Production process of 2024 high-strength aluminum alloy special thin-walled section steel

A technology for aluminum alloy profiles and production processes, applied in the field of aluminum alloys, can solve the problems of difficult control of profile formability and dimensional accuracy, and unattainable production processes, and achieve the effect of optimizing the design of quenching fixtures and reducing the degree of alloying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

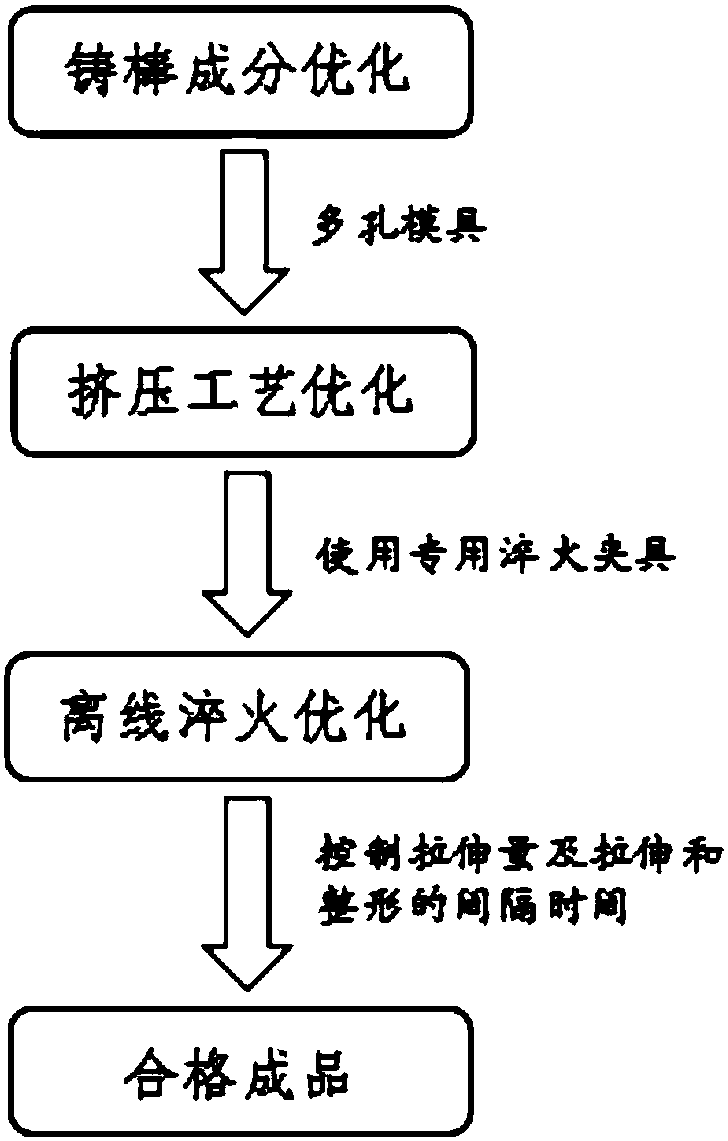

[0026] Such as figure 1 A 2024 high-strength aluminum alloy ultra-thin-walled profile production process is shown, including the following steps:

[0027] A. Melting and casting: The mass percentage ratio of each element in the aluminum alloy ingot raw material is as follows:

[0028] element

Si

Fe

Cu

mn

Mg

Cr

Zn

Ti

Al

content

0.05

0.10

3.9

0.40

1.30

0.10

0.20

0.12

margin

[0029] Single impurity ≤ 0.05%, total impurity ≤ 0.15%,

[0030] Put the prepared aluminum alloy raw materials into the smelting furnace and evenly mix them to melt them into liquid aluminum alloys, and melt and cast the liquid aluminum alloys into aluminum alloy casting rods;

[0031] B. Homogenization: heat the aluminum alloy casting rod obtained by melting and casting to 500°C, keep it warm for 25 hours, and cool to normal temperature to obtain a homogeneous aluminum alloy casting rod, wherein the length of the homogeniz...

Embodiment 2

[0038] The difference between embodiment 2 and embodiment 1 is that in step A, the mass percentage ratio of each element of the aluminum alloy ingot raw material is as follows:

[0039] element

Si

Fe

Cu

mn

Mg

Cr

Zn

Ti

Al

content

0.05

0.10

4.0

0.60

1.40

0.10

0.20

0.12

margin

[0040] Single impurity ≤ 0.05%, total impurity ≤ 0.15%.

[0041] The tensile strength of the 2024 high-strength aluminum alloy ultra-thin-walled profiles obtained in embodiment 1 and embodiment 2 is respectively 400MPa and 410Mpa, the yield strength is respectively 300MPa and 305Mpa, and the elongation at break is respectively 12% and 13%. GJB2507A standard requires R m ≥395MPa,R p0.2 ≥290MPa, A%≥10%. The dimensions of the ultra-thin-walled 2024 high-strength aluminum alloy profiles obtained in Example 1 and Example 2 meet the requirements of GB / T14864 high-precision grades, with plane gaps of ≤0.2mm, angles of 90±2°, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com