Cast wear-resistant tin bronze alloy and preparation method thereof

A technology of bronze alloy and wear-resistant tin is applied in the field of tin-bronze alloy preparation to achieve the effects of less as-cast defects, uniform alloy composition and uniform composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

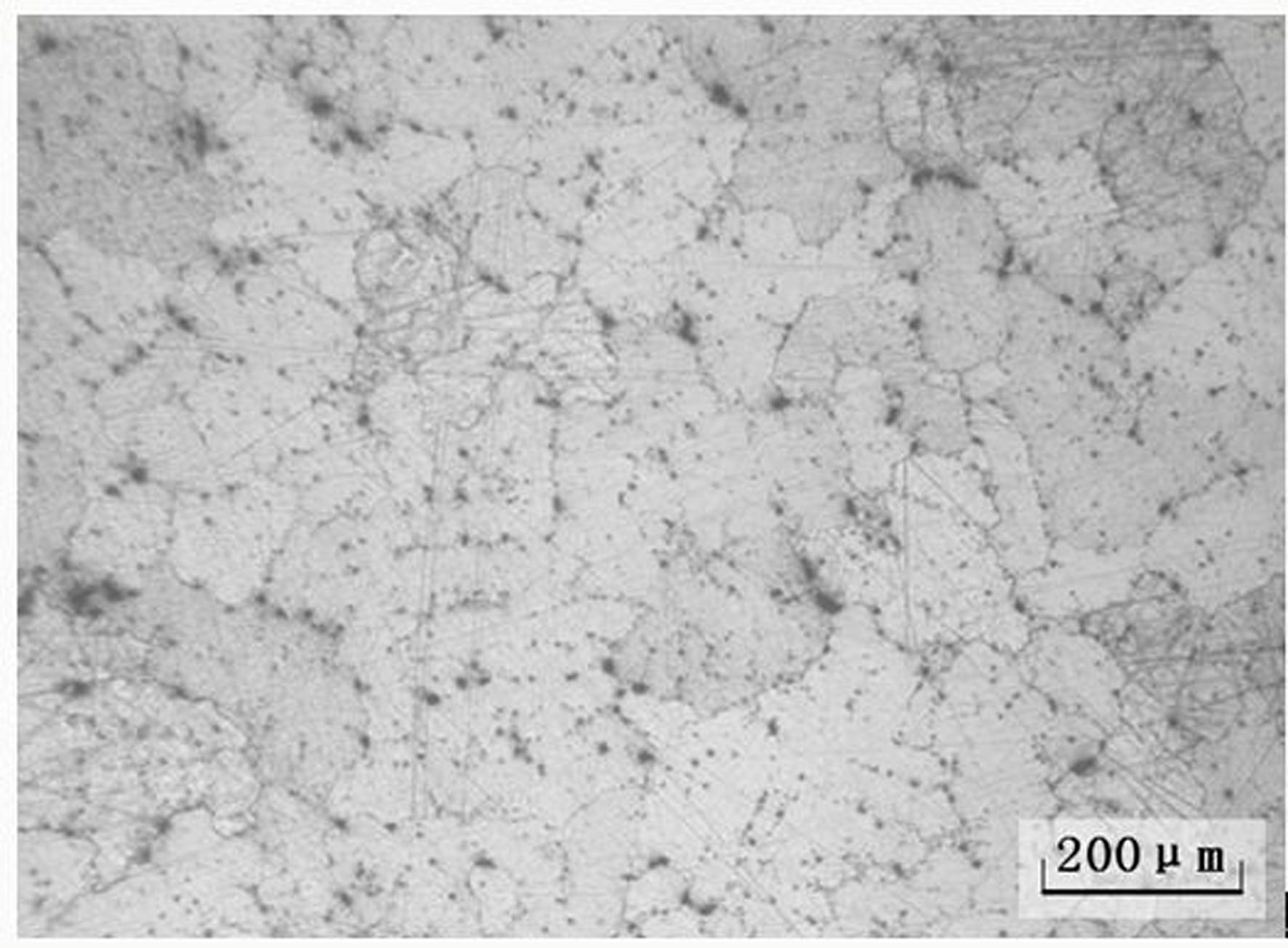

Embodiment 1

[0029] The cast wear-resistant tin-bronze alloy of this embodiment is composed of the following components in weight percentage: Sn 14%, Pb 2%, Ni 1%, impurity components Fe, Sb, Al, Zn, P, Si and Bi The total content is 0.25%, and the balance is Cu.

[0030] The preparation method of the cast wear-resistant tin bronze alloy of the present embodiment, the specific steps are:

[0031] (1) Prepare raw materials: take 1# electrolytic copper plate with a purity of 99.95%, 1# tin ingot with a purity of 99.90%, 1# nickel plate with a purity of 99.99%, 1# lead ingot with a purity of 99.994%, and then cut , drying and surface degreasing treatment, ready for use;

[0032] (2) Ingredients: Weigh the raw materials processed in step (1) according to the composition of cast wear-resistant tin bronze alloy;

[0033] (3) Melting: First add charcoal about 20cm thick into the melting furnace, then add electrolytic copper plates into the melting furnace, heat rapidly to melt the electrolytic ...

