Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35 results about "2024 aluminium alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

2024 aluminium alloy is an aluminium alloy, with copper as the primary alloying element. It is used in applications requiring high strength to weight ratio, as well as good fatigue resistance. It is weldable only through friction welding, and has average machinability. Due to poor corrosion resistance, it is often clad with aluminium or Al-1Zn for protection, although this may reduce the fatigue strength. In older systems of terminology, 2XXX series alloys were known as duralumin, and this alloy was named 24ST.Al...

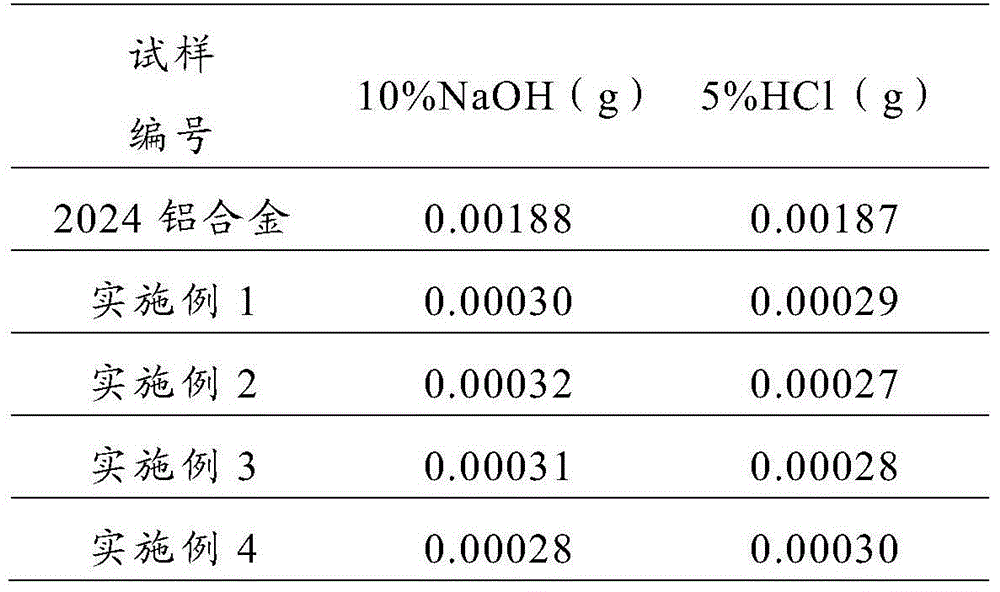

Molybdate doped polypyrrole/epoxy resin self-healing coating, preparation method thereof and application thereof

InactiveCN105001759AExcellent self-healing performanceAvoid corrosionEpoxy resin coatingsEpoxyPolypyrrole

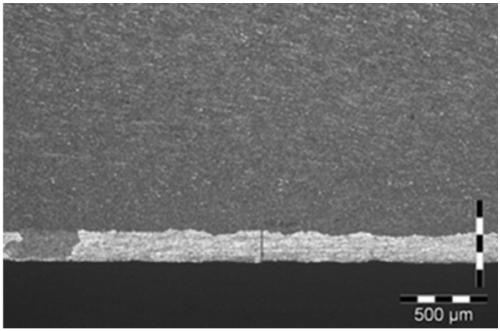

The invention relates to a molybdate doped polypyrrole / epoxy resin self-healing coating, a preparation method thereof and an application thereof, and belongs to the field of metal anti-corrosion coatings. The coating is composed of two parts, namely a polypyrrole / epoxy resin system mother liquor, and a polyamide curing agent. The polypyrrole / epoxy resin system mother liquor comprises molybdate doped polypyrrole, epoxy resin, an anti-settling agent, an anti-foaming agent, a levelling agent and an organic solvent. The molybdate doped polypyrrole is added in the organic solvent and then the mixture is uniformly dispersed in an ultrasonic dispersion instrument. After that, the anti-settling agent, the antifoaming agent and the levelling agent are added respectively, and are stirred on a magnetic stirring apparatus. Then the epoxy resin is added to form the uniformly dispersed polypyrrole / epoxy resin system mother liquor. The polyamide curing agent is added in the prepared mother liquor, and is stirred to be uniformly dispersed. In this way, a molybdate doped polypyrrole / epoxy resin self-healing coating can be obtained. The coating is sprayed or brushed onto the 2024 type aluminum alloy after being subjected to oil-removing treatment. After the drying and curing process of the coating at the room temperature, a molybdate doped polypyrrole / epoxy resin self-healing coating can be formed.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Aluminum alloy section and machining method for suppressing a coarse grain ring of aluminum alloy section

ActiveCN109136506AImprove performance indicatorsSuppress coarse crystal ringFurnace typesHeat treatment furnacesAviation2024 aluminium alloy

The invention provides an aluminum alloy section and a machining method for suppressing a coarse grain ring of the aluminum alloy section, and relates to the field of aluminum alloy machining. The machining method for suppressing the coarse grain ring of the aluminum alloy section comprises the following steps: preparing raw materials according to alloy elementary compositions of 2024 aluminum alloy, and smelting and casting into a cast stick; carrying out first-time homogenization treatment on the cast stick by a two-stage homogenization system to obtain a primary homogenized cast stick; carrying out second-time homogenization treatment on the primary homogenized cast stick to obtain secondary homogenized cast stick; carrying out peeling treatment and extrusion treatment on the secondaryhomogenized cast stick to obtain an extruded section; and carrying out pre-stretching, solid solution heat treatment, stretch flattening and natural aging on the extruded section to obtain a 2024 aluminum alloy section. By the processing method, the coarse grain ring of the coarse grain ring of the 2024 aluminum alloy extruded section can be suppressed effectively, and various performance indexesof a final product are higher than standard requirements. The strength and toughness of the prepared aluminum alloy section are greatly improved, and the requirement of aluminum alloy for aviation ismet.

Owner:SHANDONG NANSHAN ALUMINUM +1

Novel casting aluminium alloy and preparation method thereof

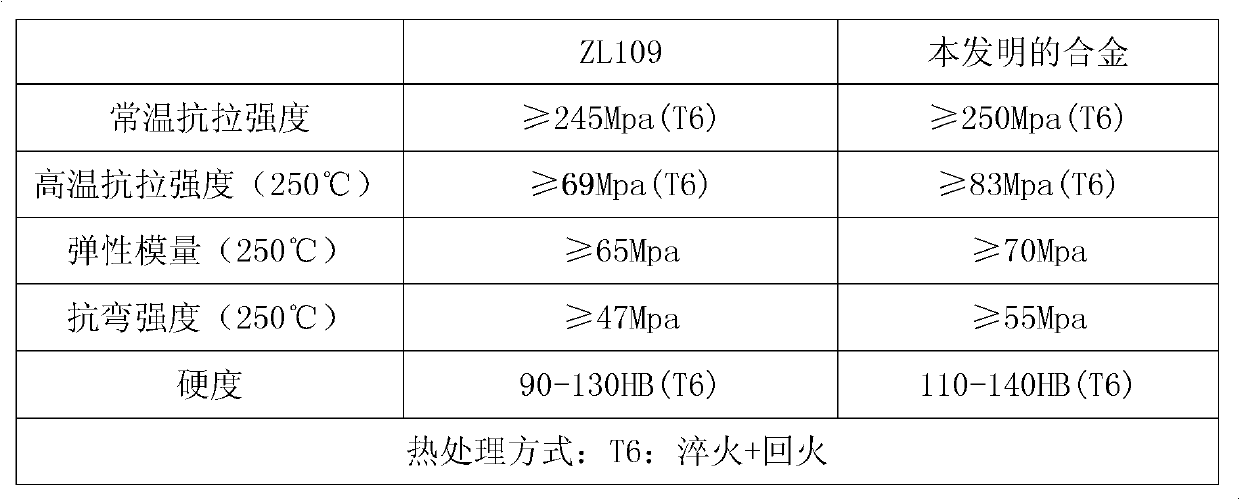

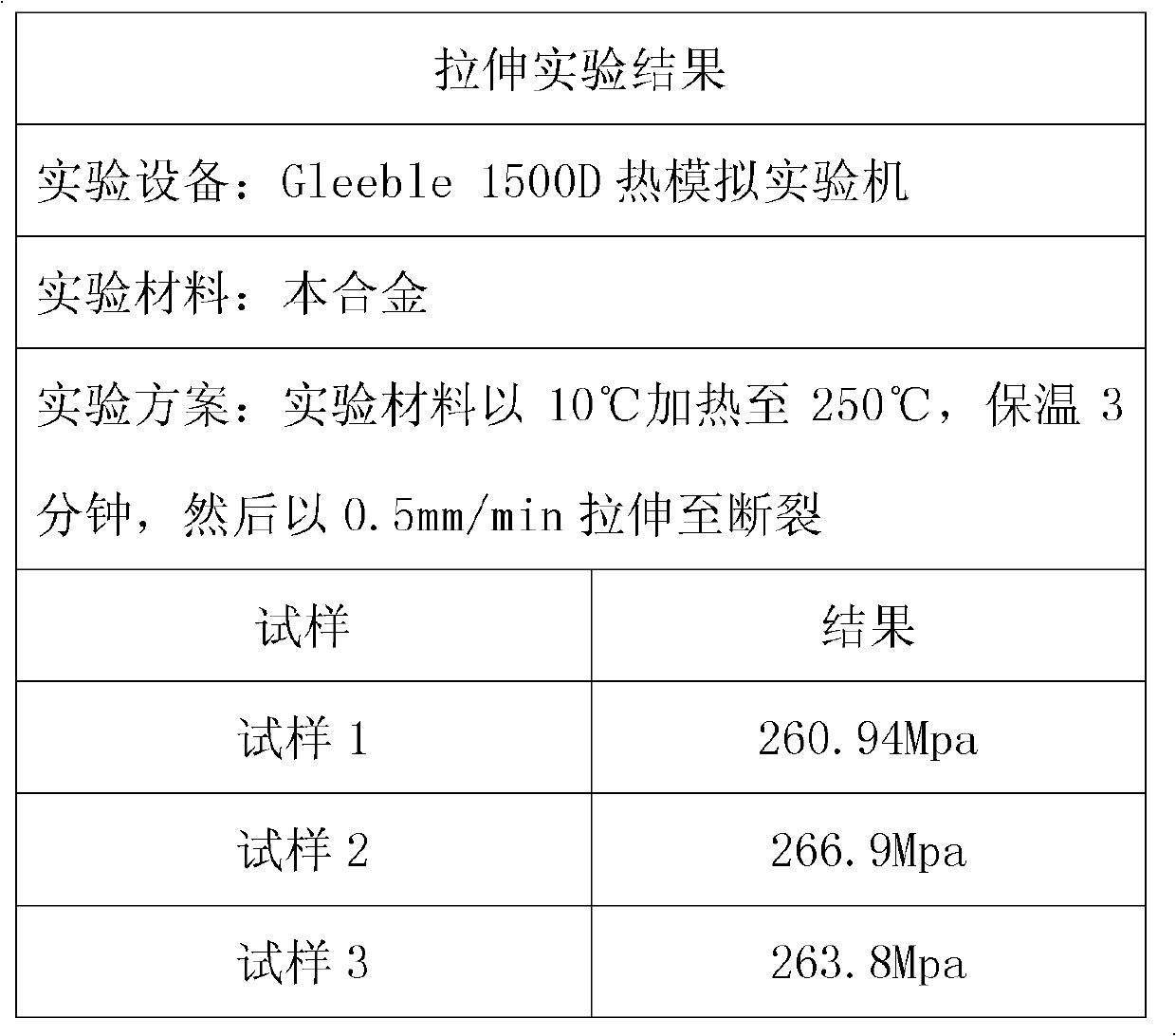

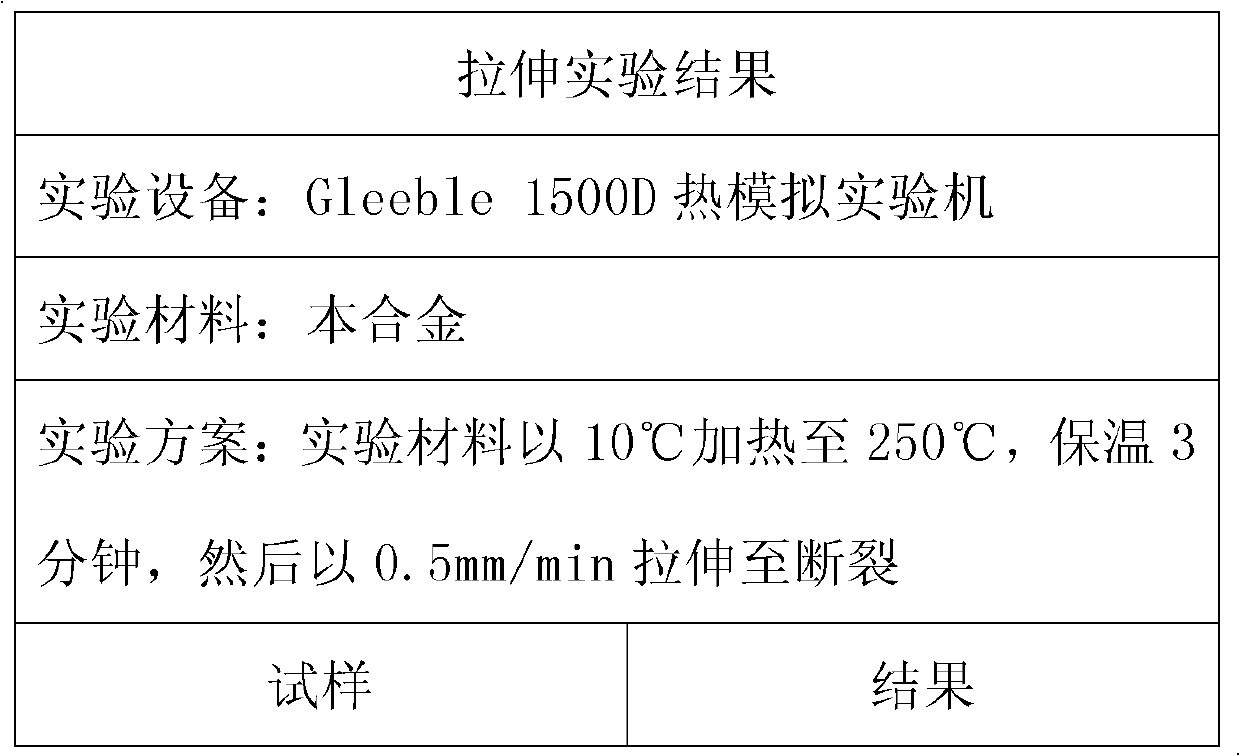

The invention discloses a casting aluminium alloy and a preparation method thereof. The casting aluminium alloy comprises the following components in percentage by weight: 11-13wt% of Si, 2-4wt% of Cu, 0.5-1.2wt% of Mg, 2-3.5wt% of Ni, 0.08-0.18wt% of Ti, 0.1-0.2wt% of V and the balance of aluminium ingot, wherein the mark of the aluminium ingot is Al99.50. Compared with the existing casting aluminium alloy ZL109, the casting aluminium alloy has the advantages that comprehensive mechanical property is greatly improved, and high-temperature thermal fatigue strength is improved by 10%. Each index of the obtained aluminium alloy is far beyond the national criterion of acceptability after the aluminium alloy is tested by the aluminium alloy tensile property experiment of the environment experiment center of the China Academy of Engineering Physics. The casting aluminium alloy is used for manufacturing engine pistons, the working performance of the engine piston can be greatly improved, and the service life of the piston can be greatly prolonged.

