High-strength steel having excellent brittle crack arrestability and welding part brittle crack initiation resistance, and production method therefor

a technology high-strength steel, which is applied in the direction of manufacturing tools, furnaces, heat treatment equipment, etc., can solve the problems of significant deformation of brittle crack arrestability, insufficient deformation, and deformation of low temperature properties on which grain sizes have the most significant effect, etc., to achieve excellent brittle crack arrestability and high yield strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

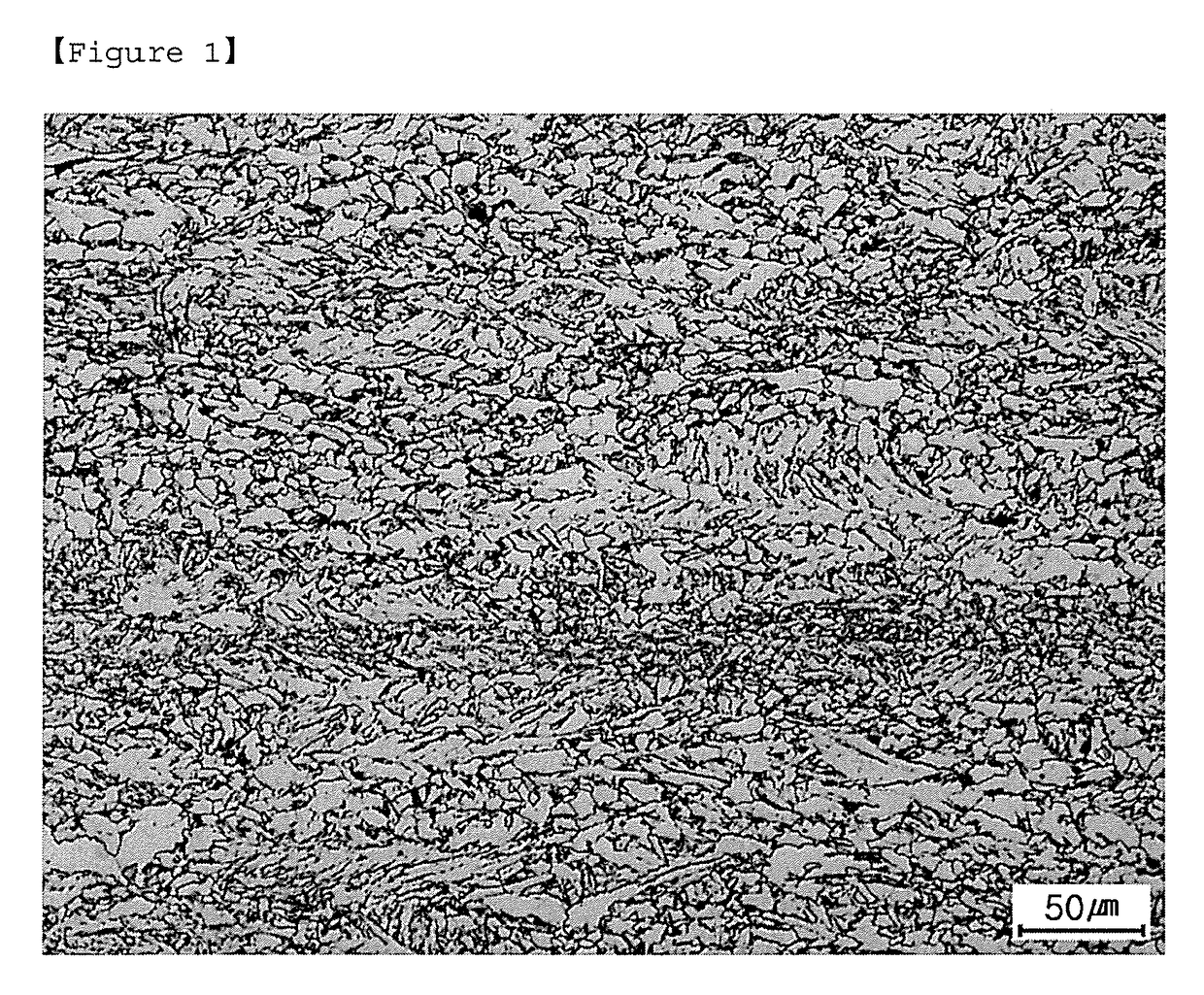

[0032]The inventors of the present disclosure conducted research and experiments to improve yield strength, brittle crack arrestability, and welding zone brittle crack initiation resistance of a thick steel material and proposed the present disclosure based on results thereof.

[0033]In an exemplary embodiment, a steel composition, a structure, and manufacturing conditions of a steel material may be controlled, thereby improving yield strength, brittle crack arrestability, and welding zone brittle crack initiation resistance of the thick steel material.

[0034]A main concept of an exemplary embodiment is as follows.

[0035]1) The steel composition is appropriately controlled to improve strength through solid solution strengthening. In detail, contents of manganese (Mn), nickel (Ni), copper (Cu), and silicon (Si) are optimized for solid solution strengthening.

[0036]2) The steel composition is appropriately controlled to improve strength by increasing hardenability. In detail, the contents ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| weight ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com