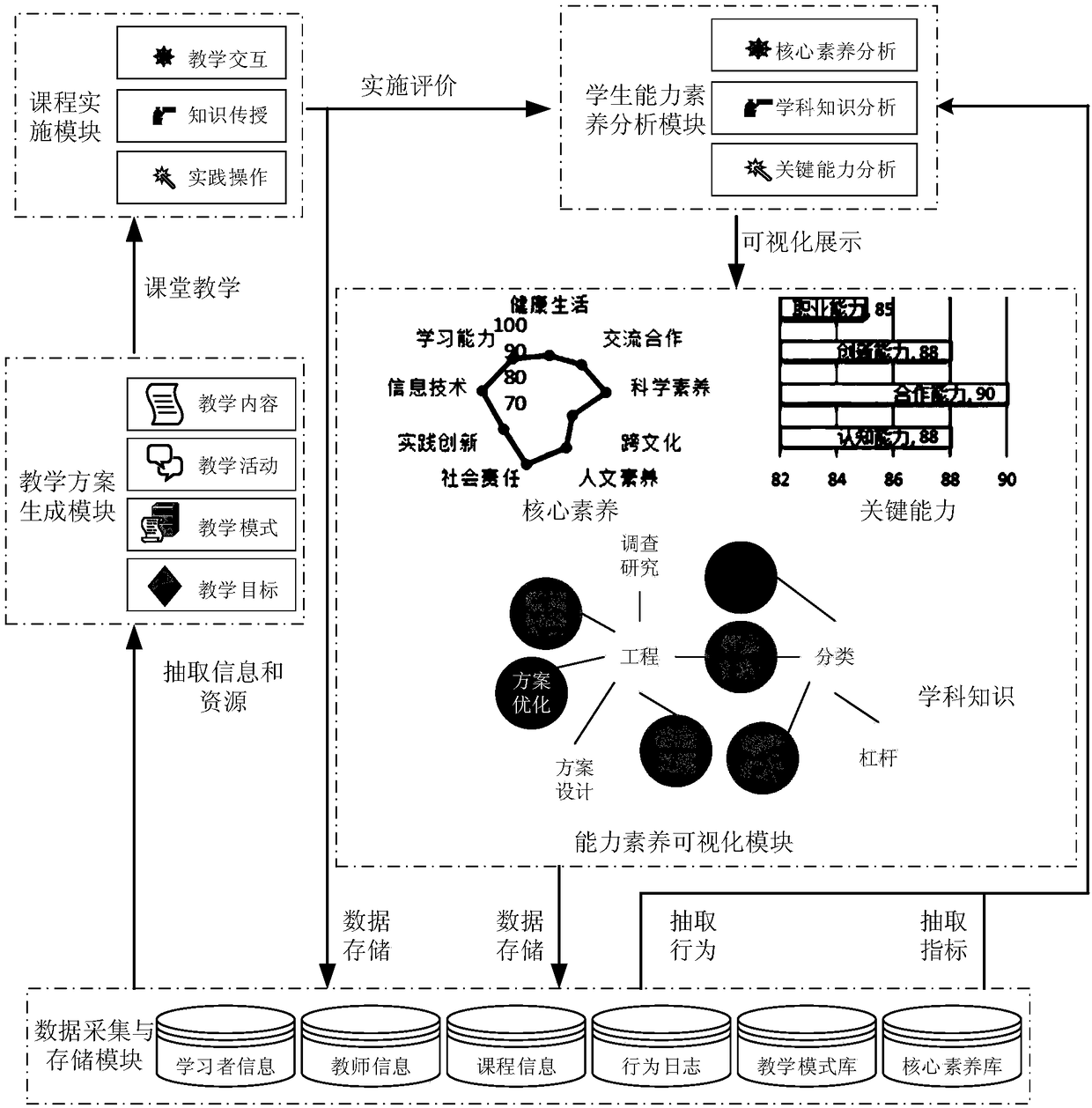

InactiveCN108491994AComprehensive evaluationObjective evaluationResourcesKnowledge levelInstructional design

The invention discloses a big data-based STEM education assessment system and method. The system mainly comprises an information collection and storage module, a teaching scheme generation module, a course implementation module, a student ability and accomplishment analysis module and an ability and accomplishment visualization module; the information collection and storage module mainly records basic information and behavior logs of a teacher and students; the teaching scheme generation module assists the teacher to develop teaching design; teaching activities are implemented in the course implementation module, and teacher and student behavior data is stored; the student ability and accomplishment analysis module analyzes core accomplishment, subject knowledge and key abilities of the students; and student assessment results are displayed in multiple ways of a radar map, a knowledge map and the like in the ability and accomplishment visualization module, and the student assessment results are stored in the information collection and storage module. The assessment system and method is applied to the STEM education assessment; the teacher and the students are assisted to accuratelyknow student ability and accomplishment development according to the assessment results; the teacher is assisted to accurately teach; and the student learning effect is improved.

Owner:BEIJING NORMAL UNIVERSITY

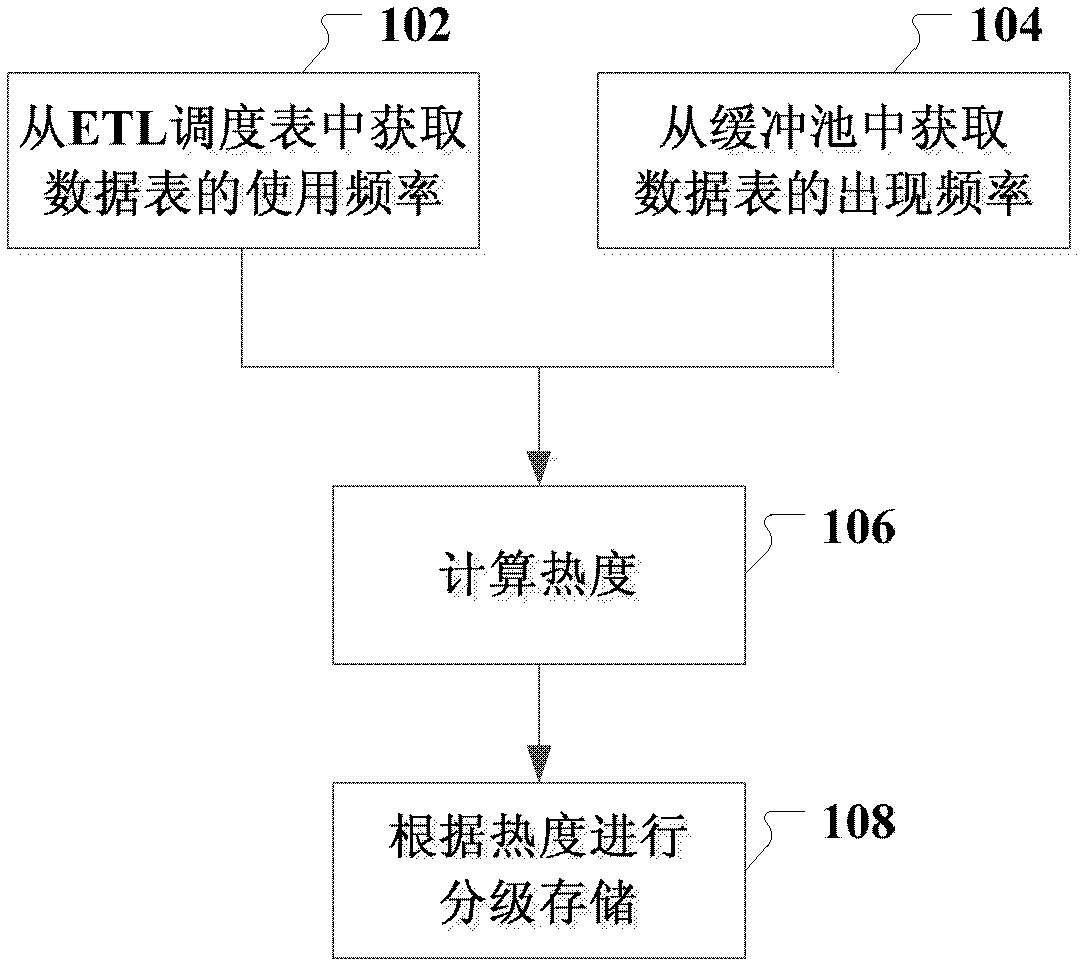

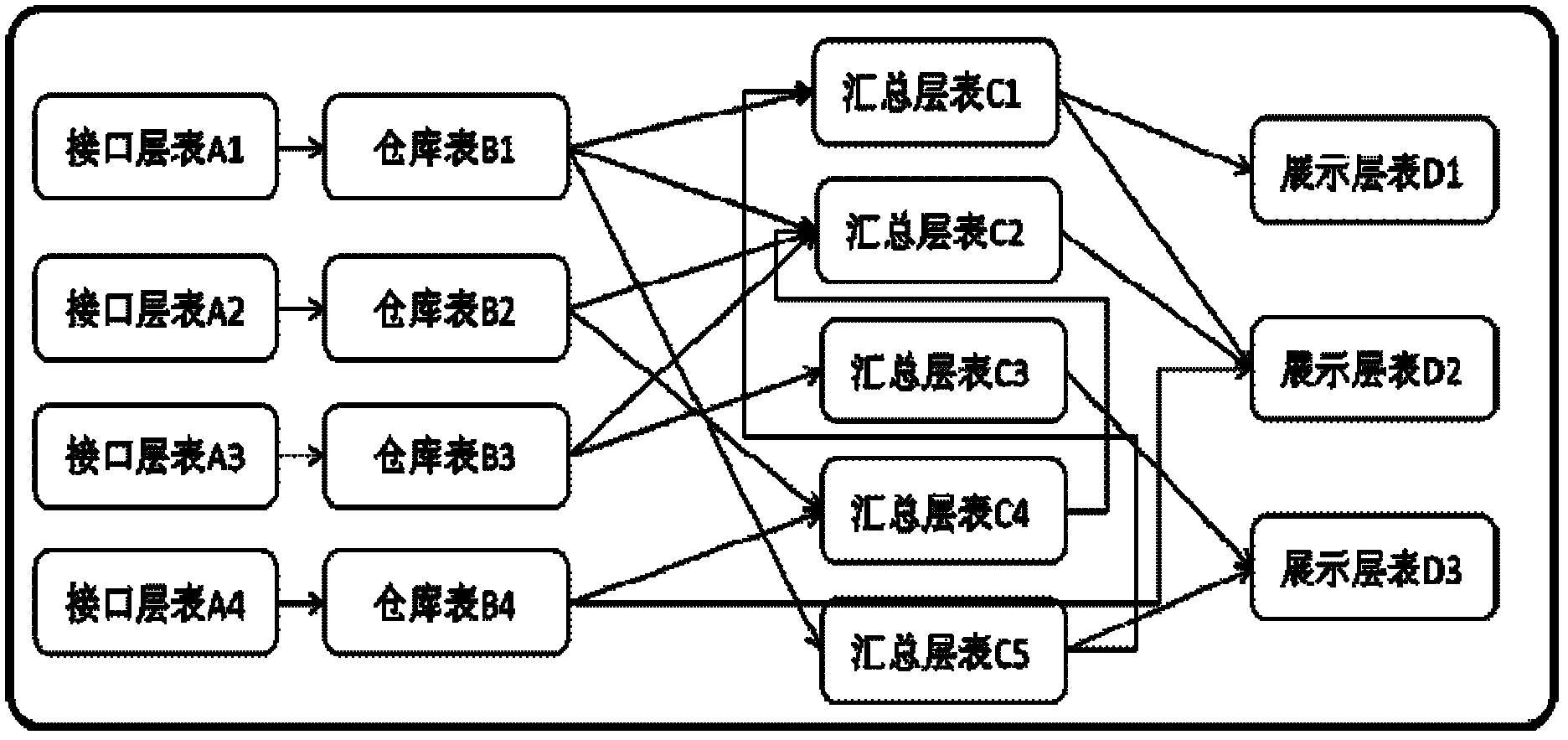

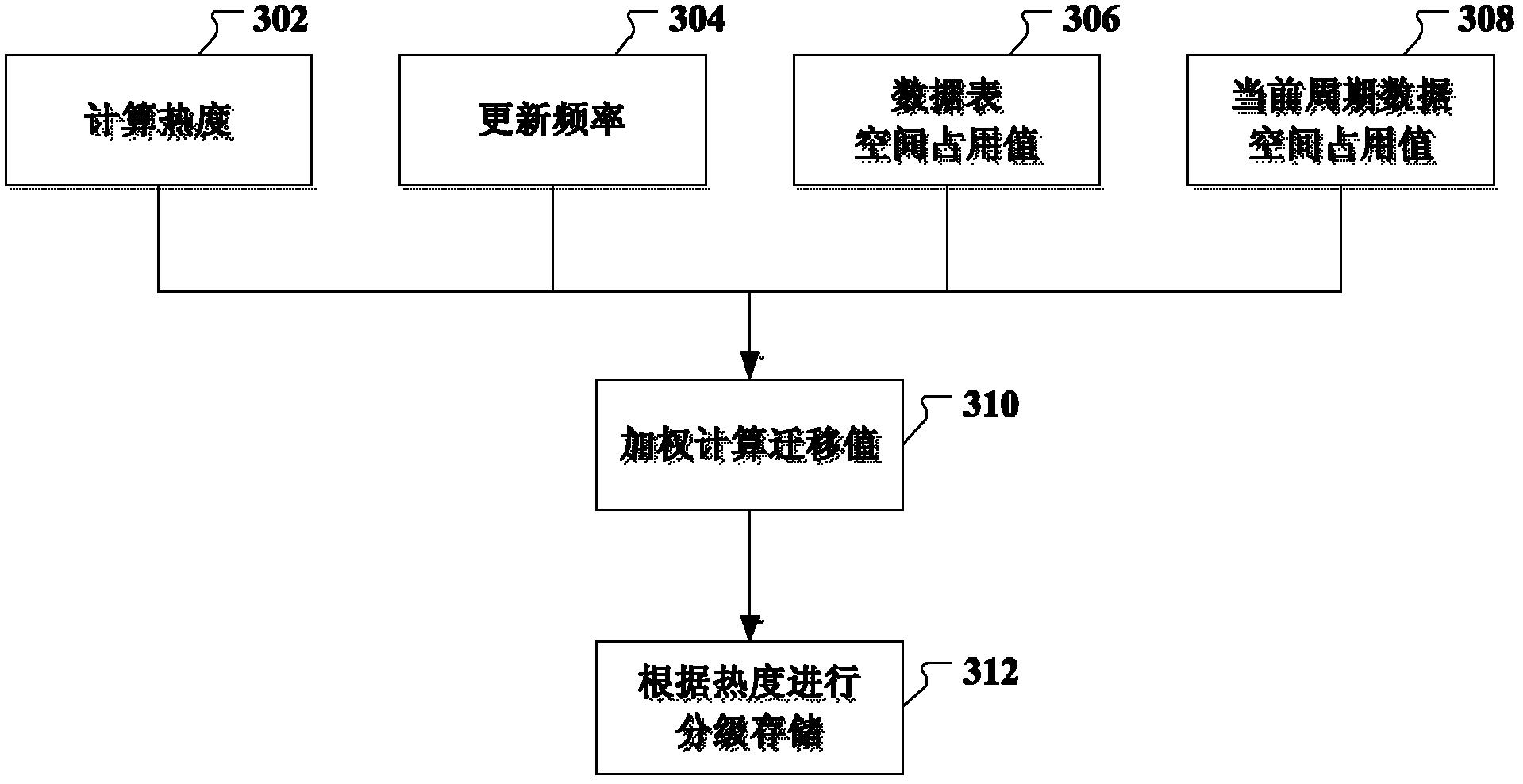

Data classification storage method, device and system

ActiveCN103186566AAccurate evaluationIn line with the actual situationSpecial data processing applicationsDatabase

The invention discloses data classification storage method, device and system, wherein the method comprises the steps: acquiring the use frequency of a data table from an ETL (Extraction Transformation Loading) schedule table, and acquiring the appearance frequency of the data table from a buffer pool; according to the usage frequency and appearance frequency of the data table, calculating the heat of the data table; and according to the level of the data table, performing classification storage on the data table. The heat of the data table is calculated according to the usage frequency of the data table, acquired from the ETL schedule table, and the occurrence frequency in the buffer pool, so that the evaluation on the data table is more accurate, the classification storage is more precise to meet the practical condition of the data table, and the system performance can be improved. Different from the traditional method of carrying out data partitioning according to time slices, data in the same one data table can be stored by means of multiple types, the data table can be used for storing data on various performances according to the condition of heat difference, the workload of shifting a great deal of data in each day can be reduced, and the usage rate of the system performance can be promoted.

