Method for evaluating long brittle crack arresting ability in thick steel plate, and testing device and method for manufacturing thick steel plate using same

A technology of brittle crack propagation and manufacturing method, applied in the direction of measuring device, using stable tension/pressure to test material strength, strength characteristics, etc., can solve problems such as unspecified details

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

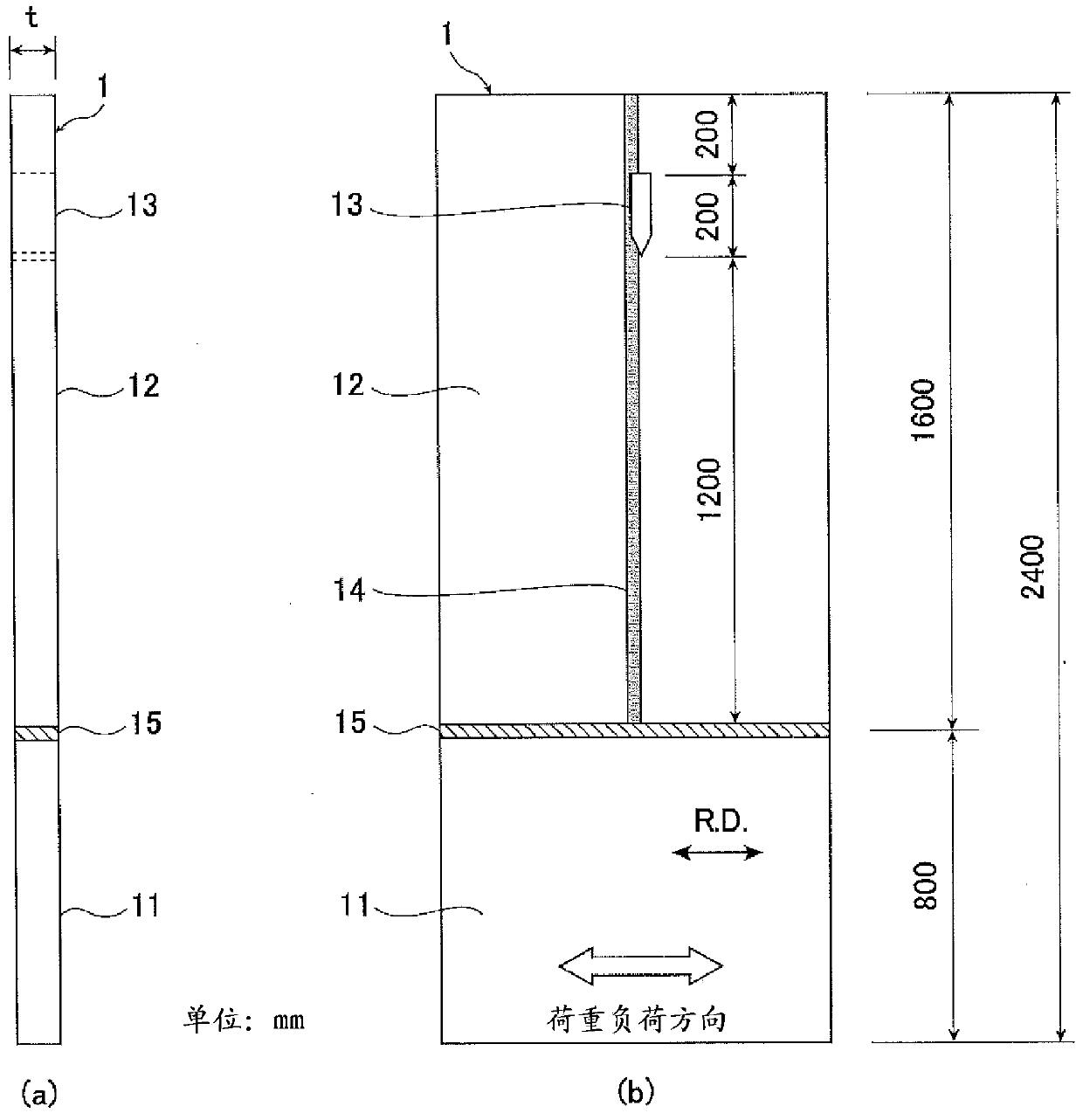

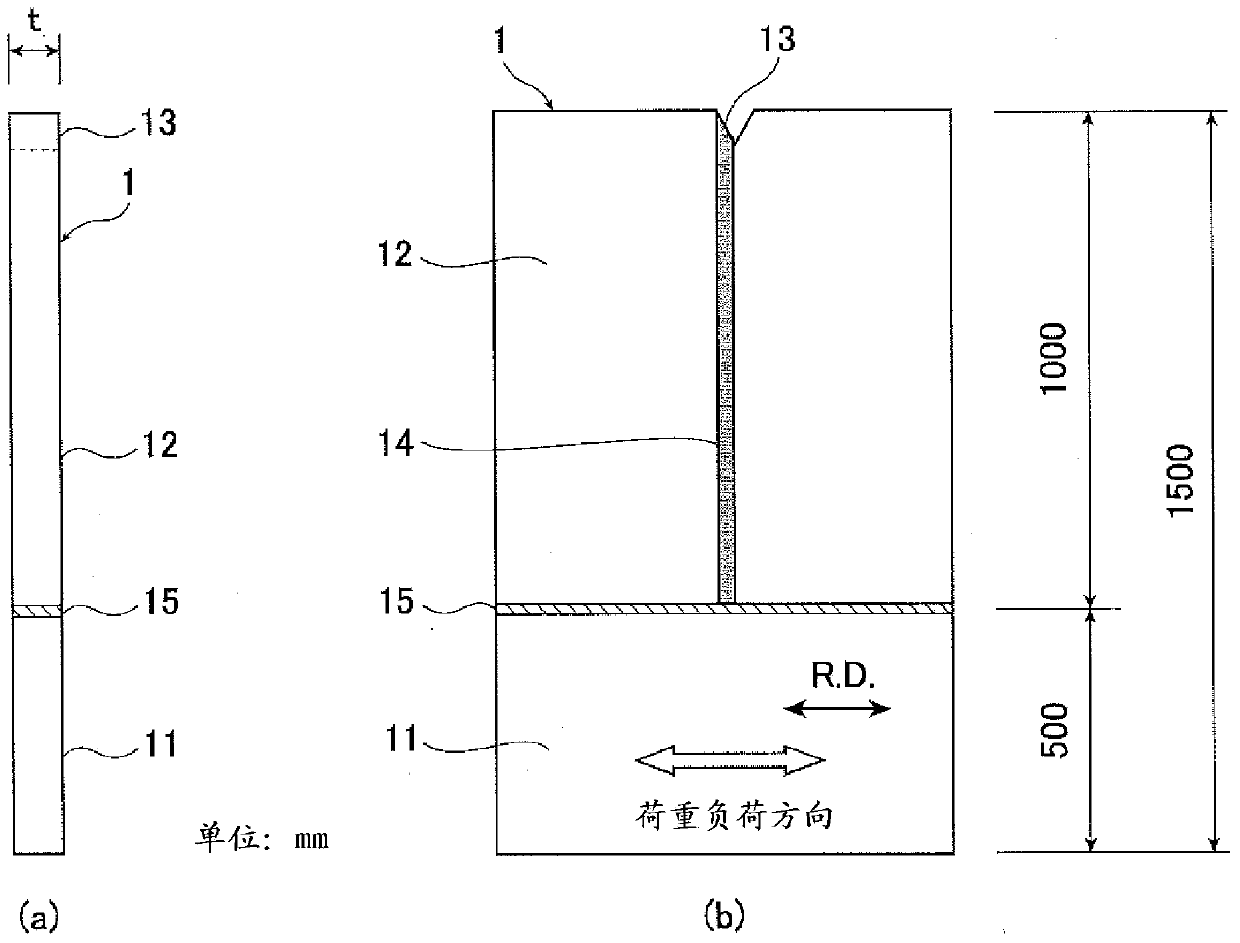

