Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

93results about How to "Guaranteed forming effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

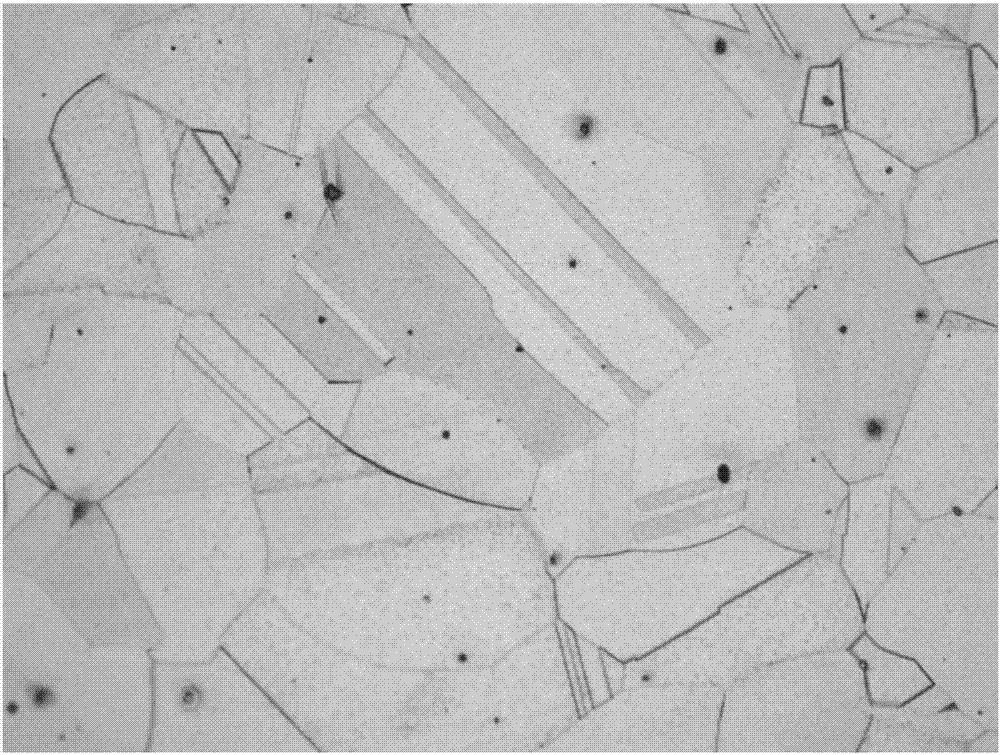

High-strength hot-rolled steel plate

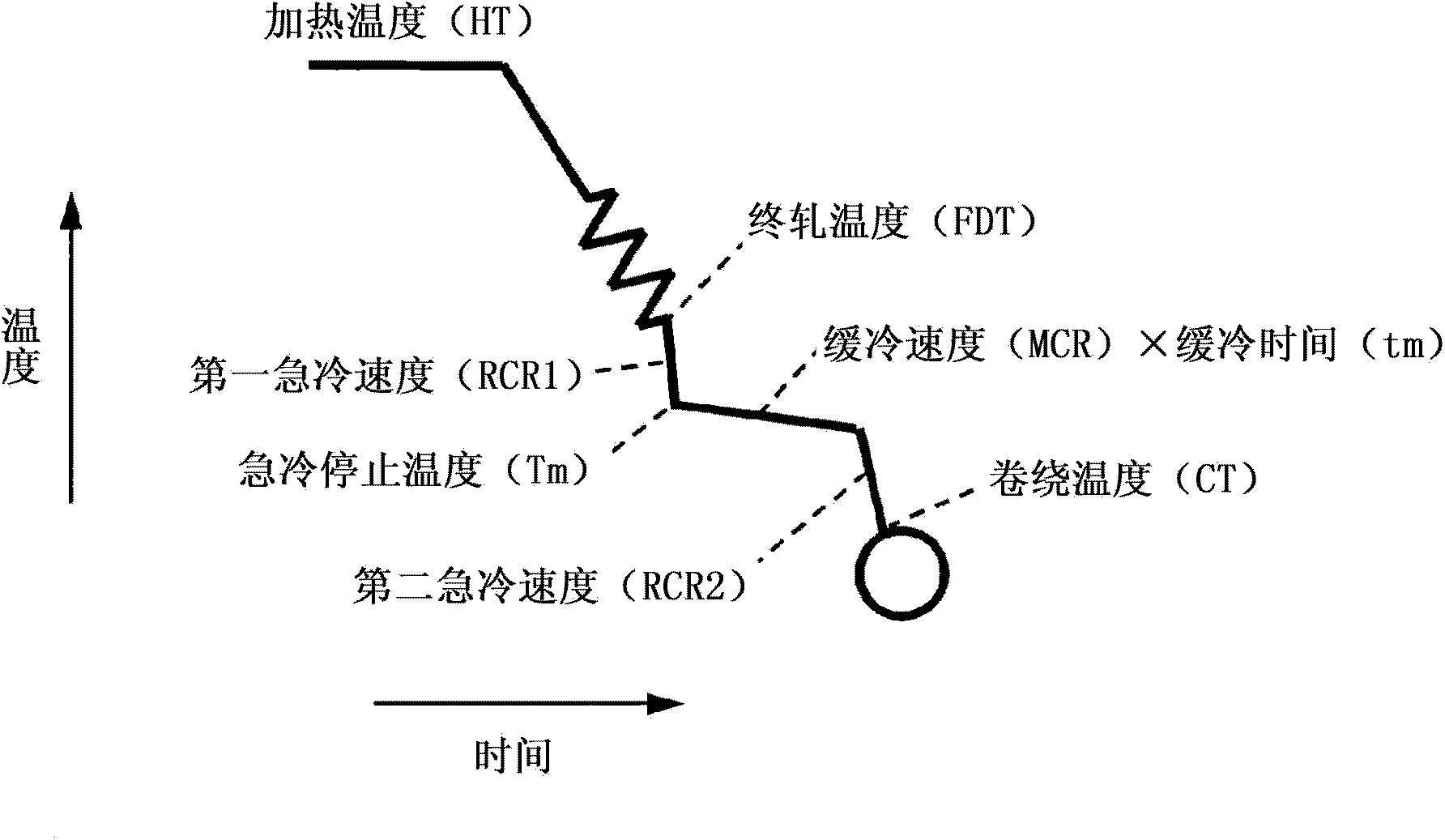

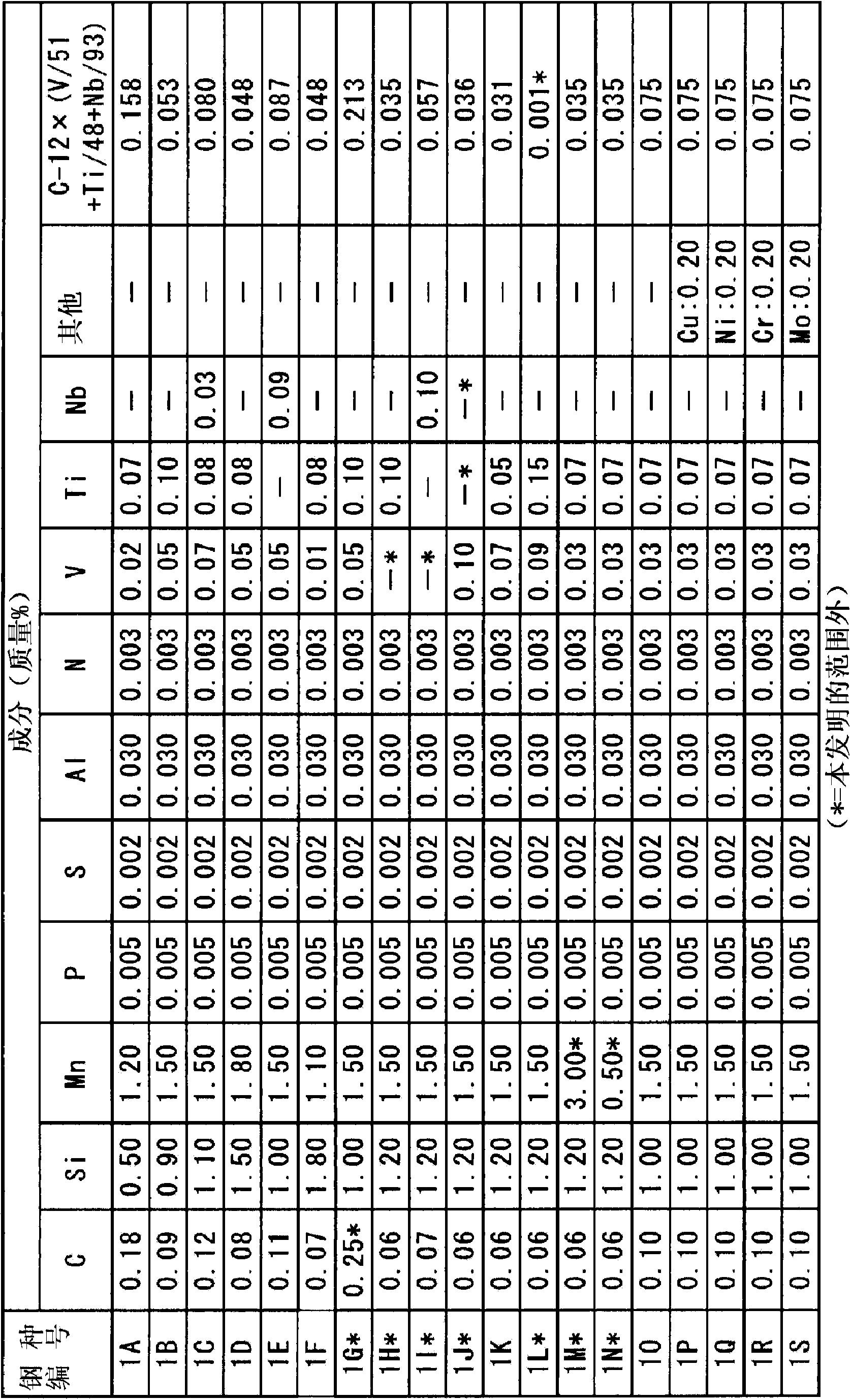

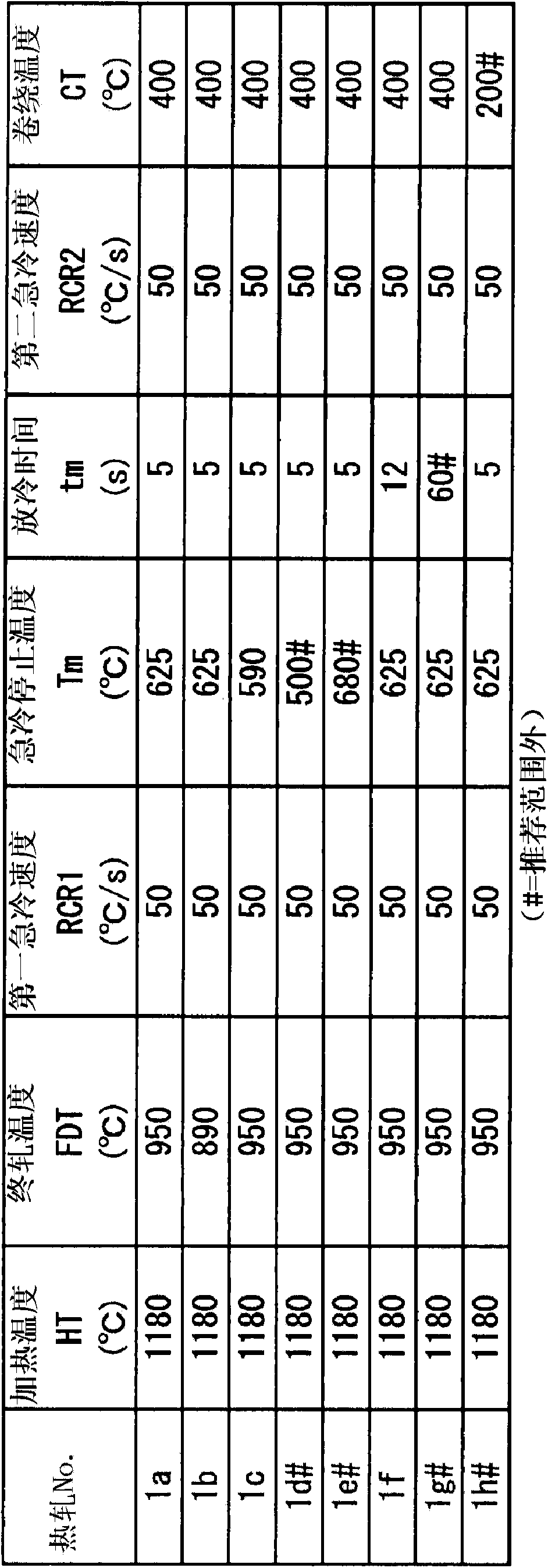

InactiveCN103732779AExcellent fatigue propertiesGuaranteed forming effectFurnace typesMetal rolling arrangementsSheet steelCarbide

Owner:KOBE STEEL LTD

Preparation method for sustainable antibacterial nano-zinc oxide alginate fibers

InactiveCN104928799AWide variety of sourcesLow costAlginate artificial filamentsWet spinning methodsFiberZno nanoparticles

The invention discloses a preparation method for sustainable antibacterial nano-zinc oxide alginate fibers. The preparation method comprises the following steps: at first, uniformly mixing sodium alginate powder and nano-zinc oxide powder; adding distilled water, and carrying out uniform ultrasonic dispersion to prepare sodium alginate-based nano-zinc oxide colloid; adding plenty of fiber-grade sodium alginate powder to prepare a spinning solution; preparing the finished product, namely the nano-zinc oxide alginate fiber by a wet spinning step. The preparation method has the advantages that a series of technological means, such as stepped introducing of sodium alginate, are adopted skillfully, nano-zinc oxide can be uniformly dispersed and exist stably in a system, the final product, namely the nano-zinc oxide alginate fiber, is uniform and stable in quality, the prepared nano-zinc oxide alginate fiber is remarkable in antibacterial effect, bacteria growth can be inhibited effectively, and the nano-zinc oxide alginate fiber is safe and nontoxic, and can be widely applied to fields of medical treatment, military, health textile and the like.

Owner:青岛源海新材料科技有限公司

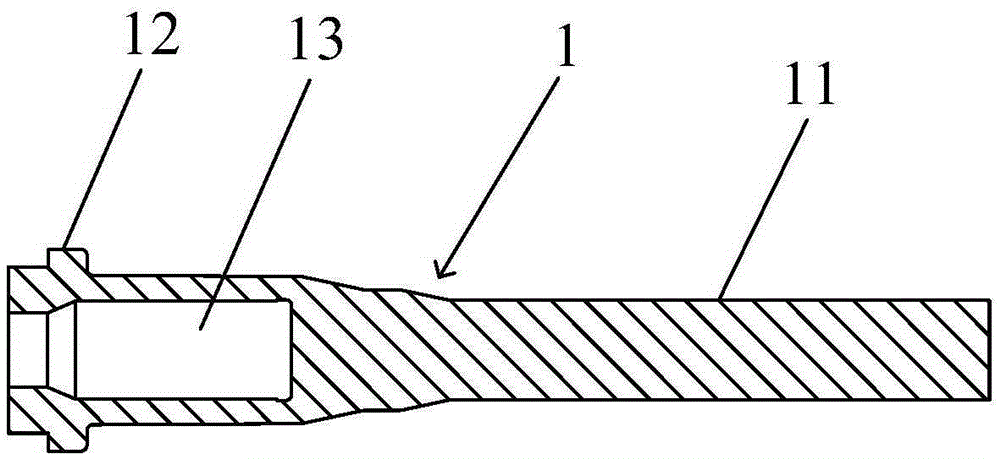

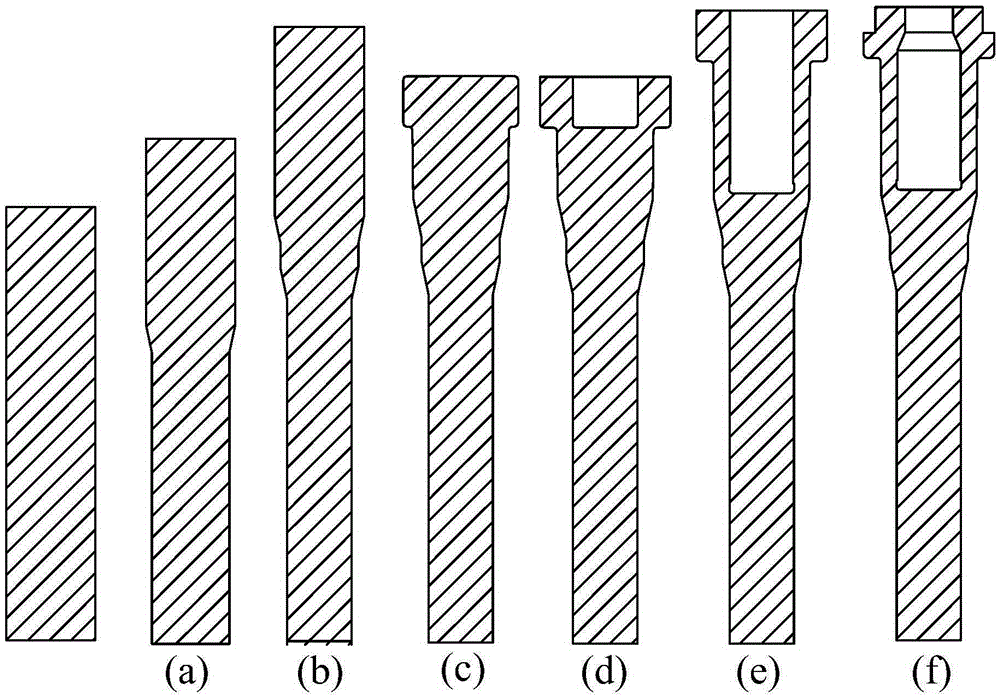

Die for pre-forming inner holes of deep-hole shaft parts, method for forming inner holes and forming process of deep-hole shaft parts

Owner:BEIJING RES INST OF MECHANICAL&ELECTRICAL TECH

Extruding, forging and rolling integrated technology of AQ80M magnesium alloy annular part

InactiveCN106944799AImprove yieldImprove mechanical propertiesMetal rollingMagnetic anisotropyFuel efficiency

The invention discloses an extruding, forging and rolling integrated technology of an AQ80M magnesium alloy annular part. The technology comprises the steps of semi-continuous casting, homogenizing annealing, heat extrusion, multi-direction forging, mechanical hole punching and annular part rolling. The extruding, forging and rolling integrated technology can be used for producing and preparing the AQ80M magnesium alloy annular part which is free of cracks on the surface, uniform in structure, good in comprehensive mechanics property, small in mechanical anisotropy and large in size, the annular part can be used for replacing annular parts made of other materials, the effects of reducing weight, improving the fuel efficiency and achieving electromagnetic shielding are achieved, and the technology has the important application value in aerospace and national defense fields.

