Steel sheet

A technology of steel plate and plate thickness, applied in the field of steel plate, can solve the problems of coarsening and descending of the structure

Active Publication Date: 2015-05-27

NIPPON STEEL CORP

View PDF47 Cites 19 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] However, the above-mentioned fracture resistance generally tends to decrease significantly at extremely low temperatures.

In addition, in order to improve welding construction efficiency and reduce costs, it is required to apply high heat input welding that can be welded in a single pass. In this case, the joint toughness is prone to coarsening, so it will be further reduced.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

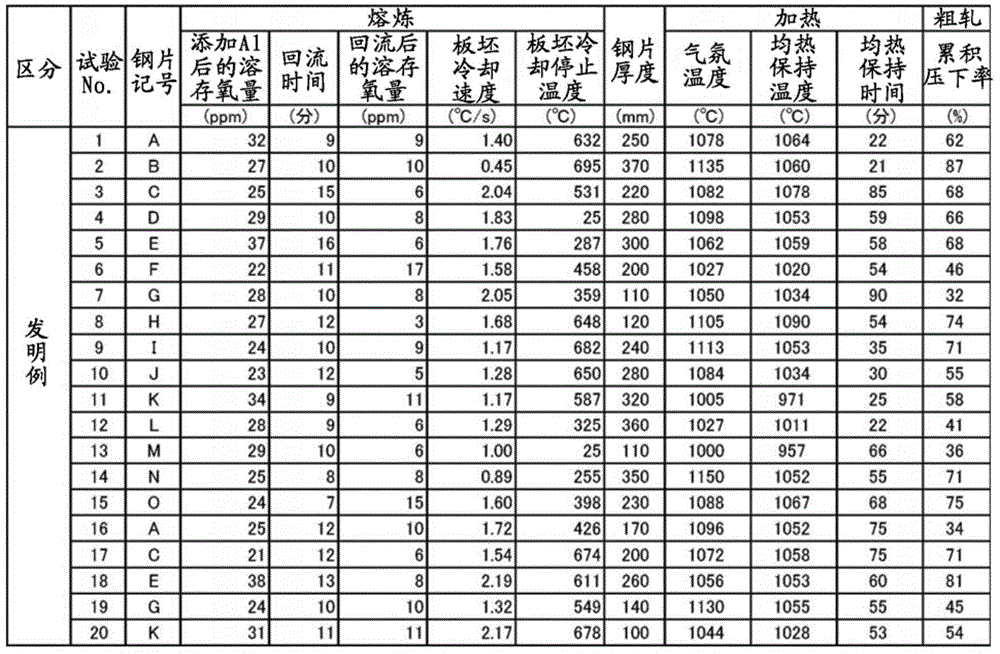

Embodiment 1~20

[0307] Examples 1 to 20 all satisfy the conditions of the present invention, and therefore the base material strength, base material toughness, base material crack arrestability, and joint toughness are all good.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