Owner:HANDAN BRANCH OF CHINA MOBILE GRP HEBEI COMPANYLIMITED

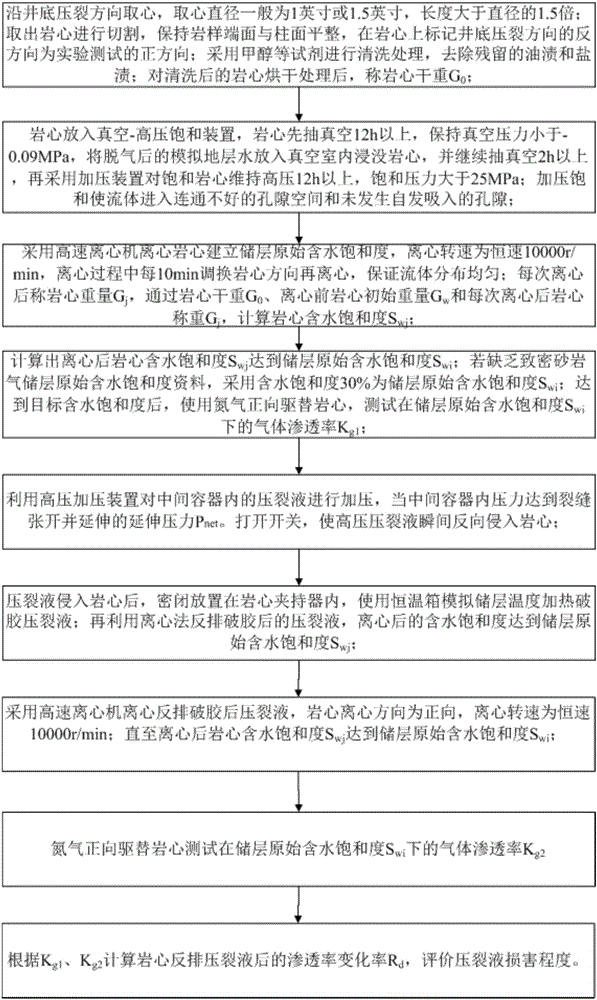

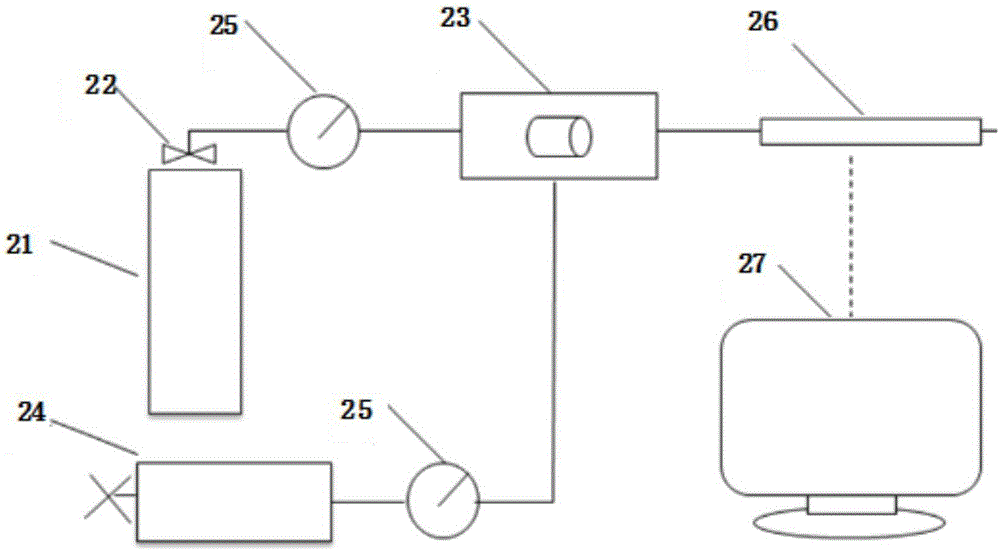

Tight sandstone gas reservoir fracturing fluid damage experimental evaluation method

InactiveCN106153518AConforms to seepage characteristicsExperimental test pressure is smallPermeability/surface area analysisWeighing by absorbing componentRock coreFracturing fluid

The invention belongs to the field of oil-gas field development and relates to an experimental evaluation method for fracturing fluid damage in an unconventional tight sandstone oil-gas exploration and development process. The method includes: subjecting fracturing fluid to high-pressure instant reverse injection into a rock core, and simulating flow invasion damages of fracturing fluid in cracks in a continuous extension process after a stratum is fractured by the fracturing fluid; adopting a high-speed centrifuge to set up original water saturation of a reservoir; under the condition of the original water saturation of the reservoir, adopting nitrogen for testing permeability before and after injection of the fracturing fluid into the rock core, and judging fracturing fluid damage degrees according to gas log permeability change rate. By complete simulation of a fracturing fluid injection mode in a fracturing process, adoption of nitrogen for testing permeability accords with seepage characteristics of the tight sandstone gas reservoir, and defects of high experimental displacement pressure, long displacement time, large experimental data errors and the like are avoided.

Owner:SOUTHWEST PETROLEUM UNIV

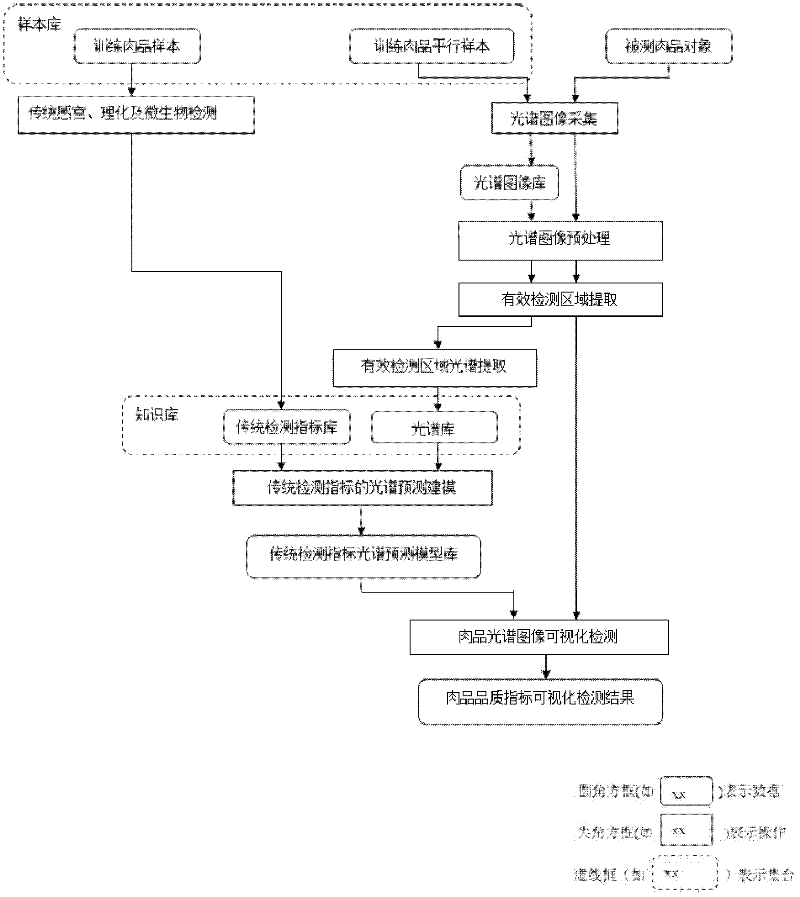

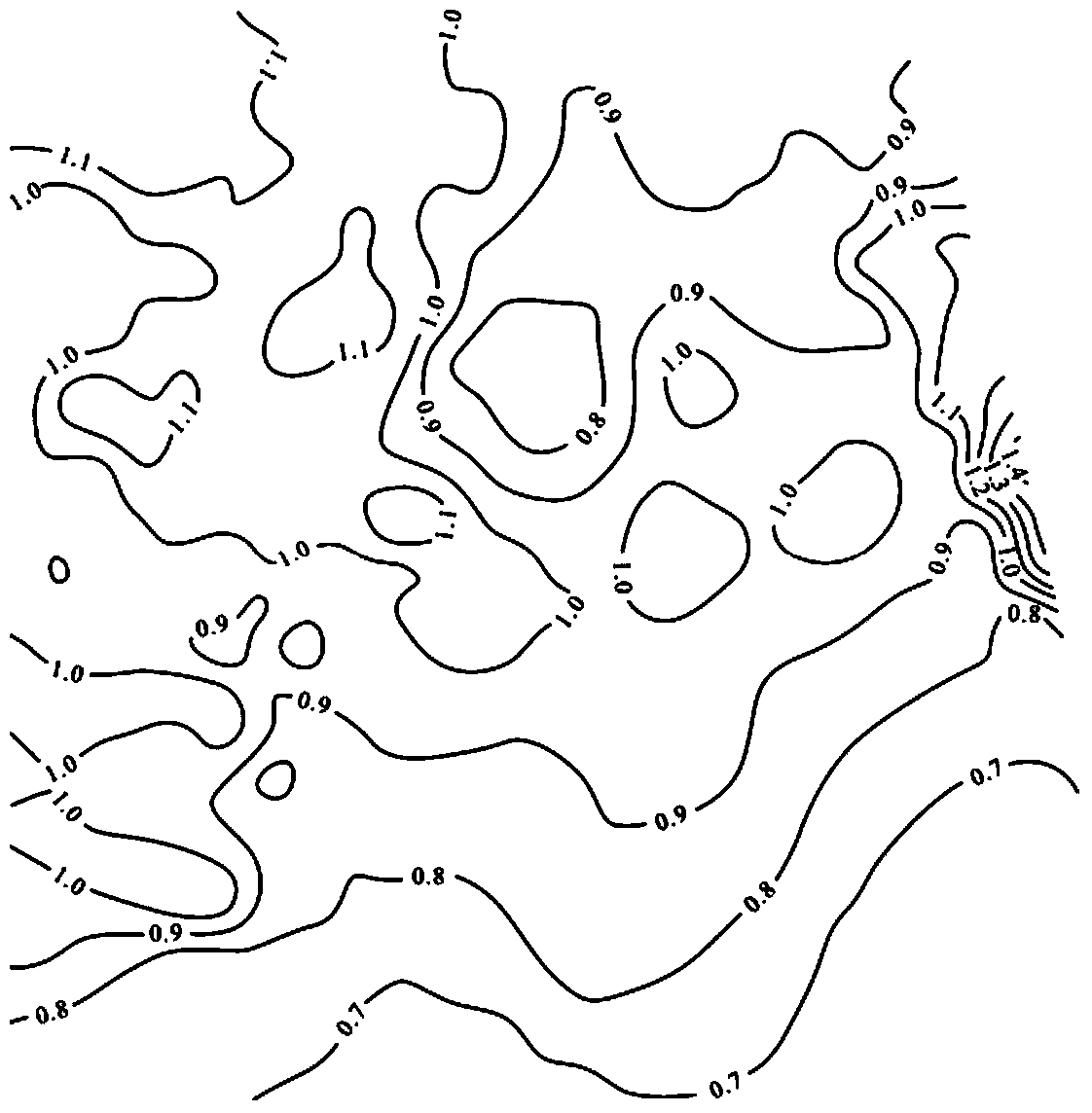

Spectral image-based meat quality visual non-contact detection method

InactiveCN102564964ABreak through subjectivityBreakthrough speedColor/spectral properties measurementsEvaluation resultWater activity

The invention discloses a spectral image-based meat quality visual non-contact detection method. By means of spatial distribution information and spectral characteristic information which are contained in a spectral image and reflect the characteristics of an object to be detected, multiple indexes of meat quality (such as water content, water activity, volatile basic nitrogen, meat color, microorganism counts, acid value and pH value) are respectively or comprehensively evaluated, and evaluation results are given in an image mode according to spatial distribution conditions of specific indexes in the object to be detected. The method can be used for quick and non-contact inspection of meat production, processing, storage, transportation and marketing links, inspection results are accurate and objective, and the expression mode is intuitive, so that a guarantee means for supervising the production and marketing quality safety of meat is provided.