Owner:CENT SOUTH UNIV

Preparation technology for large size super-high obdurability magnesium alloy thin plate

The invention relates to the preparation technology for a large size super-high obdurability magnesium alloy thin plate. The preparation technology particularly comprises the following steps that firstly, a magnesium alloy blank is heated to 250-450 DEG C and subjected to heat preservation for 1-3 h; then, the magnesium alloy blank is subjected to equal-channel angular pressing, after being extruded for one to two passes, the magnesium alloy blank is remelted and annealed, pressing is conducted for 8-12 times, and then a magnesium alloy rod material is obtained; before a rolling mill conducts rolling, a roller is preheated, the preheating temperature is 150-450 DEG C, and the roller is subjected to heat preservation treatment in the rolling process; after the obtained magnesium alloy rod material is subjected to heat preservation for 20-60 min at the temperature of 250-450 DEG C, the magnesium alloy rod material is rolled by adopting a multi-pass and small-deformation method, and the speed of the roller is 0.2-0.5 m / s; after every pass of rolling, remelting and annealing are conducted, horizontal rolling and vertical rolling are alternately conducted in the rolling process, and a magnesium alloy thin plate is obtained; and the obtained magnesium alloy thin plate is subjected to aging treatment, and then a finished magnesium alloy thin plate is obtained. According to the preparation technology of the large size super-high obdurability magnesium alloy thin plate, the prepared magnesium alloy thin plate is uniform in crystalline grain and excellent in mechanical property.

Owner:CHANGSHA ADVANCED MATERIALS IND RES INST CO LTD

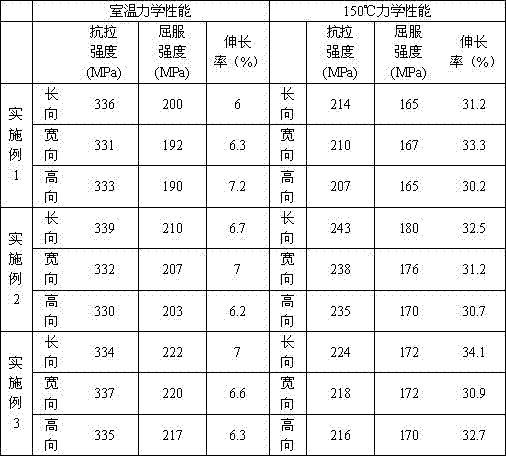

Forging process for eliminating anisotropism of large-sized AQ80M magnesium alloy bearing member

The invention relates to a forging process for eliminating anisotropism of a large-sized AQ80M magnesium alloy bearing member and belongs to the technical field of magnesium alloy material machining. The process specifically includes the steps that an ingot blank is prepared; extrusion blooming is performed with the low extrusion ratio, specifically, extrusion is performed on an extruding machine with the extrusion ratio being 3-4 and the extrusion speed being 0.3-2.8 mm / s; cooperating with intermediate annealing, multiple passes of direction-changing heading are performed on a hydraulic press so that the blank can be forged into a large-sized magnesium alloy bearing member; and the magnesium alloy bearing member is subjected to aging treatment. By means of the forging process, preparation of magnesium alloy bearing members with the size being larger than 470*390*170 mm<3> can be achieved; after aging treatment is finished, the yield strength difference among the length direction, the width direction and the height direction is smaller than or equal to 10 MPa at both the room temperature and the temperature of 150 DEG C; and the problem of anisotropism of large-sized magnesium alloy parts is solved.

Owner:湖南镁宇科技有限公司

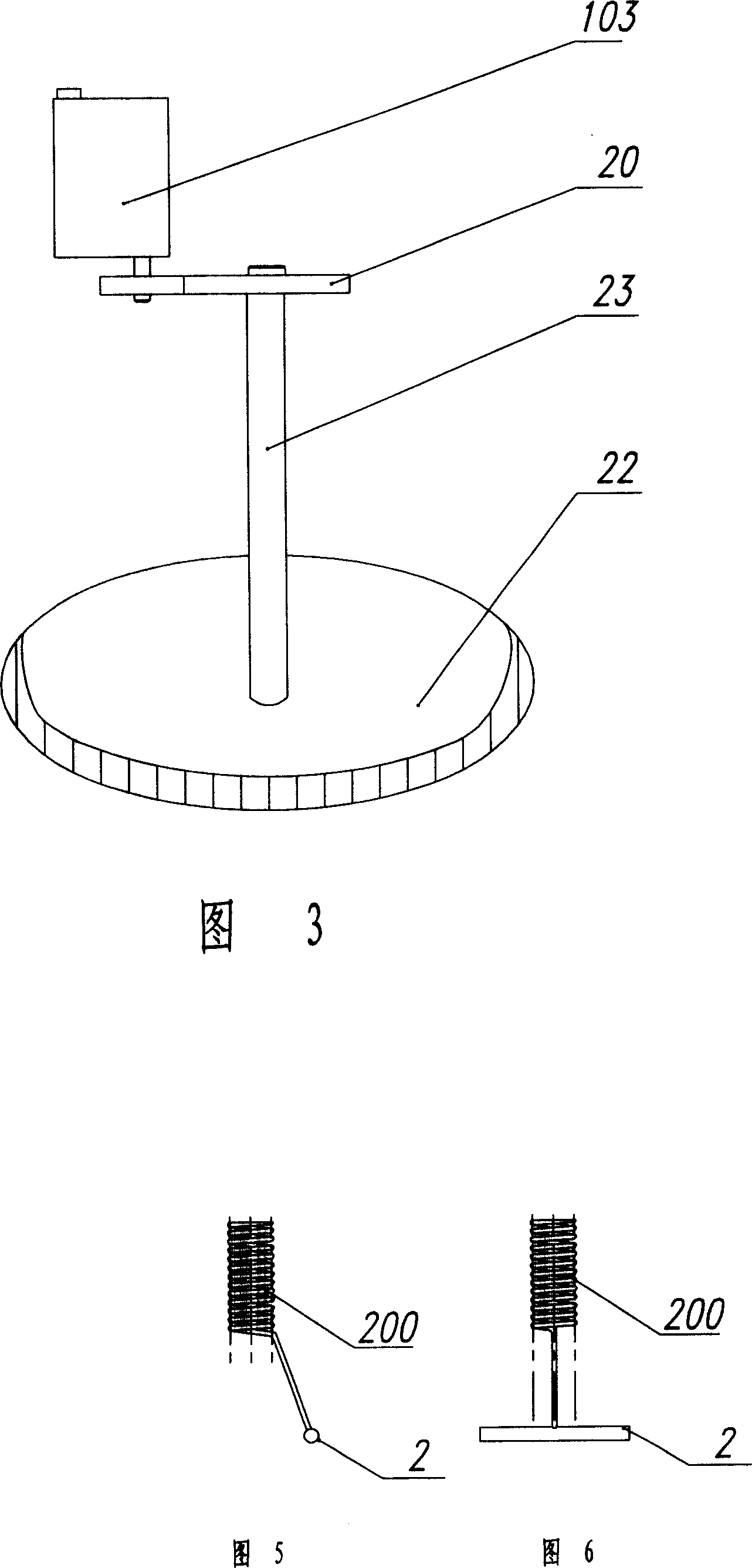

Direct microscopic method body cell/ microbe automatic counting instrument sampling device for milk

InactiveCN101007998AGuaranteed accuracyGuaranteed uniformityBioreactor/fermenter combinationsBiological substance pretreatmentsDirect microscopyRepeatability

The invention provides a sampling device of direct microscopy milk somatic cell / bacteria automatic counting apparatus. It comprisese upper lifting gearing, driving device for upper lifting gearing, one or more lower lifting gearing controlled by upper lifting gearing; said lower lifting gearing is connected with a sampling smearing head and is fixed on rotary supporting device, the position of said lower lifting gearing is relative to the position of upper lifting gearing, said sampling device is provided with driving device of rotary supporting device and driving device for upper lifting gearing and control gear of rotary supporting driving device. The invention employs simple construction to realize automatic sample and smear, fits cleaning device to realize automatic clean for sampling smear head, the work of all sampling smar head can be carried out at the same time with high efficiency; the sampling smear operation is automatically finished, the running parameter is convenient for moderation, control is accurate, repeatability is good, and the smear milk samling can be ensured accuracy, homogeneity and forming.

Owner:HANGZHOU ULTRASUN TECH

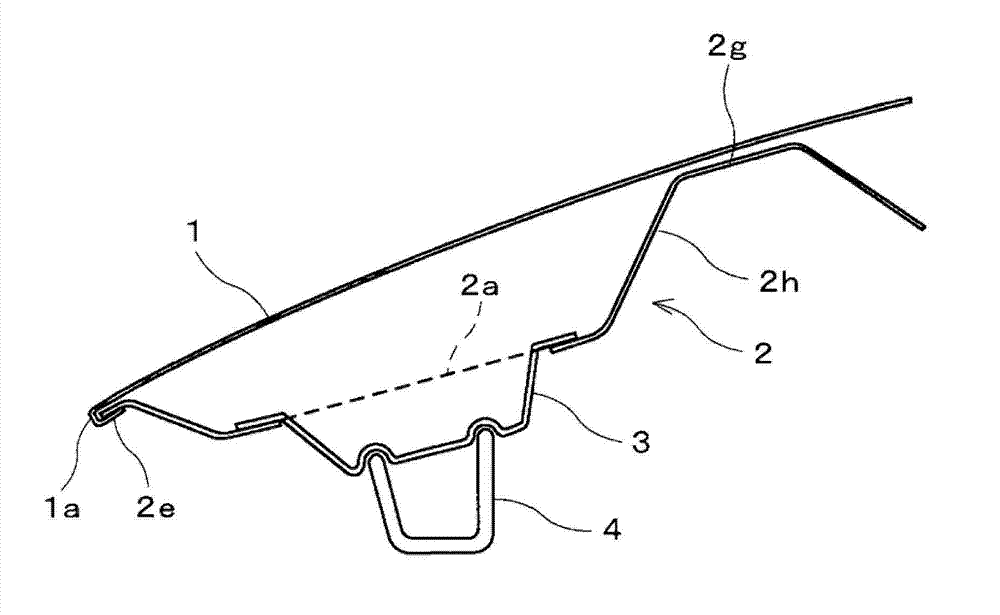

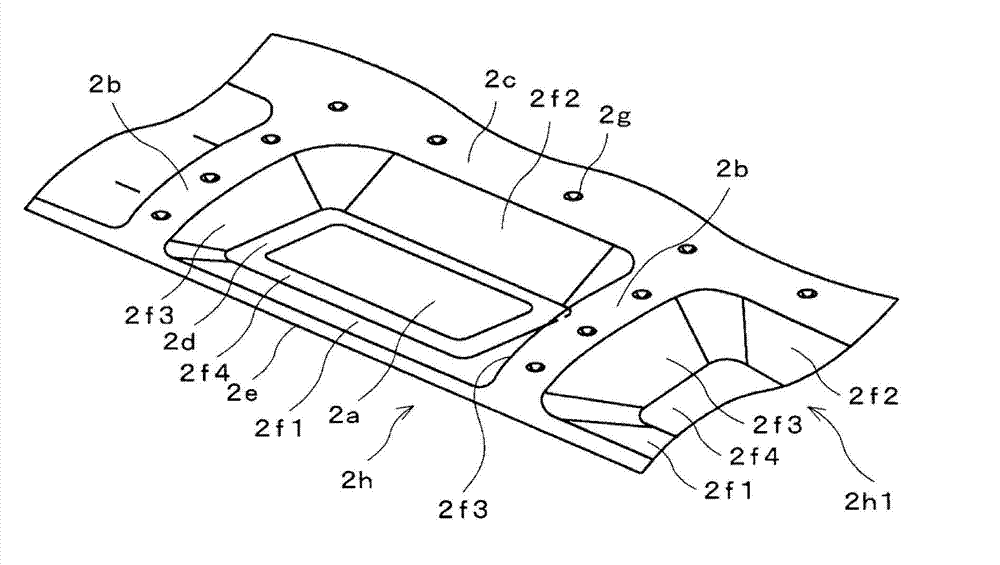

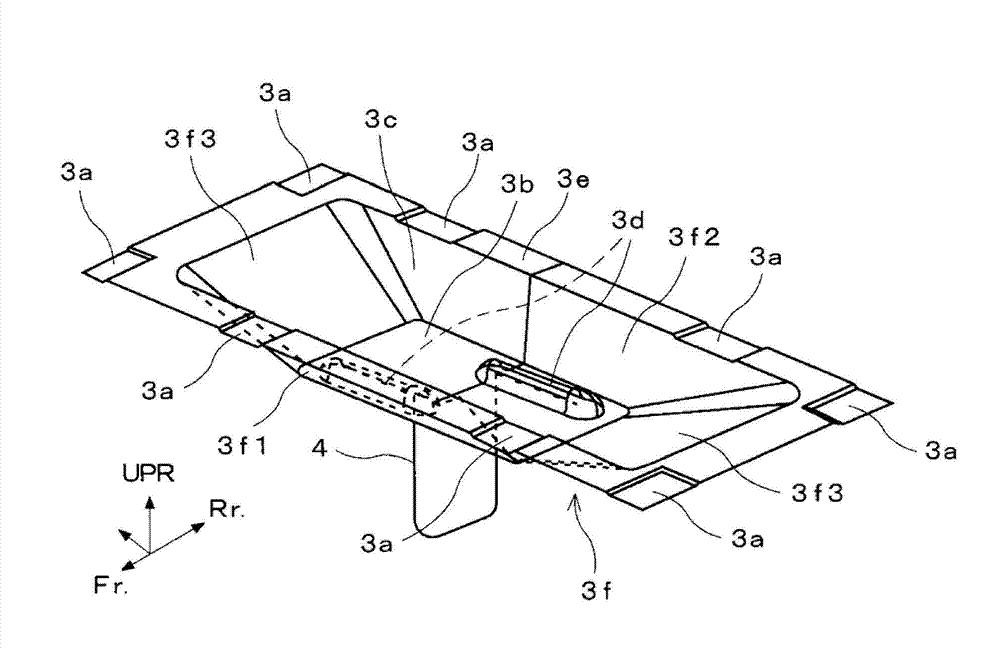

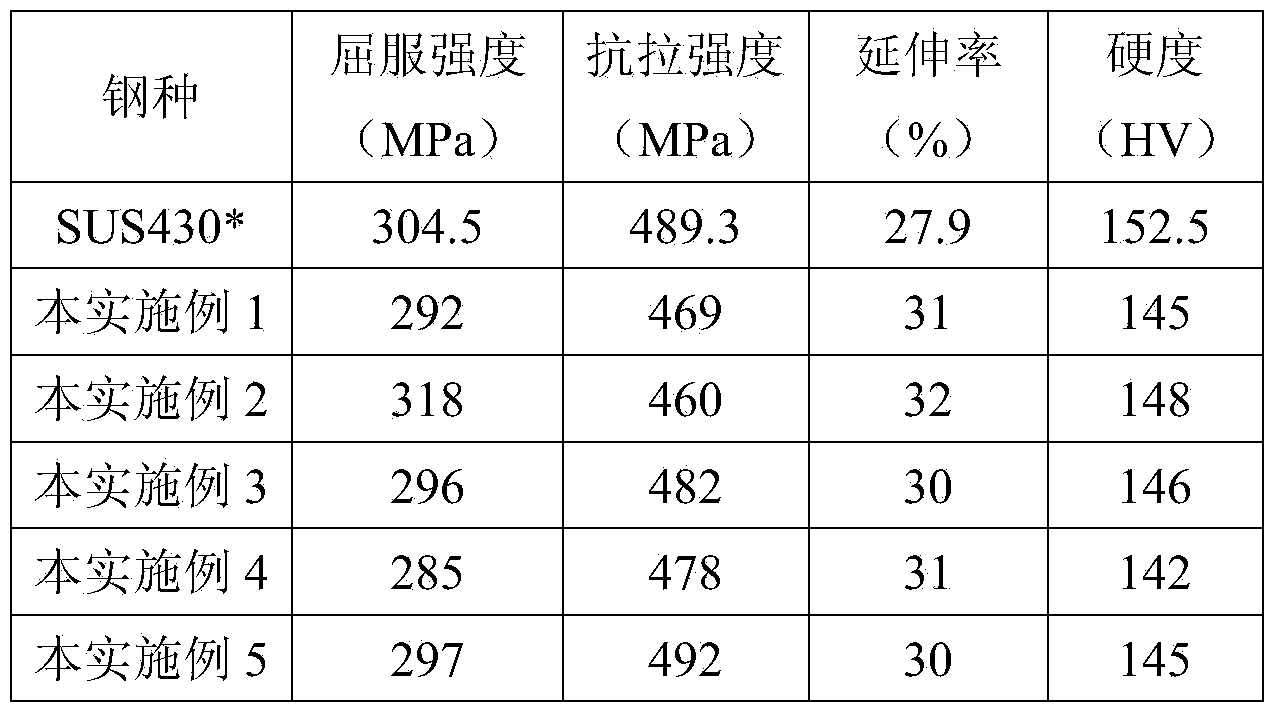

Engine cover used for vehicle

ActiveCN102849020AReduce weightImprove protectionPedestrian/occupant safety arrangementSuperstructure subunitsEngineeringFlange

Provided is an engine cover used for a vehicle, wherein an internal panel (2) has a recess (2h), a front end part thereof is fixed on an external panel (1) through curring, a rear part thereof is jointed to the external panel (1) through Mastic. A bottom of the recess (2h) is provided with a hole (2a), a downward protruding part of a locking stiffening member (3) is embedded in the hole (2a), a flange (3e) of the locking stiffening member (3) is jointed and fixed at a hole peripheral part (2d) of the internal panel (2).

