TA (1-18)/5 series aluminum alloy/TA (1-18) composite board and welding method

A technology of composite sheet and welding method, which is applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of unsolved double-sided explosive welding of titanium and high-strength aluminum alloy composite sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

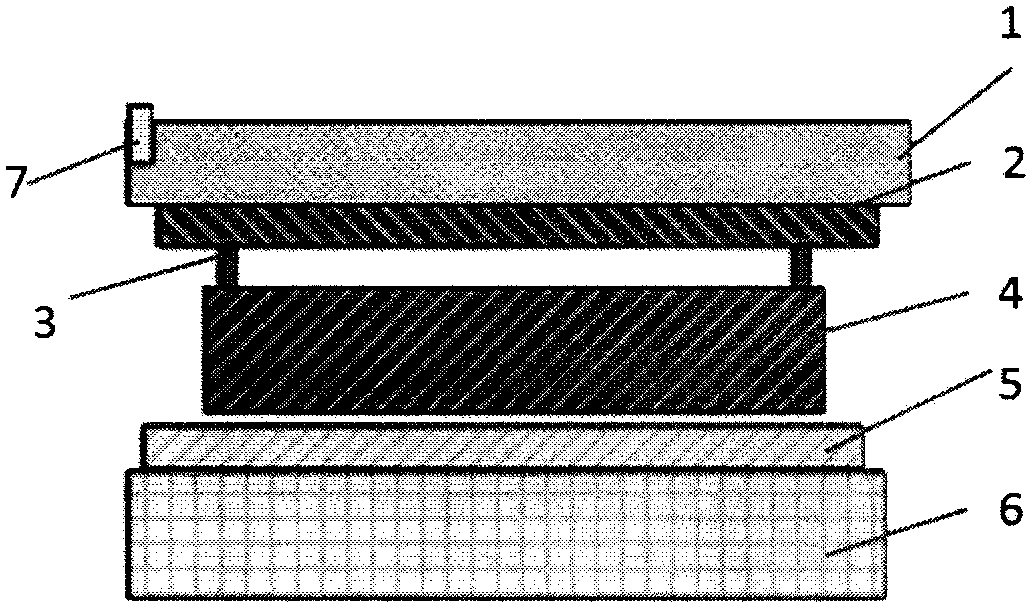

Image

Examples

Embodiment 1

[0035] The user needs TA2-5083-TA2 double-sided ballistic composite material, the size of the substrate 5083 is 5500mm×2500mm×14mm; the size of the compound board TA2 and the charge area are increased by 2δ at the detonation end 0 , increase δ on both sides and tail end respectively 0 , 1.5δ 0 , so the size of the double board is determined to be 5570mm×2550mm×1.5mm. Adopt 60# powder emulsion explosive, explosive thickness δ 0 = 20mm, use a 5mm spacing between the base plate and the doubler plate, and set a 20mm thick fiber protection board between the base plate and the foundation. Twice explosive welding is adopted, and the annealing temperature after the first explosive welding is 400°C, and after cooling with the furnace, leveling and surface treatment are carried out. Secondary explosion welding parameters: double board size is 5570mm×2550mm×1.5mm, 60 # Powdered emulsion explosive, explosive thickness δ 0 =19mm, a 4mm spacing is used between the base plate and the do...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com