Super-thick steel plate for container ships and preparation method of super-thick steel plate

A technology for extra-thick steel plates and container ships, which is applied in the field of metallurgy, can solve the problems of brittle cracks, poor low-temperature toughness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

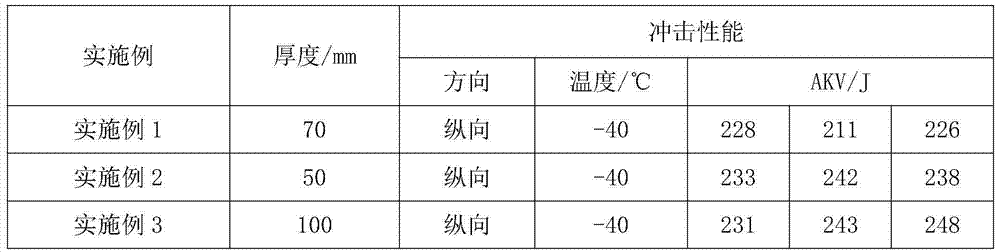

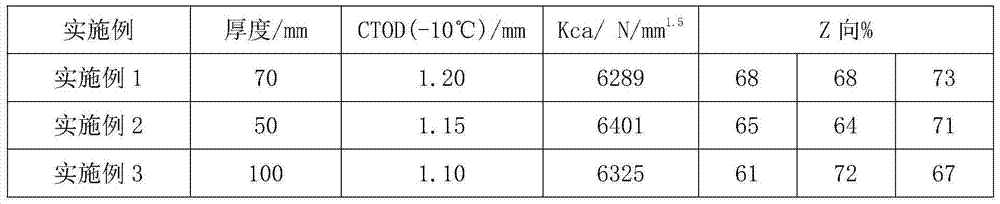

Embodiment 1

[0029] The proportions of each component of the 70mm large thickness container ship steel of the present embodiment are as follows:

[0030] C: 0.080%, Si: 0.35%, Mn: 1.55%, P: 0.0080%, S: 0.0011%, Ni: 0.45%, Nb: 0.025%, V: 0.045%, Ti: 0.020%, Alt: 0.035%, The rest is Fe and unavoidable impurities.

[0031] Among them, the content of impurities is controlled at O≤0.0015%, N≤0.0050%, H≤0.0003%, As≤0.010%, Pb≤0.010%, Sn≤0.010%, Sb≤0.010%.

[0032] During the preparation, the low-phosphorus-sulfur smelting process is adopted, and other trace alloy elements are used to effectively enhance the lamellar tear resistance and brittle crack arrest performance of the steel. Controlled rolling and controlled cooling technology is used to ensure uniform structure and performance of the steel plate, and to obtain large-thickness container ship steel with excellent tearing performance and crack arrest performance. The main process route is: hot metal desulfurization pretreatment→converter ...

Embodiment 2

[0036] The proportions of each component of the large-thickness container ship steel of the present embodiment are as follows:

[0037] C: 0.056%, Si: 0.45%, Mn: 1.64%, P: 0.0078%, S: 0.0013%, Ni: 0.55%, Nb: 0.045%, V: 0.038%, Ti: 0.019%, Alt: 0.033%, The rest is Fe and unavoidable impurities.

[0038] Among them, the content of impurities is controlled at O≤0.0015%, N≤0.0050%, H≤0.0003%, As≤0.010%, Pb≤0.010%, Sn≤0.010%, Sb≤0.010%.

[0039] During the preparation, the low-phosphorus-sulfur smelting process is adopted, and other trace alloy elements are used to effectively enhance the lamellar tear resistance and brittle crack arrest performance of the steel. Controlled rolling and controlled cooling technology is used to ensure uniform structure and performance of the steel plate, and to obtain large-thickness container ship steel with excellent tearing performance and crack arrest performance. The main process route is: hot metal desulfurization pretreatment→converter smeltin...

Embodiment 3

[0043] The proportions of each component of the large-thickness container ship steel of the present embodiment are as follows:

[0044] C: 0.096%, Si: 0.34%, Mn: 1.48%, P: 0.0068%, S: 0.0012%, Ni: 0.48%, Nb: 0.034%, V: 0.040%, Ti: 0.022%, Alt: 0.035%, The rest is Fe and unavoidable impurities.

[0045] Among them, the content of impurities is controlled at O≤0.0015%, N≤0.0050%, H≤0.0003%, As≤0.010%, Pb≤0.010%, Sn≤0.010%, Sb≤0.010%.

[0046] During the preparation, the low-phosphorus-sulfur smelting process is adopted, and other trace alloy elements are used to effectively enhance the lamellar tear resistance and brittle crack arrest performance of the steel. Controlled rolling and controlled cooling technology is used to ensure uniform structure and performance of the steel plate, and to obtain large-thickness container ship steel with excellent tearing performance and crack arrest performance. The main process route is: hot metal desulfurization pretreatment→converter smelt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com