Owner:KOBE STEEL LTD

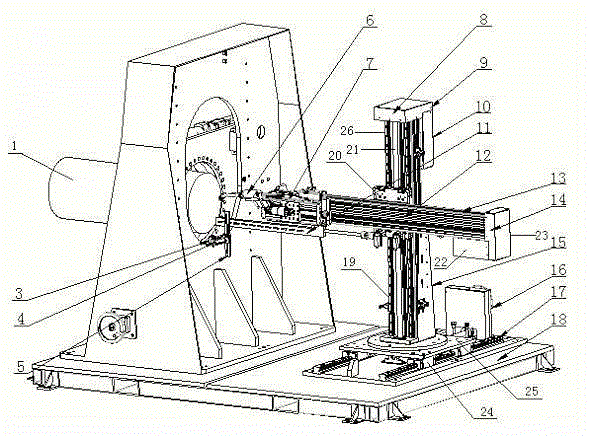

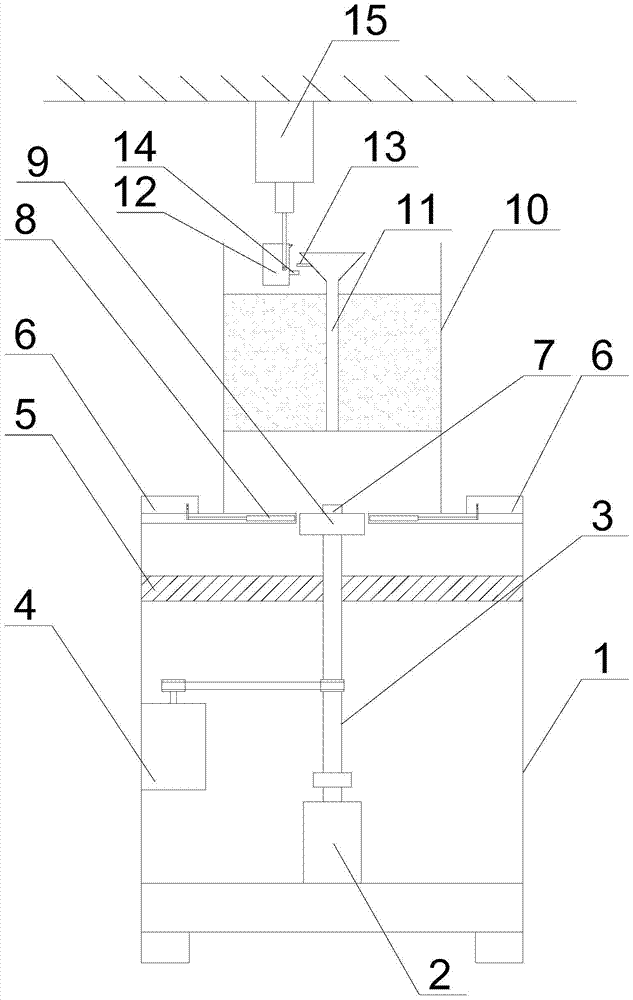

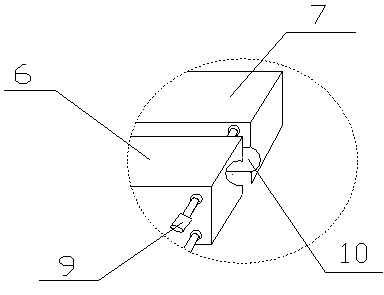

Welding tracking device for pipeline surfacing system

ActiveCN106270934AMove quickly and accuratelyGuaranteed forming effectArc welding apparatusBall screwEngineering

The invention discloses a welding tracking device for a pipeline surfacing system. The tracking device for the pipeline surfacing system comprises a sensing assembly, a welding gun, a welding gun cross-shaped sliding frame and a base; the sensing assembly comprises a sensor, a sensor Z-direction slideway and a supporting rod; the welding gun cross-shaped sliding frame is installed on a welding gun cross-shaped sliding frame installing seat; the welding gun cross-shaped sliding frame comprises a welding gun Z-direction sliding frame body and a welding gun X-direction sliding frame body; the welding gun Z-direction sliding frame body and the welding gun X-direction sliding frame body each comprises a motor, a driving tank controlling rotation of the motor, a ball screw rod connected with the motor in a transmission mode, a connecting block connected with the ball screw rod in a threaded mode and a guiding rail located at the bottom of the connecting block; the welding gun X-direction sliding frame body is fixed to the connecting block of the welding gun Z-direction sliding frame body; the welding gun is fixed to the front end of the connecting block of the welding gun X-direction sliding frame body; the sensor is fixed to one end of the supporting rod, and the other end of the supporting rod is fixed to the connecting block of the welding gun Z-direction sliding frame body; and the base is provided with a Y-direction slideway a hand wheel and the ball screw rods connected with the hand wheel, and an installing plate at the bottom of the welding gun cross-shaped sliding frame installing seat is in matched connection with the ball screw rods.

Owner:NANJING ENIGMA IND AUTOMATION TECH CO LTD

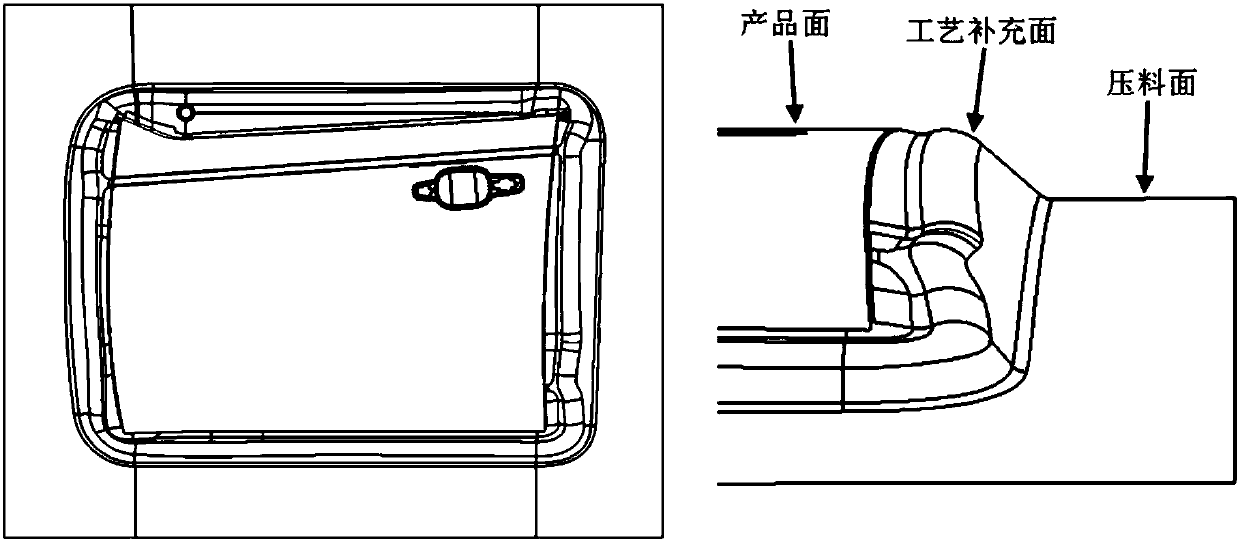

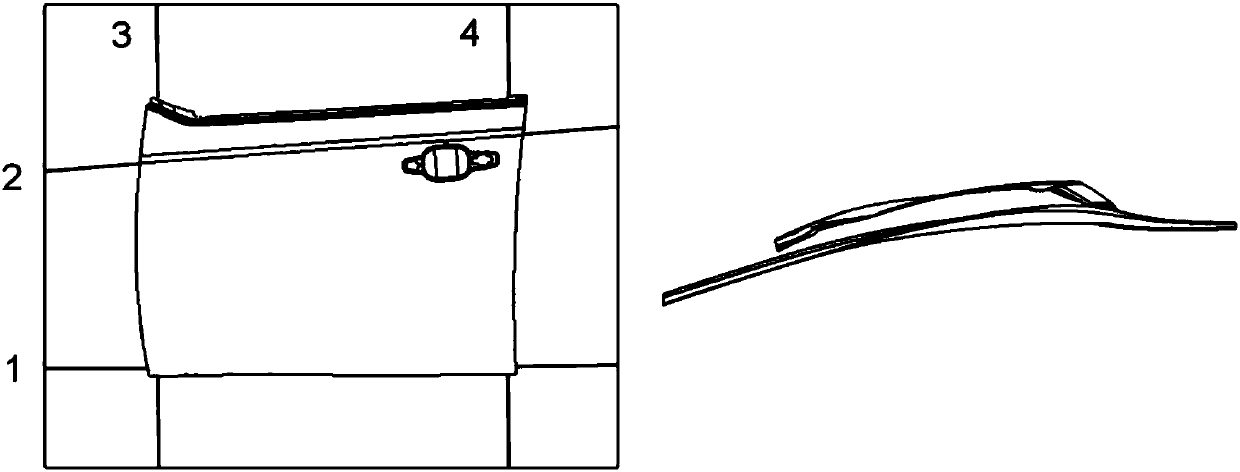

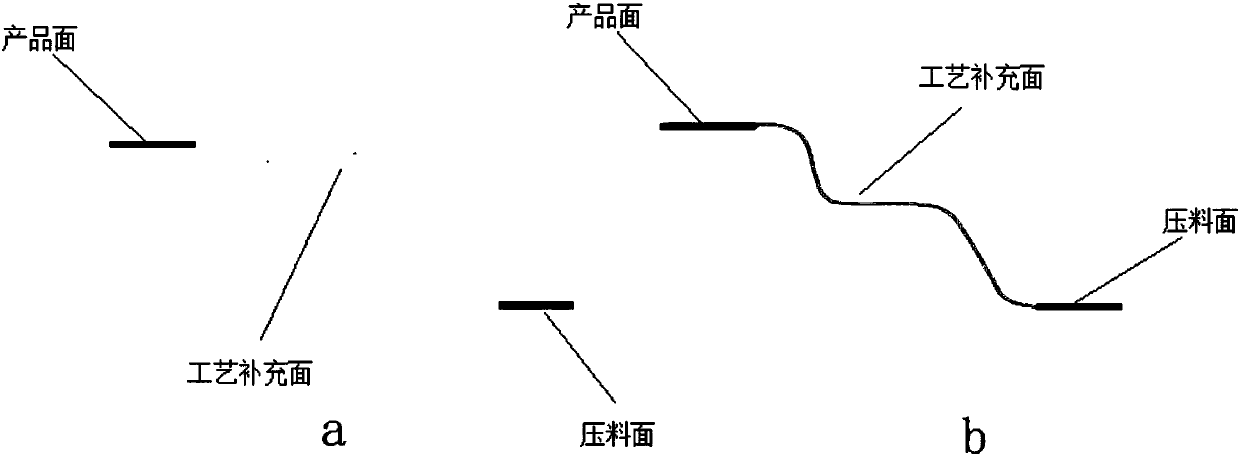

Aluminum automobile door panel drawing die and over-drawing method

ActiveCN107855412AIncrease flow resistanceReduce reboundShaping toolsVehicle componentsEngineeringProcess design

The invention provides a novel over-drawing process design method of an aluminum automobile door panel drawing die. The aluminum automobile door panel drawing die designed by using the method comprises a male die base, a male die, a binder ring and a female die, wherein the male die is arranged on the male die base, the binder ring is nested outside the male die, and the female die is arranged atthe tops of the male die and the binder ring. The aluminum automobile door panel drawing die has the following beneficial effects that the novel over-drawing process design method is adopted as a process supplement mode, a supplement surface extends out along a product surface for a certain angle, the over-drawing angle is controlled in a small range between 10 degrees and 20 degrees, and the edgeregion of the product surface is in a bending formation state and cannot cause large flow resistance to material flow; and by adopting the novel over-drawing process design method, the springback quantity of an aluminum automobile door panel can be controlled according to the large springback characteristic of the aluminum panel, and the formability and the drawing sufficiency of the aluminum automobile door panel also can be ensured according to the low extension performance characteristic of the aluminum panel.

Owner:宝武铝业科技有限公司 +1

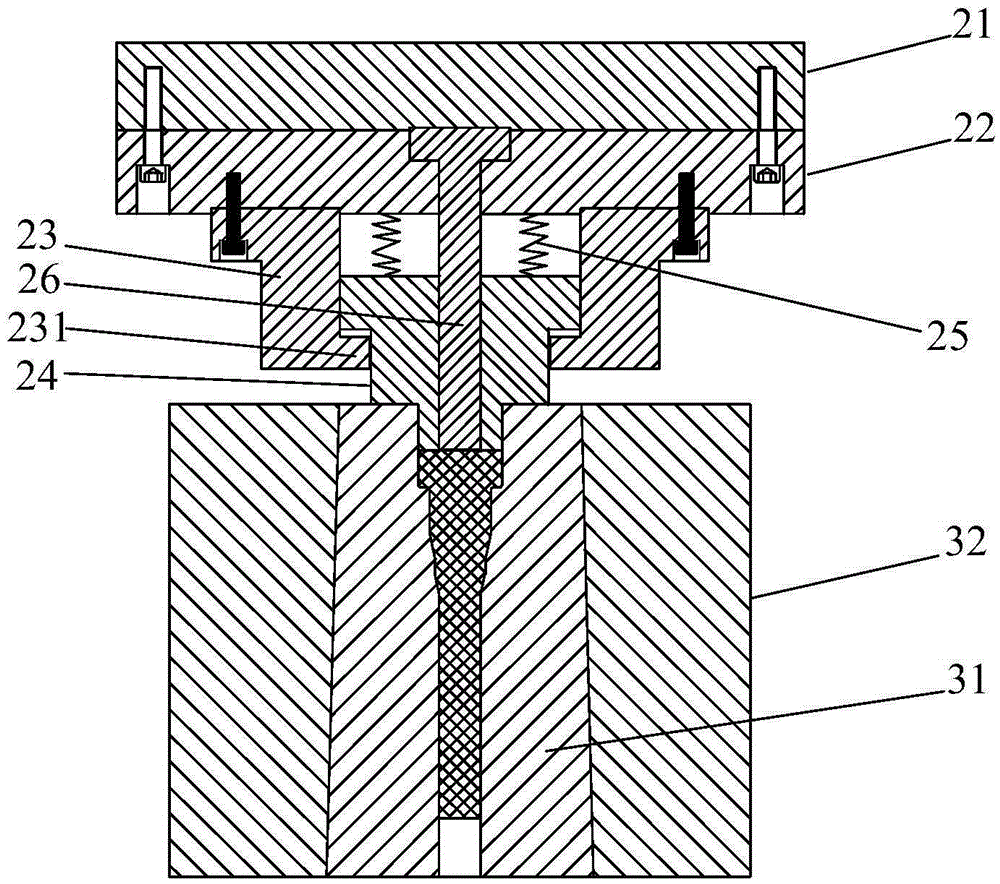

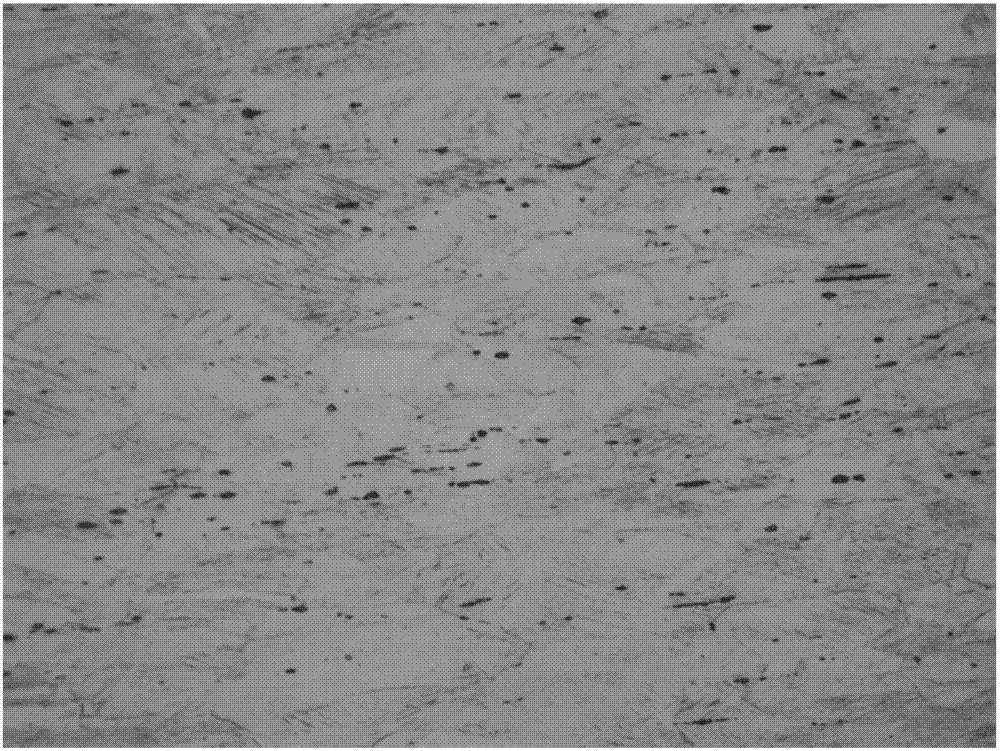

Swaging integrated forming process for large-diameter AQ80M magnesium alloy cake material

ActiveCN106890865AGuaranteed forming effectGuaranteed mechanical propertiesExtrusion control devicesPre deformationRoom temperature

The invention relates to a swaging integrated forming process for a large-diameter AQ80M magnesium alloy cake material, and belongs to the technical field of processing of a magnesium alloy material. The process comprises the following specific steps: preparing an AQ80M magnesium alloy ingot blank by semi-continuous casting; heating an extrusion die and an extrusion barrel; carrying out extrusion pre-deformation at low extrusion ratio; straightening and cutting the blank; carrying out multi-directional forging forming; and carrying out aging treatment. By the swaging integrated forming process for the large-diameter AQ80M magnesium alloy cake material, the large-diameter magnesium alloy cake material of which the diameter is phi 690 mm to phi 700 mm, the thickness is 100-110 mm, the tensile strength is greater than or equal to 330 MPa, the yield strength is greater than or equal to 190 MPa and the ductility is greater than or equal to 6% at room temperature, and the tensile strength is greater than or equal to 200 MPa, the yield strength is greater than or equal to 160 MPa and the ductility is greater than or equal to 30% at the temperature of 150 DEG C. The prepared large-size magnesium alloy cake material completely meets requirements of a large magnesium alloy part.

