Cast titanium alloy material suitable for high temperature of 650-750 DEG C and preparation method thereof

A technology for casting titanium alloy and high temperature, which is applied in the field of titanium alloy materials, can solve the problems of inability to meet aerospace engines, low room temperature plasticity and fracture toughness, and reduce thermal stability of the alloy, and achieves elimination of casting defects, good high temperature performance, and satisfying The effect of design use requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

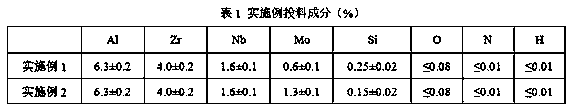

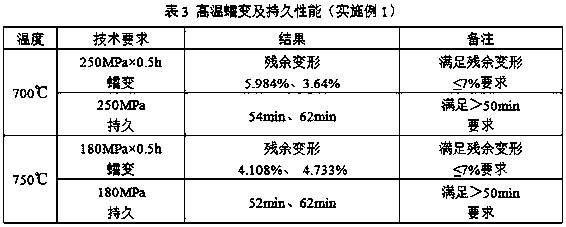

Embodiment 1

[0027] After the test plate in Example 1 was subjected to hot isostatic pressing, there were 5 defects in radiographic inspection. After one repair welding with ZTi700SR special welding wire, the defects were completely removed.

Embodiment 2

[0028] After the test plate in Example 2 was subjected to hot isostatic pressing, there were 3 defects in radiographic inspection. After one repair welding with ZTi700SR special welding wire, there is still one defect, which is a weld crack. After two repair weldings, the defect is completely removed.

[0029] It can be seen that the welding performance of the material prepared by the present invention is good, and casting defects can be completely eliminated after 1-2 times of repair welding.

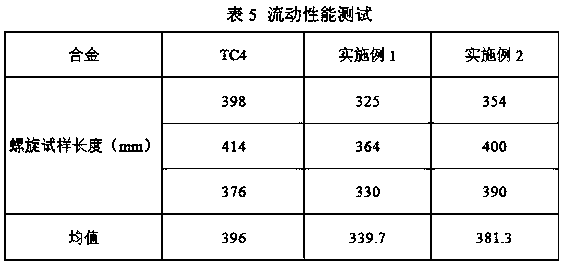

[0030] Sample preparation: the cast titanium alloy material was prepared by using the ingredients of Examples 1 and 2, and the cylindrical samples were casted respectively. After hot isostatic sandblasting, the inner and outer surfaces of the castings cast by the materials in Examples 1 and 2 were of good quality , there are no obvious cracks visible to the naked eye, and there are a small amount of flow marks and cold shuts, and the casting quality of the castings is controllable.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com