Owner:四川渝邻汽车零部件有限公司

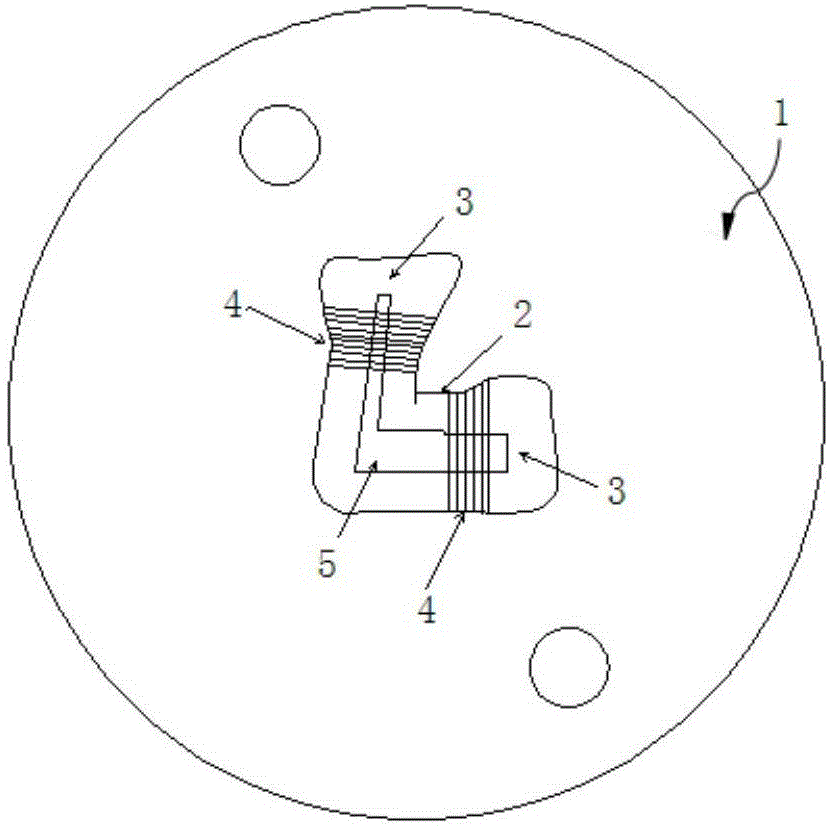

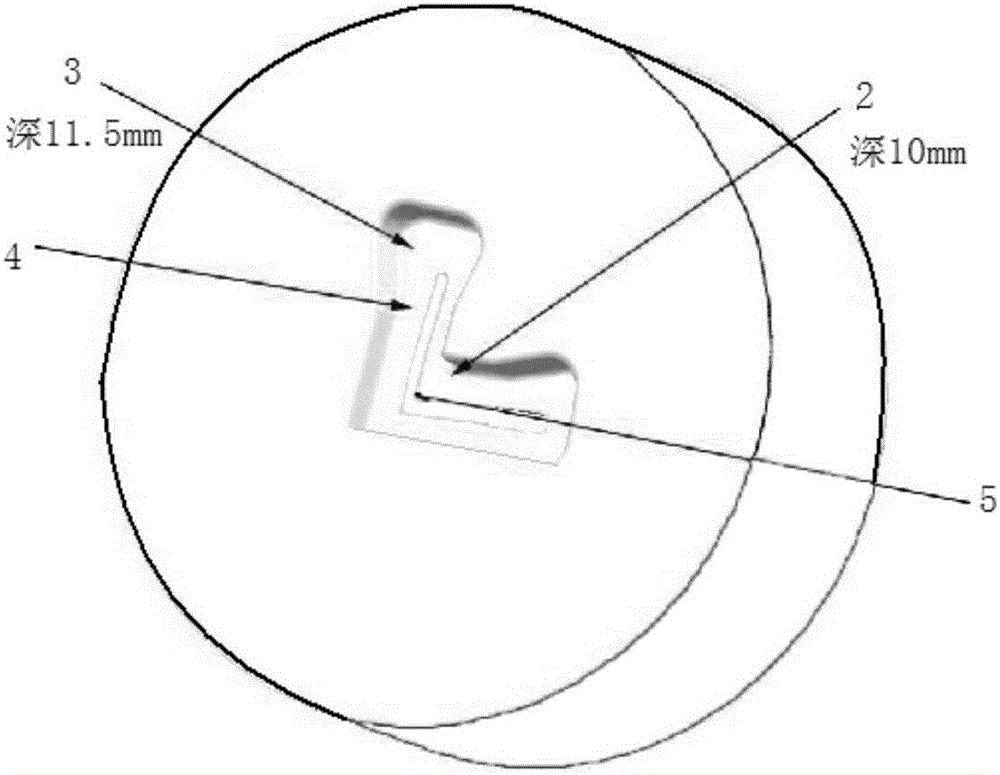

High-strength 2024 aluminum alloy thin-wall angle profile production process

ActiveCN106513456ASmall sizeHigh dimensional accuracyExtrusion dies2024 aluminium alloyNatural aging

Owner:CHINA ZHONGWANG

2024 aluminum alloy melting casting method

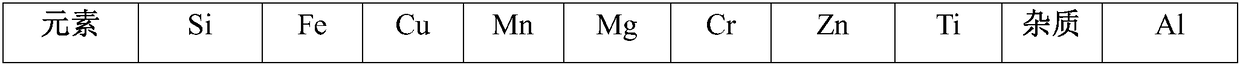

The invention belongs to the technical field of aluminum alloy, and relates to a 2024 aluminum alloy melting casting method. The aluminum alloy is prepared from the following ingredients in percentageby mass: smaller than or equal to 0.25 percent of Si, smaller than or equal to 0.35 percent of Fe, 4.55 to 4.65 percent of Cu, 0.5 to 0.7 percent of Mn, 1.55 to 1.65 percent of Mg, 0.1 percent of Cr,0.2 percent of Zn, smaller than or equal to 0.12 percent of Ti, impurities (the quantity of single impurities is smaller than or equal to 0.05 percent; the total quantity is smaller than or equal to0.15 percent) and the balance of Al; then, melting, refining, degassing, slag removal and casting are performed; a semi-continuous casting process is used for casting; in the refining process, 23 to 28 percent of NaCl, 20 to 40 percent of KCl and 40 to 60 percent of MgCl2 are added to be used as refining agents; the casting temperature is controlled to be 730 to 740 DEG C; the casting speed is 20to 22 mm / min; the single water flowrate is 300 to 310 L / min; the 2024 aluminum alloy cast ingot is obtained. An aluminum cast rod produced by the 2024 aluminum alloy melting casting method has few defects; the material performance and the finished product rate are improved; the energy consumption is reduced; the production cost is reduced; good economic benefits are realized.

Owner:YINGKOU ZHONGWANG ALUMINUM CO LTD

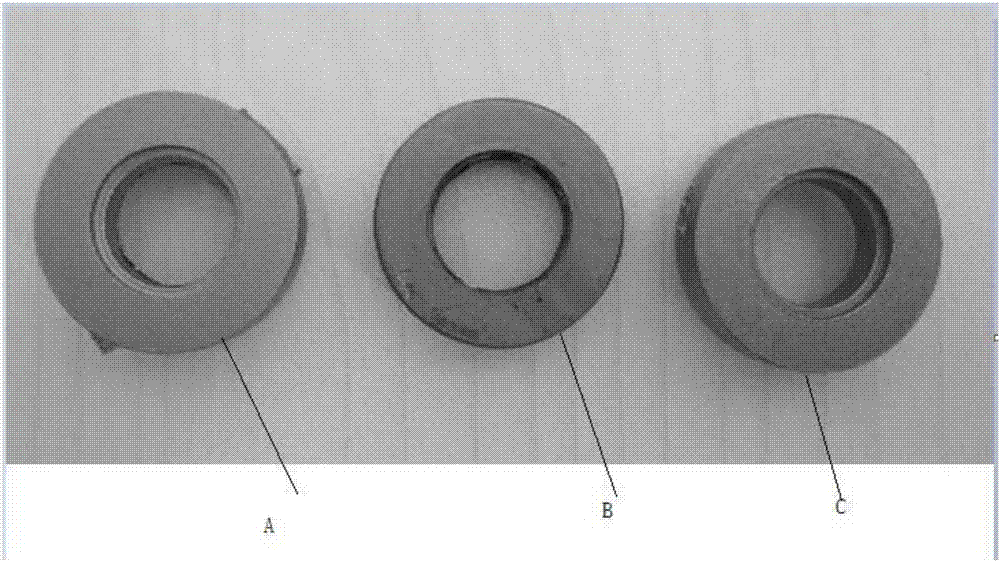

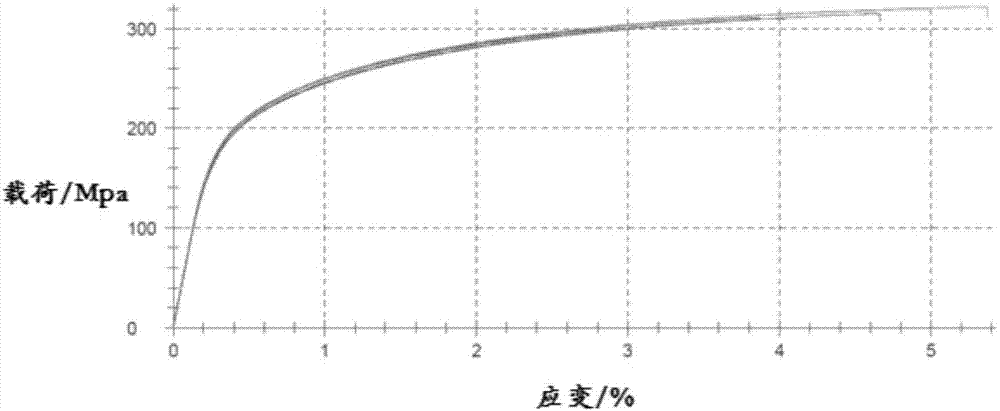

Spin-forming method for long-barrel-shaped part board

The invention discloses a spin-forming method for a long-barrel-shaped part board. The spin-forming method comprises the following steps: firstly, selecting raw materials, and selecting an equipment compartment manufacturing raw material which is a 2024 aluminum alloy board; then, calculating to obtain the diameter and the thickness of a spun circular plate blank sheet according to the length, the outer diameter and the wall thickness of an equipment compartment as well as adding process allowance by virtue of the principle that the volume before and after forming of a spun part is unchanged; determining processing precision and a bilateral jerk value of a spinning mould, and selecting parameters of a spinning machine; under a room-temperature condition, carrying out room-temperature spin-forming workpiece trial production on the spun circular plate blank, thereby obtaining spin-formed workpiece blank; and when the surface of the spin-formed workpiece blank has pits with different depths, changing room-temperature forming into heating spin-forming, heating the spinning mould to overcome material deformation resistance, thereby obtaining a spin-formed workpiece. Circular plate blank is adopted for forming a long-barrel-shaped part with a relatively great length-diameter ratio, so that use of extrusion-formed seamless metal tube blank is reduced, and therefore, the manufacturing cost is reduced, the technological process is simplified, and the qualified rate of parts is high.