Owner:湖南镁宇科技有限公司

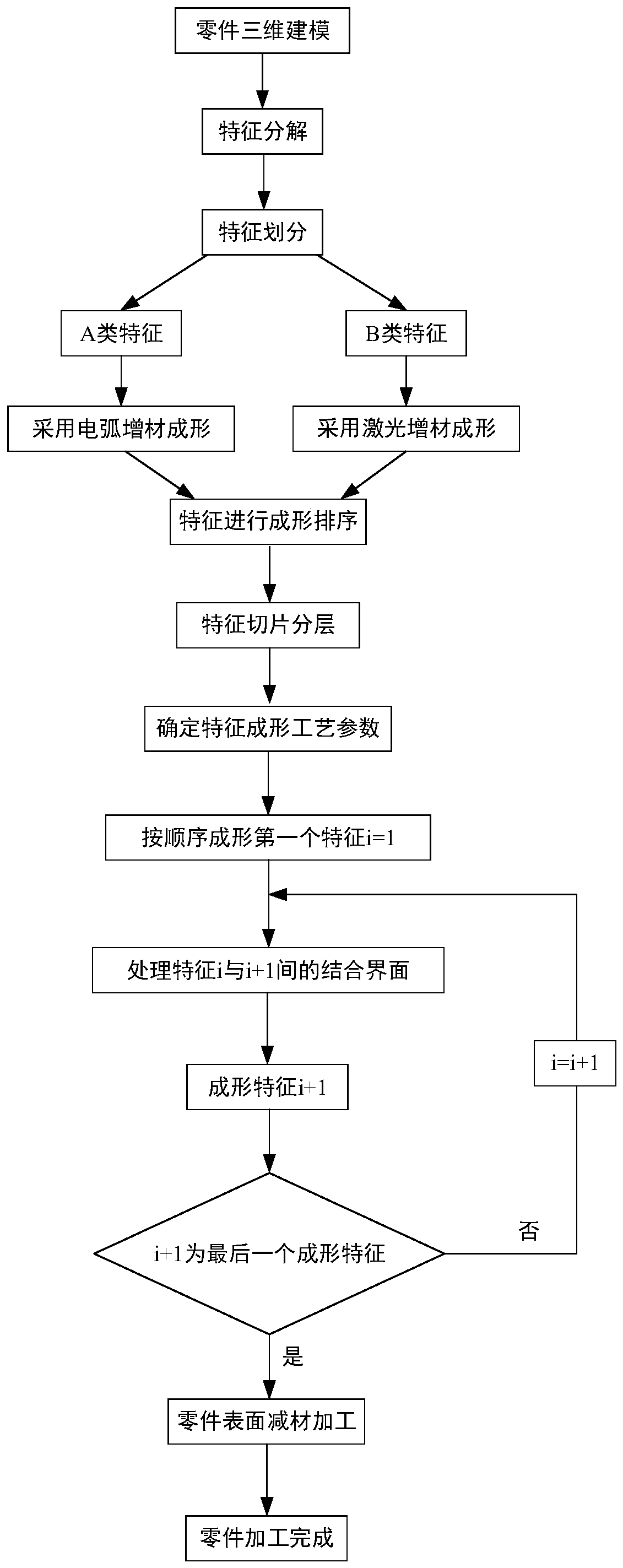

Complex metal part forming method adopting combination of electric arc additive and laser additive

ActiveCN111545915AGuaranteed forming effectImprove mechanical propertiesLaser beam welding apparatusLaser additive manufacturingMachining

The invention discloses a complex metal part forming method adopting combination of an electric arc additive and a laser additive. The complex metal part forming method comprises the steps that three-dimensional modeling is conducted on a part entity, geometric feature decomposition is conducted on a three-dimensional entity model, a part feature additive forming method is divided, forming processparameters of all features are determined, forming sorting is conducted on all the features, slicing and layering treatment is conducted on all the features, and all the features are sequentially formed according to the feature forming sorting and a treatment method of a combination interface between the adjacent features. According to the complex metal part forming method, the advantages of efficient electric arc additive manufacturing forming and fine laser additive manufacturing forming are effectively combined, compared with traditional forging, the machining period is shortened, the overall forming performance of a part is guaranteed, the quality of a fine and complex structure is guaranteed, the production efficiency is improved, and the machining cost is reduced. Meanwhile, a laserremelting method is adopted, the number of cracks and air holes in a combination interface area of a dissimilar additive process is reduced, meanwhile, structure distribution is more uniform, and themechanical property of the combination interface is improved.

Owner:XI AN JIAOTONG UNIV

Paper pulp for paper pulp molding fruit tray product

InactiveCN102182118AImprove adhesionGood film formingWater-repelling agents additionReinforcing agents additionPulp and paper industryUltimate tensile strength

The invention discloses a paper pulp for a paper pulp molding fruit tray product. The paper pulp comprises the following raw materials in percentage by mass: 89-94% of virgin wood sheet pulp or waste paper, 1-3% of alkyl ketene polymer, 5-8% of corn starch and dewatering synergist, wherein the dewatering synergist comprises the following components in percentage by mass: 0.15-0.25% of NaOH, 0.16-0.23% of H2O2 and 0.2-0.48% of borax; and the alkyl ketene polymer is an AKD (Alkyl Ketene Dimer) waterproofing agent. The paper pulp formula for a paper pulp molding fruit tray product ensures the forming performance of the pulp, reduces the wood-pulp mixture ratio, and causes less environment pollution; and the product has good strength, water resistance, breathability and other properties.

Owner:HANGZHOU LVBAO PAPER PROD

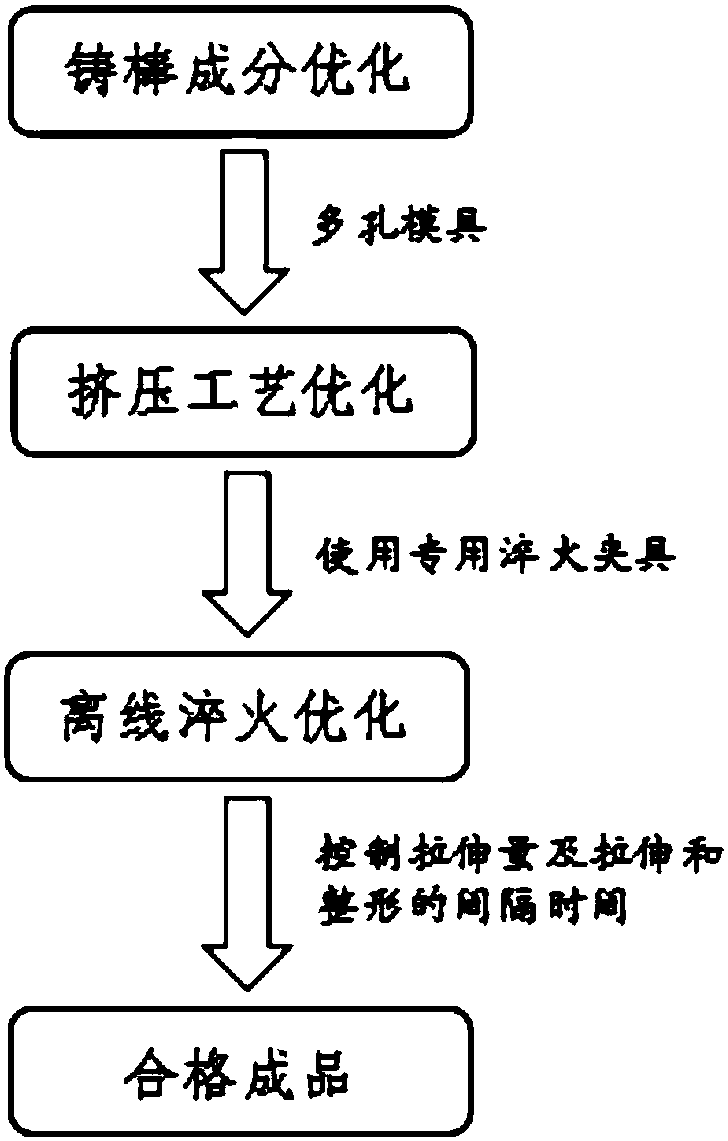

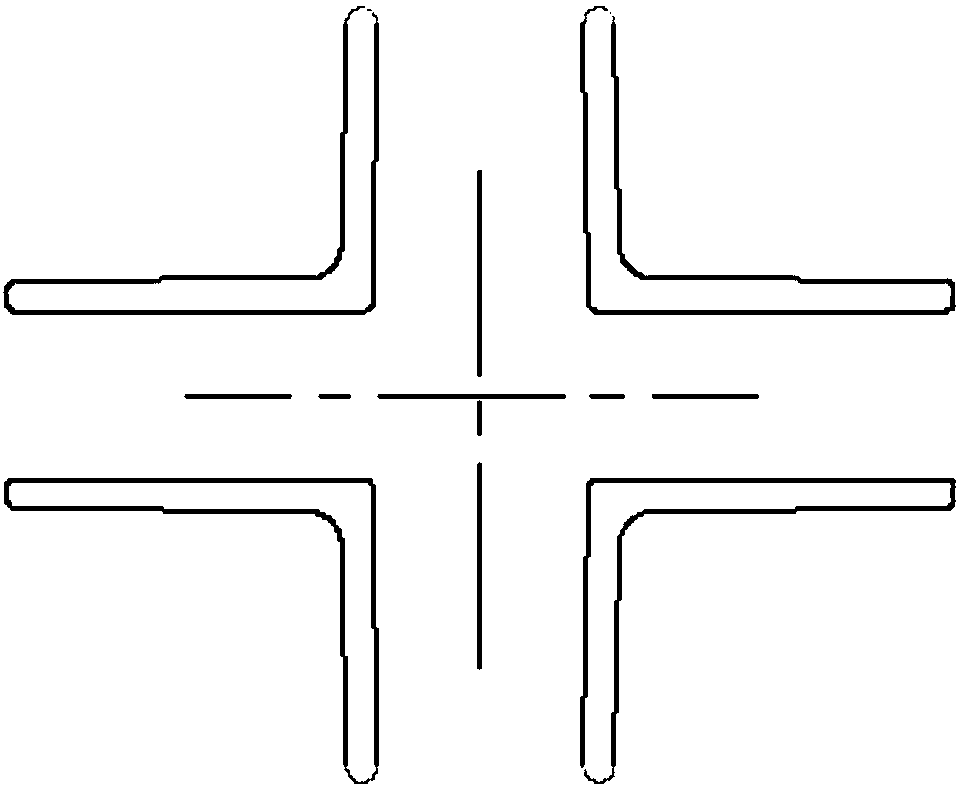

Production process of 2024 high-strength aluminum alloy special thin-walled section steel

The invention belongs to the technical field of aluminum alloys, and relates to a production process of a 2024 high-strength aluminum alloy special thin-walled section steel. flat mold form with fourextrusion holes and no flow guide pit in design aspect of a mold, an extrusion ratio of the whole section steel is reduced to 40, a 6.6MN non-standard extrusion machine is selected in the aspect of extrusion machining, the extrusion ratio is 40.2, the section steel is stretched within 1 hour after extrusion, and an off-line quenching degree is 455 DEG C * 30 minutes, the section steel is stretchedwithin 1 hour after the off-line is carried out, and the stretching amount is controlled at the upper limit of 2.5%-to 3%. The shaping and extrusion production interval time is controlled within 3 hours, a shaping rate is improved, a novel quenching clamp is designed for the section steel, so that the deformation of the section steel is reduced to the minimum while the section steel is fully quenched, the 2024 aluminum alloy section steel is subject to a serious of machining process of mold adjusting, production equipment structure is changed, extrusion, the off-line quenching, quenching clamp manufacturing, shaping and the like, all detection indexes meet the standard requirement of GJB2507A in detection aspects of mechanical property, low-magnification, high-magnification and dimensional tolerance.