Owner:沛县汉腾建设发展有限公司

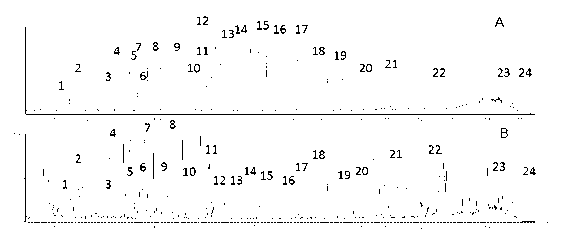

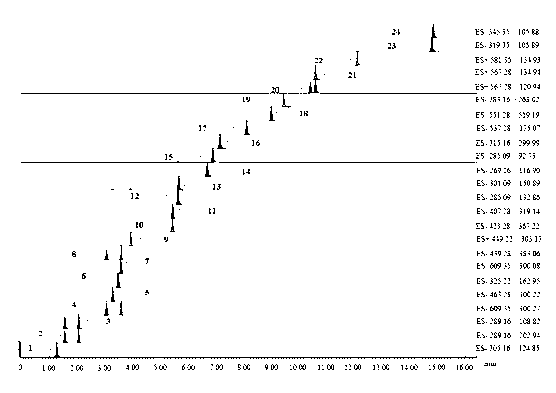

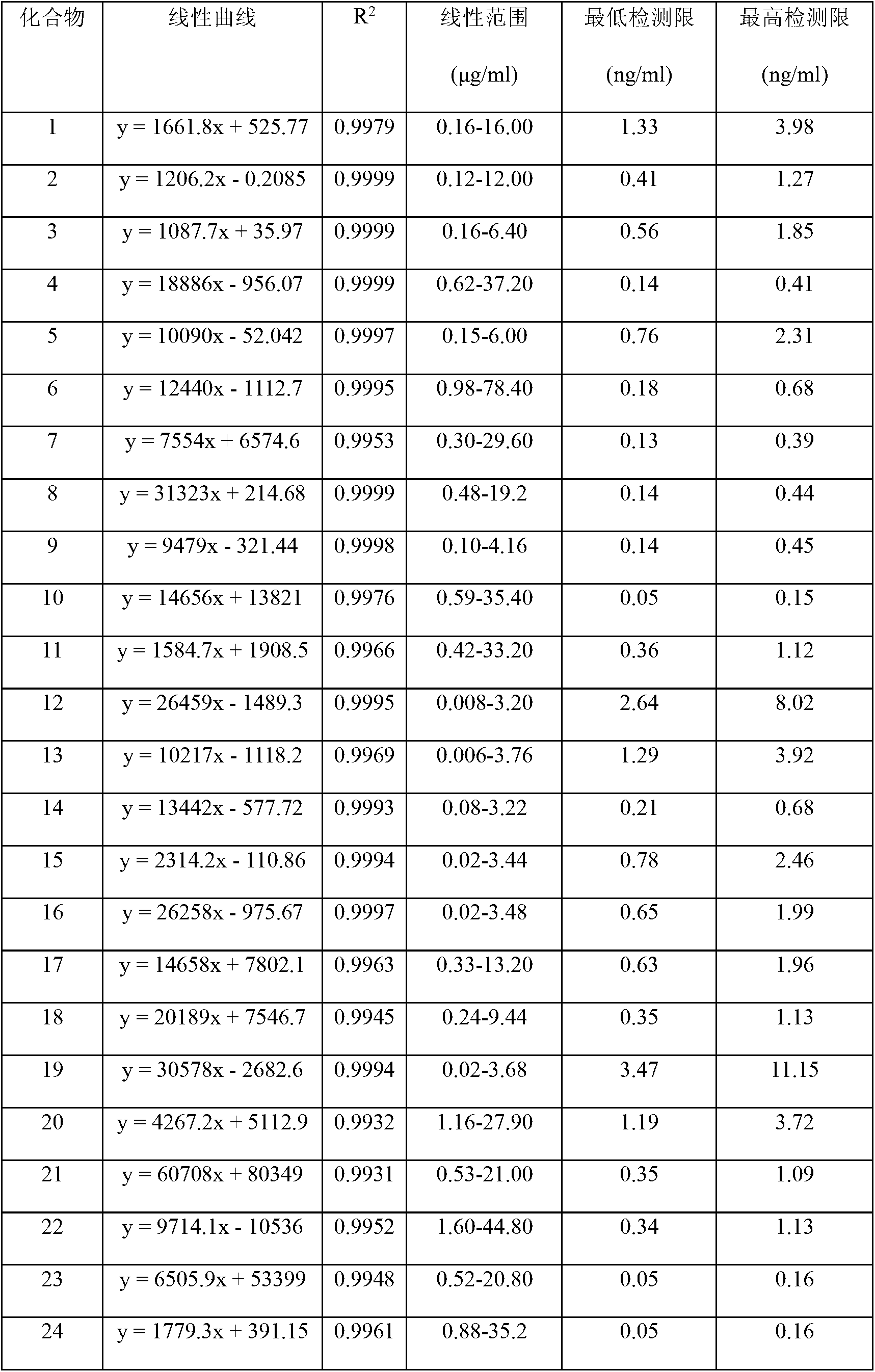

Method for controlling quality of ginkgo leaves and extract thereof

InactiveCN103175912AEasy to separateEasy CalibrationComponent separationCurative effectControl quality

The invention discloses a method for controlling the quality of ginkgo leaves and an extract thereof. After the screening of a great quantity of experiments, the method adopts ultra-high performance liquid chromatography for detection; and the method can be used for detecting three types of components including flavone, terpene lactones and phenolic acid, twenty-four active compounds in total, in the ginkgo leaves and the extract of the ginkgo leaves. The results of the experiments prove that the method is high in detection sensitivity and good in stability, and can be used for objectively, comprehensively and accurately evaluating the quality of ginkgo leaf medicines, the extract of the ginkgo leaves and ginkgo leaf preparations, thus having important significance on controlling the quality and guaranteeing the clinical treatment effect.

Owner:NANJING UNIVERSITY OF TRADITIONAL CHINESE MEDICINE

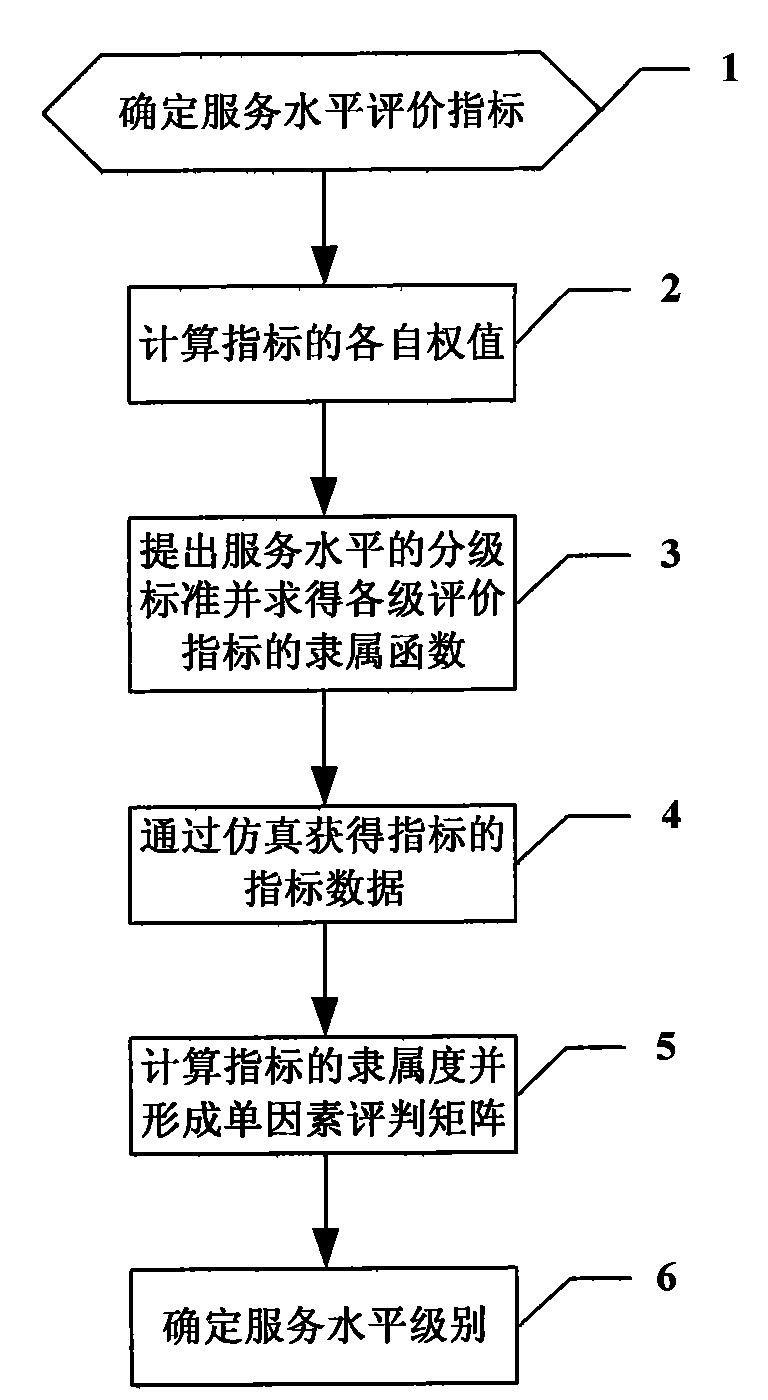

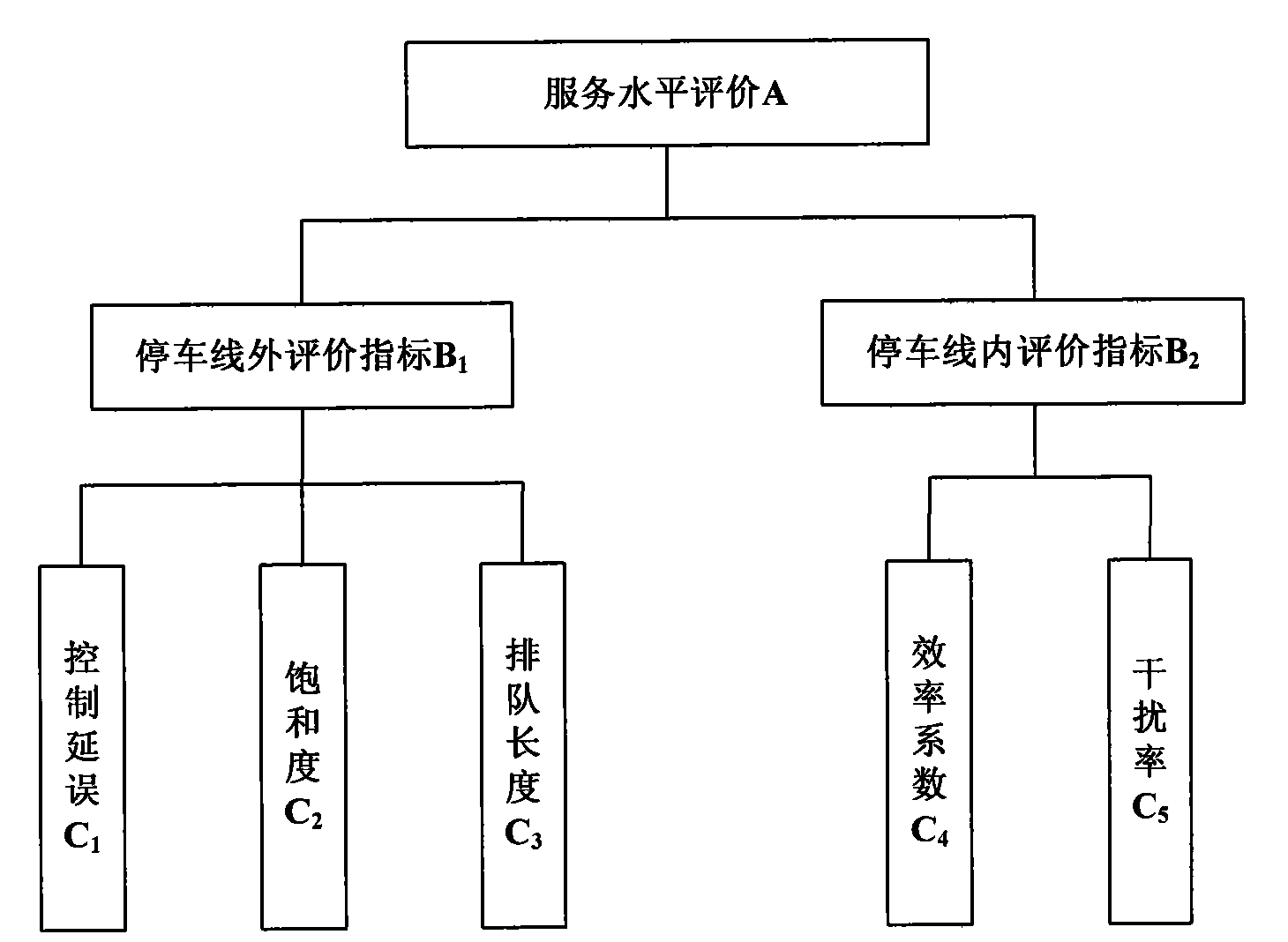

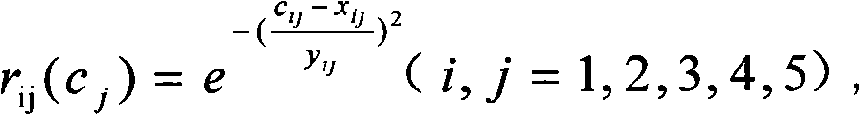

Method for evaluating service level of plane signal intersection under mixed traffic environment

InactiveCN101604479AAccurate evaluationRoad vehicles traffic controlBiological neural network modelsPedestrianTraffic planning

The invention discloses a method for evaluating service level of a plane signal intersection under a mixed traffic environment in the field of urban road traffic planning and management. The method comprises the following steps: determining evaluation indexes of the service level of the plane signal intersection under the mixed traffic environment; calculating the weight of the plane signal intersection under the mixed traffic environment of each index by using an analytic hierarchy process; calculating central points and standard differences of five service levels of the plane signal intersection under the mixed traffic environment by using a fuzzy clustering method, and solving a membership function of each evaluation index; acquiring index data of each index under the mixed traffic environment; calculating and controlling the membership degree of each level of each index to form a single-factor evaluation matrix; and using the single-factor evaluation matrix and the index weight to carry out integrated evaluation for each index under each level, and determining the service level according to the maximum membership rule. The method integrally considers the influences of various traffic factors comprising non-motor vehicle and pedestrian on the plane signal intersection, and evaluates the service level of the plane signal intersection more accurately.