Owner:JIANGXI HONGDU AVIATION IND GRP

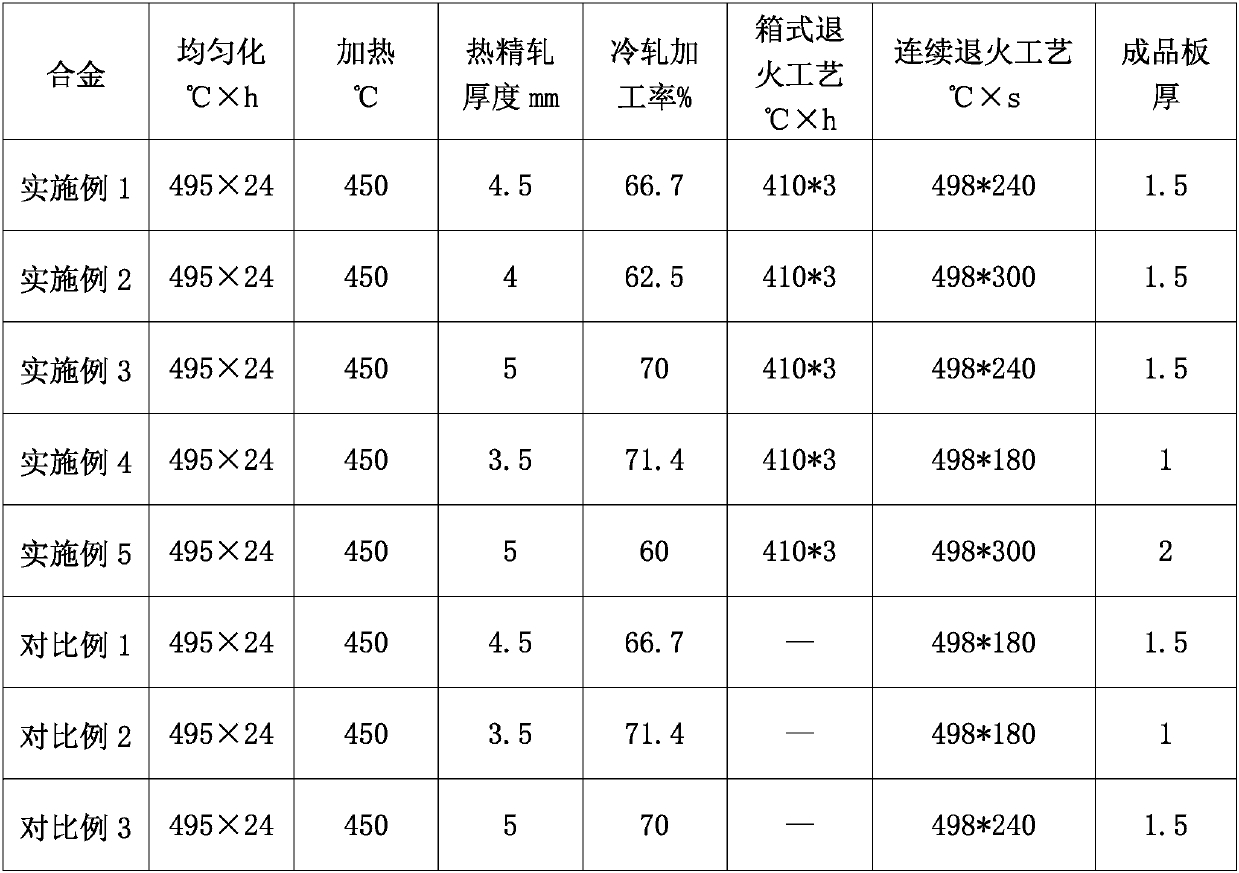

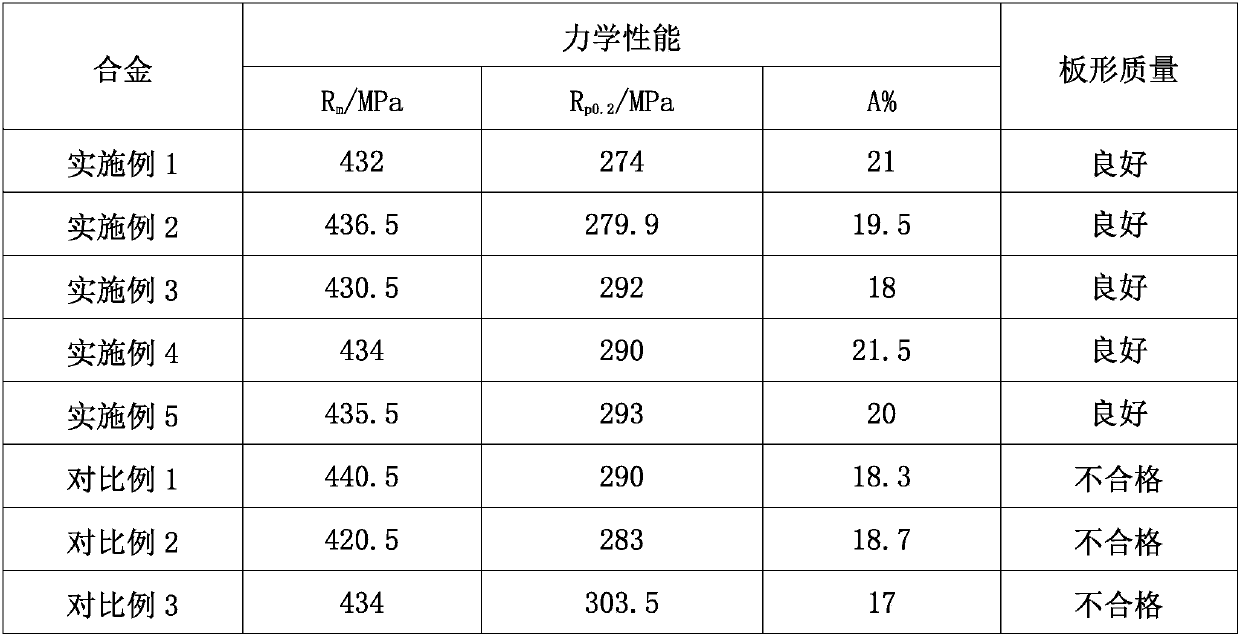

Processing method of T4-state 2024 aluminum alloy sheet

The invention belongs to the technical field of aluminum alloys, and relates to a processing method of a T4-state 2024 aluminum alloy sheet. The processing method comprises the following steps of casting, homogenizing, ingot casting heating, hot rolling, cold rolling, bending and straightening, box type annealing, continuous annealing and finishing. Compared with the prior art, the box type annealing is added before solid solution quenching, the internal stress generated in the cold rolling process is released, so that the non-uniformity of stress in the width and the length direction of coiled materials is reduced, thus effectively solving the problem of poor plate shape of the T4-state 2024 aluminum alloy sheet prepared by an existing process.

Owner:TIANJIN ZHONGWANG ALUMINUM IND CO LTD

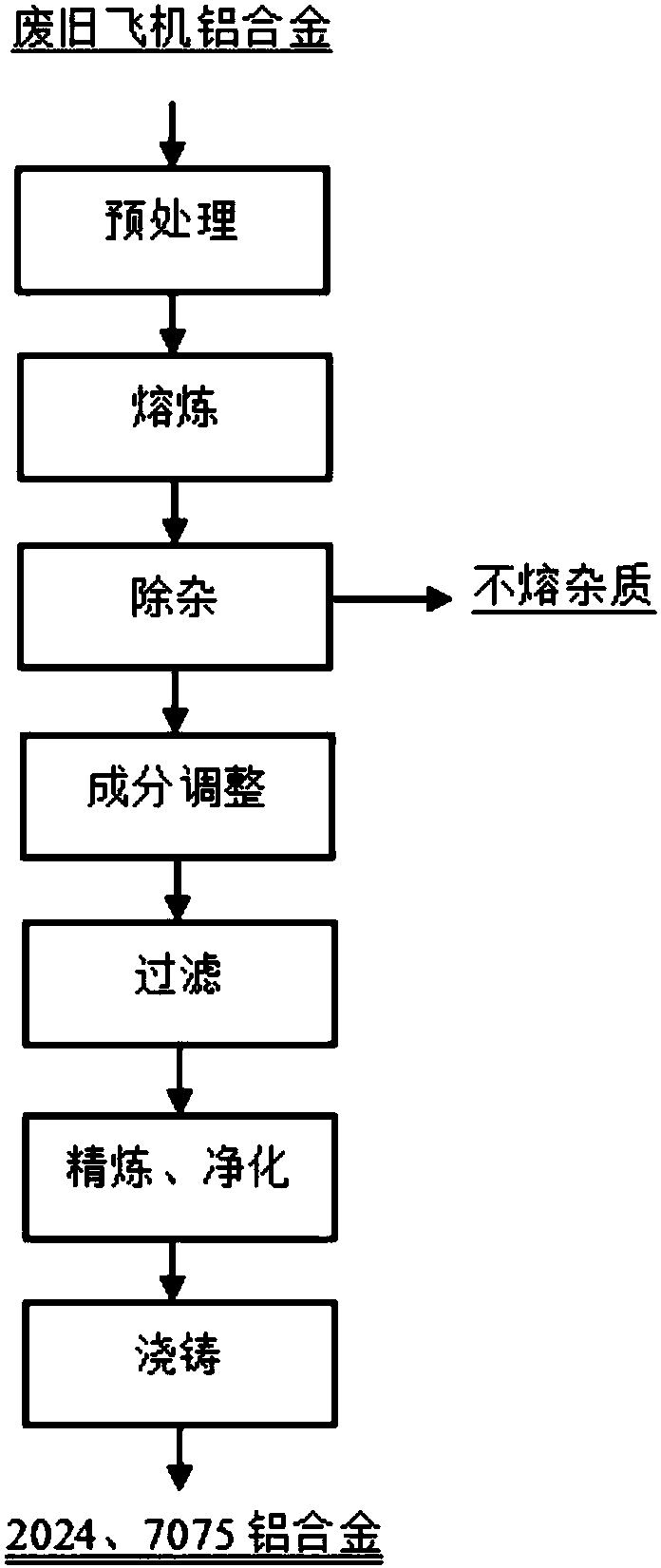

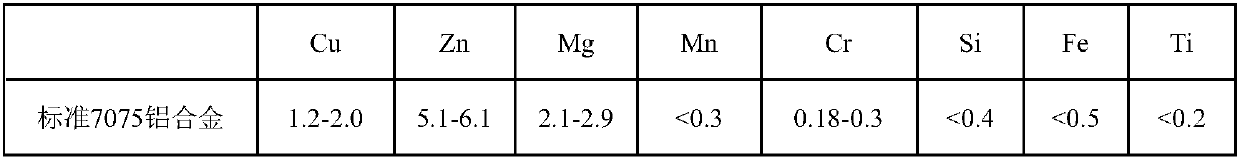

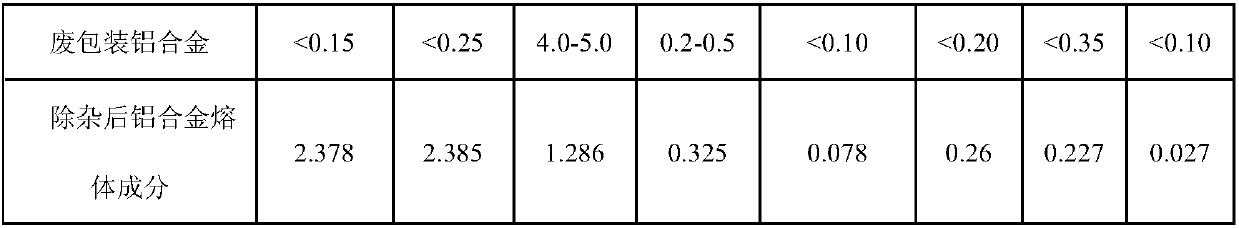

Method of aluminum alloys of scrap aircraft reused to produce 2024 or 7075 aluminum alloy

PendingCN109518045AReduce manufacturing costEase of industrial applicationFoundry mouldsCasting cleaning apparatus2024 aluminium alloyFiltration

The invention provides a method of an aluminum alloy of scrap aircraft reused to produce a 2024 or 7075 aluminum alloys, belongs to circular economy technologies, and particularly relates to a methodfor scrap aluminum alloys preservation and recycling. According to the method, the aluminum alloys of the scrap aircraft is adopted as a raw material, and the 7075 or 2024 aluminum alloys are obtainedafter pretreatment, smelting, impurity removal, composition adjustment, filtration, refining, purification, and casting; and in the composition adjustment step, low-cost preservation and recycling ofthe aluminum alloys of the scrap aircraft are realized by using other waste aluminum alloys and / or intermediate alloys for composition adjustment. According to the method of the aluminum alloys of the scrap aircraft reused to produce the 2024 or 7075 aluminum alloys, the production cost can be obviously lowered, and industrial application is facilitated.