Owner:CHINA ZHONGWANG

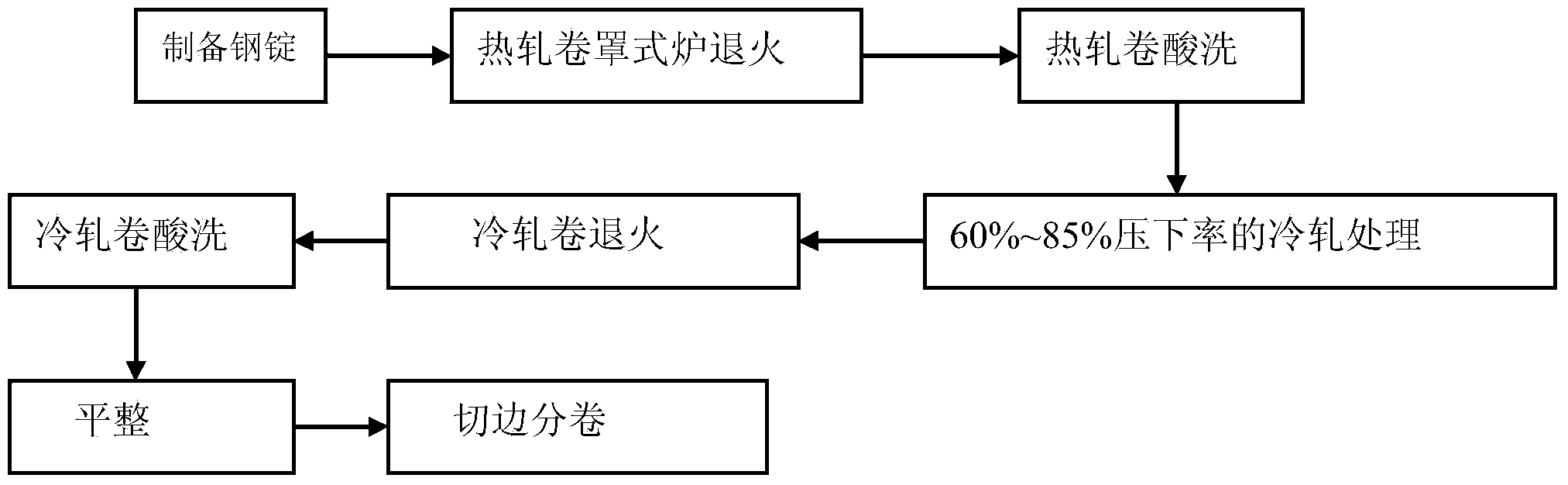

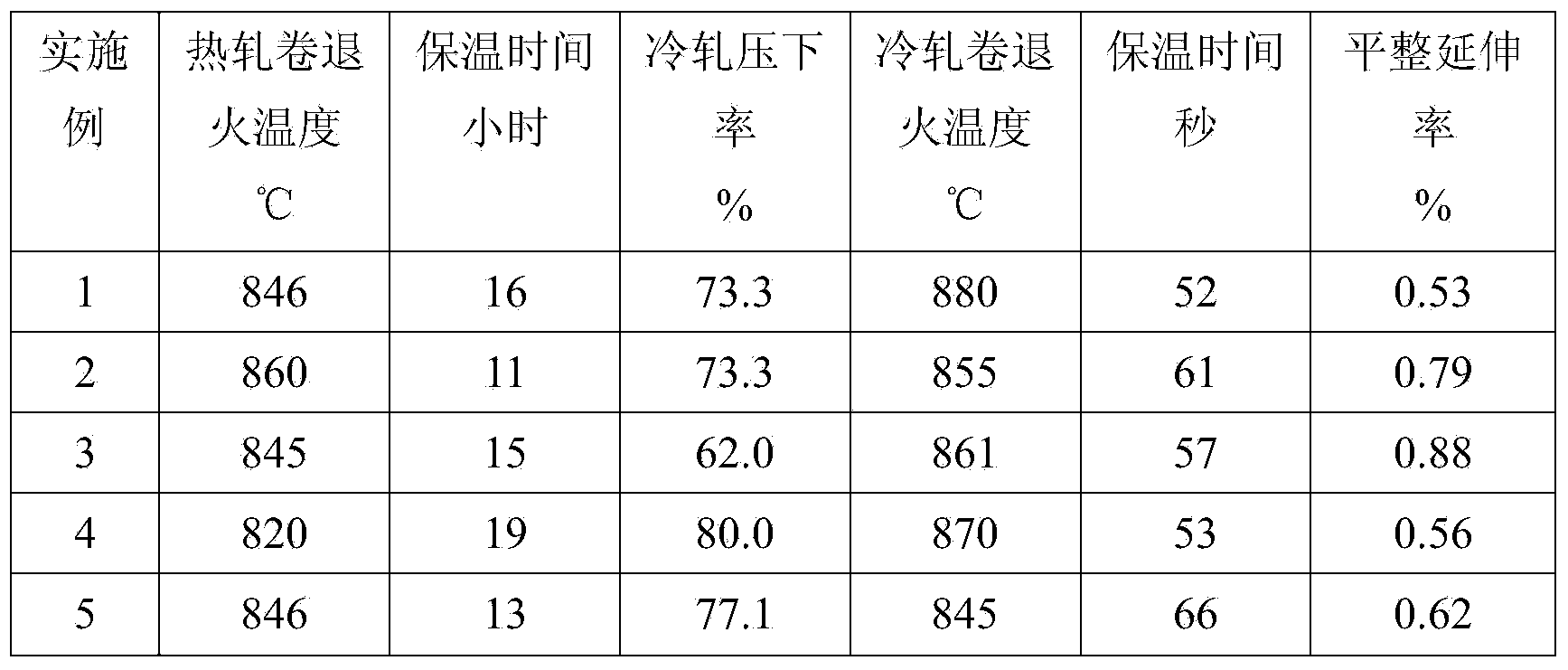

430 stainless steel for cold stamping processing, and manufacturing method thereof

InactiveCN103667950AGuaranteed cold stamping performanceGuaranteed forming effectThermal insulationAcid washing

The present invention discloses a 430 stainless steel for cold stamping processing, and a manufacturing method thereof. The 430 stainless steel comprises 0.03-0.08 wt% of C, 0-0.85 wt% of Si, 0-0.6 wt% of Mn, 0-0.030 wt% of S, 16.00-18.00 wt% of Cr, 0-0.75 wt% of Ni, 0-0.07 wt% of N, and the balance of Fe and inevitable trace impurities, wherein the trace impurity P content is less than 0.040 wt%. The production method comprises steps such as hot rolling coil annealing, acid washing, cold rolling, finished product annealing, acid washing, temper rolling, and trimming coil cutting, and is characterized in that the hot rolling coil annealing temperature is controlled at 820-860 DEG C, and the thermal insulation time is 10-19 h. Compare with the manufacturing method in the prior art, the manufacturing method of the present invention has the following characteristics that: it can be ensured that the elongation after fracture of the finished product is more than 26%, and the cold stamping molding performance can be ensured.

Owner:NINGBO BAOXIN STAINLESS STEEL

Forming method for achieving different-area performance stable transition of high-strength steel hot-forming part

ActiveCN104475527AReduce manufacturing costGuaranteed forming effectShaping toolsVehicle componentsHot stampingPower flow

The invention relates to the technical field of hot stamping forming, in particular to a forming method for achieving different-area performance stable transition of a high-strength steel hot-forming part. The forming method utilizes induction heating to control electromagnetic fields and vortex fields of different areas, accordingly controls the heating temperatures in different areas of a plate and obtains different strengths after stamping is completed. The heating temperature ranges from 850 DEG C to 1000 DEG C and is kept for 0-10 min, a steel plate is heated to be in a complete austenitizing state, and the strength of the hot-formed steel plate is higher than1500 MPa. The heating temperature ranges from 25 DEG C to 850 DEG C and is kept for 0-10 min, the steel plate is heated to be in an incomplete austenitizing state, and the strength of the hot-formed steel plate ranges from 500 MPa to 900 MPa. The shape of an induction heating coil, the distance between the coil and the plate, current and frequency are designed according to the demand for different area strengths of the part, and the part has best collision performance matched with strength and plasticity after being subjected to hot stamping forming.

Owner:东莞市豪斯特热冲压技术有限公司 +1

Organic adhesive composite used for silicon solar cell silver paste and preparation method thereof

InactiveCN102304287AGood dispersionEasy to wrapInksNon-conductive material with dispersed conductive materialSilver pasteOrganic solvent

The invention provides an organic adhesive composite used for silicon solar cell silver paste, comprising the following raw materials according to parts by weight: 5-13% of polyamide resin, 8-25% of abietic resin or phenolic aldehyde modified terpene resin, 65-80% of organic solvent and 0-1% of wetting dispersant. The organic adhesive composite exists in silver paste to serve as a carrier or dispersion medium, proper fluid performance is endowed to slurry to fully wet silver powder or inorganic adhesive powder in the wetting silver paste, and the slurry can be dissolved with other accessory ingredients in a mixed mode.

Owner:IRICO

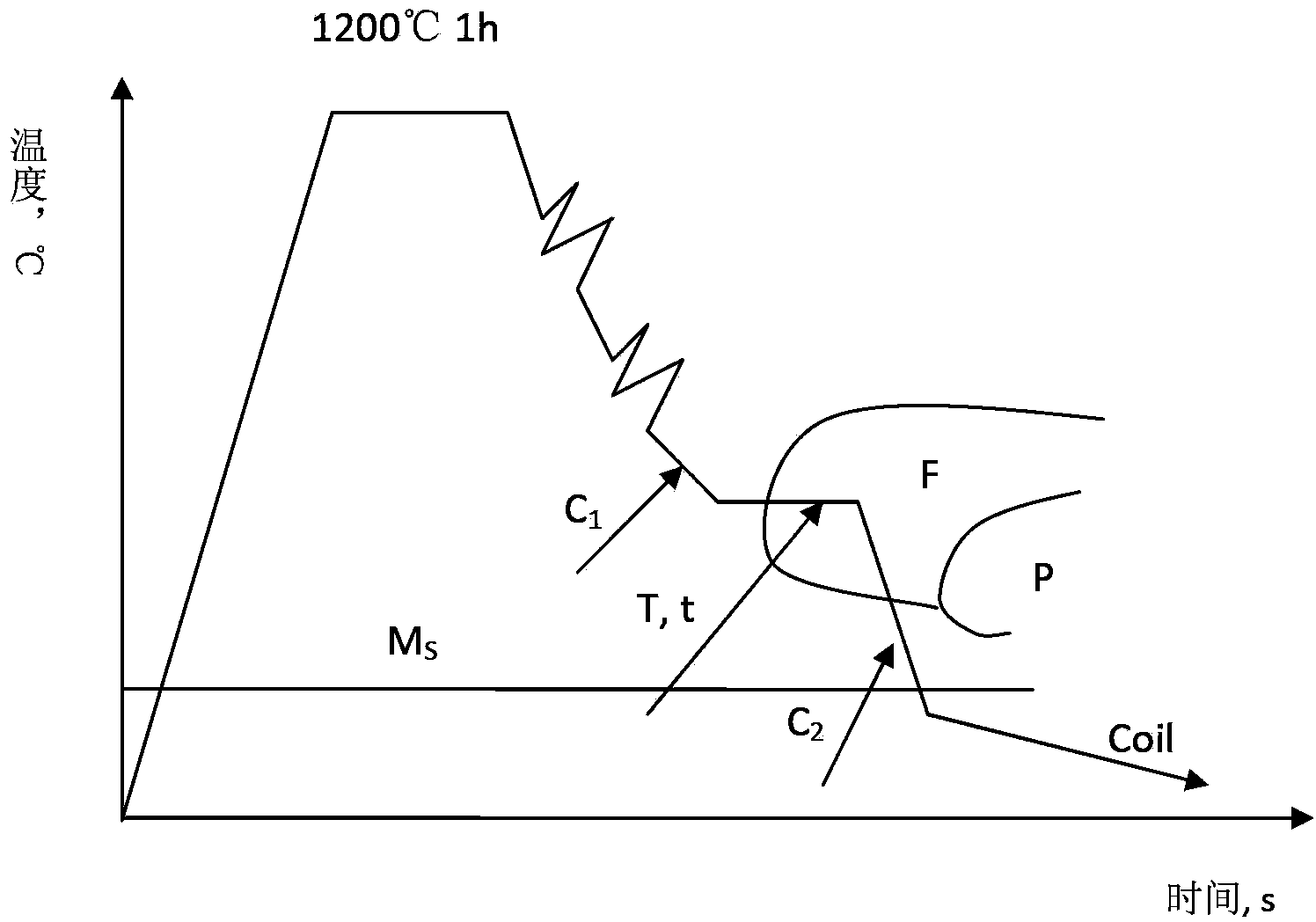

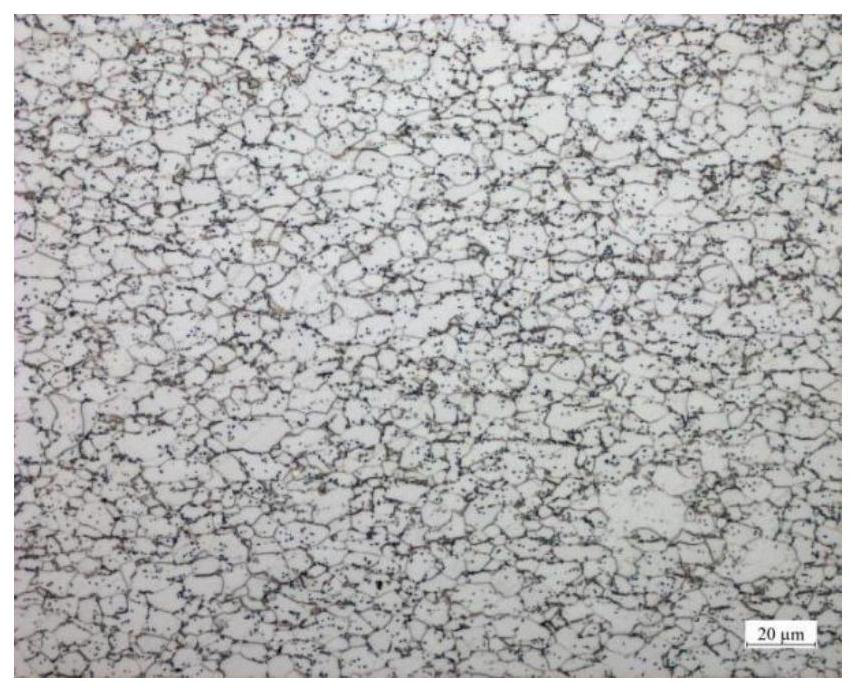

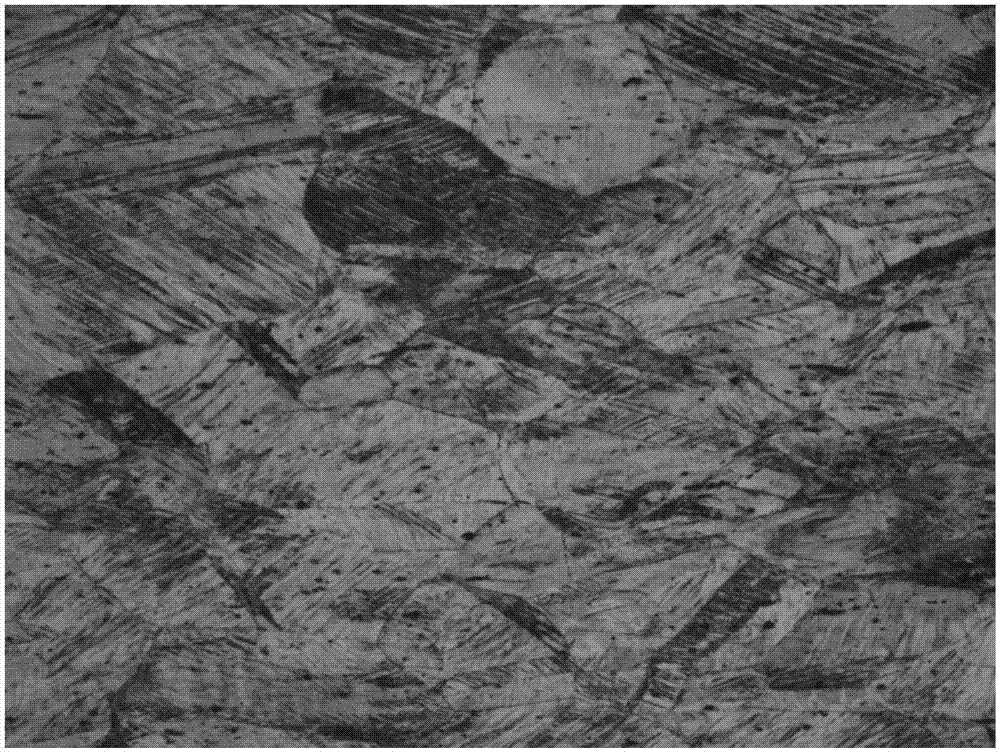

Niobium-containing high-strength fine-grain 700MPa-level hot-rolled dual-phase steel and production method thereof

The invention discloses a niobium-containing high-strength fine-grain 700MPa-level hot-rolled dual-phase steel and a production method thereof. A steel plate with a polygonal ferrite and martensite dual-phase structure is obtained by a hot rolling and sectional control cooling process. The dual-phase steel comprises the following chemical components in percentage by weight: 0.07-0.10% of C, 0.20-0.50% of Si, 1.20-1.50% of Mn, less than or equal to 0.03% of P, less than or equal to 0.03% of S, 0.08-0.11% of Nb and the balance of Fe and unavoidable impurities. The production method of the dual-phase steel comprises the following steps: preparing materials according to the chemical components of the dual-phase steel; smelting in a vacuum induction furnace, and pouring the molten steel to obtain a steel ingot; heating the steel ingot and starting rolling; controlling the rolling at two stages; after the rolling, performing sectional cooling; and finally conveying the product to a coil storehouse. The dual-phase steel disclosed by the invention has the advantages of good strength-toughness match of steel plate, high tensile strength of steel plate, low yield ratio and good stamping property.

Owner:UNIV OF SCI & TECH LIAONING

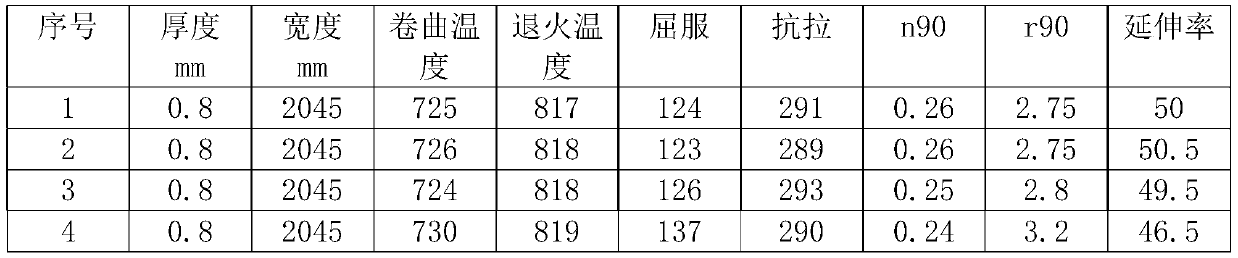

Low-cost ultra-wide automobile shell plate and preparation method thereof

The invention relates to a low-cost ultra-wide automobile shell plate and a preparation method thereof. The chemical component of the steel plate is controlled to be prepared from, by weight, smallerthan or equal to 0.0020% of C, smaller than or equal to 0.03% of Si, 0.08-0.16% of Mn, smaller than or equal to 0.01% of P, smaller than or equal to 0.01% of S, smaller than or equal to 0.003% of N, 0.04-0.06% of Ti, 0.003-0.007% of Nb, 0.02-0.05% of Als, and the balance other trace elements. Compared with a traditional technological method for preparing an ultra-wide cold rolling plate, the method has the advantages that the cost is low, the defect is well controlled, the forming property of strip steel is guaranteed, the rate of finished products is high, close to that of the common cold rolling plate, and in addition, the economical benefit and social benefit are brought to the enterprise.