Owner:BEIJING JIAOTONG UNIV

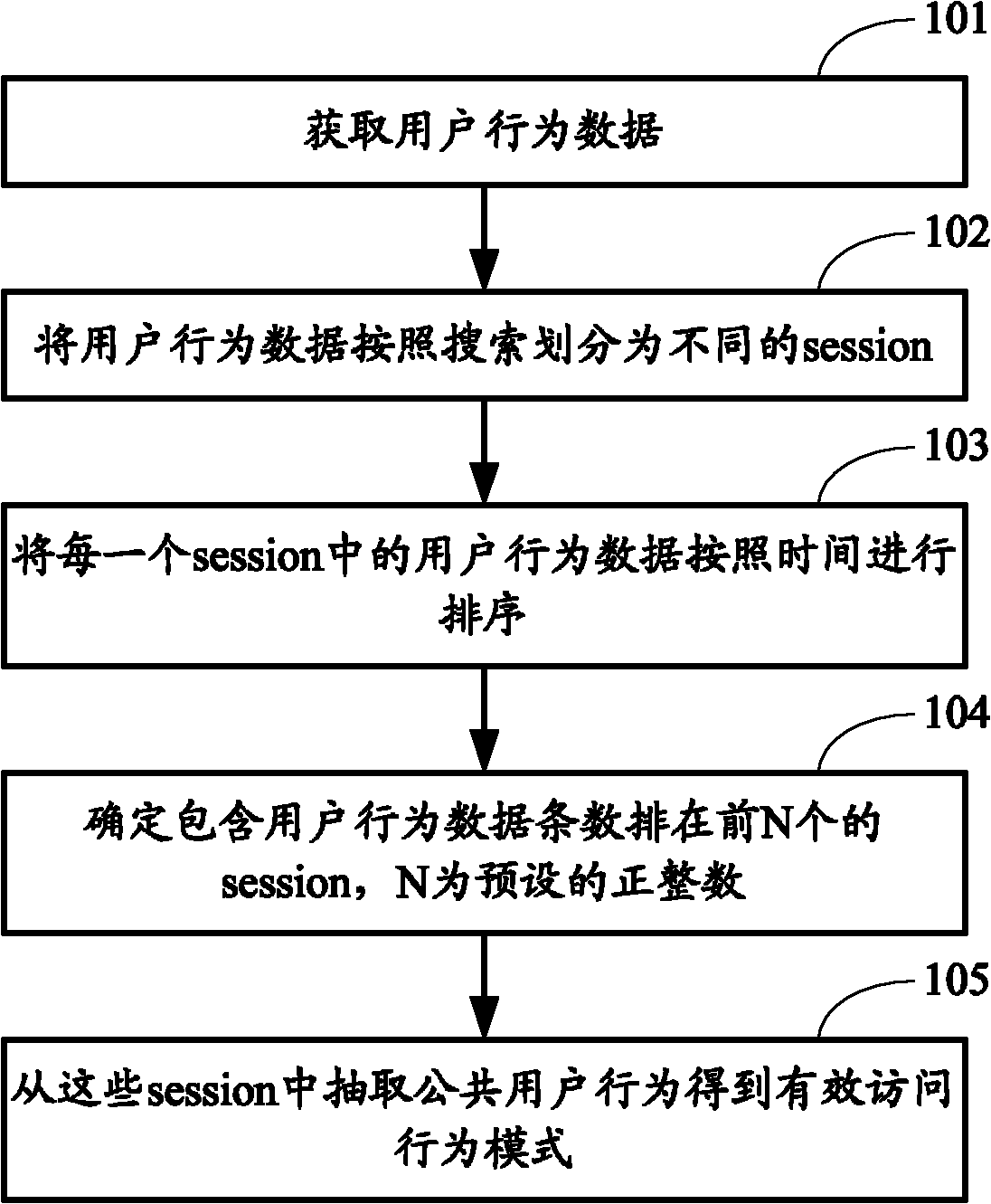

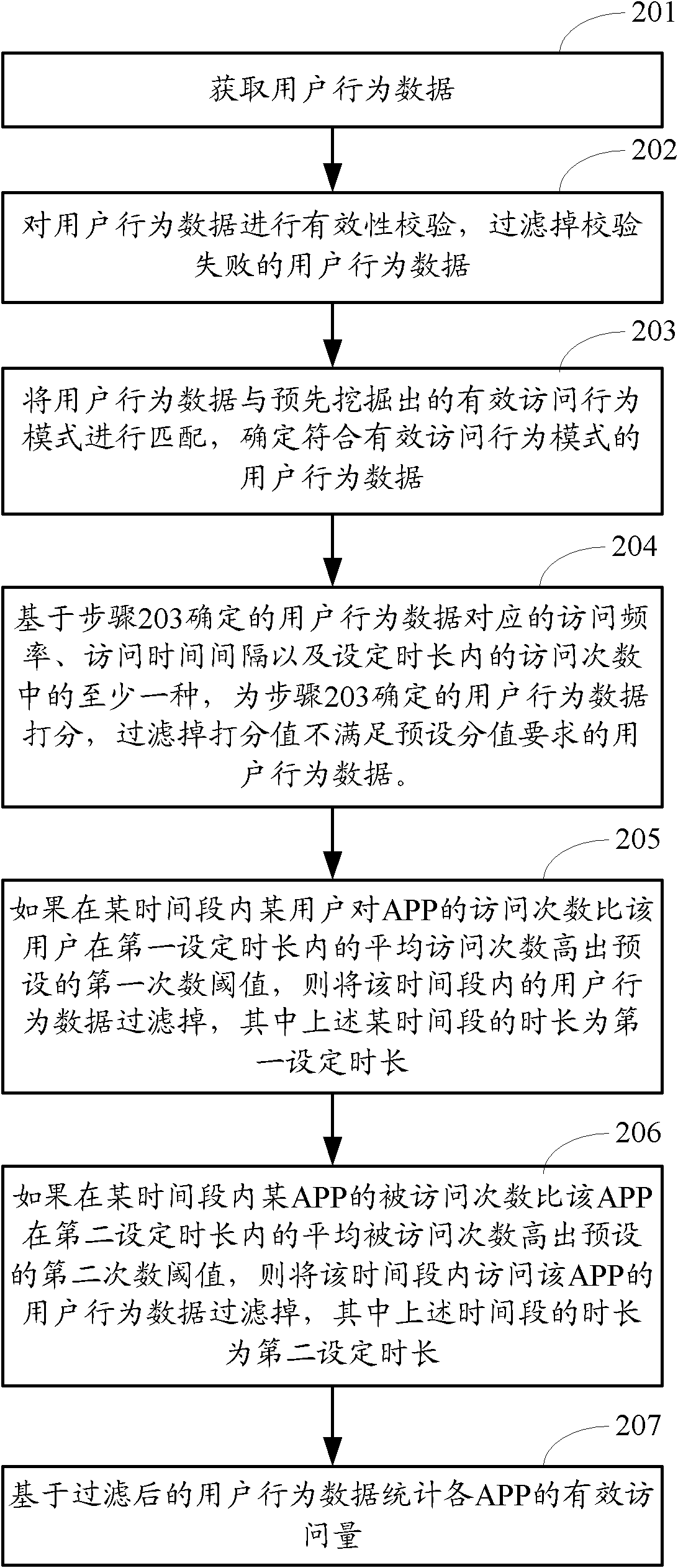

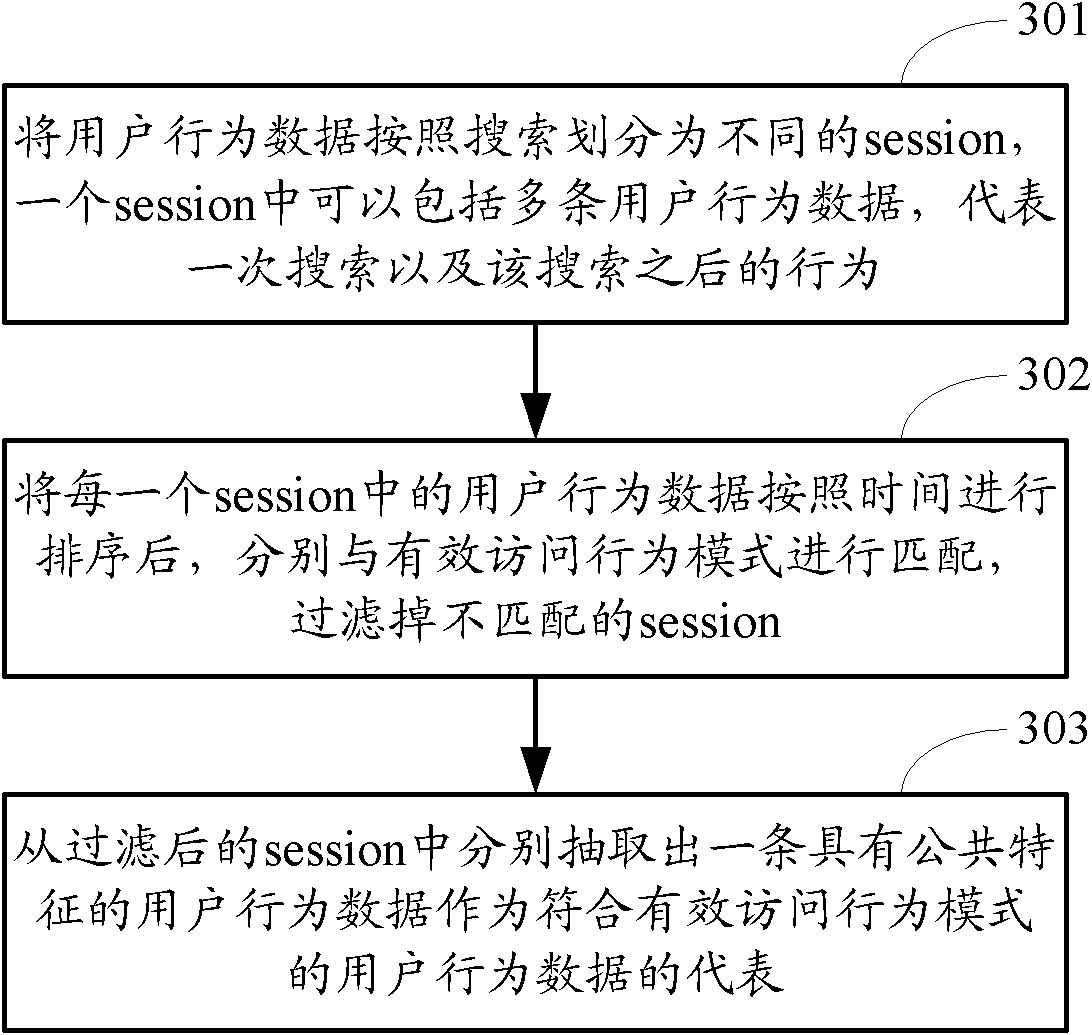

A method and device for monitoring effective visits of application programs

ActiveCN102279786AStatistical effective visitsAccurate evaluationHardware monitoringApplication softwareResidence time

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

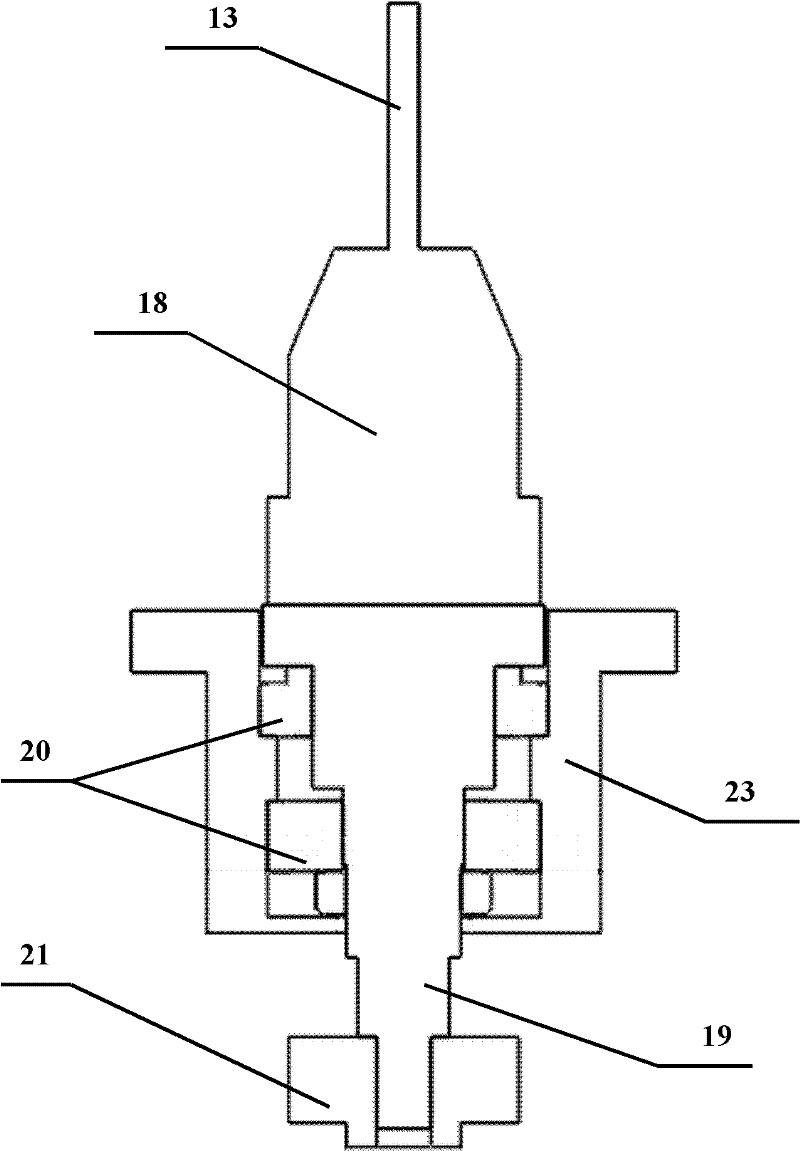

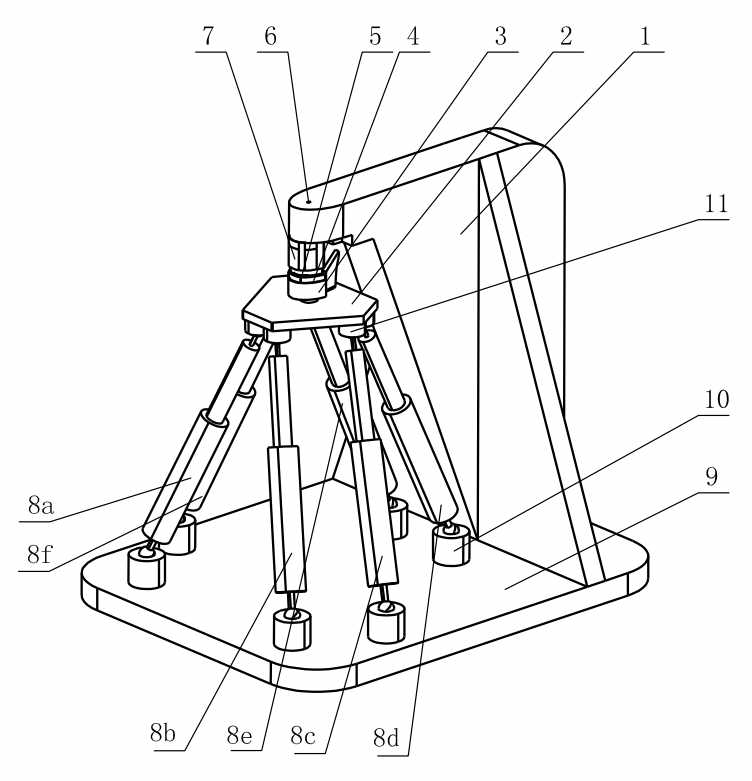

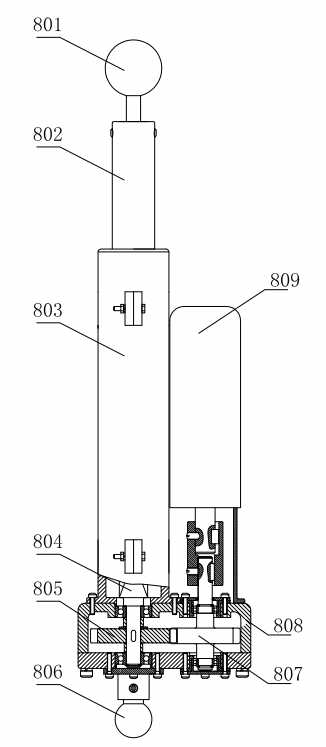

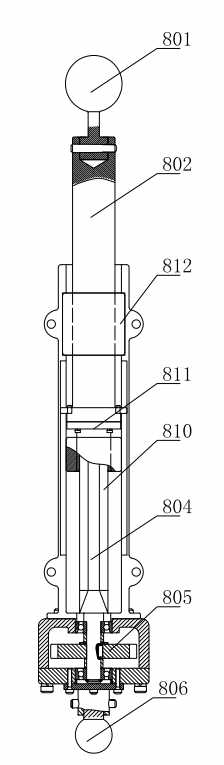

Bionic examination robot for physical properties of food and examination method thereof

InactiveCN101915708AHigh precisionControl oral temperature and humidityFlow propertiesTesting foodChinEngineering

The invention relates to a bionic examination robot for physical properties of food and an examination method thereof. The bionic examination robot comprises a control device and a bionic oral cavity, wherein the bionic oral cavity is composed of a palate and a chin, upper teeth of the palate is matched with lower teeth of the chin; the top part of the palate is fixed to the upper part of a frame, the bottom part of the chin is fixed to a movable platform, the movably platform is connected with a pedestal of the frame via a plurality of ball pairs-movable pairs-ball pair mechanisms; a plurality of sensors are arranged at different positions inside the oral cavity; and the control device controls the movement of the moveable pairs, and receives data from the sensors and stores and processes the data. The bionic examination robot can evaluate the physical properties of food scientifically, accurately and objectively, and the examination method can take the place of traditional food evaluation methods in which identification of a texture analyzer and sensuous identification are combined, thereby not only reducing examination cost and enhancing examination efficiency, but also enhancing examination accuracy, thus a scientific theoretical basis is provided for the processing and the development of food.

