Steel sheet for use at lower temperatures, and method for producing same

A manufacturing method and steel plate technology, applied in the field of low-temperature steel plate and its manufacture, can solve the problems such as difficulty in the height and safety of LNG storage tanks, and achieve the effect of excellent brittle crack propagation stop characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

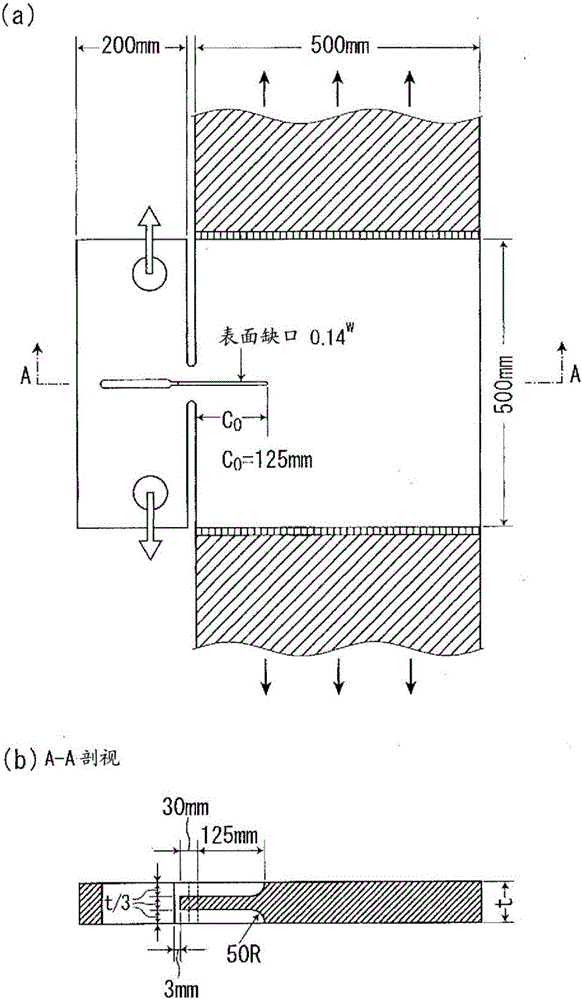

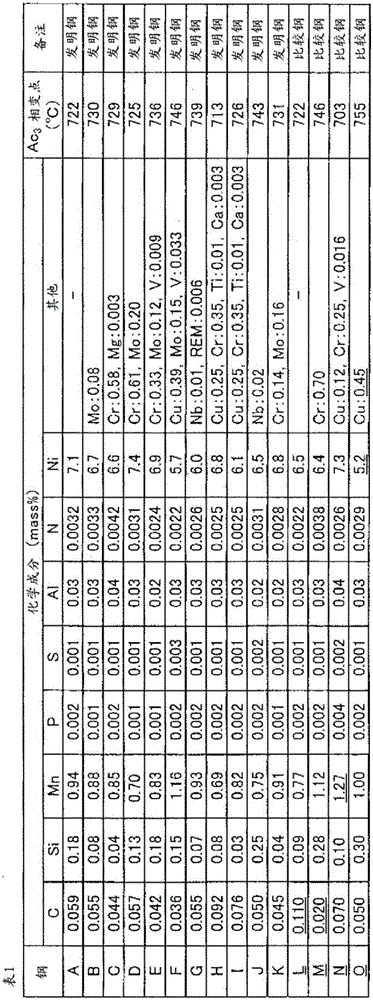

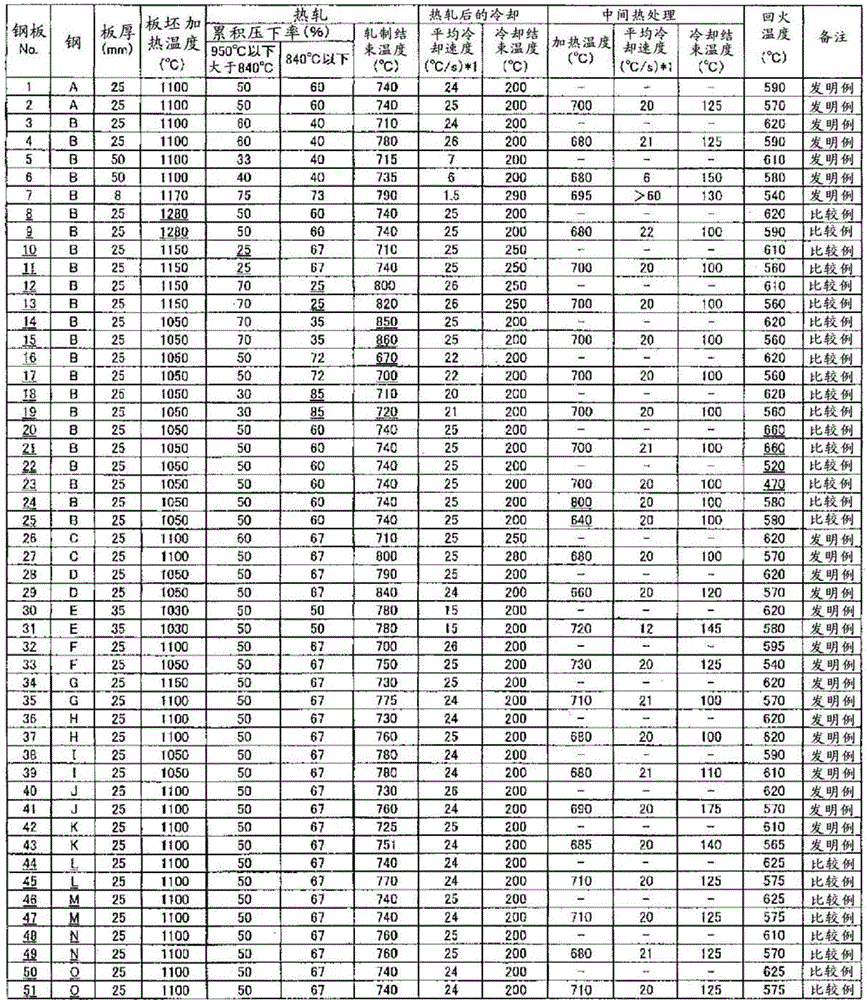

[0155] After heating and hot-rolling a slab (steel material) with a wall thickness of 125 to 250 mm having the chemical composition shown in Table 1, it is forced to cool within 150 seconds after the completion of rolling, and then tempered to obtain a slab with a thickness of 8 mm. ~50mm steel plate. In addition, for some slabs (steel materials), intermediate heat treatment is provided between forced cooling and tempering after hot rolling. Table 2 shows the heating temperature of the slab (steel material), hot rolling conditions, forced cooling conditions after hot rolling, intermediate heat treatment conditions, tempering conditions, and steel plate thicknesses.

[0156] Ac shown in Table 1 3 The transformation point was obtained from the thermal expansion curves of the thermal expansion measurement samples taken from the respective steel sheets when they were heated from room temperature at 5°C / min to 850°C.

[0157] It should be noted that the temperature (below 950° C....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com