Owner:BENGANG STEEL PLATES

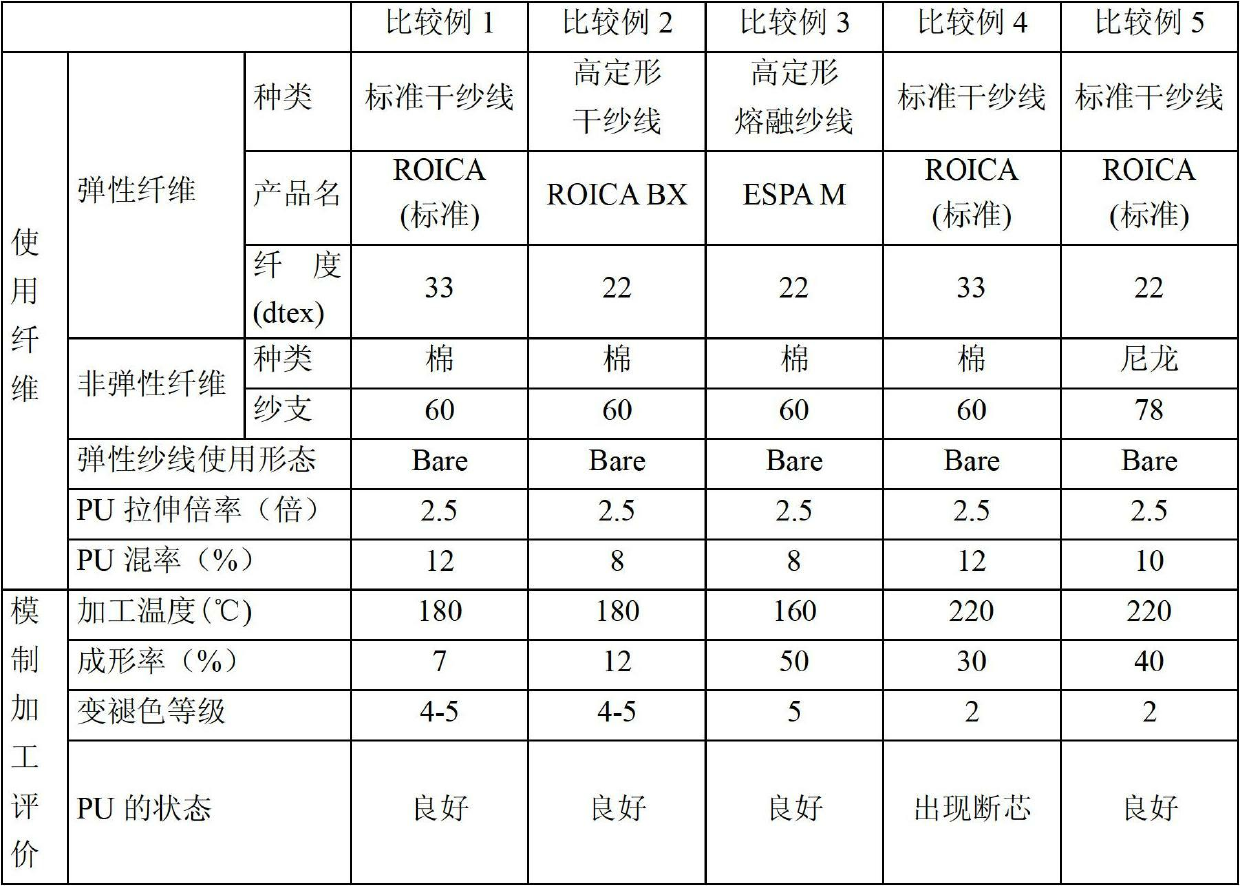

Woven or knitted fabric

A woven and knitted fabric according to an embodiment of the present invention includes a yarn containing elastic fibers and at least one kind of non-elastic fibers. The woven and knitted fabric is subjected to mold processing. The elastic fibers contain heat-fusible polyurethane elastic filaments each having a fineness of 17 dtex or more, and at least part of the heat-fusible polyurethane elastic filaments is heat-fused in the woven and knitted fabric. The woven and knitted fabric is subjected to the mold processing at 120 to 190 DEG C.

Owner:NISSHINBO IND INC

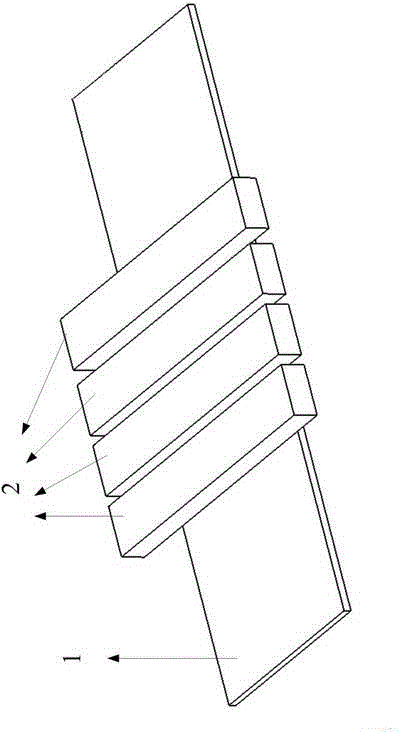

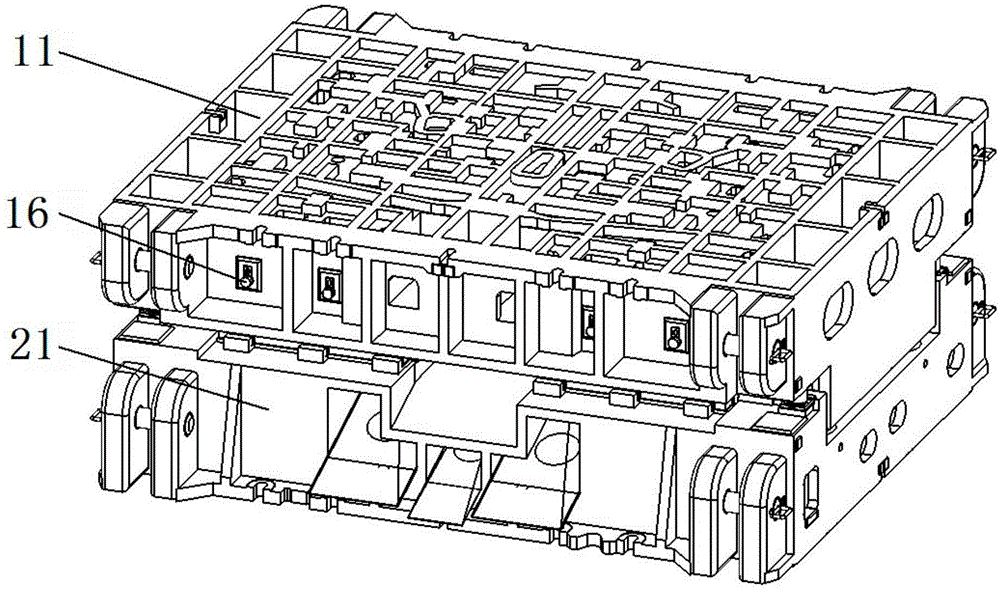

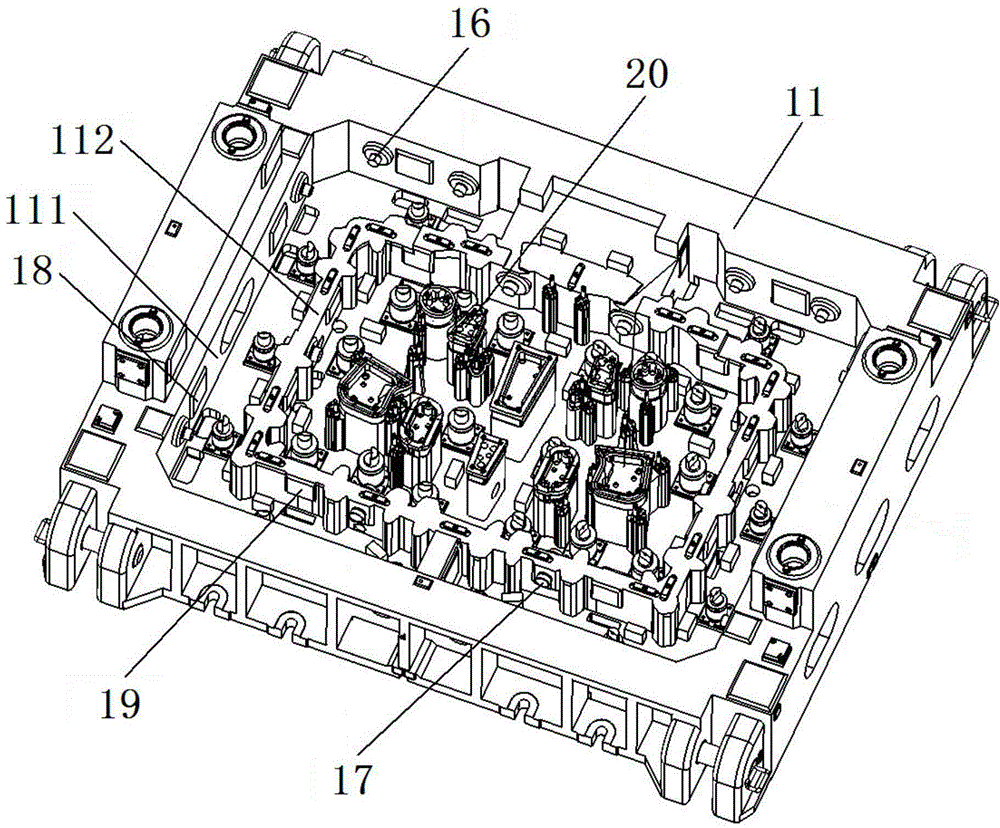

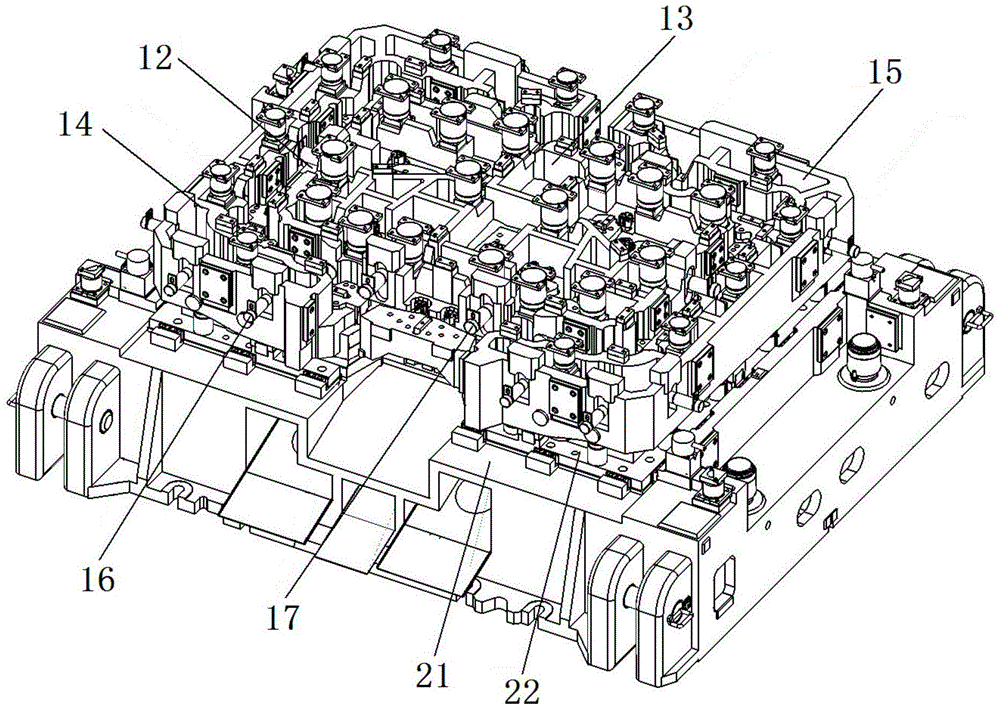

Processing die assembly of vehicle door inner plate

ActiveCN104384330AGuaranteed forming effectMitigate the adverse effects of mobilityShaping toolsCar doorEngineering

The invention discloses a processing die assembly of a vehicle door inner plate. The processing die assembly comprises a drawing die and a shaping die, wherein the drawing die comprises a drawing concave die, the shaping die comprises an upper die holder, a lower die holder, a material pressing core, a convex die, a trimming embedding block and a circumferential shaping embedding block, the convex die is arranged on the lower die holder, the part, corresponding to the circumference of the vehicle door inner plate, of the drawing concave die is provided with a drawing plane, the circumferential shaping embedding block is used for processing the circumference, the material pressing core comprises an inner material pressing core and an outer material pressing core, the inner material pressing core, the circumferential shaping embedding block, the outer material pressing core and the trimming embedding block can mutually act with the convex die along the movement direction of the upper die holder, the inner material pressing core and the outer material pressing core are respectively positioned at the two sides of the circumferential shaping embedding block, and the trimming embedding block is positioned in the inner side of the inner material pressing core. The processing die assembly has the advantages that the shaping effect of a middle area of the vehicle door inner plate is guaranteed, and the shaping effect of the edge of the vehicle door inner plate is also guaranteed.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Preheating method for improving bake-hardening performance and forming performance of 6022 aluminum alloy

InactiveCN101985728AExcellent bake hardenabilityGuaranteed forming effectSolution treatmentQuenching

The invention provides a preheating method for improving the bake-hardening performance and the forming performance of a 6022 aluminum alloy, comprising the following steps: performing solution treatment on the 6022 aluminum alloy sheet for 10-20 min at the temperature of 530-555 DEG C, and performing water quenching; and preheating the aluminum alloy sheet after water quenching within one day for 20-60s at the temperature of 180-250 DEG C by implementing the preheating process, the bake-hardening performance of the 6022 aluminum alloy can be obviously improved, and the forming performance of the 6022 aluminum alloy can be improved to some extent at the same time.

Owner:苏州有色金属研究院有限公司

Method for improving optical fiber laser-MIG arc hybrid welding back forming

InactiveCN104028893AGuaranteed stabilityGuaranteed forming effectLaser beam welding apparatusLaser-hybrid weldingPower flow

The invention provides a method for improving optical fiber laser-MIG arc hybrid welding back forming. The method includes the following steps that (1) the minimum power Pd of an optical fiber laser device during single-laser welding and through welding is determined; (2) the minimum power Pf of the optical fiber laser device during optical fiber laser-MIG arc hybrid welding and through welding is set, the current of MIG arc welding is I, the ratio of Pd to Pf is determined according to the following formula that Pd:Pf=(1+a)*Pd*(1+bI / 120-b), a is 20-30%, when I is larger than or equal to 90A and when I is larger than or equal to 90 A and smaller than 120A, b is 0, and when I is larger than or equal to 120A, b is 1; (3) optical fiber laser-MIG arc hybrid welding is carried out according to the following welding mode that in the welding direction, an MIG welding point is in front, a laser welding point is at back, a heat source distance ranges from 1 mm to 2 mm, the lengthening quantity of a welding wire is 8-12 mm, a welding torque inclined angle is 55-60 degrees, and a welding gap is 0-0.5 mm. Hybrid welding is carried out according to the method, so that the back forming effect during single-side through welding of hybrid welding can be guaranteed, and meanwhile stability of MIG welding can be guaranteed.

Owner:武汉钢铁有限公司

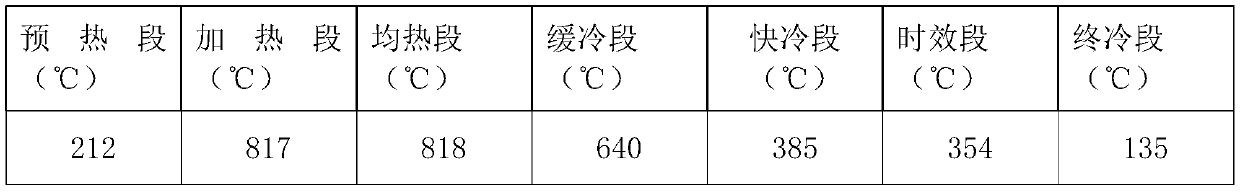

High-elongation high-strength hot-dip galvanized steel sheet and production method thereof

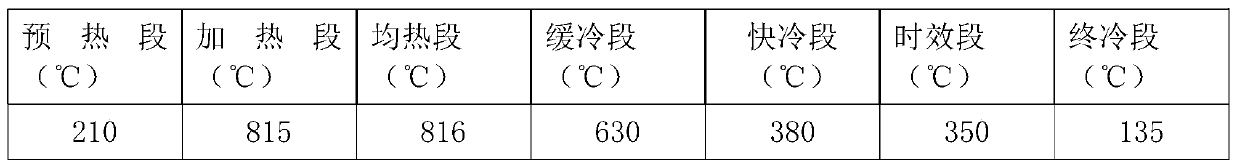

PendingCN113512679AGuaranteed weldingGuaranteed forming effectHot-dipping/immersion processesFurnace typesChemical compositionSteel plates

The invention belongs to the technical field of steel smelting, and particularly relates to a high-elongation high-strength hot-dip galvanized steel sheet and a production method thereof. The technical purpose of the invention is to provide the high-elongation high-strength hot-dip galvanized steel sheet and the production method thereof. The high-elongation high-strength hot-dip galvanized steel sheet provided by the invention comprises the following chemical components in percentages by weight: 0.03-0.10% of C, 0.20-0.60% of Si, 1.20-2.00% of Mn, 0.015-0.070% of Als, less than or equal to 0.020% of P, less than or equal to 0.010% of S, less than or equal to 0.006% of N and the balance of Fe and inevitable impurities. The production method comprises the following steps: smelting, hot rolling, acid rolling, annealing and hot-dip galvanizing. The hot-dip galvanized steel prepared by the method has high strength, high elongation and obvious economic benefit.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

