High-strength steel having superior brittle crack arrestability, and production method therefor

a high-strength steel and brittle crack technology, applied in the field of high-strength steel, can solve the problems of difficult to improve the brittle crack arrestability of an extremely thick high-strength steel, difficult to secure impact toughness in a central portion, coarse structure of a central portion, etc., and achieve excellent brittle crack arrestability and high yield strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

[0127]After a steel slab with a thickness of 400 mm having a composition of Table 1 was reheated at a temperature of 1050° C., rough rolling was performed at a temperature of 1020° C., so a bar was manufactured. When a slab was rough rolled, an average temperature difference between a central portion and a surface is illustrated in Table 2, a cumulative reduction ratio of 50% is equally applied.

[0128]The average temperature difference between a central portion and a surface during rough rolling of Table 2 refers to a difference between a temperature of a surface of a slab or bar measured immediately before rough rolling, and a temperature of a central portion calculated in consideration of an amount of water sprayed to a bar and a slab thickness immediately before rough rolling, and is a result in which a temperature difference for each pass of rough rolling is measured and a total average value is calculated.

[0129]A thickness of the bar having been rough rolled was 180 mm, and a cr...

embodiment 2

[0142]Except for a change in a Cu / Ni weight ratio of a steel slab as illustrated in Table 3, a steel sheet was manufactured with the same composition and manufacturing conditions as Inventive steel 2 of Embodiment 1, surface properties of the steel sheet having been manufactured were investigated, and a result thereof is illustrated in Table 3.

[0143]In Table 3, surface properties of the steel sheet refer to a measure of whether a star crack in a surface occurred due to hot shortness.

TABLE 3Steel Composition (wt %)Cu / NiSteelPSweightSurfaceGradeCSiMnNiCuTiNb(ppm)(ppm)ratioPropertiesInventive0.0820.311.360.840.410.0160.01777250.48Non-occurrencesteel 7Inventive0.950.440.46Non-occurrencesteel 2Inventive0.370.120.32Non-occurrencesteel 8Inventive0.280.100.35Non-occurrencesteel 9Comparative0.230.180.78Occurrencesteel 7Comparative0.480.330.71Occurrencesteel 8

[0144]As illustrated in Table 3, when a Cu / Ni weight ratio is properly controlled, it is confirmed that surface properties of a steel s...

embodiment 3

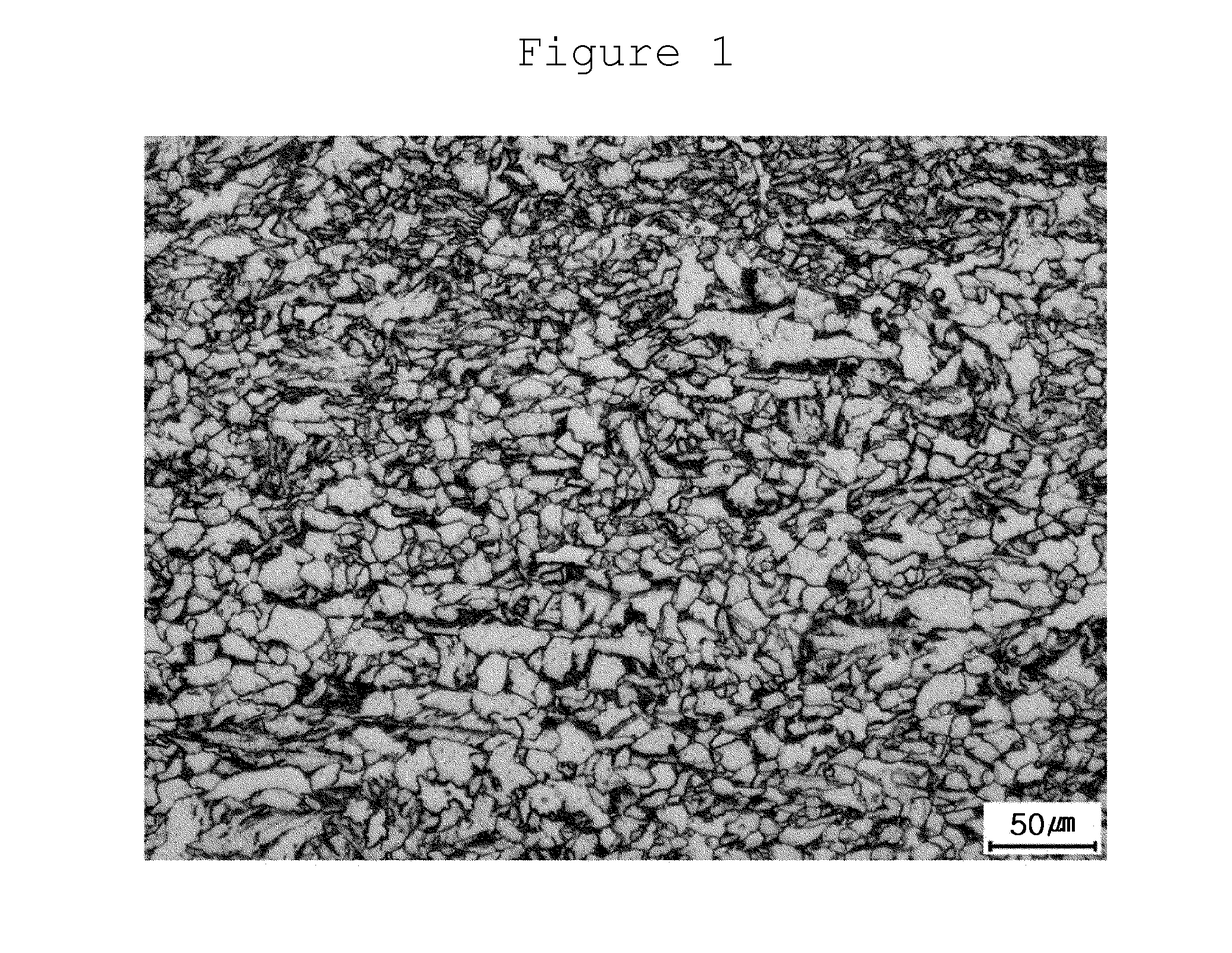

[0145]Except for a change in a crystal grain size (μm) before finish rolling after rough rolling as illustrated in Table 4, a steel sheet was manufactured in the same composition and manufacturing condition as Inventive steel 1 of Embodiment 1. Properties of an average grain size of a central portion of a steel sheet having been manufactured were investigated, and a result thereof is illustrated in Table 4.

TABLE 4Crystal grain size (μm)before finish rolling afterAverage grain size (μm) ofSteel Graderough rollingcentral portionInventive steel 18021.2Inventive steel12529.710Inventive steel10725.611Inventive steel7519.812Inventive steel15521.513Inventive steel11024.514

[0146]As illustrated in Table 4, as a crystal grain size of a central portion of a bar after rough rolling decreases, it is confirmed that an average grain size of a central portion is refined. Thus, it is expected that brittle crack propagation resistance is to be improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com