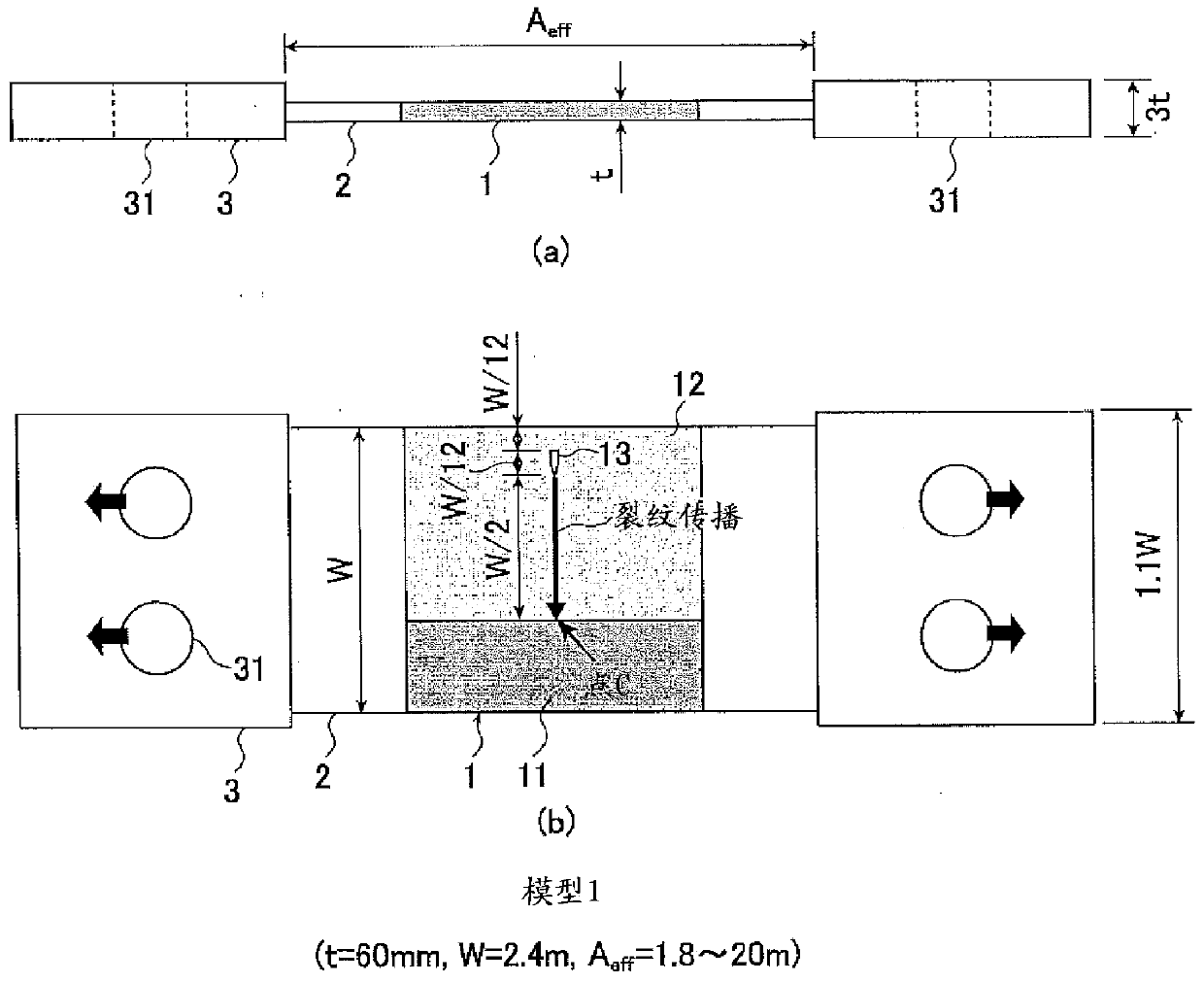

[0116] Using steel slabs adjusted to various chemical compositions shown in Table 1, thick steel plates were produced under the conditions shown in Table 2. For each thick steel plate obtained in this way, make figure 1 The grown ESSO test piece of the size and shape shown was used for the test using the above-mentioned method of the present invention. Tested at a stress of 257N / mm 2 , Test temperature -10 ℃ under the conditions of implementation. Here, the stress is 257N / mm 2 The yield strength (yield strength) commonly used in the hull is 40kgf / mm 2 The maximum allowable stress of grade steel plate, the temperature -10℃ is the design temperature of the ship. grown up ESSO test Figure 7 The large tensile test fixture shown is performed.

[0117]Table 2 shows the results of the grown-up ESSO test. Nos. 2, 3, 5, 6, 8, 9, 12, and 14 are invention examples of the production method of the present invention, and brittle cracks stopped in the test panels. Therefore, they ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com