Owner:UNIV OF SCI & TECH BEIJING +1

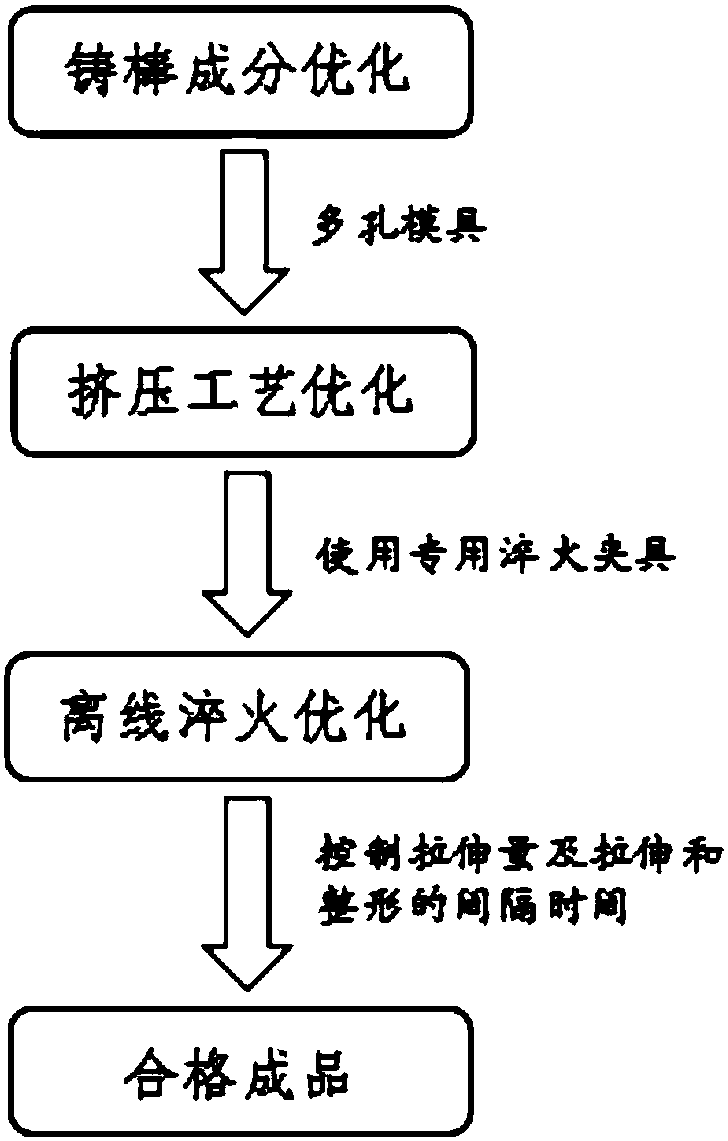

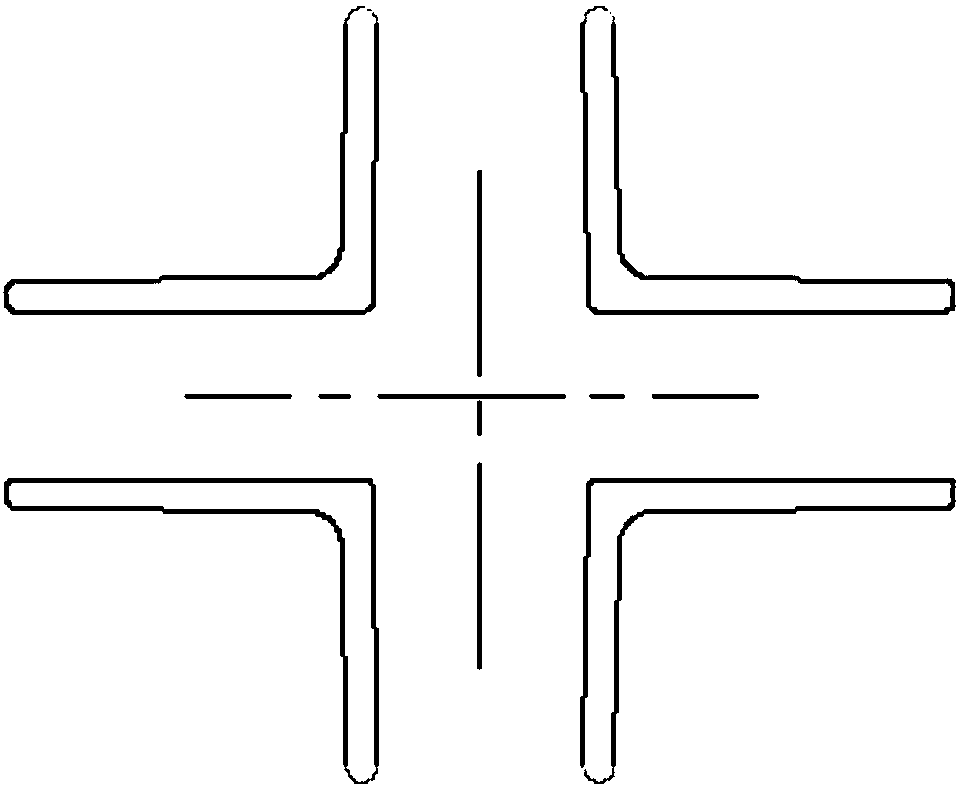

Production process of 2024 high-strength aluminum alloy special thin-walled section steel

The invention belongs to the technical field of aluminum alloys, and relates to a production process of a 2024 high-strength aluminum alloy special thin-walled section steel. flat mold form with fourextrusion holes and no flow guide pit in design aspect of a mold, an extrusion ratio of the whole section steel is reduced to 40, a 6.6MN non-standard extrusion machine is selected in the aspect of extrusion machining, the extrusion ratio is 40.2, the section steel is stretched within 1 hour after extrusion, and an off-line quenching degree is 455 DEG C * 30 minutes, the section steel is stretchedwithin 1 hour after the off-line is carried out, and the stretching amount is controlled at the upper limit of 2.5%-to 3%. The shaping and extrusion production interval time is controlled within 3 hours, a shaping rate is improved, a novel quenching clamp is designed for the section steel, so that the deformation of the section steel is reduced to the minimum while the section steel is fully quenched, the 2024 aluminum alloy section steel is subject to a serious of machining process of mold adjusting, production equipment structure is changed, extrusion, the off-line quenching, quenching clamp manufacturing, shaping and the like, all detection indexes meet the standard requirement of GJB2507A in detection aspects of mechanical property, low-magnification, high-magnification and dimensional tolerance.

Owner:CHINA ZHONGWANG

High-strength anodizing die-casting aluminium alloy and preparation method thereof

ActiveCN107447134ATo promote floatingImprove filtration efficiency5005 aluminium alloy6061 aluminium alloy

The invention belongs to the technical field of aluminium alloy and particularly relates to high-strength anodizing die-casting aluminium alloy and a preparation method thereof. Mg, Mn, Fe, Zn, Mo, Zr, Cr and Al constitute die-casting alloy elements, and the high-strength anodizing die-casting aluminium alloy is prepared by a smelting procedure and a die-casting procedure. The types, the contents and the adding modes of all the alloy elements are strictly controlled, so that lots of the elements mainly exist in a matrix in a solid solution format under the die-casting (fast cooling) condition; Zr and Mo ensure more uniform alloy tissue and refined crystal grains, so that the alloy has high strength and favorable die-casing performance and excellent anodizing performance; on a die-casting machine, die-casting molding can be performed by a die to directly obtain the required product without heat treatment or deformation, so that the production cost is greatly lowered; and the high-strength anodizing die-casting aluminium alloy is suitable for thin-walled shell members demanding much on the strength, the die-casting performance and the anodizing demand of the aluminium alloy.

Owner:苏州慧驰轻合金精密成型科技有限公司

Silane hydrolysate applied to surface of 2024 aluminum alloy and use method of silane hydrolysate

InactiveCN108103490AGood storage stabilityGood resistance to salt sprayMetallic material coating processes2024 aluminium alloySilanes

The invention relates to the field of surface environmental protection of aluminum alloy, in particular to a silane hydrolysate applied to the surface of 2024 aluminum alloy and a use method of the silane hydrolysate. The silane hydrolysate is prepared from the following components based on content: 5-30 g / L of silane, 5-40 g / L of a cosolvent, 0.1-10 g / L of a corrosion inhibitor, 0.1-4 g / L of an oxidant, 0.1-3 g / L of a pH regulator and the balance of deionized water. During use, firstly, the aluminum alloy is first polished, washed in alkali and pickled; then, the aluminum alloy is soaked in the silane hydrolysate for 1-10 min, taken out and solidified at 25-200 DEG C to form a silane film. The silane hydrolysate applied to the surface of the 2024 aluminum alloy does not contain hexavalentchromium or heavy metal ion compounds of lead, mercury and cadmium, does not contain volatile toxic solvents such as benzene and xylene and meets environmental requirements, the process is simple, industrialization is easy, and the silane film has excellent corrosion resistance.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

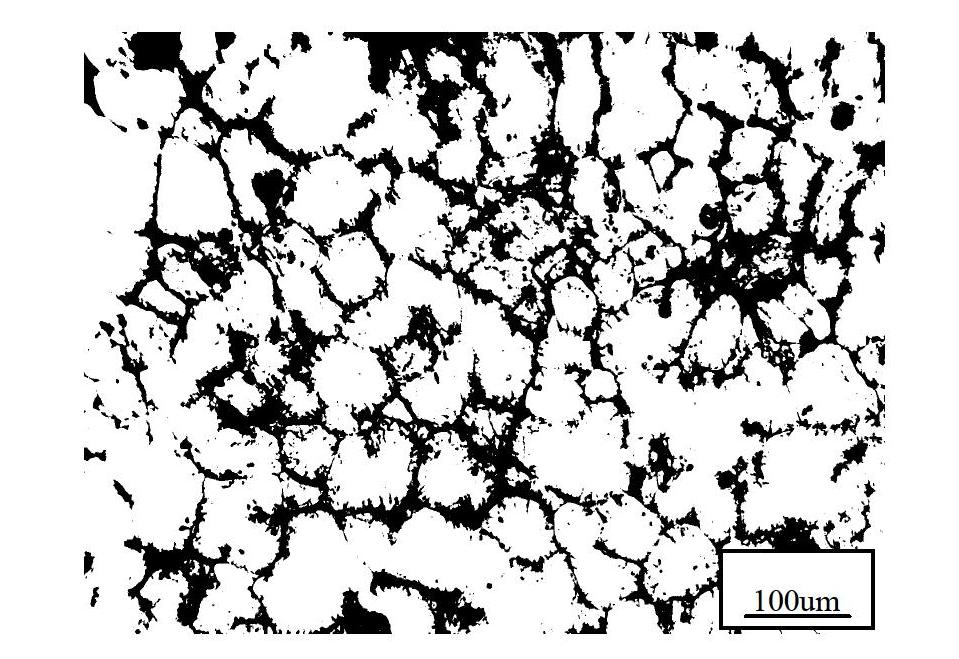

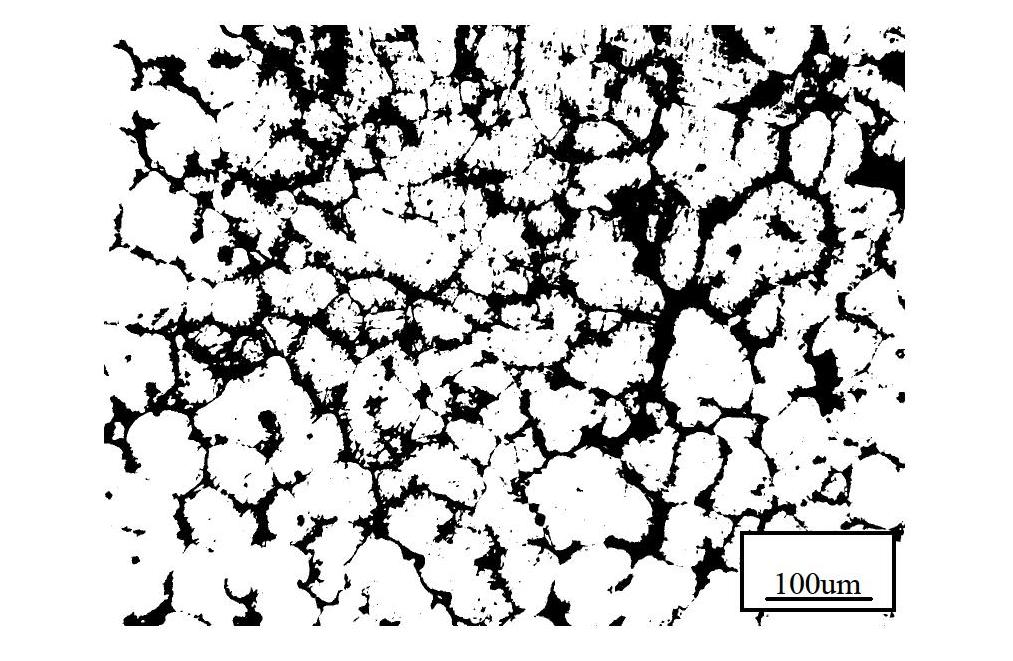

Aluminium alloy semi-solid preform body and preparation method thereof

InactiveCN102644011ADoes not cause rheologyRatio accuracy requirements are low2024 aluminium alloy5005 aluminium alloy

The invention discloses an aluminium alloy semi-solid preform body and a preparation method thereof, and is characterized in that: the preform body is deformed aluminium alloy and comprises components as following: Mg, Zn, Cu, Al and component A, the component A is selected from at least two ingredients of Cr, Si, Fe or Mn. By the adoption of the deformed aluminium alloy according to the aluminium alloy semi-solid preform body, the corrosion resistance is good, and the requirement on proportioning precision between components is lower, i.e. an obvious fluctuation on rheological, thixotropy and mechanical behavior of aluminium is not caused by a tiny fluctuation of the component. The alloy semi-solid preform body is prepared by the method of ultrasonic vibration according to the invention, the tensile strength is as high as 480MPa, the crystalline particles are small, with average diameters smaller than 40mum, the forming property is good, the requirement on process condition is lower, and the method is convenient to control and operate.

Owner:CSIC NO 12 RES INST

Processing method of 2024 aluminum alloy board

InactiveCN104372269AImprove mechanical propertiesGood mechanical properties2024 aluminium alloyAlloy

The invention provides a processing method of a 2024 aluminum alloy board. The processing method comprises the following steps: quenching the 2024 aluminum alloy board at 510-530 DEG C and preserving the heat for 20-40 hours; preserving heat of the quenched 2024 aluminum alloy board at -50 DEG C to -30 DEG C for 2-10 hours; applying 2%-4% tensile deformation in the thickness direction of the 2024 aluminum alloy board; and preserving the heat of the 2024 aluminum alloy board subjected to tensile deformation at 160-180 DEG C for 5-18 hours. Compared with the prior art, after the aluminum alloy board is quenched, low-temperature ageing treatment is firstly performed and then tensile deformation is applied to the aluminum alloy board, so that the mechanical performances of the aluminum alloy board are improved. Moreover, by combining low-temperature aging treatment, tensile deformation and high-temperature ageing treatment and controlling the temperatures of high-temperature aging treatment and low-temperature aging treatment, the 2024 aluminum alloy board is guaranteed to have good mechanical performances, and meanwhile, the corrosion resistance of the 2024 aluminum alloy board is improved.

Owner:陈帆

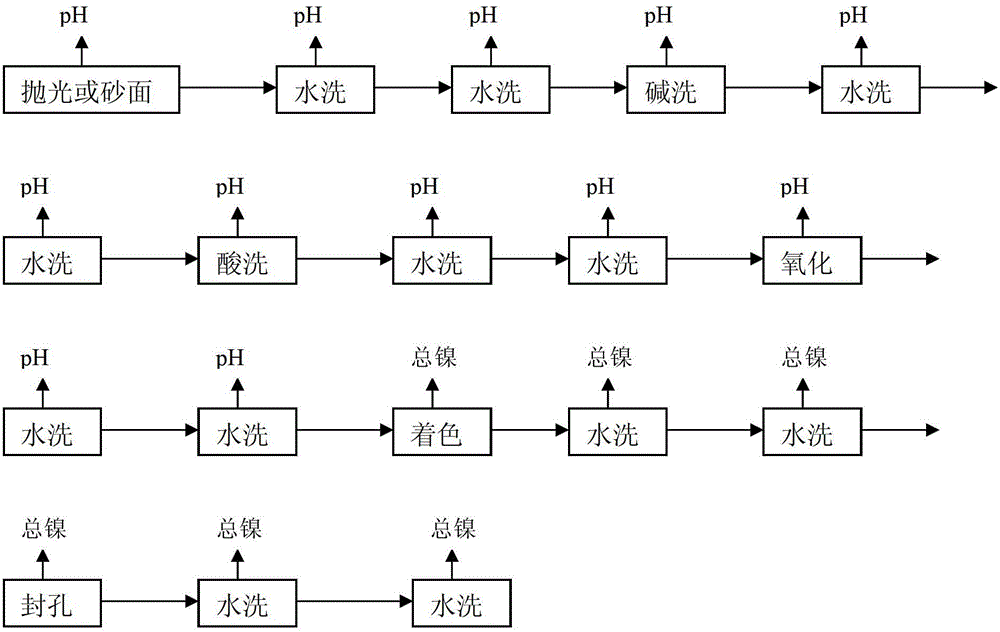

Method for performing low-voltage electrolytic black coloring on 2024 aluminum alloy by means of nickel-tungsten mixed salt

ActiveCN104060314ALow coloring voltageSave energySurface reaction electrolytic coatingLow voltageArea ratio

The invention relates to a method for performing low-voltage electrolytic black coloring on a 2024 aluminum alloy by means of nickel-tungsten mixed salt, which comprises the following steps: pretreating a whole aluminum alloy workpiece, taking the pretreated workpiece as an anode, taking a lead plate as a cathode, and performing electrolytic oxidation, wherein the cathode-anode area ratio is 3:1, and the electrolytic distance is 5 cm; in an electrolyte comprising 150 g / L of sulfuric acid, 2.5 g / L of boric acid and 2 g / L of aluminum sulfate, oxidizing for 30 minutes, and ensuring that an oxidation film layer is formed on the aluminum alloy workpiece; and then taking the aluminum alloy workpiece as the cathode, taking the lead plate as the anode, and performing electrolytic coloring, wherein the coloring time is 3-12 minutes, the voltage is 3-7 V, the cathode-anode area ratio is 1:3, the interelectrode distance is 5 cm, and an electrolyte comprises 10 g / L of nickel sulfate, 5 g / L of sodium tungstate, 3 g / L of tartaric acid, 2.5 g / L of ammonium sulfate and 2.5 g / L of boric acid. The method is simple in process, low in coloring voltage and energy-saving.

