Crack-free multilayer high-barrier packaging film prepared by adopting rotary radio frequency magnetron sputtering method

A radio frequency magnetron sputtering and packaging film technology, which is applied in sputtering coating, coating, metal material coating process, etc., can solve the problems of poor barrier performance and durability of silicon oxide film, and achieve good barrier properties and Effects of durability, increased flexibility, and reduced brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

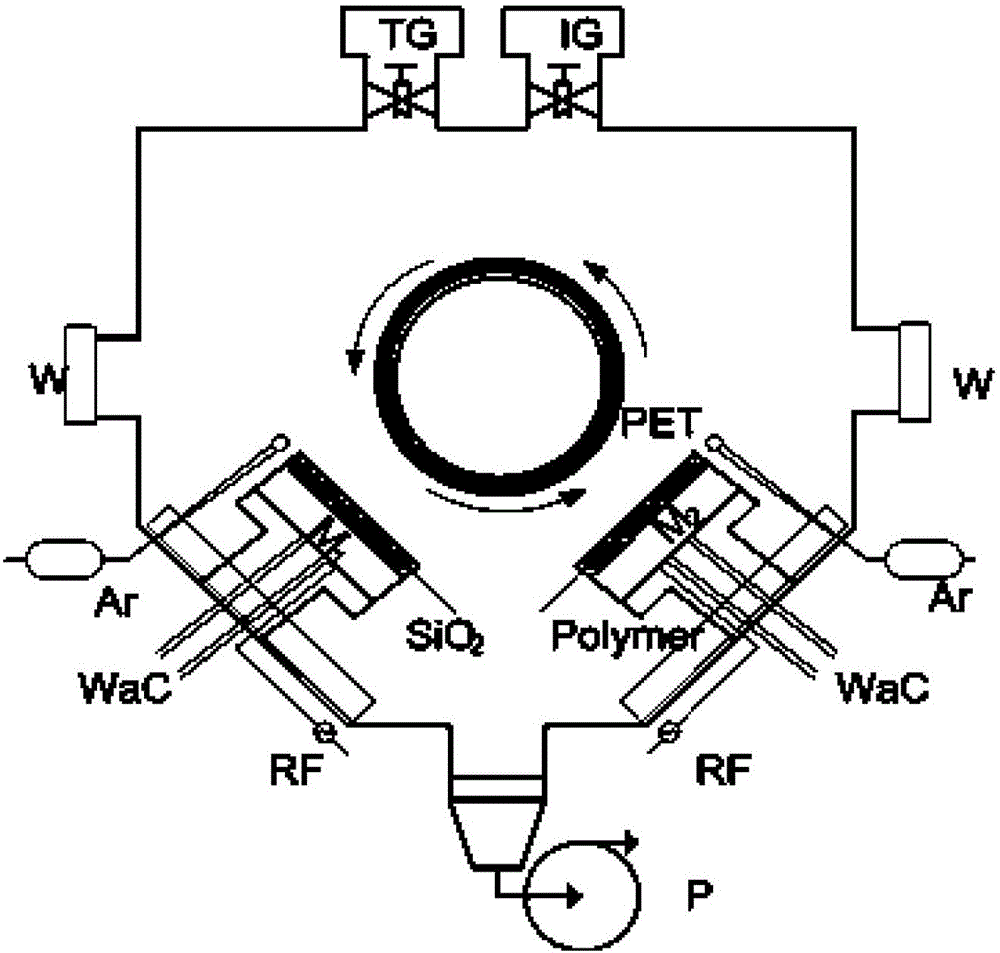

[0018] Specific implementation mode 1: In this implementation mode, the preparation of non-crack multi-layer high barrier packaging film by the rotary radio frequency magnetron sputtering method is carried out according to the following steps:

[0019] 1. Use anhydrous alcohol to ultrasonically clean the plastic substrate with a thickness of 12 to 200 microns for 10 to 20 minutes, then dry it, and then corona treat the substrate for 2 to 6 minutes before placing it in a vacuum chamber;

[0020] 2. Wrap the substrate on the substrate roller and fix it. Start the mechanical pump until the thermocouple gauge shows 380-420Pa. Start the Roots pump until the thermocouple gauge shows 6.5-6.8Pa. Start the molecular pump. Bottom vacuum to 3×10 -4 Pa~5×10 -4 Pa;

[0021] 3. Unscrew the mass flow meter to control the Ar gas flow to 30-120sccm, adjust the working air pressure to 0.2-0.8Pa, then turn on the rotating motor to make the drum drive the substrate to rotate, and the drum rotat...

specific Embodiment approach 2

[0028] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the plastic substrate in step 1 is polyethylene (PE), polypropylene (PP), polyethylene terephthalate (PET) or polyethylene Ethylene naphthalate (PEN). Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0029] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that step four will SiO 2 The RF power density of the ceramic target is adjusted to 1.35~2.86W / cm 2 , Adjust the RF power density of the cured epoxy resin target to 1.12-2.95W / cm 2 . Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com