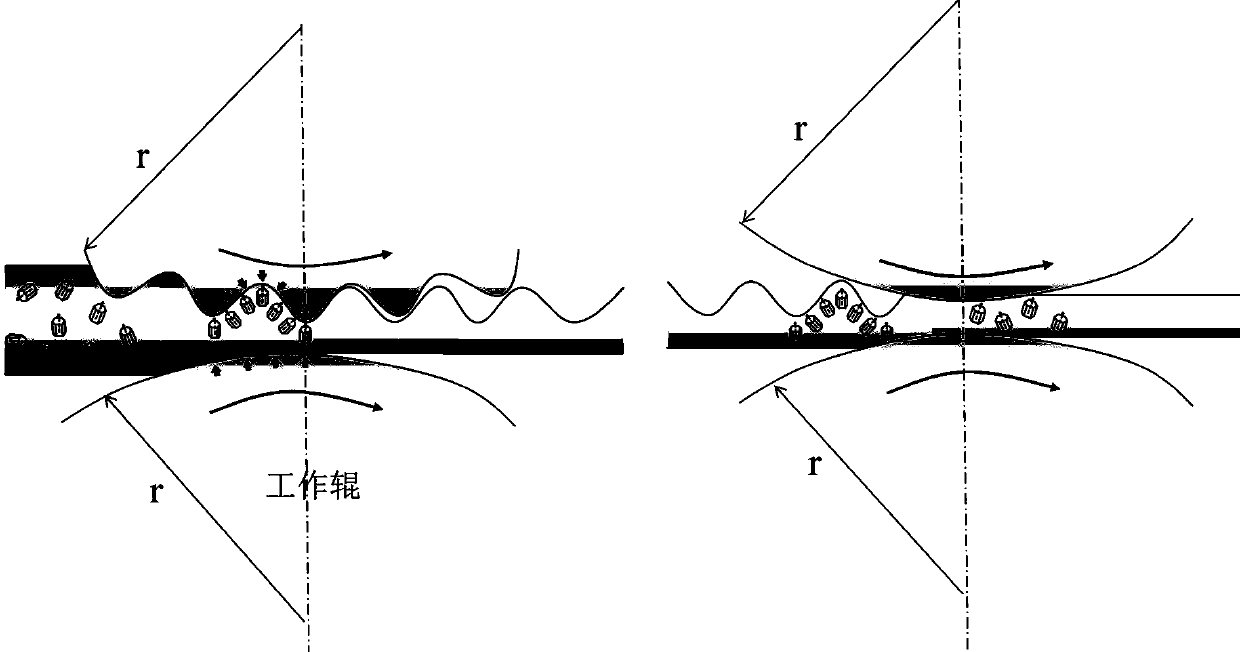

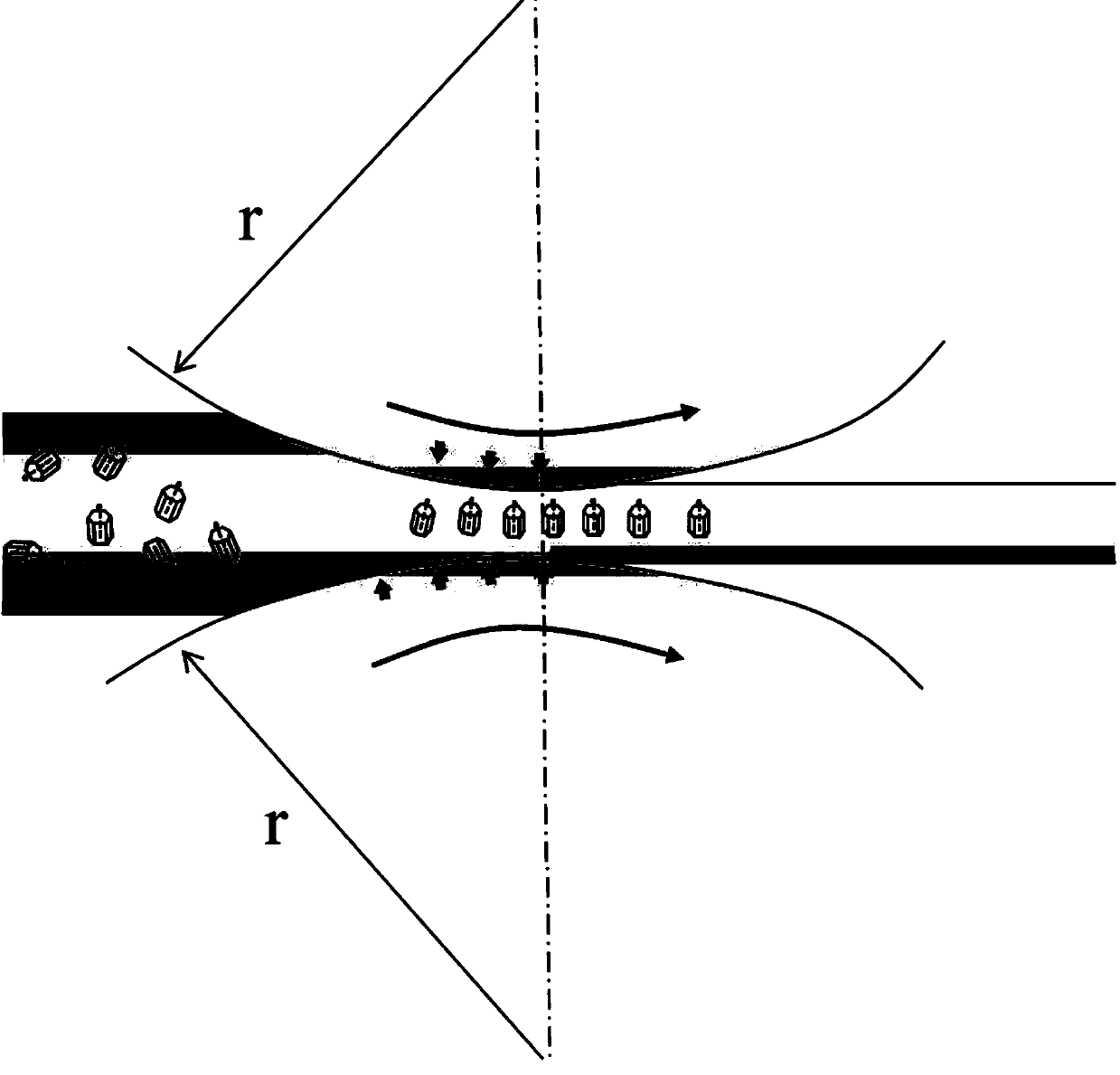

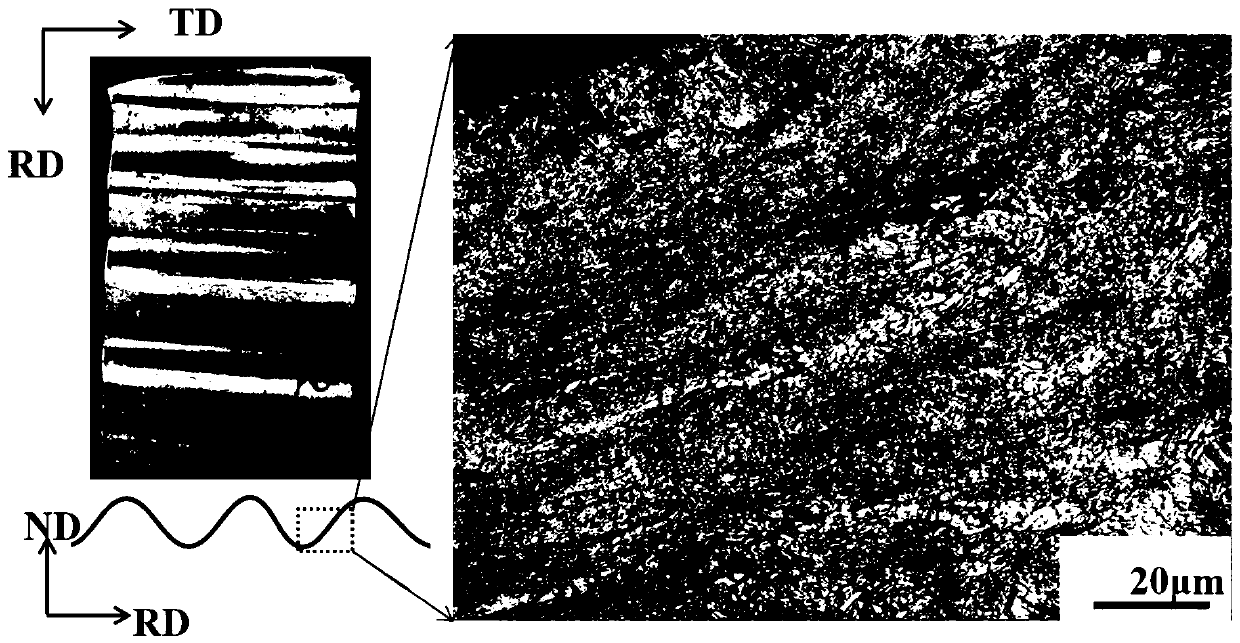

Method for continuous production of magnesium alloy strip basal plane texture through corrugated pre-rolling weakening

InactiveCN110670005AImprove mechanical propertiesImproved room temperature formabilityMetal rolling arrangementsMetal machiningUltimate tensile strength

The invention belongs to the technical field of metal machining, and discloses a method for continuously producing of magnesium alloy strip basal plane texture through corrugated pre-rolling weakening. The method comprises the following steps that firstly, the method is used for carrying out corrugated rolling on the magnesium alloy strip, local strain is introduced, and the subsequent traditionalflat binding is carried out. The rolling process of the method comprises the following steps of (1) enabling the original magnesium alloy strip to pass through a corrugated roller, and rolling the original magnesium alloy strip into a wavy shape; and (2) enabling a corrugated strip to bite into a subsequent flat roller, and rolling the corrugated strip into a flat strip with the required thickness through the flat roller. The magnesium alloy strip prepared by the method has the advantages that the Schmid factor of the magnesium alloy strip is increased, the activity of the non-basal plane sliding system including the mechanical twin crystal is remarkably promoted, continuous arc grooves of the magnesium alloy strip can control the evolution of tissue and texture, the elongation at break is improved, the texture strength of the basal plane is weakened, and the comprehensive performance required by production is met. In addition, the forming rate of the magnesium alloy cold strip is improved, the process is simple, and the rolling productivity of equipment is high.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