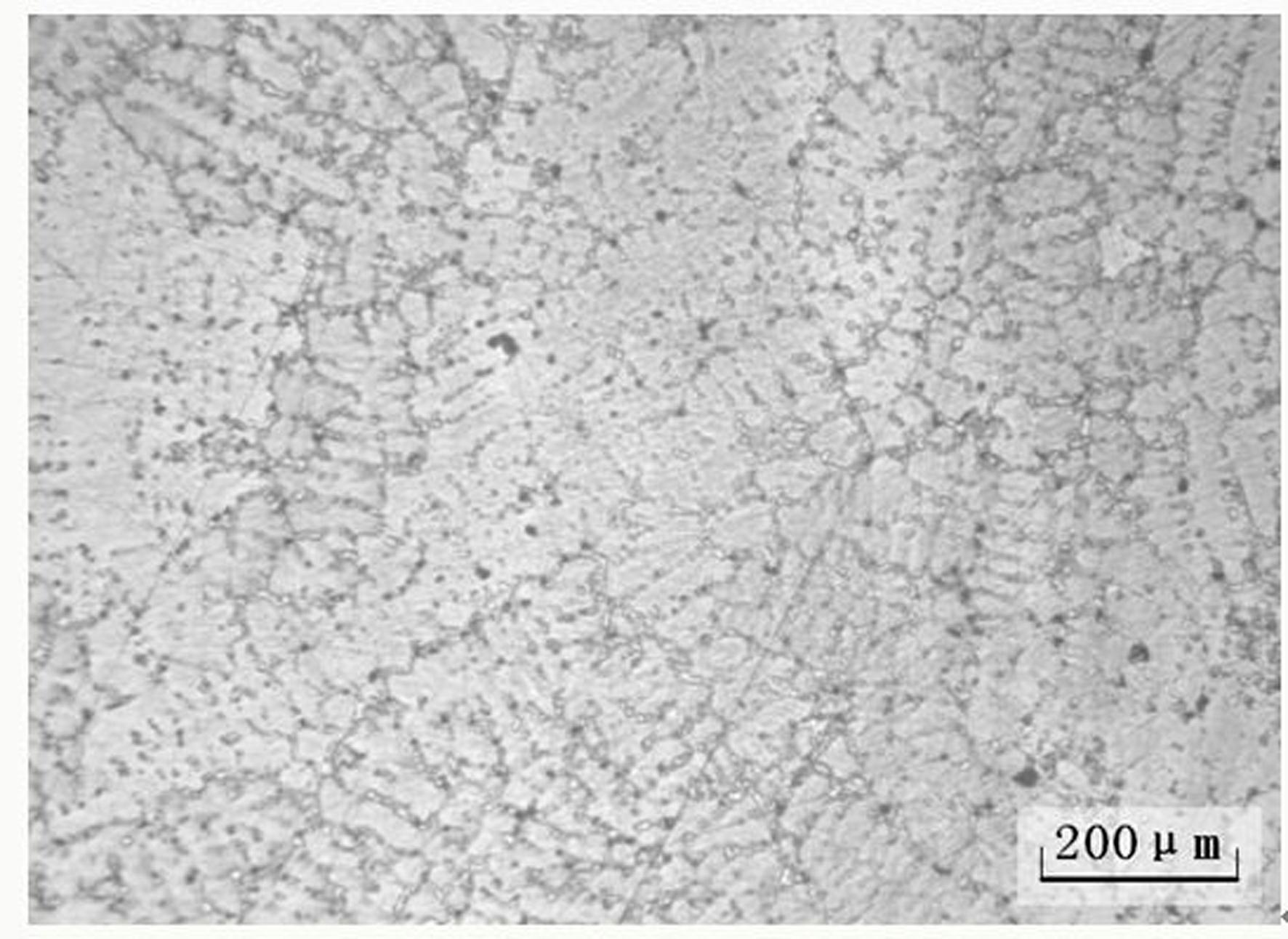

Embodiment 2

[0041] The cast wear-resistant tin-bronze alloy of this embodiment is composed of the following components in percentage by weight: Sn 12%, Pb 3.5%, Ni 2.5%, impurity components Fe, Sb, Al, Zn, P, Si and Bi The total content is 0.23%, and the balance is Cu.

[0042] The preparation method of the cast wear-resistant tin bronze alloy of the present embodiment, the specific steps are:

[0043] (1) Prepare raw materials: take 1# electrolytic copper plate with a purity of 99.95%, 1# tin ingot with a purity of 99.90%, 1# nickel plate with a purity of 99.99%, 1# lead ingot with a purity of 99.994%, and then cut , drying and surface degreasing treatment, ready for use;

[0044] (2) Ingredients: Weigh the raw materials processed in step (1) according to the composition of cast wear-resistant tin bronze alloy;

[0045] (3) Melting: First add charcoal about 20cm thick into the melting furnace, then add electrolytic copper plates into the melting furnace, heat rapidly to melt the electr...