Owner:南通双耀冲压有限公司

Heat treatment technology of 2024 aluminum alloy thin plates

InactiveCN104593703AOvercoming tensile propertiesOvercome the situationFurnace typesHeat treatment furnacesProduction schedule2024 aluminium alloy

The invention discloses a heat treatment technology of 2024 aluminum alloy thin plates. Technological parameters of heat treatment are changed to obtain the following optimal technological parameters: solid solution is carried out at 498DEG C for 20min, and ageing is carried out at 185DEG C for 10h. The technology solves a problem that the production schedule of a company is influenced by no warehousing of raw materials or part discarding due to unqualified tensile property and unqualified intercrystalline corrosion of 6061 aluminum alloys prepared in the prior art. The optimized heat treatment technology obviously improves the mechanical properties, the corrosion resistance and the fatigue resistance of the 2024 aluminum alloy thin plates.

Owner:青岛齐力铸钢有限公司

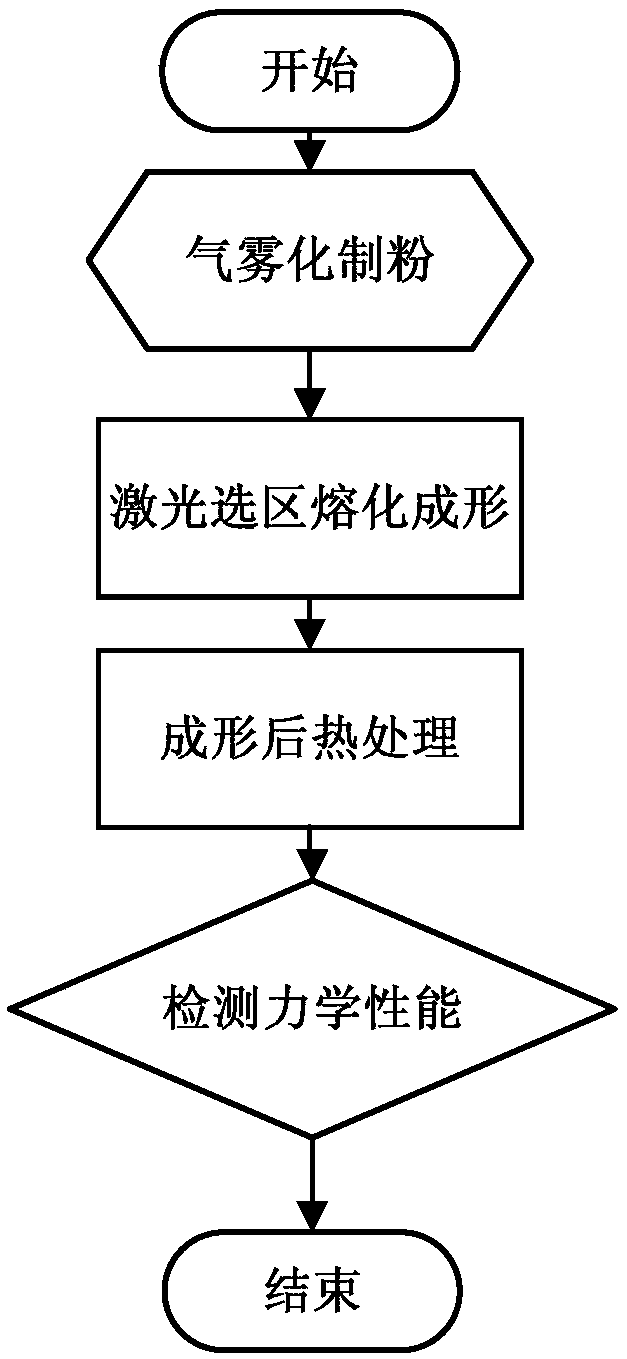

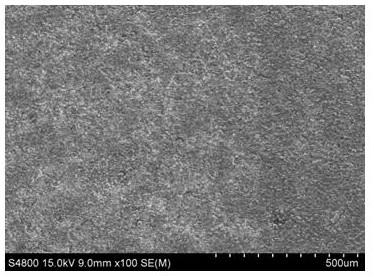

2024 aluminum alloy laser selective melting forming method

InactiveCN109332696AMeet material needsSolve the problem that it cannot be used in the forming of 2024 aluminum alloy turbo oxygen pumpAdditive manufacturing apparatusIncreasing energy efficiency2024 aluminium alloyRoom temperature

The invention discloses a 2024 aluminum alloy laser selective melting forming method. The method comprises the following steps that (1) gas atomization powder making is carried out by using a 2024 aluminum alloy bar to obtain metal powder; (2) the powder obtained by the step (1) is subjected to laser selective melting forming to obtain a 2024 aluminum alloy member meeting shape satisfying requirements; and (3) the 2024 aluminum alloy member meeting the shape requirements and obtained in the step (2) is subjected to solution aging treatment, and a 2024 aluminum alloy member with the shape and the mechanical property both meeting the requirement is obtained. By means of the above process, a 2024 aluminum alloy is characterized in that the room temperature tensile strength is not less than 500 MPa, the yield strength is not less than 320 MPa, the ductility is not less than 10%, and the requirements of aerospace products for the strength and plasticity of the 2024 aluminum alloy can be met.

Owner:XIAN SPACE ENGINE CO LTD

Method for improving adhesion performance of nature rubber vulcanized rubber through argon gas medium low temperature plasma treatment

InactiveCN108752609AHigh peel strengthAdhesive processes with surface pretreatment2024 aluminium alloyAdhesive

The invention discloses a method for improving the adhesion performance of vulcanized rubber through argon gas medium low temperature plasma treatment. The method comprises: (1) carrying out low-temperature plasma treatment on 1142 vulcanized rubber for 200-240 s at a treatment power of 120-160 W under a vacuum degree of (40+ / -5) Pa by using argon gas as a treatment atmosphere; and (2) adhering alayer of a 2024 aluminum alloy plate film to the surface of the 1142 vulcanized rubber by using a JQ-1 polyisocyanate adhesive within 4 h after the treatment of the 1142 vulcanized rubber, vulcanizingfor more than 90 min in a room temperature environment after the adhering, and testing peel strength according to standard. According to the present invention, with the method, the peel strength between the 1142 vulcanized rubber and the 2024 aluminum alloy plate is increased to at least 300 N / m from 25 N / m.

Owner:NANCHANG HANGKONG UNIVERSITY

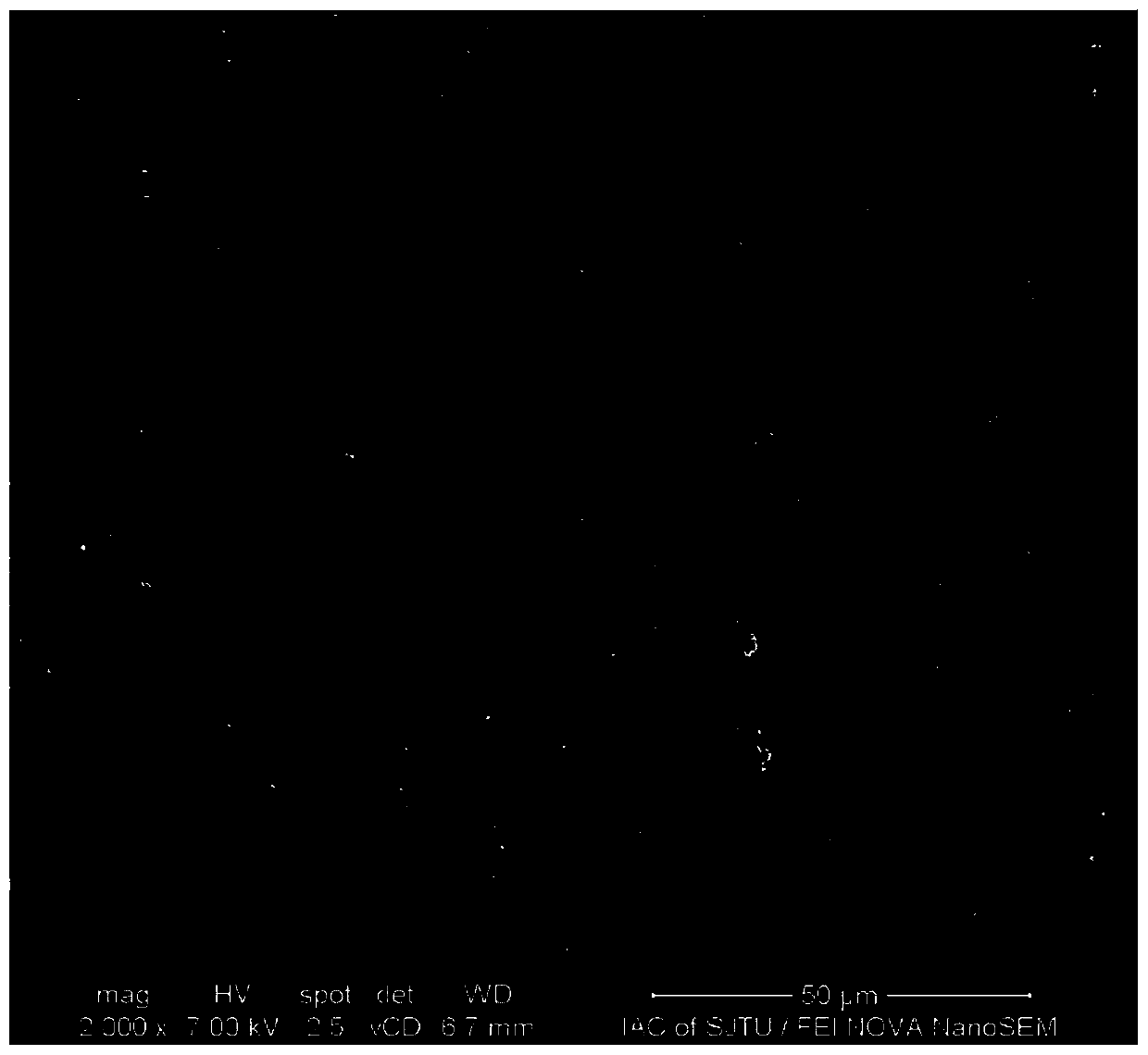

Preparation method for low-voltage micro-arc oxidation ceramic film on aluminum alloy surface

InactiveCN109183112AReduce consumptionShort processing timeAnodisationPlasma electrolytic oxidationMicro arc oxidation

The invention provides a preparation method for a low-voltage micro-arc oxidation ceramic film on the aluminum alloy surface and relates to an aluminum alloy surface treatment method. The preparationmethod comprises the steps that adopted electrolyte belongs to a silicate system, and Na2SiO3, H3BO3 and NaOH are added to prepare a solution; glycerinum, sodium diethyl dithiocarbamate, sodium citrate and sodium dodecyl sulfate are selected as surface active agents correspondingly; and an adjustable alternating current power source is adopted to prepare the micro-arc oxidation ceramic film for a2024 aluminum alloy plate material. According to the preparation method for the low-voltage micro-arc oxidation ceramic film on the aluminum alloy surface, a micro-arc oxidation process of low voltageand the weak alkaline electrolyte is adopted, and green production and zero discharge of waste water, waste gas and waste residue are realized; the electrolyte can be recycled through reasonable andscientific proportion again after being used for many times; and the preparation method for the low-voltage micro-arc oxidation ceramic film on the aluminum alloy surface has the characteristics of being low in voltage, energy consumption and treatment cost, high in efficiency and environment protection and capable of performing cyclic utilization, and no damage is generated to the surfaces of base materials.