Owner:JIANGNAN UNIV

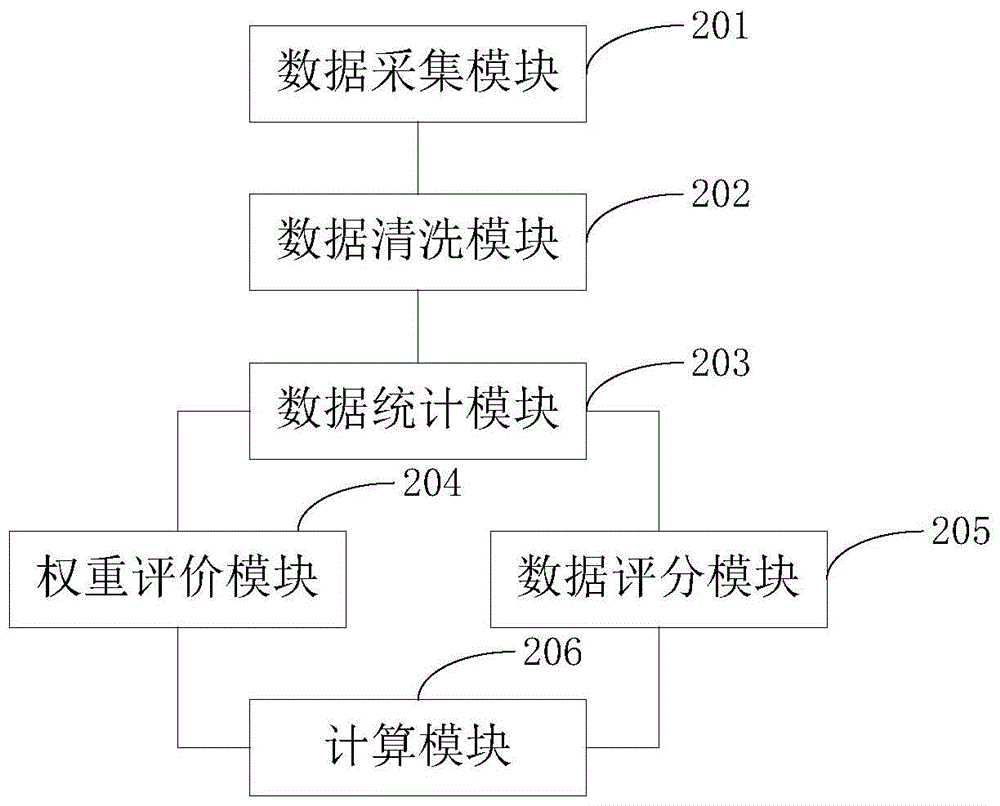

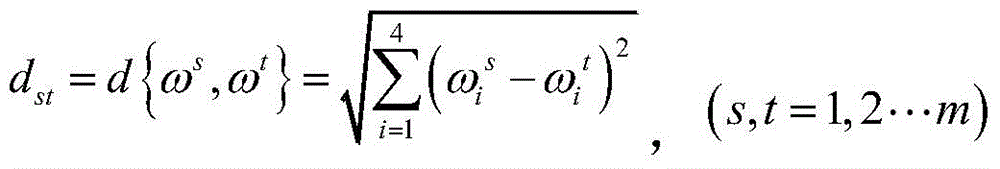

Driving behavior analyzing method and evaluation system based on vehicle-mounted data

The invention discloses a driving behavior analyzing method based on vehicle-mounted data. The driving behavior analyzing method comprises the following steps of collecting driving data of automobiles in a real time manner; deleting invalid driving data according to bit mask; performing deletion or modification on exceptional data; performing descriptive statistic on the driving data so as to obtain statistic driving data; through an analytic hierarchy process of group decision, obtaining the weight distribution of evaluating indicators; through a method for scoring by an expert, obtaining scores during a stroke period; through a conformability principle, obtaining the duration of the stroke, the average velocity of the stroke, and the ride comfort scores of the stroke; and according to the weight distribution of the evaluating indicators and the score, obtaining a scoring matrix of the driving data. The invention further discloses a driving behavior evaluation system based on the vehicle-mounted data. According to the driving behavior analyzing method and evaluation system based on the vehicle-mounted data, through the level analysis method of the group decision, the weight of the driving data is obtained, and through the conformability principle, the score of the driving data is obtained, so that the driving behavior of a user can be accurately analyzed and evaluated.

Owner:UNITED ELECTRONICS

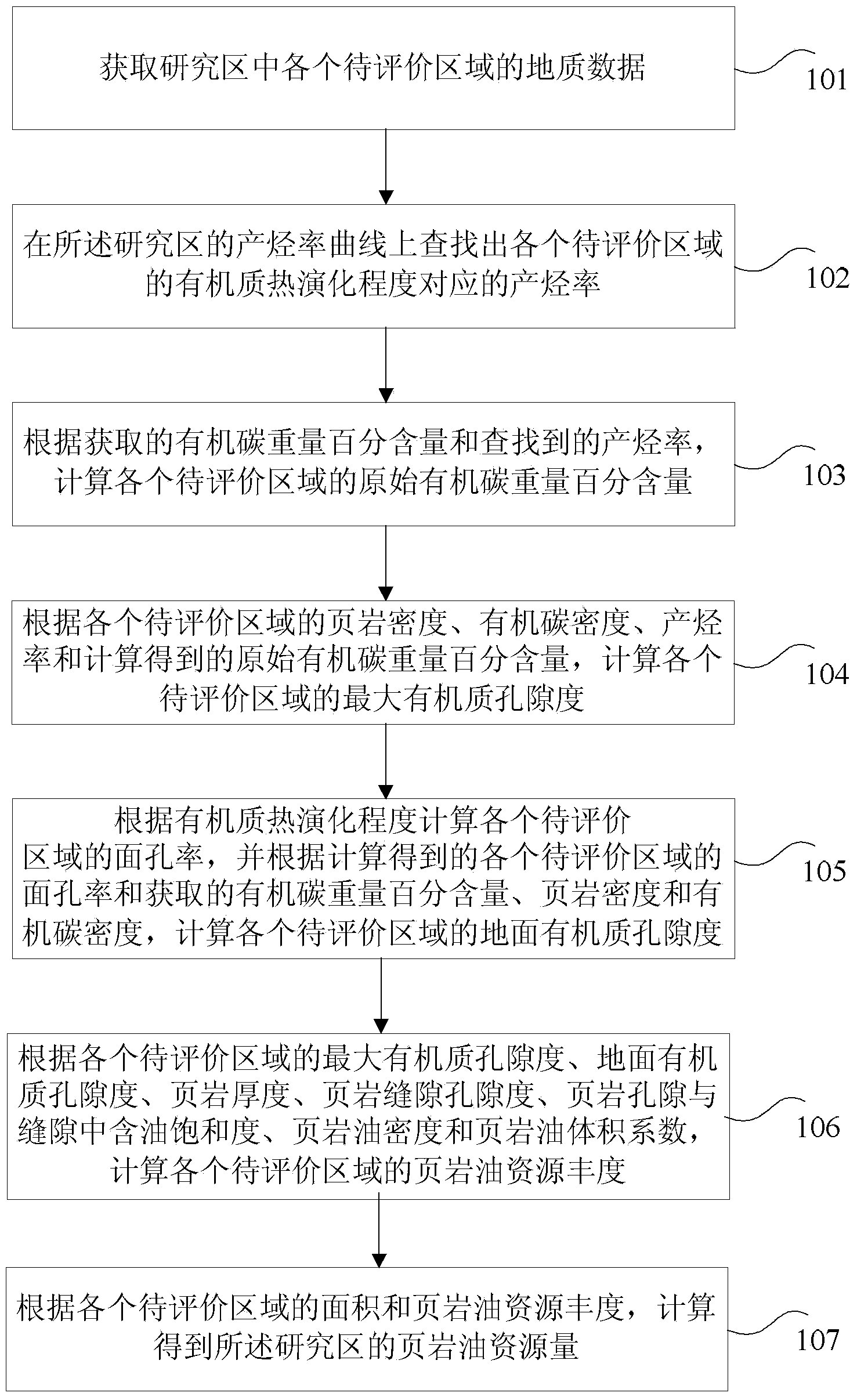

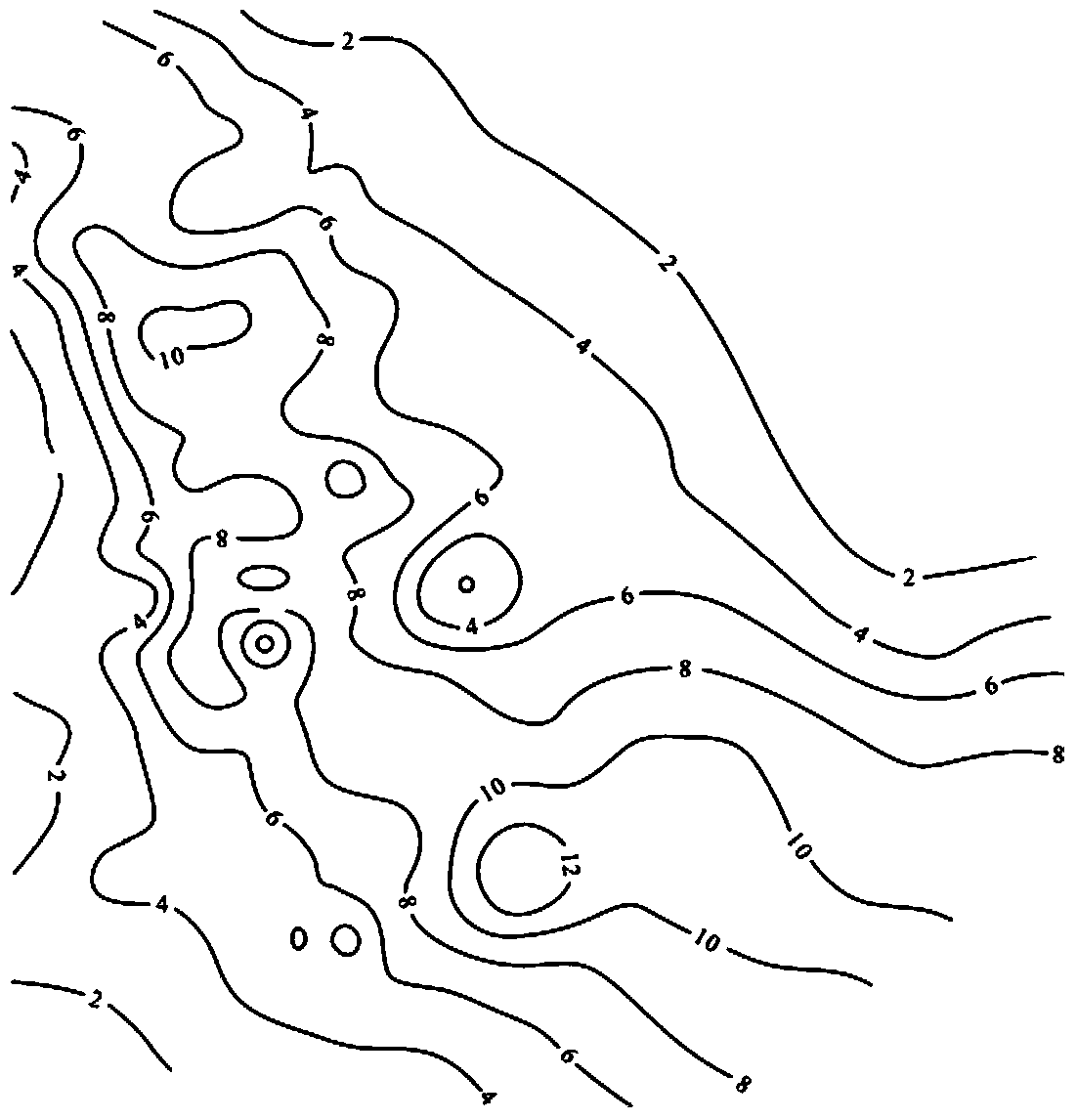

Shale oil resource evaluating method and device

The invention provides a shale oil resource evaluating method and device. The method comprises the steps that geological data of each region to be evaluated in a research region are obtained; a hydrocarbon production rate curve of the research region is searched for the hydrocarbon production rate corresponding to the organic matter thermal evolution degree of each region to be evaluated; the original organic carbon weight percentage composition of each region to be evaluated is calculated; the maximum organic matter porosity of each region to be evaluated is calculated; the ground organic matter porosity of each region to be evaluated is calculated; the shale oil resource abundance of each region to be evaluated is calculated; according to the area and the shale oil resource abundance of each region to be evaluated in the research region, the shale oil resource quantity of the research region is obtained through calculation. According to the shale oil resource evaluating method and device, the problem that when shale oil is evaluated in the prior art, only organic matter porosity is considered, factors such as non-movable oil are not removed, and therefore the determined shale oil resource quantity is inaccurate is solved, and the evaluating result accuracy is improved.