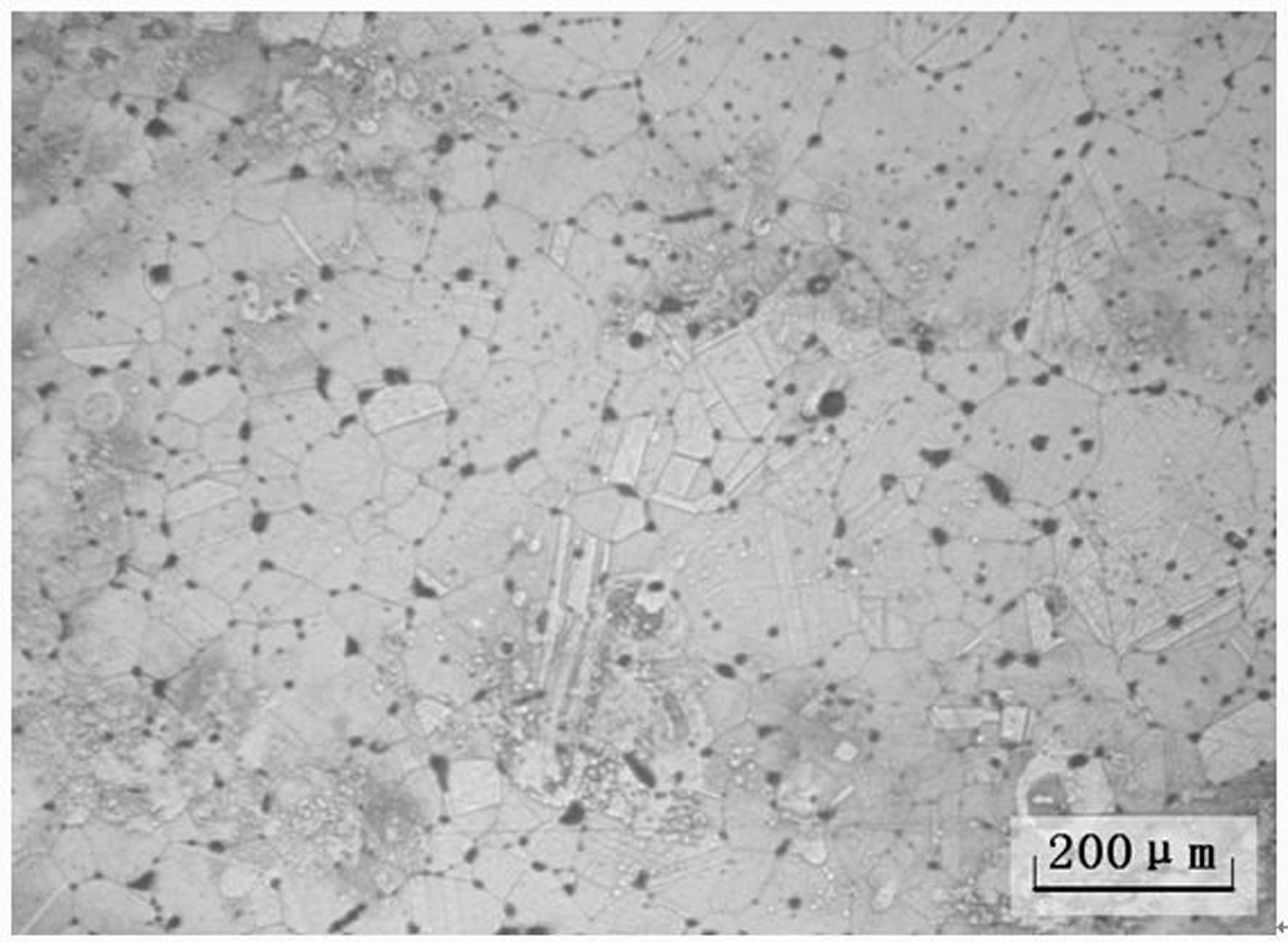

Embodiment 3

[0052] The cast wear-resistant tin-bronze alloy of this embodiment is composed of the following components in weight percentage: Sn 10%, Pb 5%, Ni 4%, impurity components Fe, Sb, Al, Zn, P, Si and Bi The total content is 0.20%, and the balance is Cu.

[0053] The preparation method of the cast wear-resistant tin bronze alloy of the present embodiment, the specific steps are:

[0054] (1) Prepare raw materials: take 1# electrolytic copper plate with a purity of 99.95%, 1# tin ingot with a purity of 99.90%, 1# nickel plate with a purity of 99.99%, 1# lead ingot with a purity of 99.994%, and then cut , drying and surface degreasing treatment, ready for use;

[0055] (2) Ingredients: Weigh the raw materials processed in step (1) according to the composition of cast wear-resistant tin bronze alloy;

[0056] (3) Melting: First add charcoal about 20cm thick into the melting furnace, then add electrolytic copper plates into the melting furnace, heat rapidly to melt the electrolytic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Elongation | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com