Method for preparing high-purity tantalum target

A tantalum target, high-purity technology, applied in the field of high-purity tantalum target preparation, can solve the problems of high resistivity, slow sputtering speed, unevenness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062]The present invention mainly realizes the production of tantalum target crystal grains for semiconductor sputtering by controlling the deformation rate of plastic deformation, the temperature and time of heat treatment, and combining the plastic deformation with specific deformation rate and heat treatment at a specific temperature for multiple times. Tantalum target material according to the requirements and crystal orientation requirements.

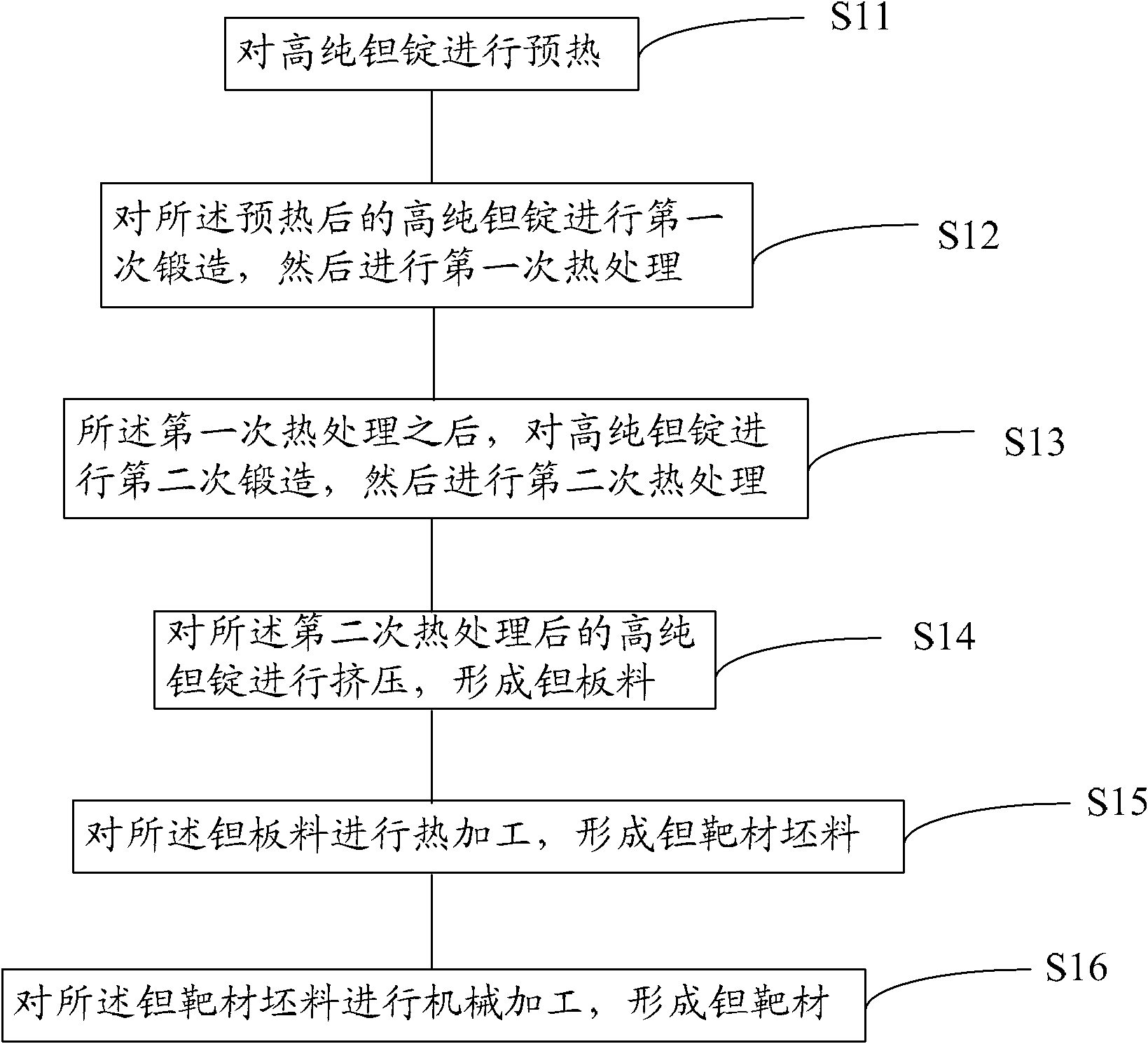

[0063] After the inventor's painstaking research and many practical improvements, the optimal method for making tantalum targets has been obtained, such as figure 1 As shown, it mainly includes the following steps:

[0064] Step S11, preheating the high-purity tantalum ingot;

[0065] Step S12, performing the first forging on the preheated high-purity tantalum ingot, and then performing the first heat treatment;

[0066] Step S13, after the first heat treatment, the high-purity tantalum ingot is forged for the second time, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com