Owner:PETROCHINA CO LTD

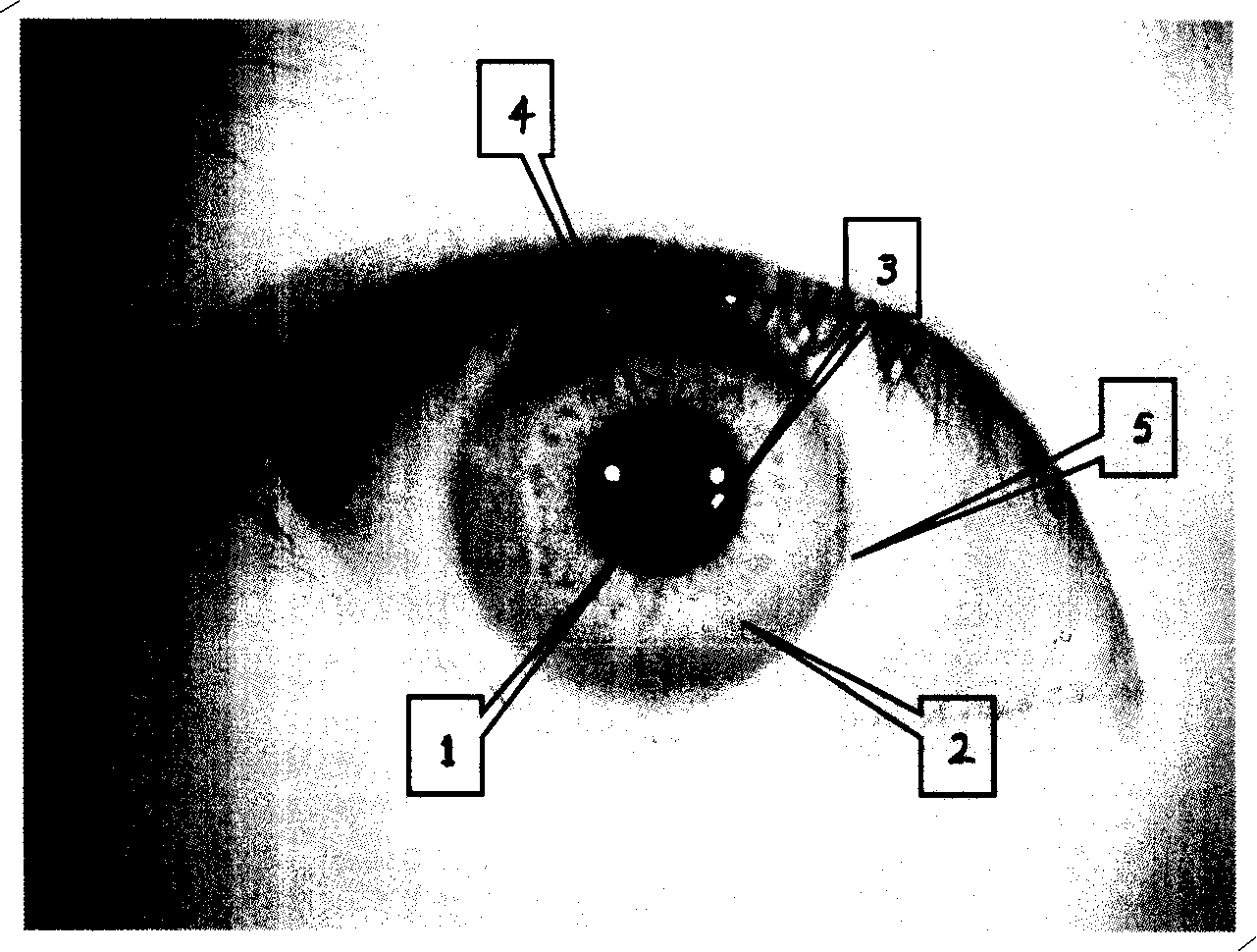

Iris recognizing preprocessing method based on grey level information

InactiveCN101201893AHigh positioning accuracyImprove versatilityCharacter and pattern recognitionComputer visionGray level

The invention provides a pretreatment method of iris images based on gray information. A rough circle center (xo, yo) of a pupil is located through binary, mathematical morphology, gray projection and other operations, the point, which has a gray value larger than T and the shortest distance to the (xo, yo), is searched at a plurality of lines close to the (xo, yo) from the center to the two sides as a pupil boundary point; the accurate circle center and the radius of the pupil can be located through curve fitting; the gray level first difference of the lines where the searched pixel points lie is calculated and the point with the largest value of the sum of the level first difference is searched in the range of places where iris external boundary point possibly appears and taken as the iris external boundary point; the accurate circle center and radius of the iris external boundary is obtained after curve fitting. The quality of iris image is judged through calculating point sharpness and number of effective pixel points according to the normalized image. The pretreatment method of iris images of the invention not only can decrease the time needed by repeated iteration during location, but also can judge the quality of iris image accurately and quickly according to the extracted iris image.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA ZHONGSHAN INST

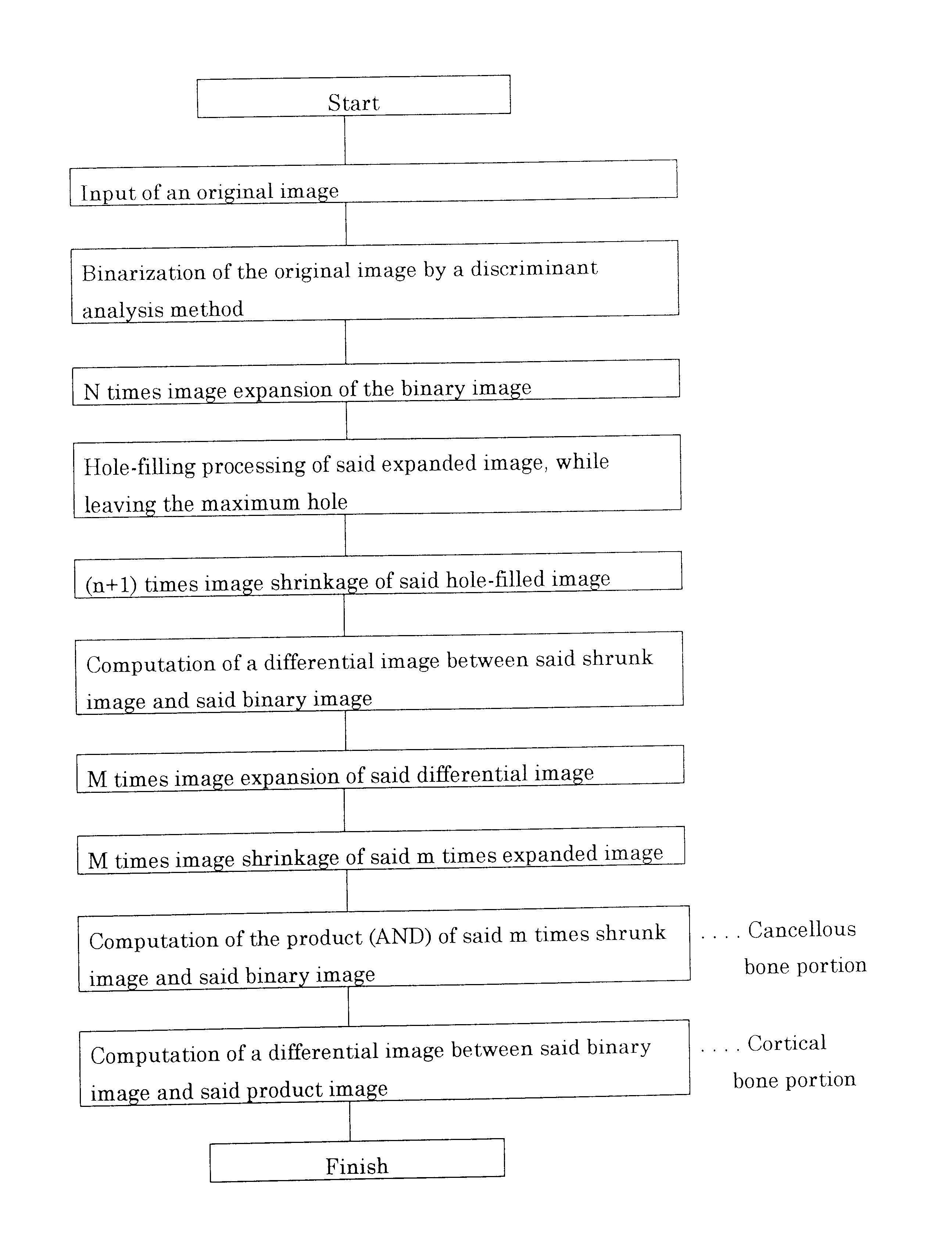

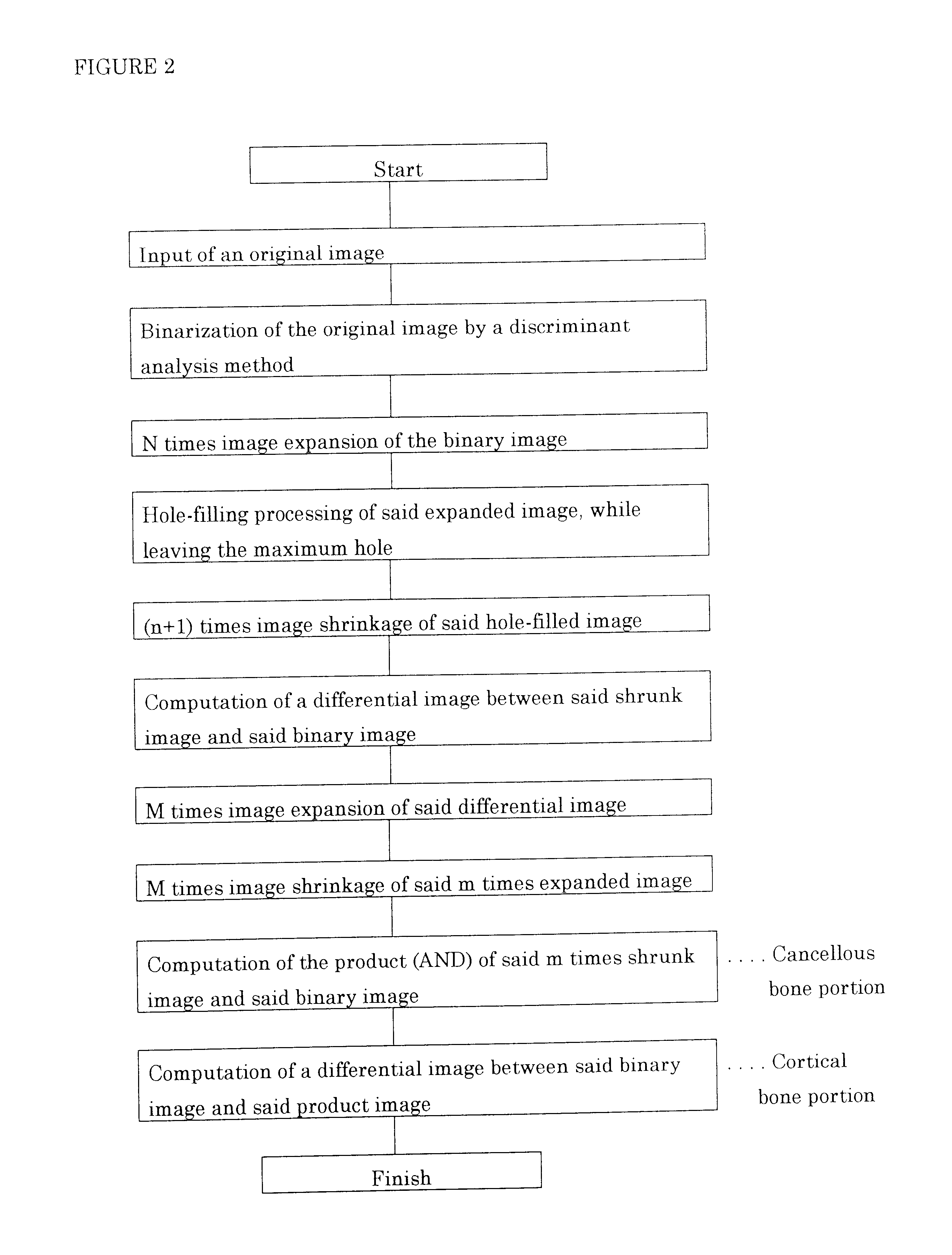

Bone measuring method

InactiveUS6839457B1Increase speedGood repeatabilitySurgeryCharacter and pattern recognitionBone structureBone Cortex

This invention relates to a bone measurement method for measuring a bone shape, structure and architecture on the basis of the tomographic images of a test bone or joint, in more detail, to a bone measurement method characterized by having a template image extraction step for obtaining a wholly continued template image of a bone inner portion surrounded by a cortical bone from the binary image of a test bone cross section, and separating a cortical bone and a cancellous bone by the product of said template image and said binary image, as a bone measurement method which enables the automatic, high-speed and repeatable separation of a cortical bone and a cancellous bone on the basis of the binary image of a test bone or joint cross section and by which a separated three-dimensional image of the cortical bone portion and the cancellous bone portion is obtained as the bases for a non-invasive analyses of three-dimensional bone structure, bone strength, and the like.