Owner:SHENYANG UNIV

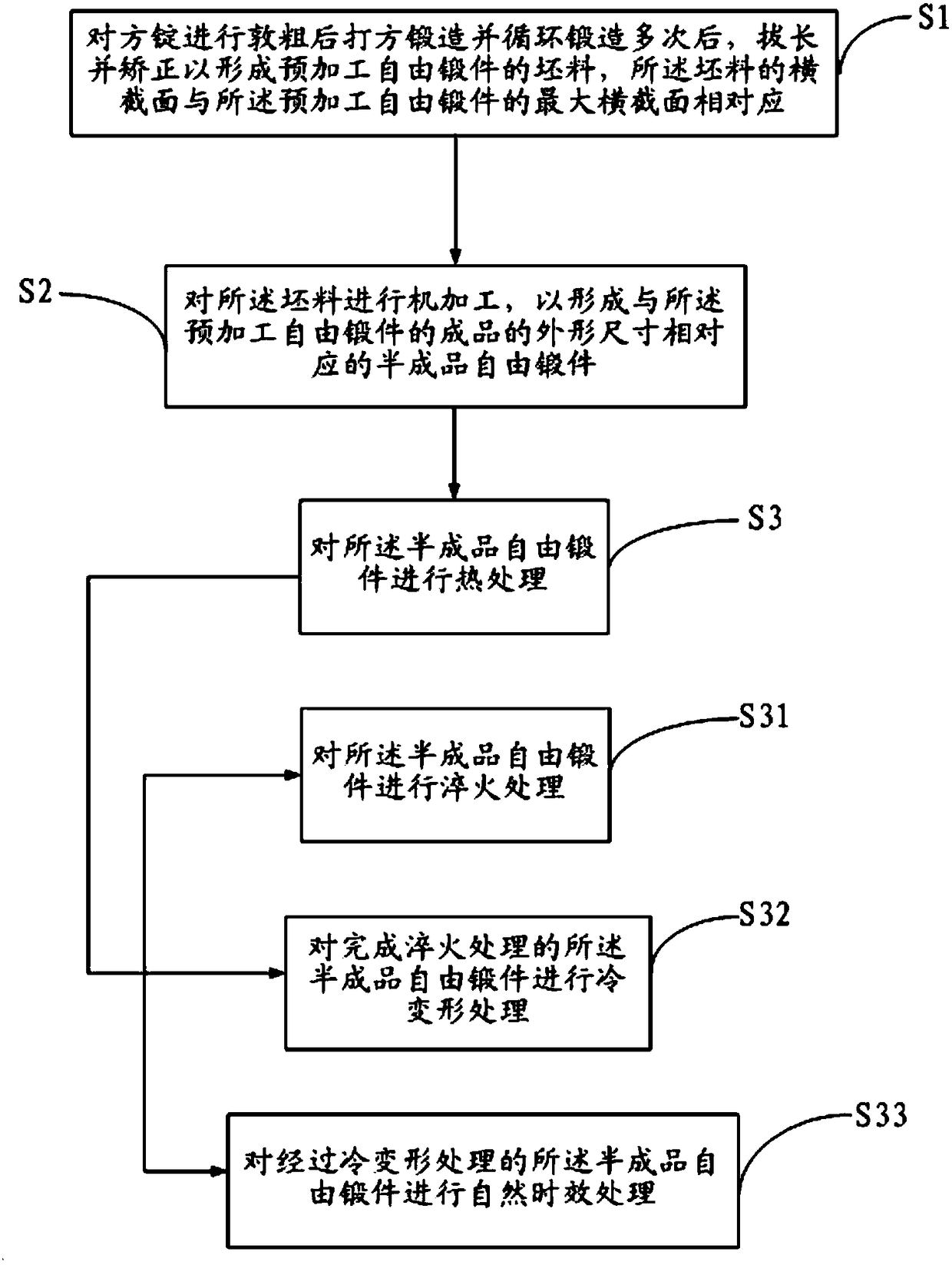

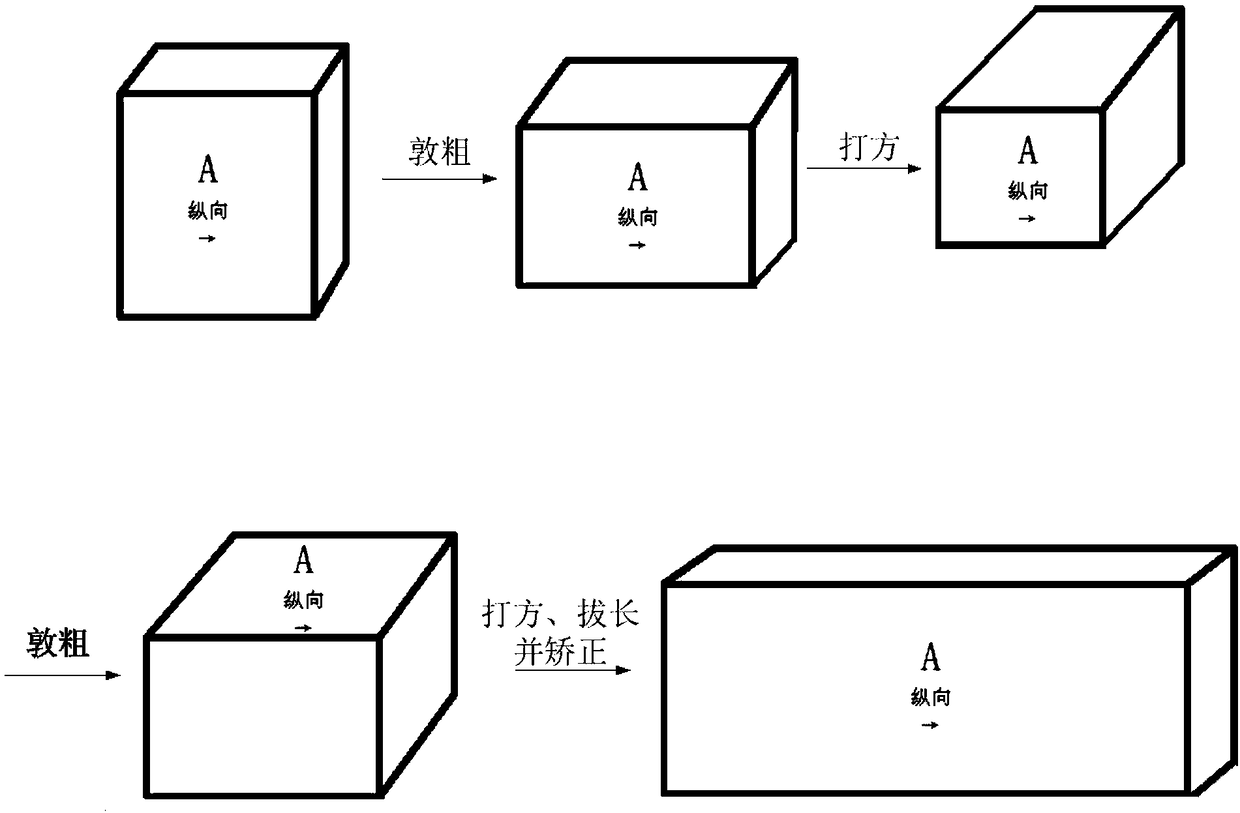

Machining method of 2024 aluminum alloy free forged piece

The invention discloses a machining method of a 2024 aluminum alloy free forged piece. The method comprises the steps that a square ingot is subjected to heading, then squaring forging and repeated cyclic forging, then the ingot is drawn and straightened to form a blank of a pre-processed free forged piece, and the cross section of the blank corresponds to the largest cross section of the pre-processed free forged piece; the blank is machined to form a semi-finished free forged piece corresponding to a finished pre-processed free forged piece product in outline size; and the semi-finished freeforged piece is heated. By means of the machining method, the 2024 aluminum alloy free forged piece can be obtained, all properties can reach or even exceed the properties of a traditional 2024 aluminum alloy band plate structure, and thus the application field of 2024 aluminum alloys is broadened.

Owner:SOUTHWEST ALUMINUM GRP

Preparing method of Al-Cu-Mg series aluminum alloy surface composite ceramic membrane layer based on potassium tetraborate

InactiveCN108486626AImprove flexural strengthImprove fracture toughnessAnodisationChemical reactionMicro arc oxidation

The invention provides a preparing method of an Al-Cu-Mg series aluminum alloy surface composite ceramic membrane layer based on potassium tetraborate. The Al-Cu-Mg series 2024 aluminum alloy workpiece serves as an anode, a stainless steel plate of an electrolytic bath serves as a cathode, the workpiece anode is immersed in work liquid, bipolar pulse electricity is applied to the position betweenthe cathode and the anode, micro-arc oxidation treatment is carried out, potassium tetraborate in the work liquid and aluminum in a 2024 aluminum alloy matrix are subject to a plasma chemical reaction, and the Al2O3-AlB12 composite ceramic membrane layer on the surface of the Al-Cu-Mg series aluminum alloy can be obtained. The problems that an existing Al2O3-AlB12 composite ceramic membrane layeris complex in preparing process, long in time and high in energy consumption are solved, and the anti-bending strength and the fracture toughness of the Al-Cu-Mg series aluminum alloy surface micro-arc oxidation ceramic membrane layer can be improved.

Owner:DALIAN UNIV

Aluminium alloy for motorcycle

The invention discloses an aluminium alloy for a motorcycle. The aluminium alloy is composed of the following components in parts by weight: 70-80 parts of aluminium, 0.5-0.8 part of manganese, 5-8 parts of sodium, 0.3-0.6 part of cobalt, 0.2-0.5 part of magnesium and 0.12-0.35 part of tungsten. The aluminium alloy disclosed by the invention has the following beneficial effects: the proportioning is scientific and reasonable; aluminium is taken as a main metal element; the strength of the aluminium alloy is enhanced and the wear-resistant effect and corrosion resistance are improved due to the added magnesium, tungsten and sodium; the aluminium alloy is applicable to the motorcycle; and the stability of the metal material is improved.

Owner:太仓东旭精密机械有限公司

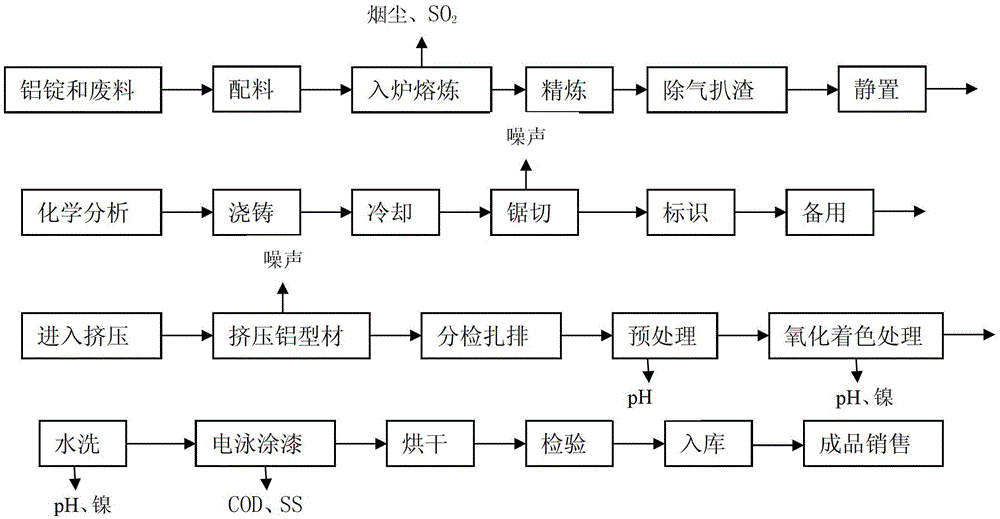

Production method of oxidation-colored electrophoresis-painted aluminum alloy section bars

ActiveCN102925770BImprove performanceHigh strengthSurface reaction electrolytic coatingPlasma treatmentRaw material

The invention disclosed a production method of oxidation-colored electrophoresis-painted 2024 aluminum alloy section bars. The production method comprises the steps of aluminum ingot and other raw material preparation, aluminum alloy round ingot smelting and casting; casting and sawing; annealing treatment; extrusion molding, oxidation coloring treatment, electrophoresis painting treatment, baking, and the like. According to the invention, anodic oxidation treatment and electrophoresis painting methods are adopted, such that an anti-corrosion performance is improved. According to the invention, waste aluminum material is added into the raw materials, such that aluminum section bar property stability can be promoted, and the possibility of influences on aluminum section bar qualities caused by undetected materials appeared at molten aluminum smelting is reduced. Silicon carbide and modified fly ash are added, such that aluminum alloy strength and hardness are improved, and aluminum alloy comprehensive performance can be improved. The surface of the aluminum section bar is subjected to a plasma treatment, such that painting firmness is improved.