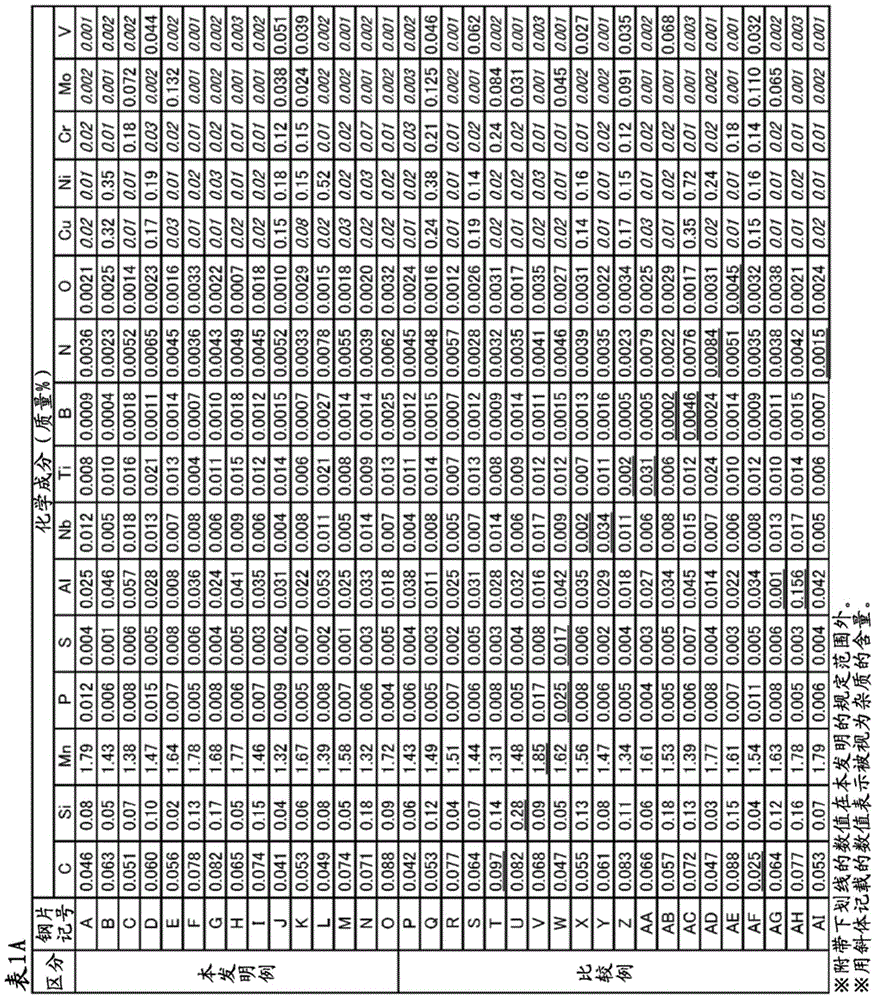

The invention provides a steel sheet which has the characteristics of low manufacturing cost, high production efficiency, base metal brittle crack propagation stop performance and excellent tenacity of a welding heat affected zone in high heat input welding. The steel sheet has prescribed chemical components: 0.30-0.40 mass% of a carbon equivalent, and -0.0015-+0.0015 mass% of SOLB. At 1 / 2 part of a sheet thickness, the weighted average DAVE of a grain size of a grain is 3.0-17.0 [mu] m; at 1 / 2 part of a sheet thickness, the weighted average DAVE of a grain size of a grain is 3.0-17.0 [mu] m; the area percentage of a surface (100) forming a angle within 15 DEG relative to a surface in a rolling direction is 2.0-20.0%; at 1 / 4 part of a sheet thickness, the total number density of circle diameter TiN particles, MnS particles and composite particles with 0.5-2.0 [mu] m equivalents is 20-200 / mm2; at 1 / 4 part of a sheet thickness, the number density of circle diameter oxide particle with 1-10 [mu] m equivalents is 20-200 / mm2, the sheet thickness being 10-35mm, and the yield stress being 300-500 MPa.

Description

technical field [0001] The present invention relates to a steel plate excellent in toughness of a welded heat-affected zone and excellent brittle crack propagation arrest performance of a base material when welded. Background technique [0002] For thick steel plates used in structures such as shipbuilding, construction, tanks, marine structures, and line pipes, in order to suppress brittle fracture of structures, performance to suppress brittle cracks from welded joints is required (hereinafter referred to as joint toughness) ). In addition, for the above-mentioned thick steel plate for structures, even if brittle fracture occurs at the welded joint, performance (hereinafter, crack arrestability) that can stop the propagation of brittle cracks in the base metal is also required. Especially in recent years, the development of oil fields in cold regions such as ice seas where there are large amounts of buried energy such as oil and natural gas has been active. Therefore, in ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C38/14C22C38/54C22C38/32C21D8/02C22C38/16

CPCC01P2002/60C22C38/001C22C38/02C22C38/04C22C38/06C22C38/42C22C38/44C22C38/54C22C38/58C22C2202/00

Inventor 中岛清孝狮狮堀明

Owner NIPPON STEEL CORP

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com