Owner:TEIJIN LTD

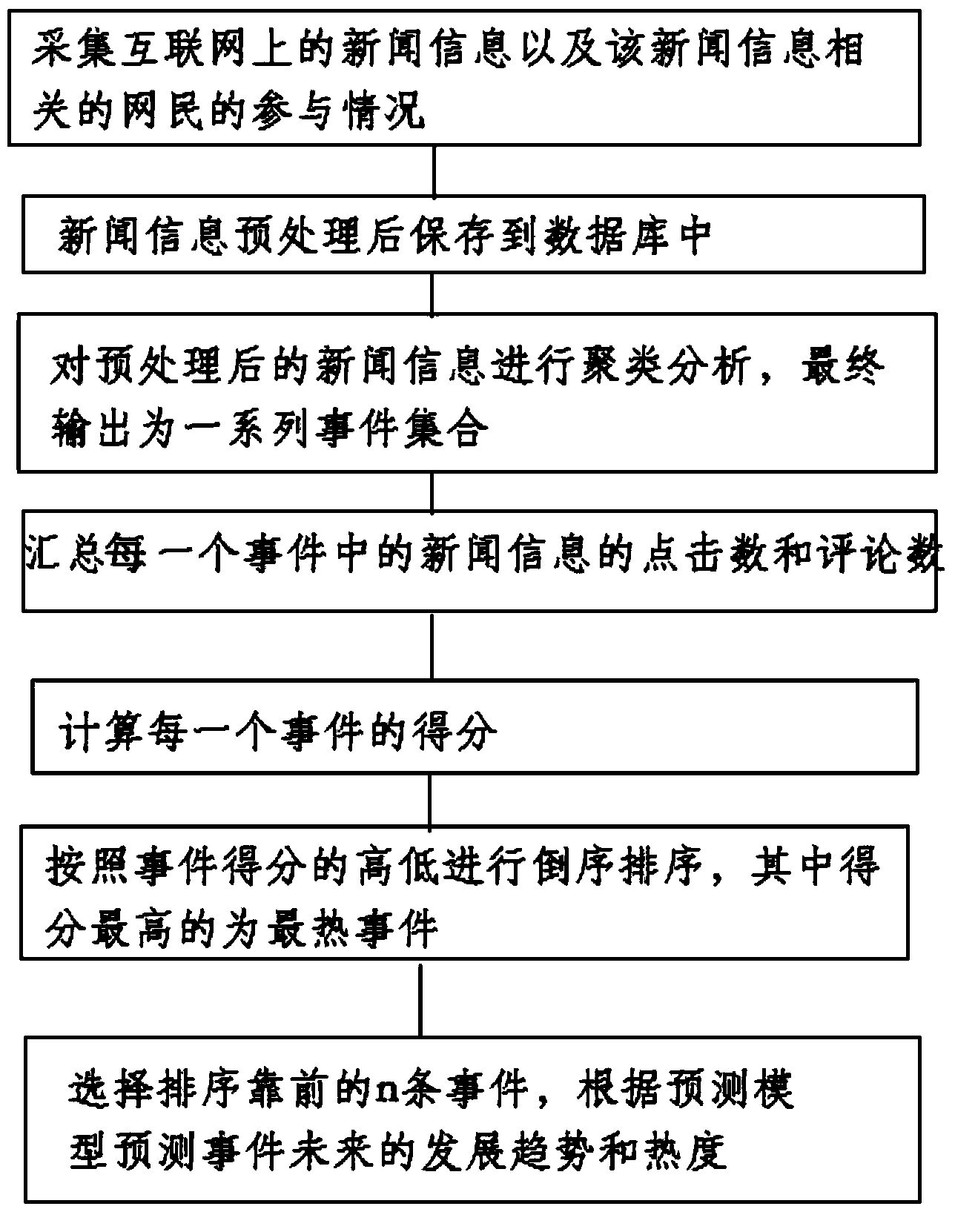

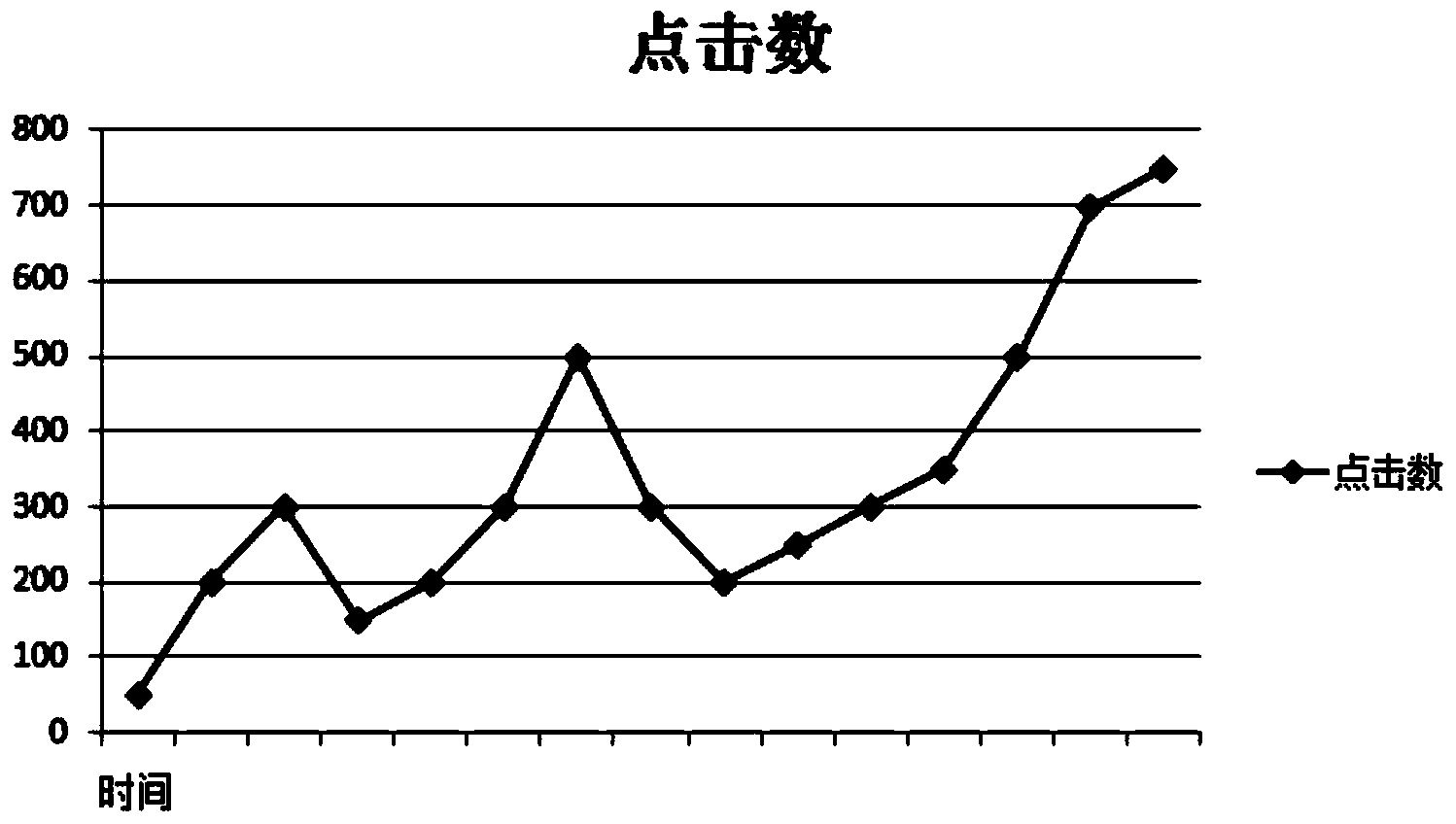

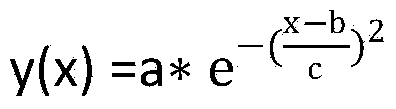

Internet information hotspot predicting method

InactiveCN104035960AAccurate evaluationWeb data retrievalSpecial data processing applicationsThe InternetAnalysis method

The invention relates to a network information collecting and analyzing method, in particular to an internet information hotspot predicting method. The internet information hotspot predicting method aims to meet wide requirements for information hotspot prediction and solve bottlenecks in the prior art, a hotspot information evaluation model is built according to the characteristic that users actively participate in internet information activities under Web2.0, and an internet popularity evaluation algorithm is given. Experiment results show that the algorithm can accurately evaluate information popularity through comprehensive use of user feedback, web pages and other information.

Owner:DONGGUAN QOOCC INFORMATION TECH

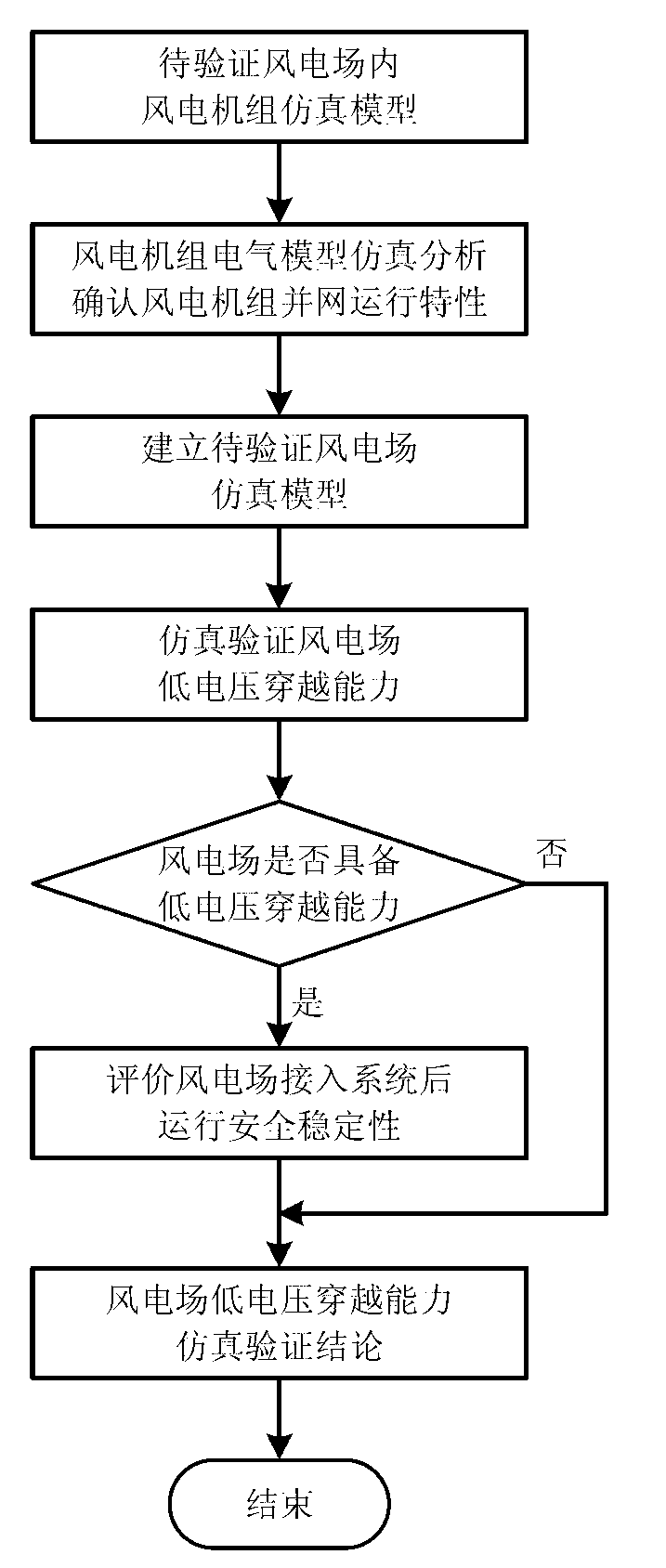

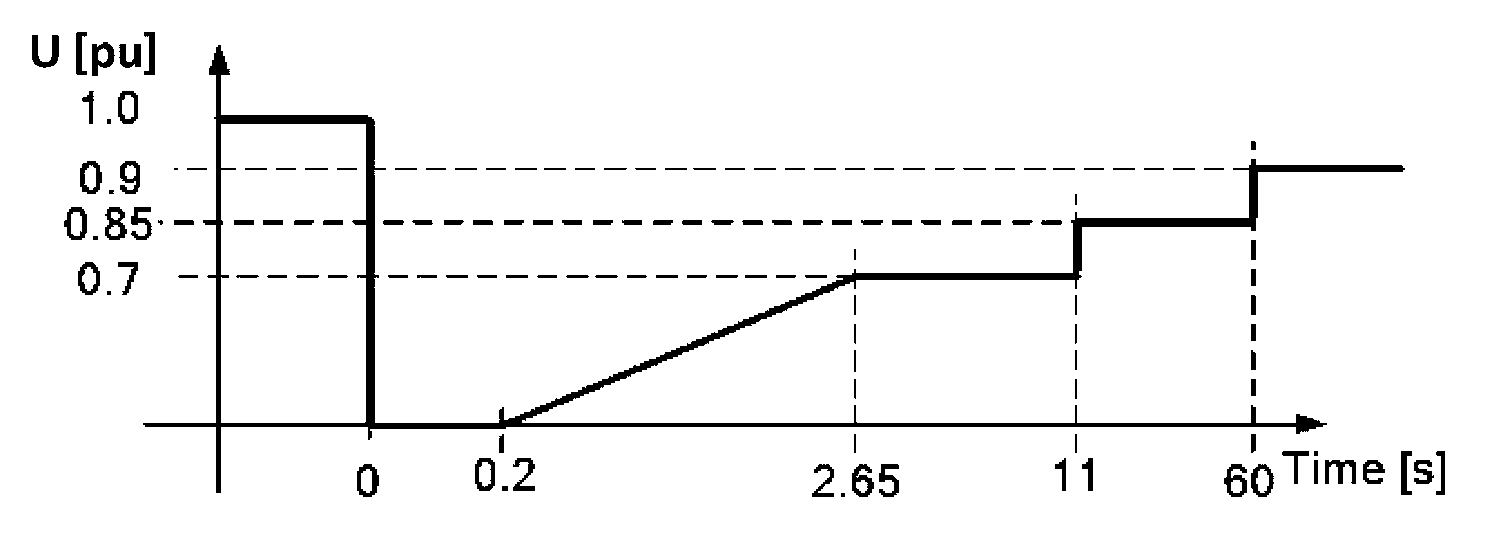

Simulation verification method for low voltage ride through (LVRT) of wind farm

ActiveCN102799722AEnsure safe and stable operationAvoid large-scale wind power off-grid accidentsWind motor controlEngine fuctionsElectricityPower grid

The invention provides a simulation verification method for low voltage ride through (LVRT) of a wind farm. The method comprises the following steps of: analyzing operating characteristics of a wind generation set according to a verified wind generation set electric simulation model; establishing a wind farm electric simulation model, and verifying whether the wind farm has LVRT or not; and establishing a regional power system simulation model comprising the wind farm electric simulation model, and verifying influence of wind farm grid connection on secure and stable operation of a power system. The invention provides a complete and effective method for verifying the LVRT of the wind farm; and the method has positive significance on judging whether the wind farm meets the grid connection requirement or not, avoiding large-scale wind power off-line accidents and ensuring secure and stable operation of a power grid, and lays a foundation for establishing and perfecting a wind power grid-connected authentication system in China.

