High strength thick steel plate for high heat input welding with excellent brittle crack arrestability and manufacturing method therefor

A technology for high-intensity welding and brittle crack propagation, applied in the field of high-strength thick steel plates, can solve the problems of difficult control of production scale, and achieve the effect of high-intensity welded joints with excellent toughness and improved safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

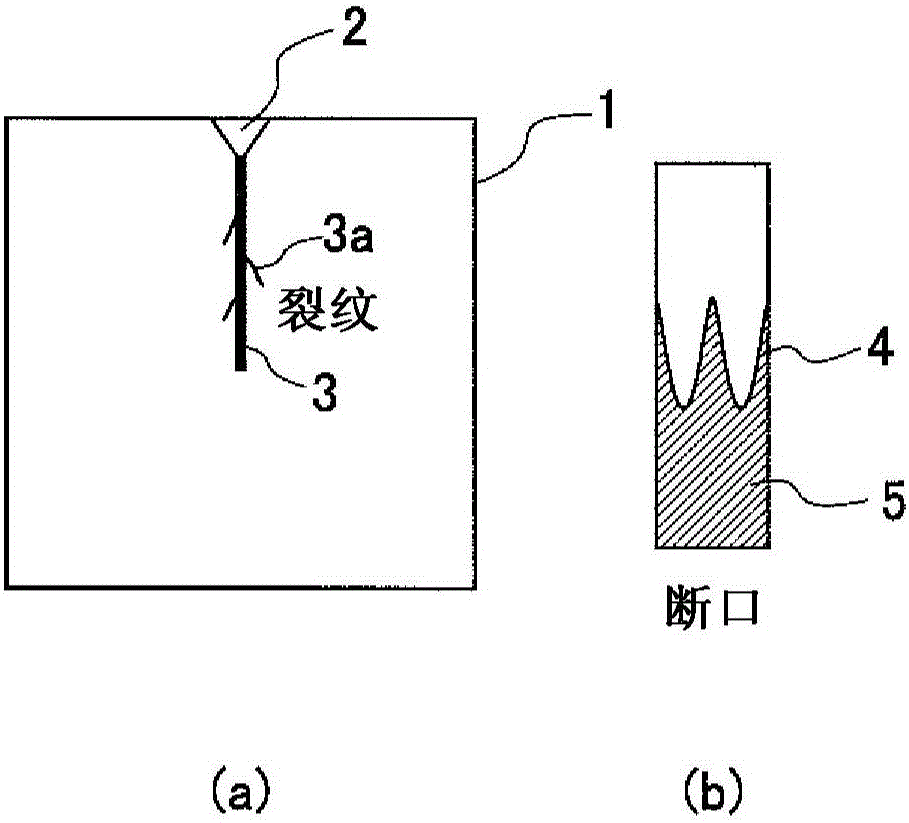

Image

Examples

Embodiment

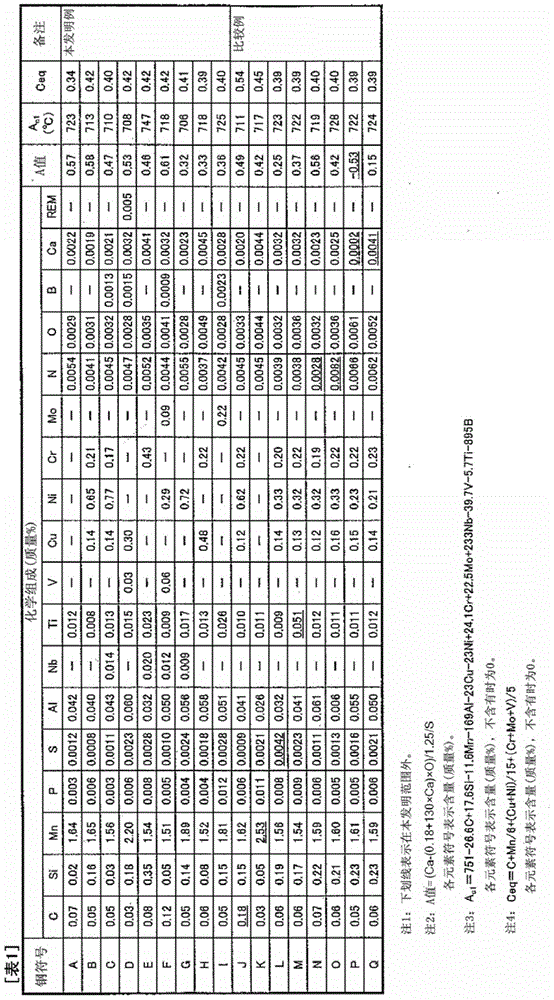

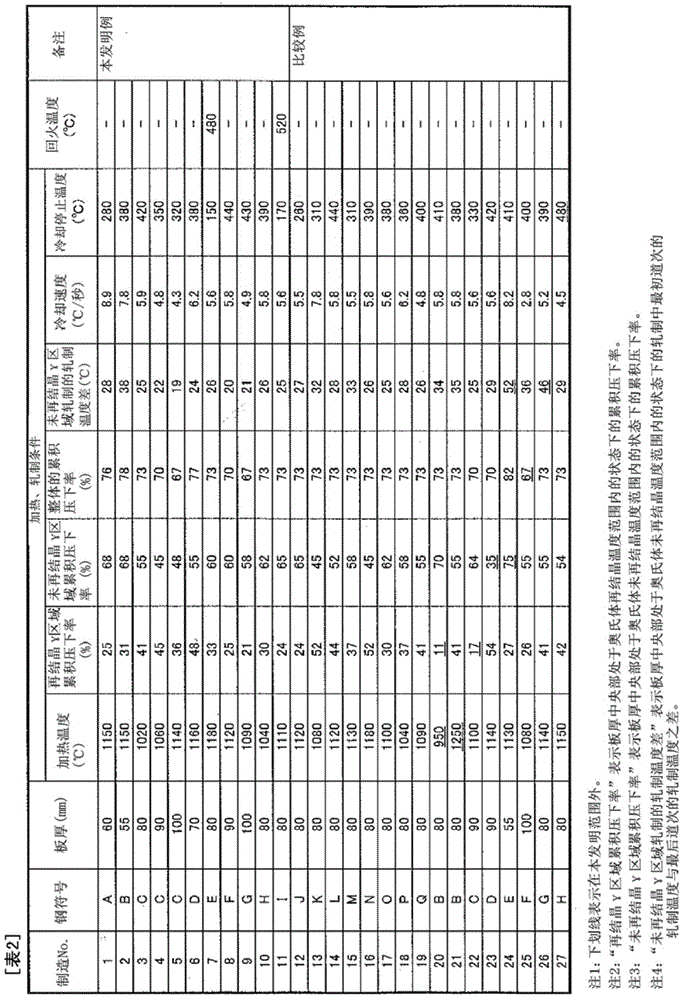

[0136] Melt molten steel (steel codes A to Q) of each composition shown in Table 1 using a converter, and make steel raw materials (slab thickness of 250mm or 300mm) by continuous casting, hot rolling to a plate thickness of 55 to 100mm, and then carry out Cool to obtain No.1-27 test steels. For some, tempering was also performed after cooling. Table 2 shows hot rolling conditions and cooling conditions.

[0137] From the obtained thick steel plate, a φ14mm JIS14A test piece was cut from 1 / 4 of the plate thickness so that the longitudinal direction of the test piece was at right angles to the rolling direction, and a tensile test was performed to measure the yield strength (YS) and tensile strength (TS).

[0138] In addition, in order to evaluate the toughness value, JIS 4 is cut out from the thickness surface layer part and the thickness center part (hereinafter, the thickness center part may be referred to as 1 / 2t part) so that the longitudinal direction of the test piece ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com