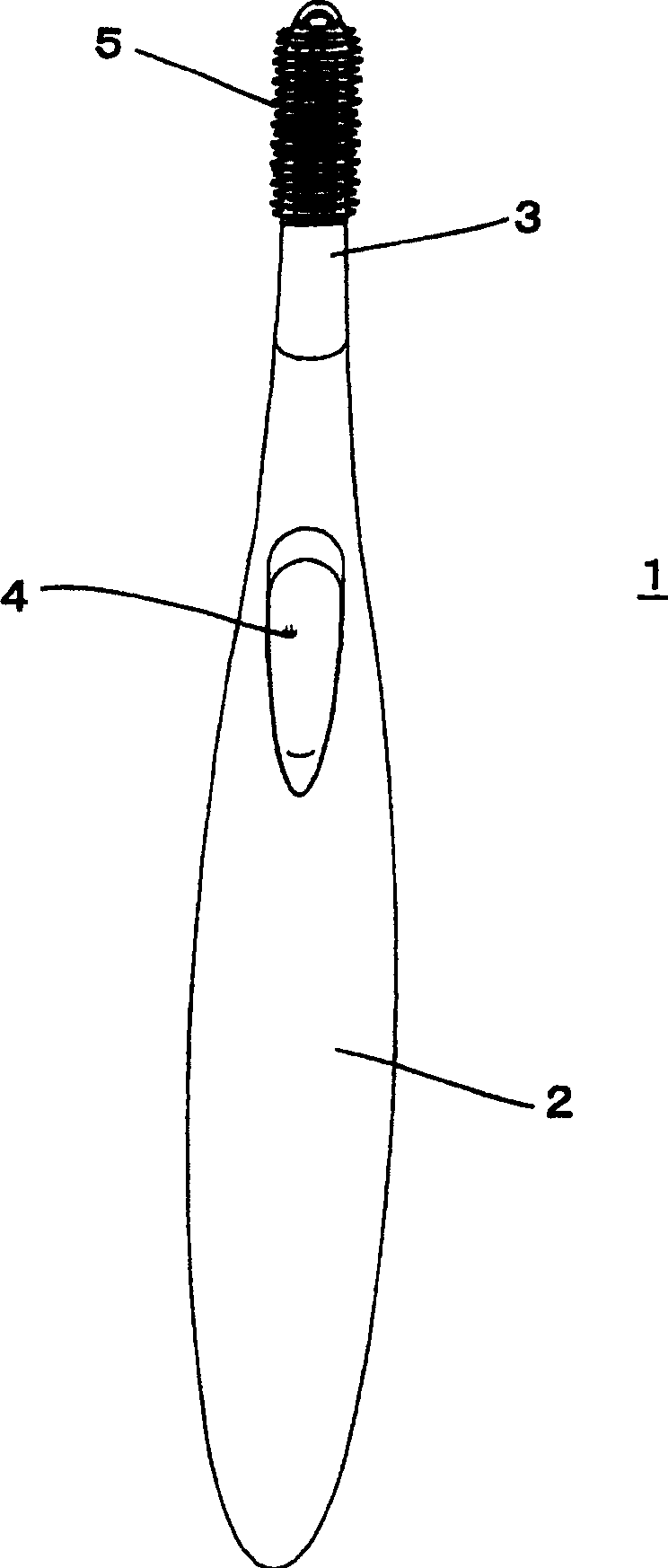

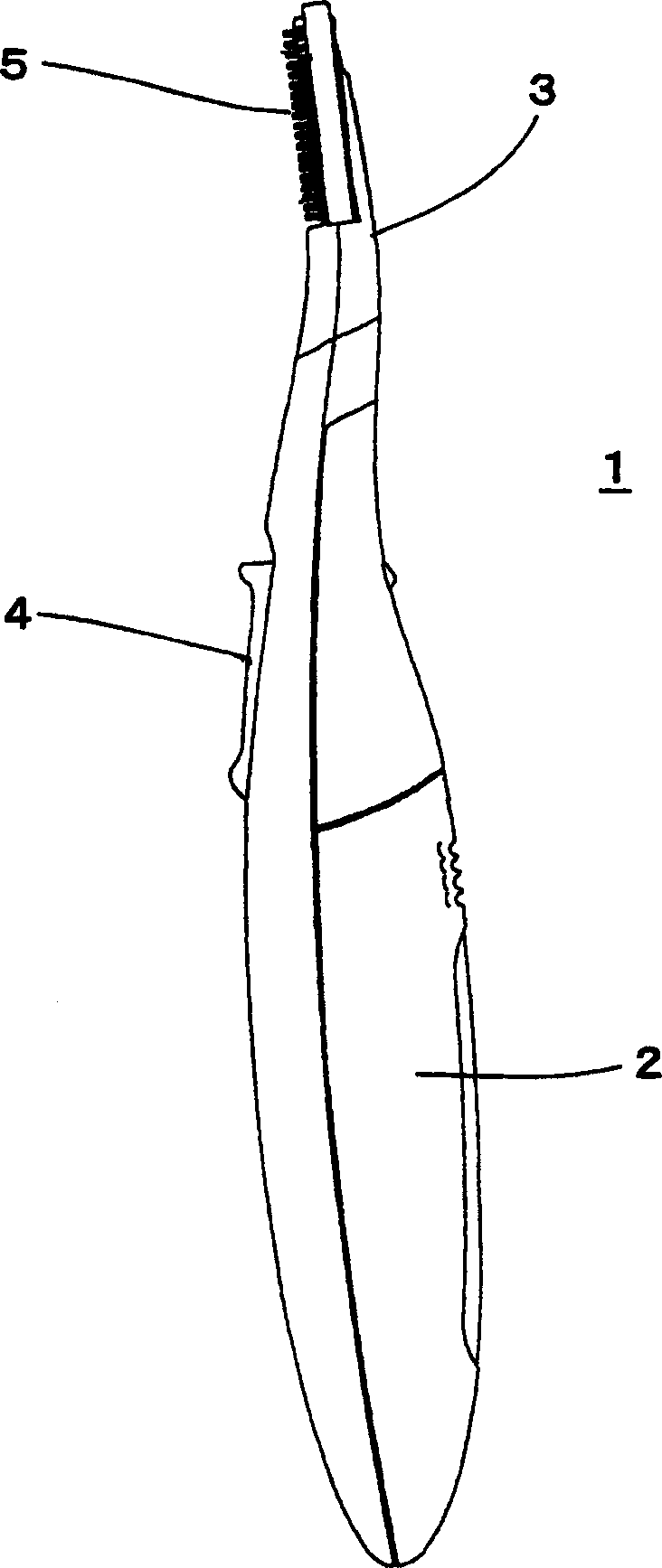

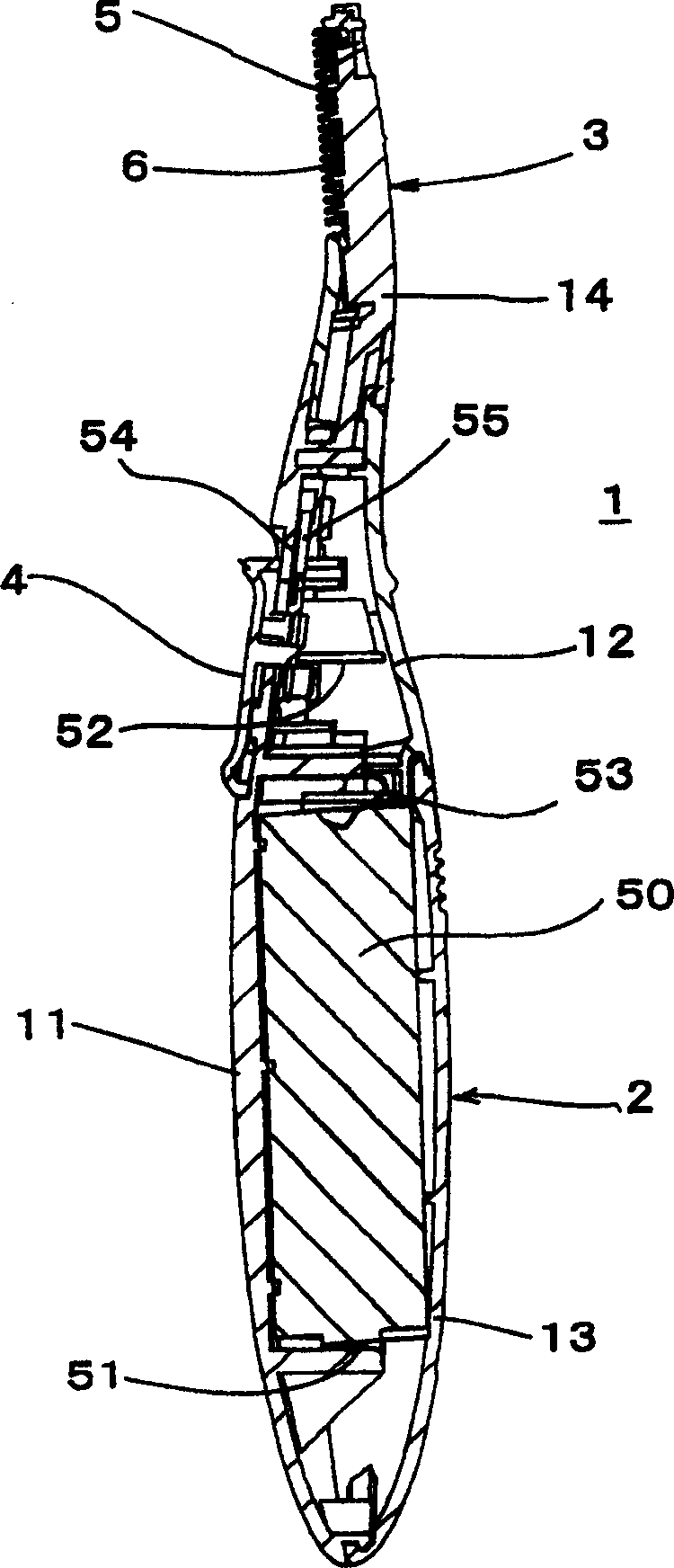

Eyelash forming device

InactiveCN1293839CSmooth assembly and disassemblySimple and compact disassembly structureCurling-ironsCurling-tongsEyelashEngineering

Owner:MATSUSHITA ELECTRIC WORKS LTD

Method for achieving TWIP steel superplasticity based on deformation twin degradation

The invention discloses a method for achieving TWIP steel superplasticity based on deformation twin degradation. The method comprises the following steps that (1) a TWIP steel bar in the perfect recrystallization state is selected and is stretched under the room temperature, the stretching deformation rate is 1-10 mm / s, and the stretching deformation quantity is 40%; (2) deformation twin degradation treatment is conducted, the stretched TWIP steel bar is subjected to heat preservation, so that deformation twin degradation and disappearance occur in the structure of the stretched TWIP steel bar, the temperature is 650-850 DEG C, heat preservation is conducted for 30-60 min, and quenching is conducted after heat treatment; (3) the quenched TWIP steel bar is stretched under the room temperature, the stretching deformation rate is 10<1>-1 mm / s, and the stretching deformation quantity is 30%; and (4) the (2)-(3) steps are repeated, and thus the total elongation after deformation is larger than 100%, that is, superplasticity is achieved. Through the method, the problems that the deformation quantity of the TWIP steel bar is too large in the hot rolling process, consequently, deformation resistance is large, cracks are liable to be produced, and the superplasticity forming rate is low are solved.

Owner:ZHEJIANG IND & TRADE VACATIONAL COLLEGE

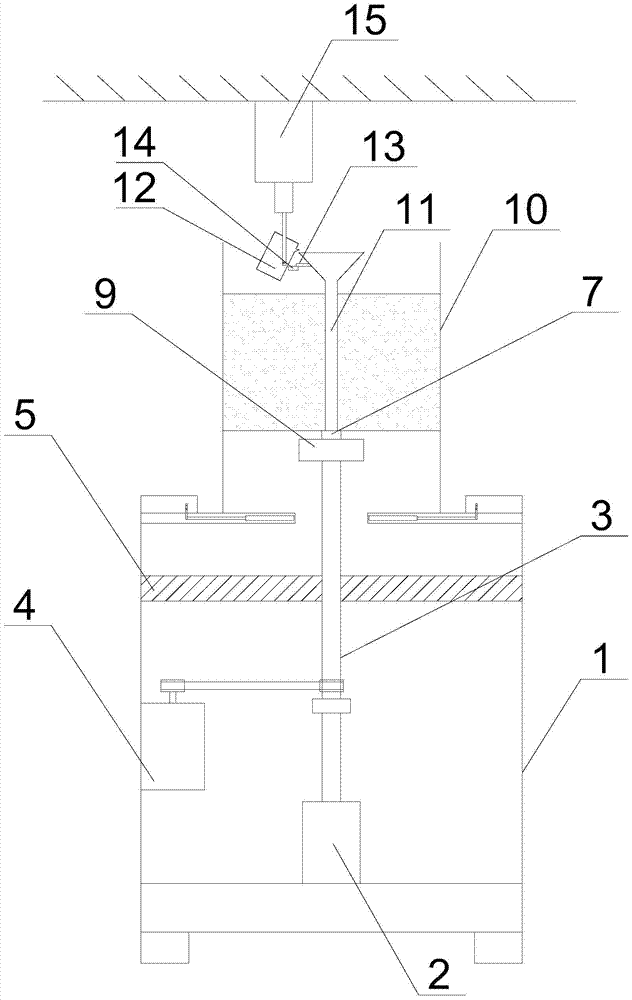

a casting equipment

ActiveCN104588626BImprove casting effectImprove operational flexibilityMolten metal conveying equipmentsCastingInertia

The invention discloses a casting method and casting equipment for implementing the casting method. The method comprises the steps of S1, pouring casting liquid into a mold through a pouring gate arranged on the mold; S2, enabling the casting liquid to fully fill a casting cavity of the mold through movement of the mold; S3, cooling and solidifying the casting liquid to form a casting blank. The equipment comprises a mold, a pouring device and a movement device, wherein the mold is provided with a casting cavity and a pouring gate and the casting cavity is communicated with the pouring gate; the pouring device is used for preparing casting liquid and pouring the casting liquid into the pouring gate; the mold is installed on the movement device, the movement device is driven by a movement drive mechanism to drive the mold to move, and the casting liquid in the casting cavity fully fills the casting cavity through inertia thereof. The casting method and the casting equipment for implementing the casting method have the beneficial effects that the casting liquid in the casting cavity fully fills the entire casting cavity under the effect of inertial force through the movement of the mold under the drive of the movement device and the casting effect is good.

Owner:山西建邦集团铸造有限公司

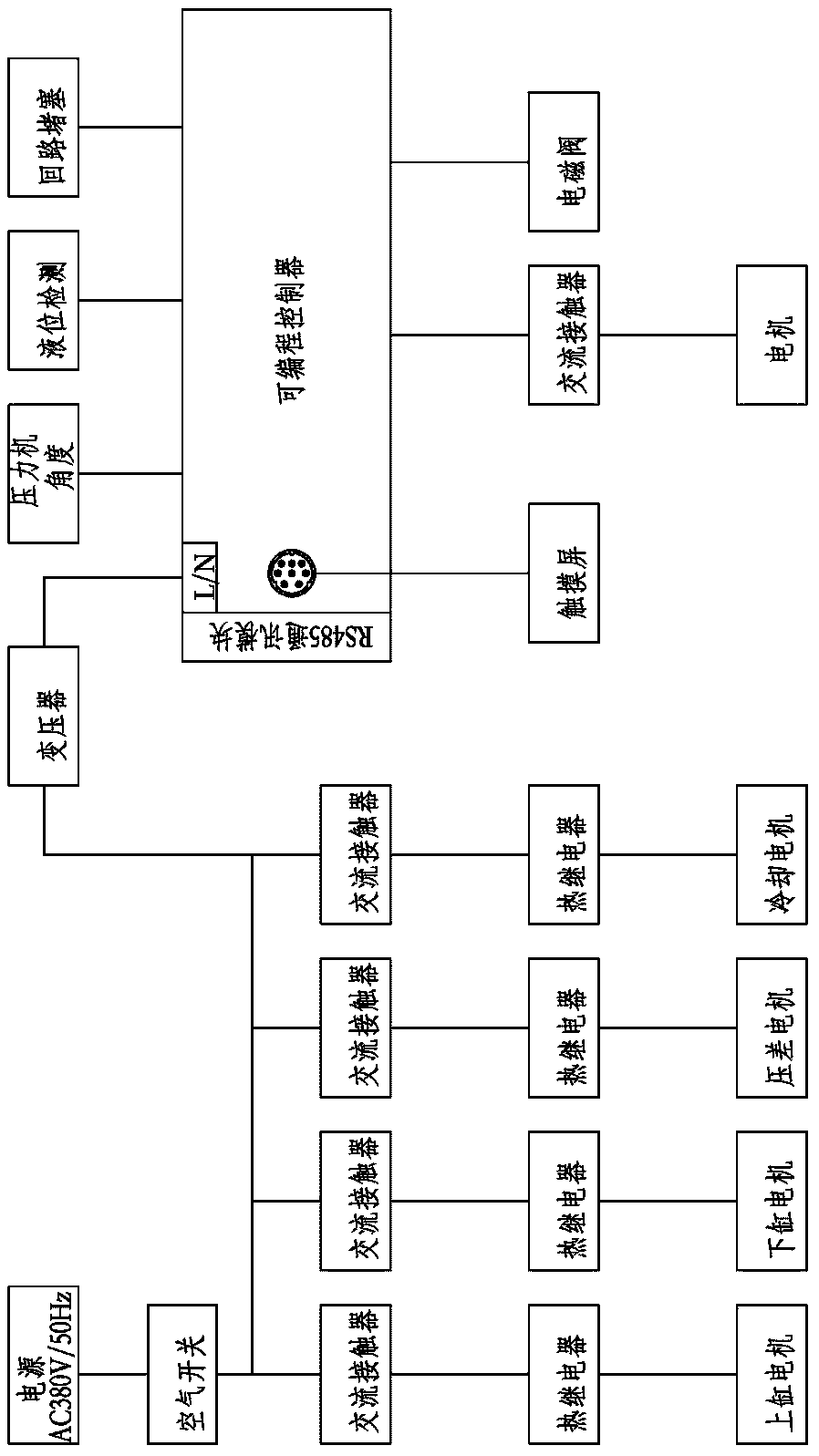

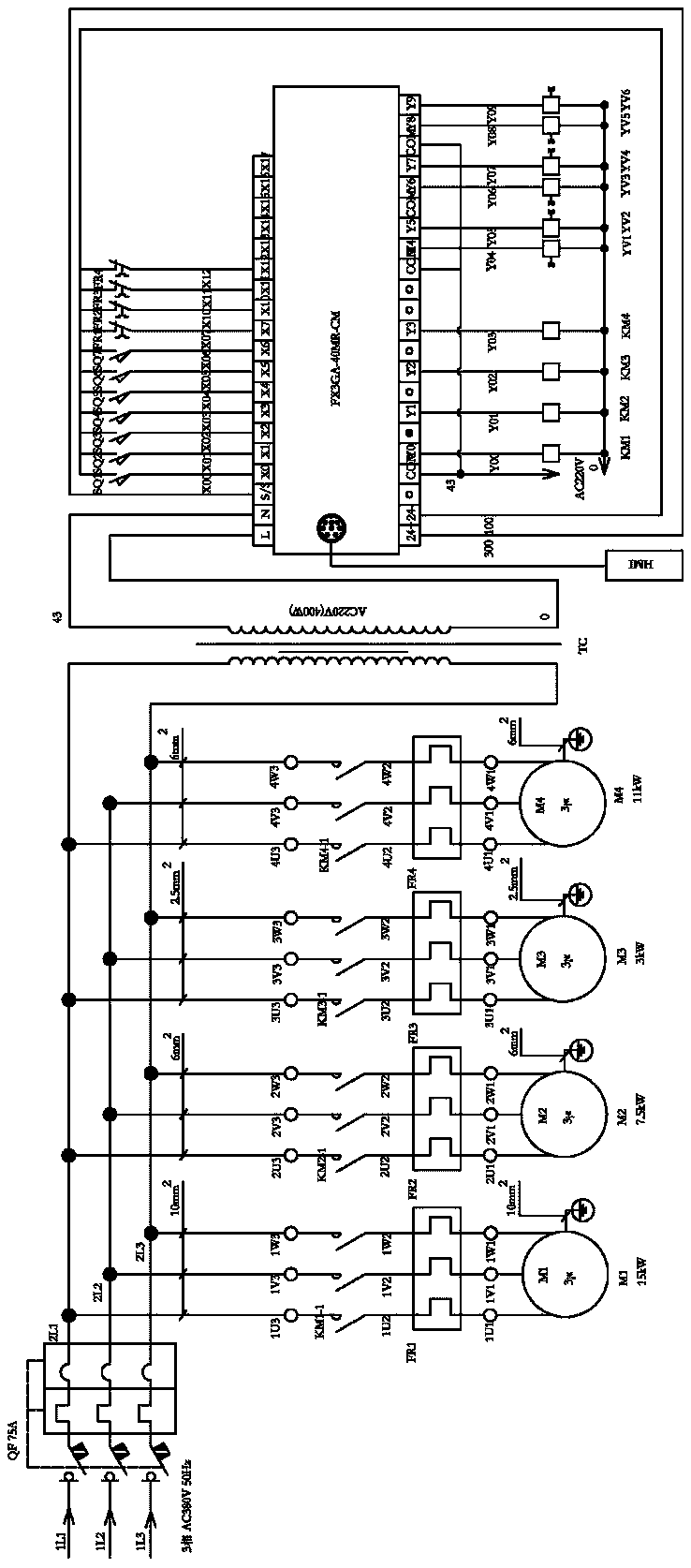

Double-cylinder hydraulic ejection control system and method thereof

ActiveCN109203555AImprove workpiece processing speedGuaranteed forming effectPressesContactorOil pressure

The invention discloses a double-cylinder hydraulic ejection control system in the field of a pressing machine. The system includes a main circuit unit and a main control unit, wherein the main circuit unit includes an upper cylinder motor and a lower cylinder motor which are connected with the power source through an AC contactor contact, the main control unit includes a control unit used for controlling the work process of the pressing machine, a detection unit used for detecting a stroke state of a pressing machine sliding block and sending the stroke state to the control unit, and an action unit used for receiving a control signal from the control unit, the upper cylinder motor and the lower cylinder motor are controlled by an AC contactor for operation, and the oil pressure in an upper cylinder and a lower cylinder is controlled by a solenoid valve. The system is advantaged in that workpiece forming of various specifications can be adapted to, according to the material thickness of the stamped workpiece, precise adjustment of the oil pressure of the upper and lower cylinders is set, and the system can be used in two-cylinder pressing machine control.

Owner:JIANGSU YANGLI FORGING PRESS

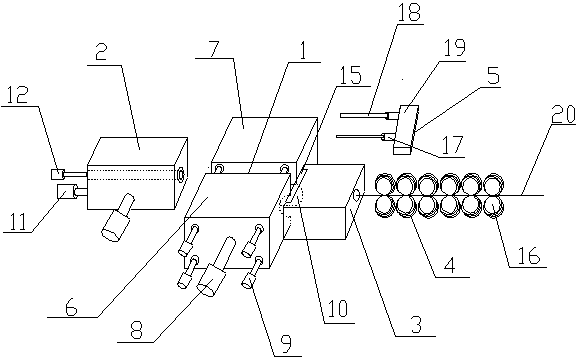

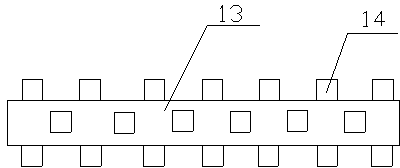

Automatic pier head equipment of automobile hollow lifting hooks

ActiveCN103522065AGuaranteed forming effectReasonable structureOther manufacturing equipments/toolsHandling devicesPipe fittingEngineering

The invention provides automatic pier head equipment of automobile hollow lifting hooks. The automatic pier head equipment of the automobile hollow lifting hooks comprises a positioning device, a forming device, a guide cutting-off device, a round broaching device and a conveying device, wherein the forming device is arranged at the left side of the positioning device, the guide cutting-off device is arranged at the right side of the positioning device, the round broaching device is arranged at the right side of the guide cutting-off device, and the conveying device is arranged at the back of the guide cutting-off device. The automatic pier head equipment of the automobile hollow lifting hooks is reasonable in structure, can effectively, rapidly and automatically complete the whole machining process from automatic feeding of the automobile hollow lifting hooks to material receding of pier heads, accurately processes pipe fittings to be machined, is simple in machining working procedure, guarantees the forming effect of the hollow lifting hooks, adopts automation machining, reduces manual operation, saves machining cost, and improves work efficiency.

Owner:安徽振华汽车部件有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com