Owner:CHINA ELECTRIC POWER RES INST +2

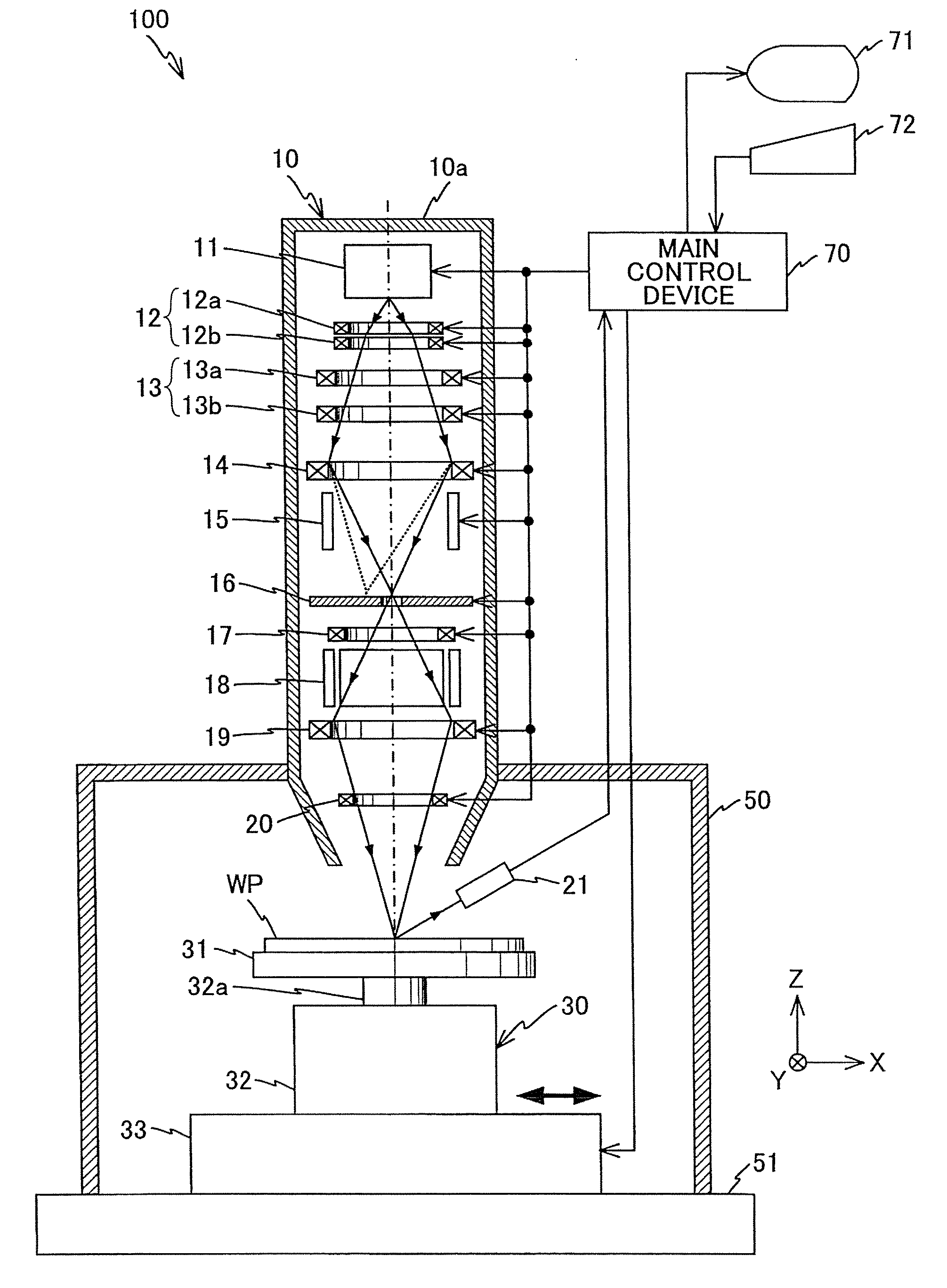

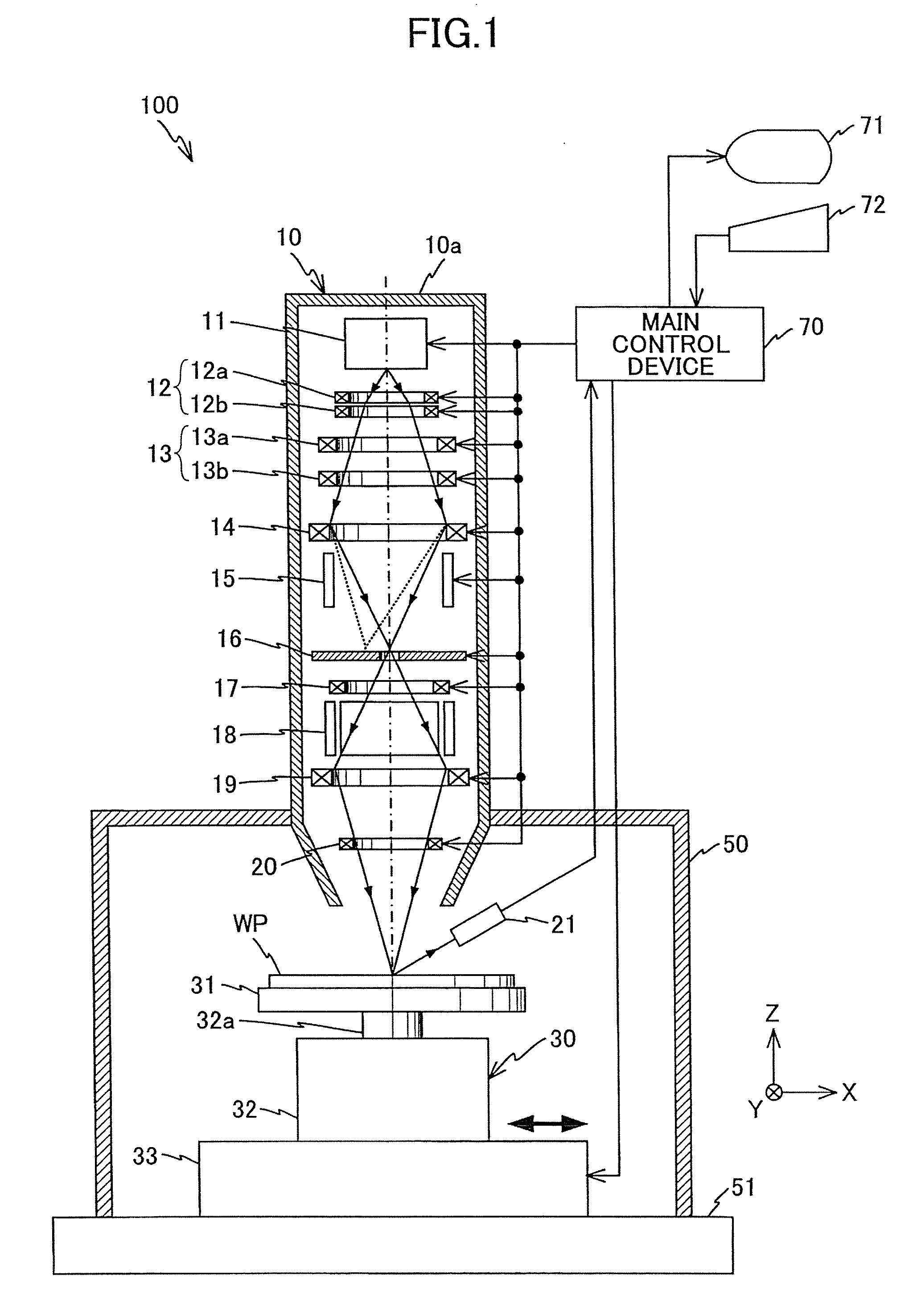

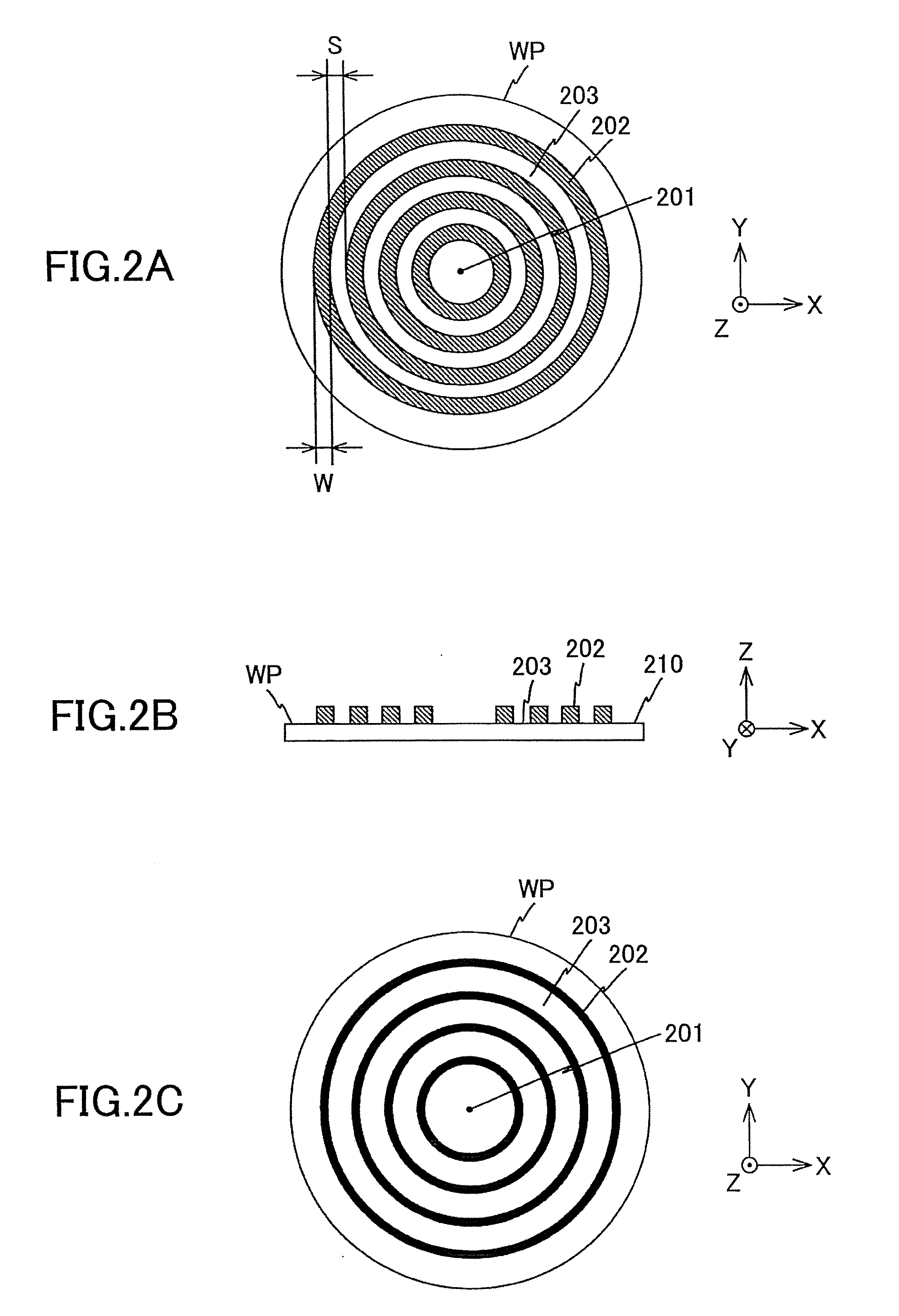

Aberration evaluation pattern, aberration evaluation method, aberration correction method, electron beam drawing apparatus, electron microscope, master, stamper, recording medium, and structure

InactiveUS20100227200A1Accurately observeAccurately manufactureRecord information storageCharacter and pattern recognitionPhysicsAstigmatism

A method of evaluating astigmatism of an irradiation system irradiating an electron beam is disclosed. In this method, a figure pattern consisting of plural (for example, four) concentric circles is formed on a reference sample “WP” and an image (scanned image) is formed based on an electron signal obtained by scanning the electron beam onto the reference sample “WP”. In the scanned image, the image has a blur in a region with its longitudinal direction parallel to the generating direction of the astigmatism and the size of the blur depends on magnitude of the astigmatism. Therefore, the direction and the magnitude of the astigmatism of the irradiation system of an irradiation apparatus can be detected based on the obtained scanned image.

Owner:RICOH KK +1

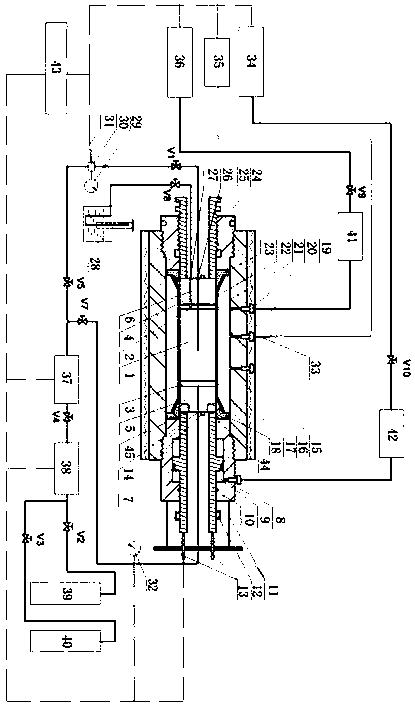

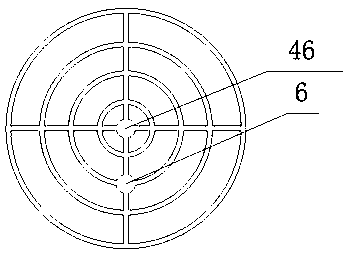

Supercritical carbon dioxide fracture-creepage-seepage test device for high-temperature high-pressure coal petrography

InactiveCN110057739AMonitor pressureRich researchPermeability/surface area analysisEngineeringHigh pressure

The invention discloses a supercritical carbon dioxide fracture-creepage-seepage test device for high-temperature high-pressure coal petrography. The device comprises a triaxial cell, a supercriticalcarbon dioxide generator system, an axle load and confining pressure loading system, an acoustic emission monitoring system, a temperature rise control system, a deformation-pressure monitoring systemand a permeability measuring system. The device is capable of realizing the supercritical carbon dioxide fluid fracture test of coal petrography under high temperature and high pressure, monitoring and recording the temperature and pressure changes of supercritical carbon dioxide and characteristics of fracture cracking and extension in the supercritical carbon dioxide fracture process in real time, monitoring and recording the axial and radial deformations of coal petrography samples in real time, directly and effectively measuring the DH4 permeability of the coal petrography before and after the fracture without unloading the coal petrography sample stress, and measuring the CH4 permeability of the coal petrography after the fracture under the action of creepage. The measurement methodis high in precision, intuitional and high in automation degree, and the device is simple in structure.

Owner:TAIYUAN UNIV OF TECH

Travel time index entropy traffic circulation evaluation method

ActiveCN103413263AAccurate evaluationAccurate measurementData processing applicationsRoad vehicles traffic controlLower limitRoad networks

The invention discloses a travel time index entropy traffic circulation evaluation method which comprises the following steps of a, calculating the free stream speed of each road section in a road network according to historical speed data provided by road network vehicle detection equipment, b, calculating the travel time index of each road section, c, calculating cut-off positions of the travel time indexes according to a quantile method or road capacity, d, calculating discrete probability distribution of the travel time indexes of a probe vehicle, e, calculating the entropy of the travel time indexes, f, calculating the highest possible value of the entropy as the upper limit of a dynamic range through the maximum entropy theorem, g, using the minimum entropy value Hmin of the travel time indexes as the lower limit of the dynamic range of the entropy of the travel time indexes, and h, carrying out normalization processing between the upper limit and the lower limit of the dynamic range of the entropy to obtain a road network traffic circulation evaluation value. The travel time index entropy traffic circulation evaluation method is a scientific characterization method of traffic circulation states, and measurement of traffic jam severity degree is achieved from the aspects of system confusion and randomness and uncertainty of travel time.

Owner:北京交通发展研究院

Small multifunctional sample room for LIBS (laser-induced breakdown spectroscopy)

The invention discloses a small multifunctional sample room for LIBS (laser-induced breakdown spectroscopy), whose structure mainly includes an openable closed cavity, a focusing lens arranged on a casing top of the cavity, a sample plate mounted on a rotatable lifting column table positioned at the center of the bottom of the cavity, and a signal collection device placed on the casing wall of the cavity and connected with an external detector, wherein no less than one sample cell is designed on the sample plate, is positioned in the sample plate and can rotate to the position below the focusing lens during the rotation of the sample plate; and a lens of the signal collection device points to the sample cell rotating to the position below the focusing lens. The small multifunctional sample room disclosed by the invention can be used for bearing solid particulates, powders and liquid samples simultaneously for measurement, has the characteristics of excellent focusing performance, tightness and working performance, small volume and the like, can be integrated in a laser optical spectrum analyzer or used independently, and is particularly suitable for simultaneously analyzing in-situ collected scraps, rock and slurry samples in petroleum drilling and geological exploration.

Owner:SICHUAN UNIV

Quantitative determination RBP4 kit by chemiluminescence magnetic enzymoimmune method

ActiveCN101452001AExtended storage timeStable LuminescenceChemiluminescene/bioluminescenceBiological testingImmunocompetenceMagnetic bead

The invention relates to a medical testing kit for performing quantitative detection on human serum RBP4 using chemiluminescence magnetic-enzyme immunotherapy. The kit is composed of four reagent parts: specificity mouse anti-human RBP4 custodite immunomagnetic beads, enzyme labelling specificity mouse anti-human RBP4 antibody II, chemiluminescence substrate, corresponding titer and quality control liquid. The using method of the kit comprises: using bead particulates as solid phase carrier, combining specificity mouse anti-human RBP4 antibody I on the surface, forming RBP4 specificity immunocompetence beads, capturing antigen RBP4 to be detected in the enzyme labelling specificity mouse anti-human RBP4 antibody II, forming double antibody sandwich composite on the surface of the beads, wherein enzyme marked on the composite reacts with corresponding irradiance substrate in the reaction system to form stable luminous signals, thereby reaching quantitative detection and analysis on RBP4 through strength of the detection light signals. The invention has the advantages of high sensitivity, high specificity, simple and fast operation.

Owner:WUHAN EASYDIAGNOSIS BIOMEDICINE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com