Owner:安徽家园铝业有限公司

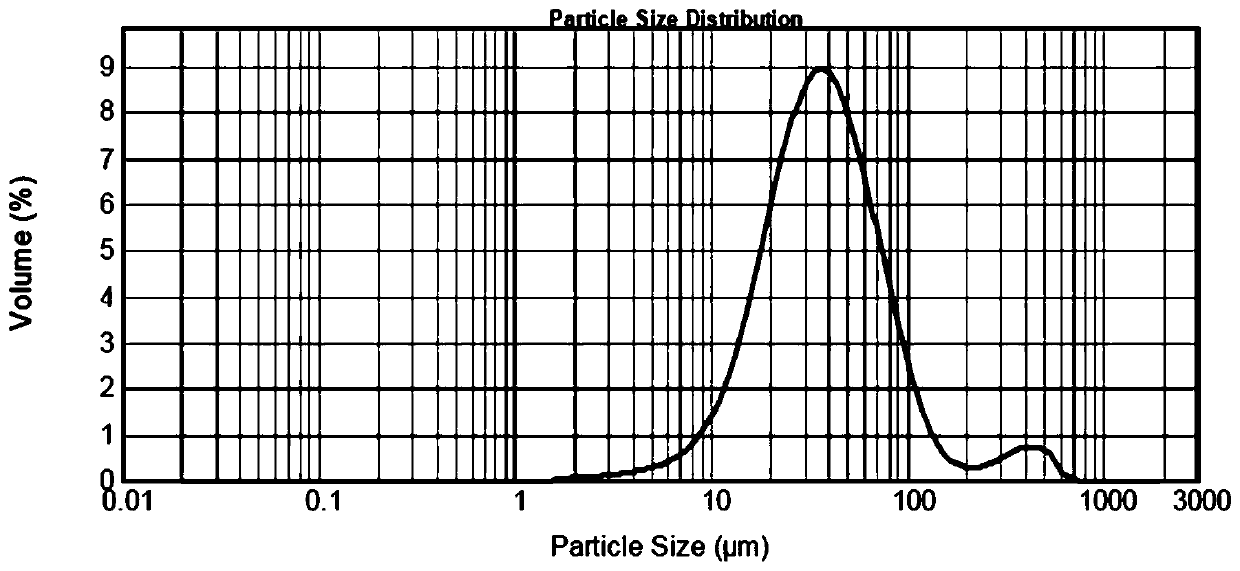

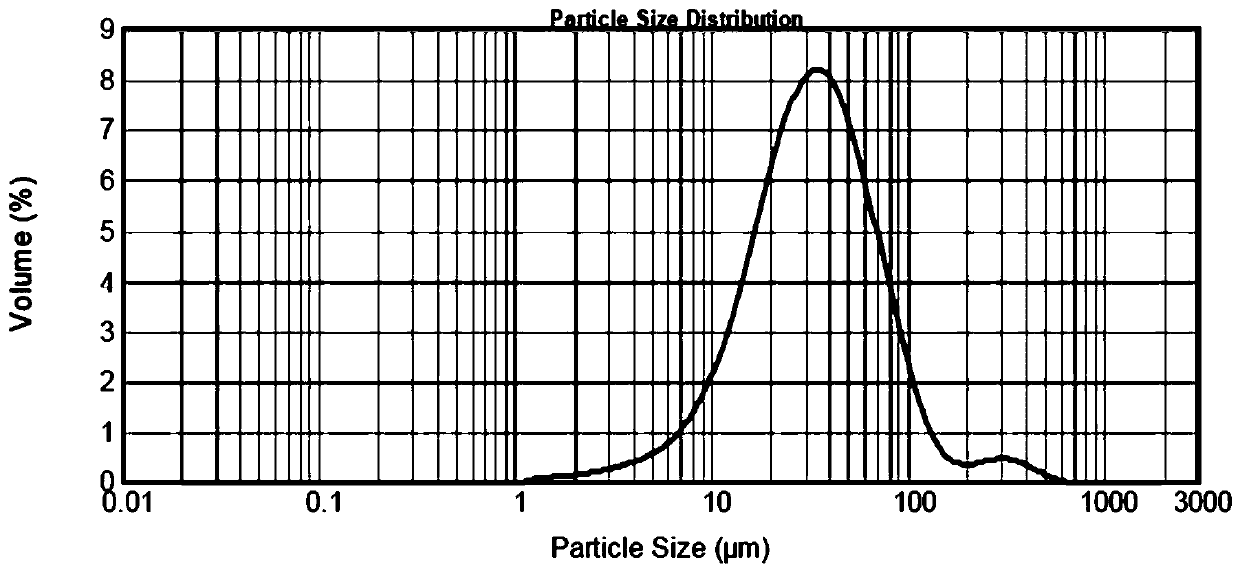

Nano ceramic-aluminum composite powder and preparation method and device thereof

The invention provides nano ceramic-aluminum composite powder and a preparation method and device thereof. The nano ceramic-aluminum composite powder is prepared from following components by volume including 1-10 parts of aluminum alloy powder and 90-99 parts of ceramic nano particles, wherein the aluminum alloy powder is pure aluminum or 6061 aluminum alloy or 2024 aluminum alloy or 7075 aluminum alloy, the ceramic nano particles are silicon carbide or aluminum oxide or boron nitride or titanium diboride with the grain diameter of 1-50 nm, and the product is obtained after drying, ball-milling and passivating are completed. The product is high in added value, the raw materials are cheap, the preparation method is efficient, the equipment is simple, the grain diameter and the structure of the final product can be adjusted and controlled by adjusting and controlling the ball-milling time and the proportions of the raw materials, and industrial large-scale production is facilitated.

Owner:WUHAN NANRUI ELECTRIC POWER ENG TECH EQUIP +4

Low pressure aluminium alloy and preparation method thereof

The invention belongs to the technical field of aluminium alloy machining and discloses a low pressure aluminium alloy and a preparation method thereof. The low pressure aluminium alloy comprises thefollowing components in parts by weight: 70-80 parts of aluminium, 0.1-0.2 part of titanium, 0.1-0.3 part of praseodymium, 5-10 parts of zinc, 4-8 parts of copper, 2-3 parts of silicon, 4-9 parts of magnesium, 1-2 parts of manganese, 2-4 parts of zirconium and 4-5 parts of iron. The low pressure aluminium alloy is obtained by casting the components by using a low pressure casting method. The low pressure aluminium alloy has the advantages that the corrosion resistance of the low pressure aluminium alloy is high, the corrosion situation in the modern environment can be satisfied, the making method is convenient to implement, has lower cost and is easy to popularize; by adding the manganese to the aluminium alloy, a dispersed phase and a matrix can form a coherent interface so that performance such as hardenability, toughness and corrosion resistance of the alloy can be improved; by adding the zirconium to the aluminium alloy, the recrystallization during alloy hot rolling and solid solution is more effectively hindered to be beneficial for improving the toughness.

Owner:广东华劲金属型材有限公司

Aluminium alloy

The invention provides an aluminium alloy. The aluminium alloy is composed of, by weight, 0.1 to 0.5 part of manganese, 0.1 to 0.5 part of nickel, 2 to 2.5 parts of silicon, 1.5 to 2 parts of iron, 0.5 to 2 parts of copper, 0.1 to 0.2 part of zinc, 1 to 2.5 parts of chromium, the balance aluminium, and a small amount of inevitable impurities. Casting performance of the aluminium alloy is excellent; electrical conductivity, thermal conductivity, strength, and toughness are improved; corrosion resistance, welding performance, and machinability are excellent; and the aluminium alloy is suitable to be used for preparing housing parts.

Owner:余姚市朗霞镇大众铸件精工厂

Stabilizing processing method of 5052 aluminium alloy

ActiveCN101935786BUniform and stable mechanical propertiesSmall individual differencesMetal rolling arrangements2024 aluminium alloy5005 aluminium alloy

The invention provides a stabilizing processing method of a 5052 aluminium alloy, belonging to the technical field of alloy materials and solving the problem of unstable mechanical property of the 5052 aluminium alloy. The stabilizing processing method of the 5052 aluminium alloy comprises the following steps of: A. rolling: selecting an aluminium alloy coiled material or an aluminium alloy sheetmaterial to be processed to achieve the thickness of 1.0-3.0mm through hot rolling or / and cold rolling; B. intermediate annealing: carrying out the intermediate annealing on the rolled aluminium alloy coiled material or aluminium alloy sheet material under the condition of the temperature of 520-580 DEG C, and keeping the temperature for 10-15 hours; and C. cold rolling: carrying out the cold rolling with the cold deformation processing rate of 20-50 percent on the aluminium alloy coiled material or the aluminium alloy sheet material subjected to the intermediate annealing to manufacture a 5052 aluminium alloy material which has stable property. The stabilizing processing method of the 5052 aluminium alloy has the advantages of low energy consumption, high production efficiency, uniform and stable mechanical property of manufactured finished products and small individual difference.

Owner:ZHEJIANG GKO ALUMINUM

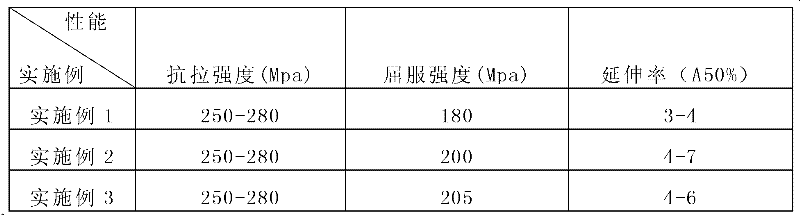

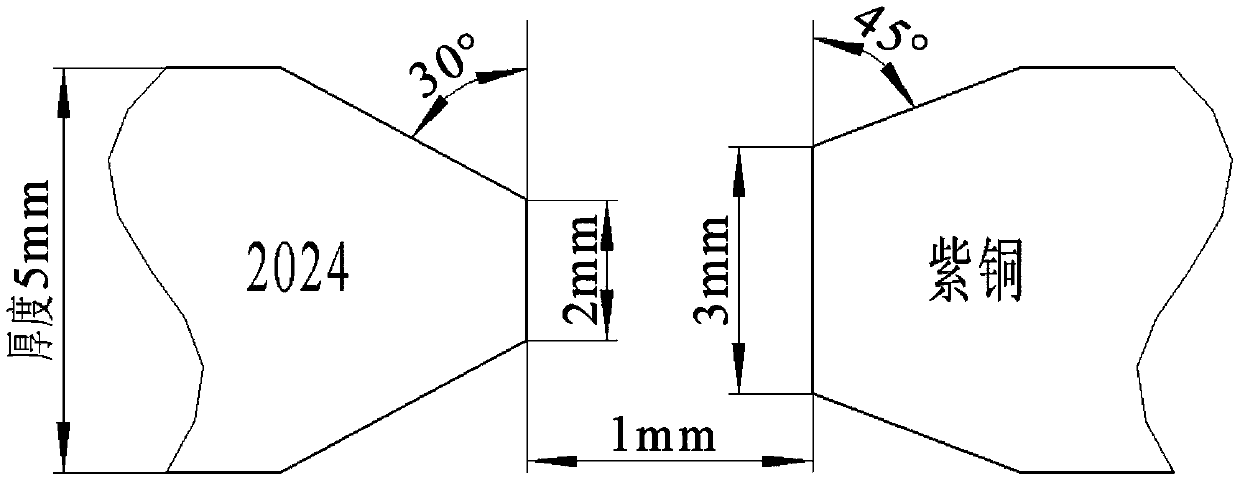

Welding method for aluminum and copper heterogeneous metal materials

ActiveCN108672868AImprove mechanical propertiesIncrease temperatureSoldering apparatusPower flow2024 aluminium alloy

The invention relates to a welding method for aluminum and copper heterogeneous metal materials. The welding method for aluminum and copper heterogeneous metal materials mainly for problems that deformation of the 2024 aluminum alloy and the copper heterogeneous metal material in the T0 state of 5-8mm thick due to the difference in thermal conductivity and the unevenness of the joint structure. The main step comprises: (1) performing groove machining and welding assembling on the 2024 aluminum alloy and the copper base material respectively; (2) pre-welding the copper base metal, wherein the parameters are voltage 15-50V, current 60-150A, speed 1-10m / min; (3) brazing the 2024 aluminum alloy and the copper heterogeneous metal base material, wherein the brazing flux composition is AlCu2, thewelding parameters are voltage 20-60V, current 60-200A, speed 1-10m / min. According to the welding method for aluminum and copper heterogeneous metal materials, by selecting and controlling the groovesize, pre-welding and brazing parameters of different materials, the welding of two kinds of heterogeneous metals of the 2024 aluminum alloy and the copper can be realized, and the welding joint withexcellent welding performance is obtained.

Owner:JIANGSU UNIV OF TECH

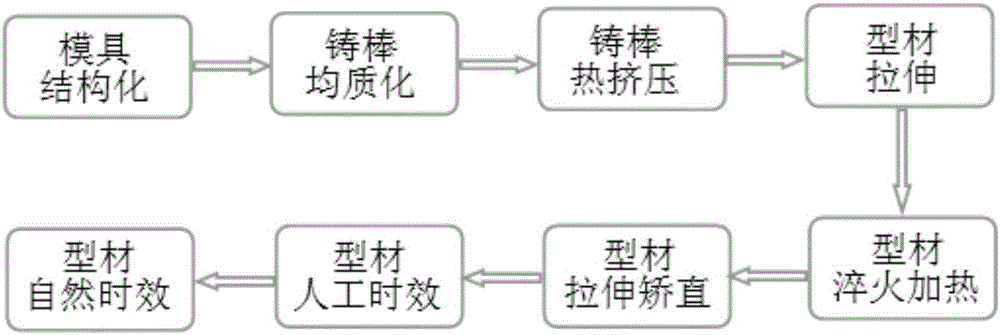

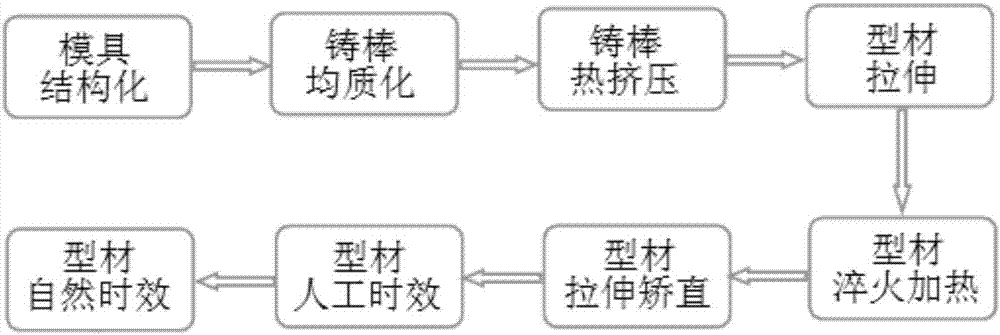

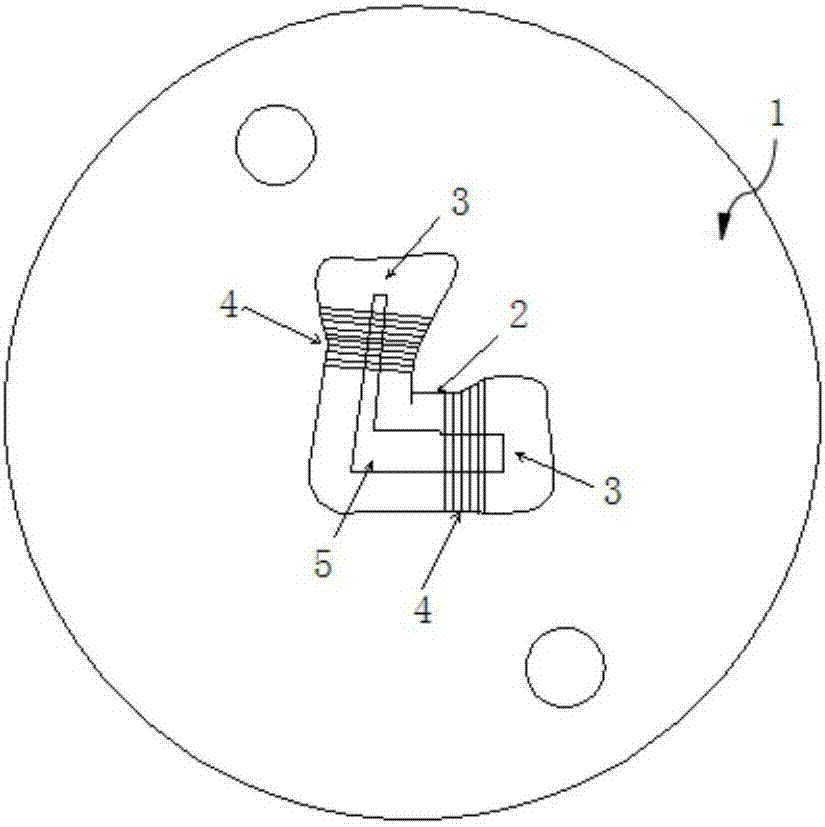

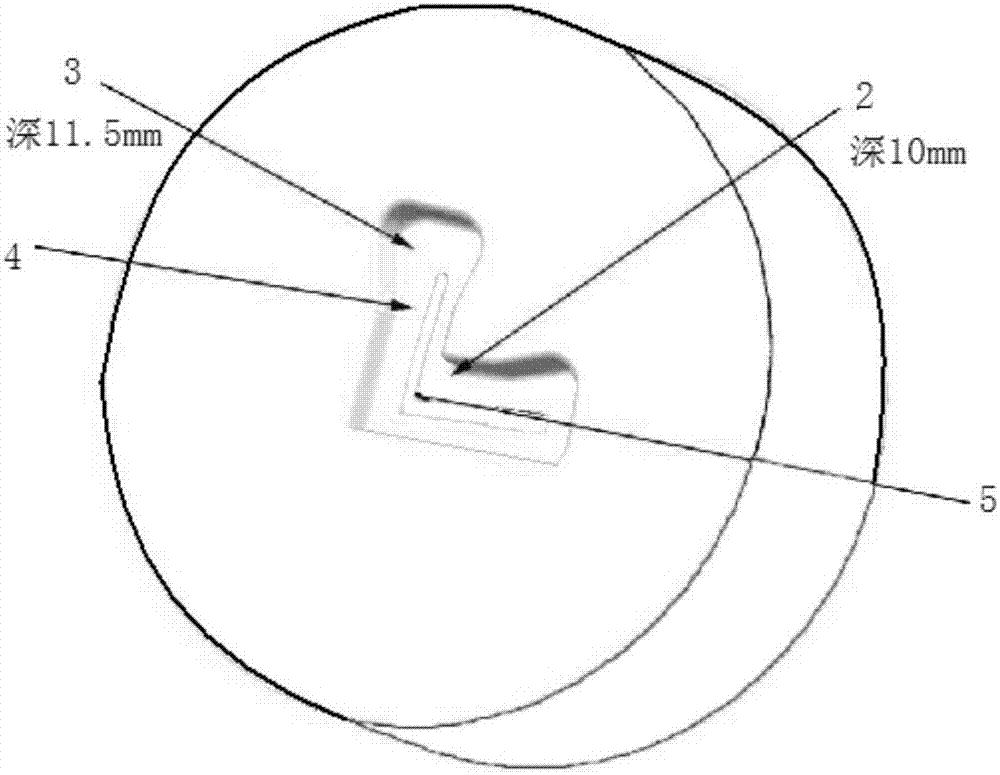

A production process of high-strength 2024 aluminum alloy thin-walled corner profiles

ActiveCN106513456BSmall sizeHigh dimensional accuracyExtrusion dies2024 aluminium alloyNatural aging

The invention discloses a production process of high-strength 2024 aluminum alloy thin-walled corner profiles, which belongs to the technical field of aluminum alloys and comprises the following steps: firstly, performing structural treatment on the mold; then, performing homogenization treatment on the cast rod; then, performing The rod is subjected to hot extrusion treatment; then, the profile is subjected to stretching treatment; then, the profile is subjected to quenching and heating treatment; then, the profile is subjected to stretching and straightening treatment; finally, the profile is subjected to natural aging treatment. The present invention mainly studies the extrusion process technology of high-strength 2024 aluminum alloy thin-walled corner profiles. Through the combination of mold optimization design, extrusion, stretching and heat treatment process development, etc., the finished product rate and production efficiency of the profile products can be improved, which can be achieved. Substitute foreign imported products.

Owner:CHINA ZHONGWANG

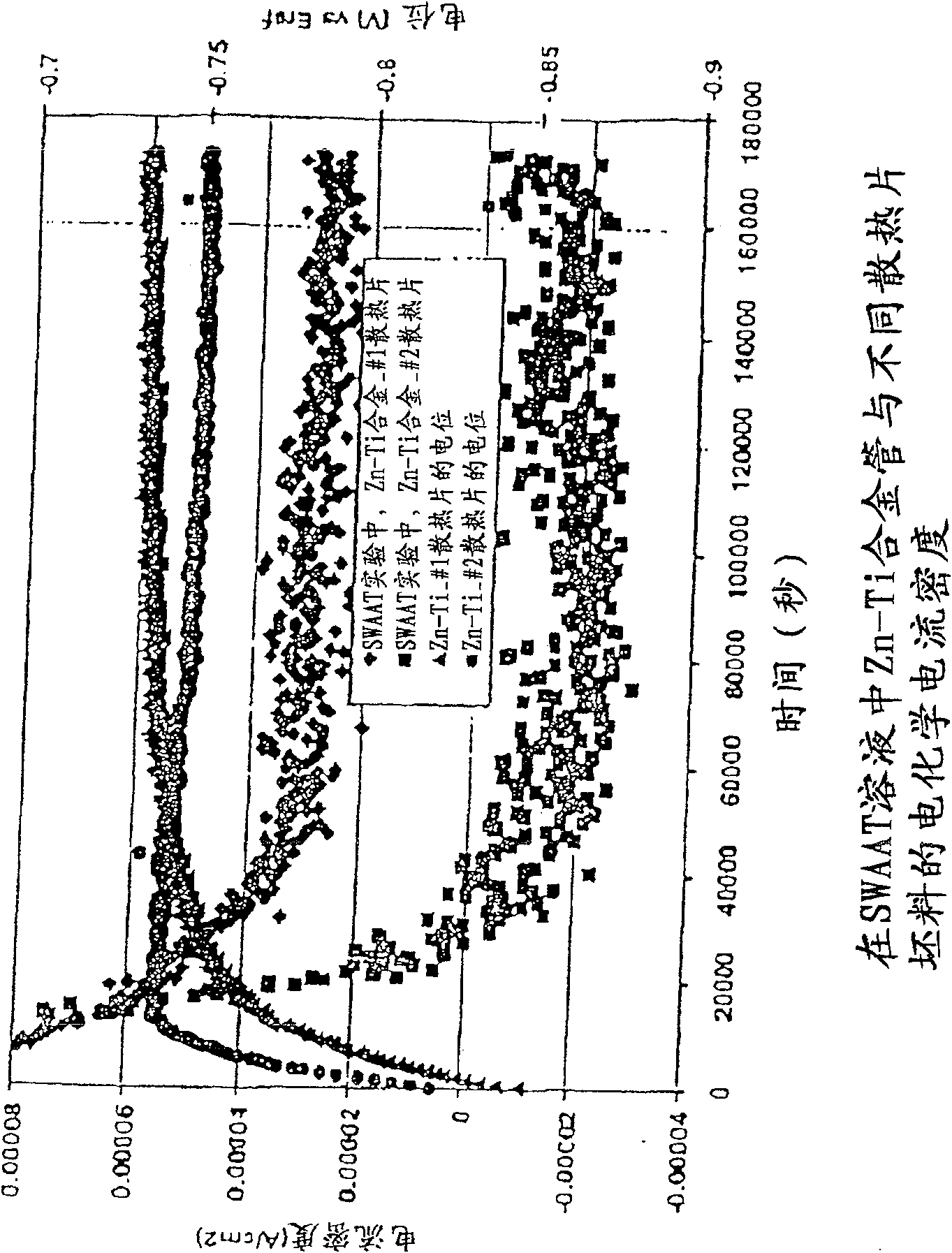

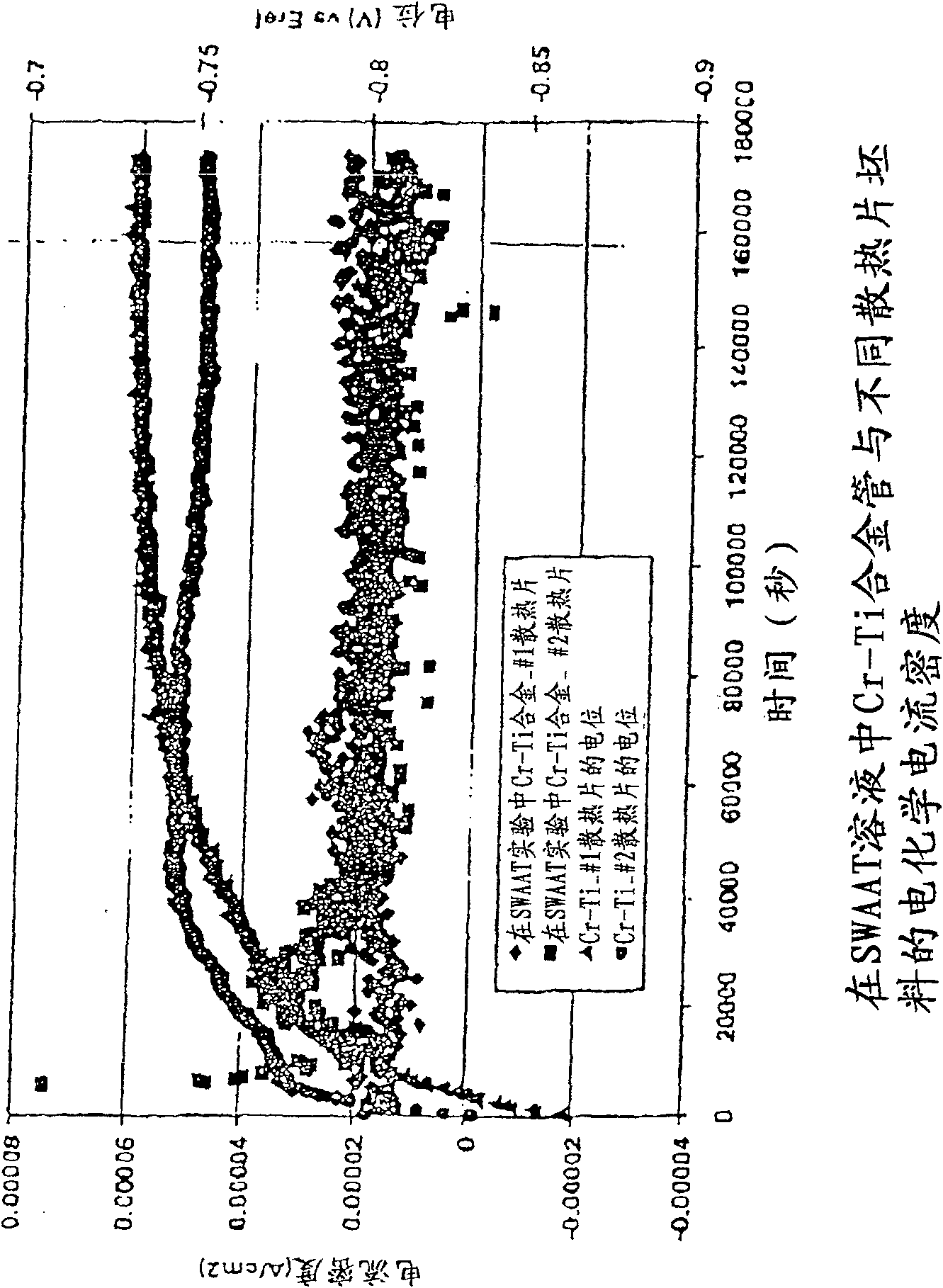

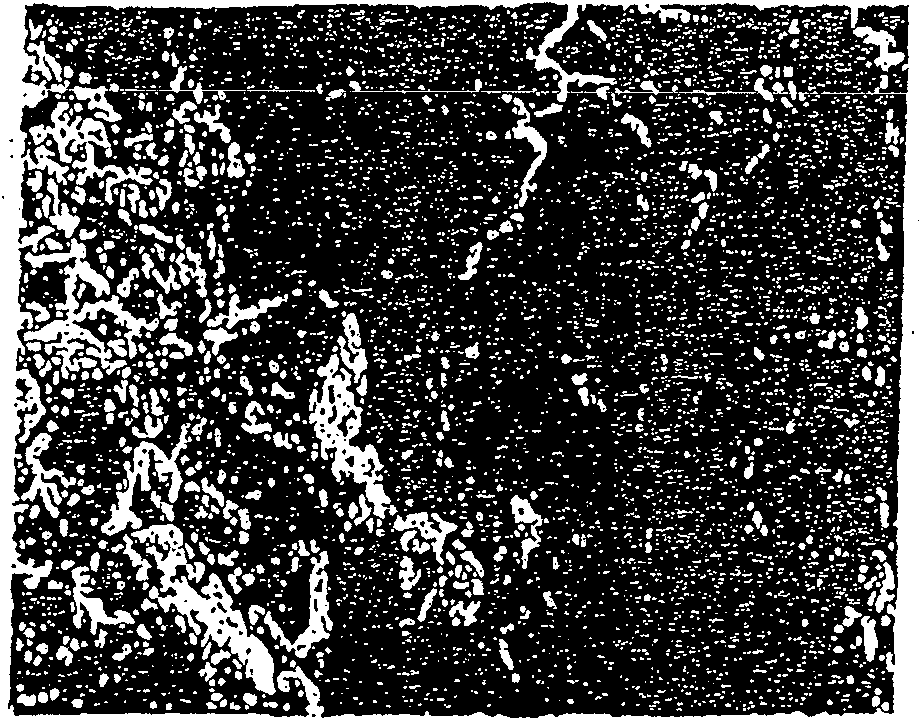

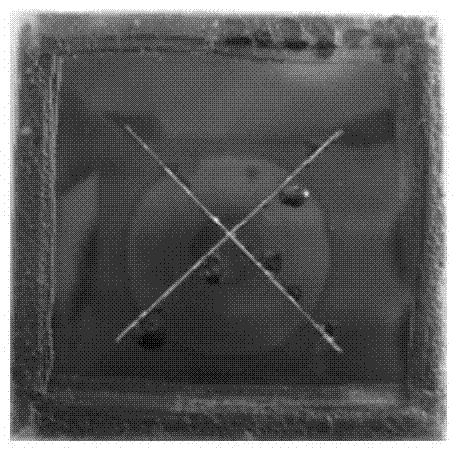

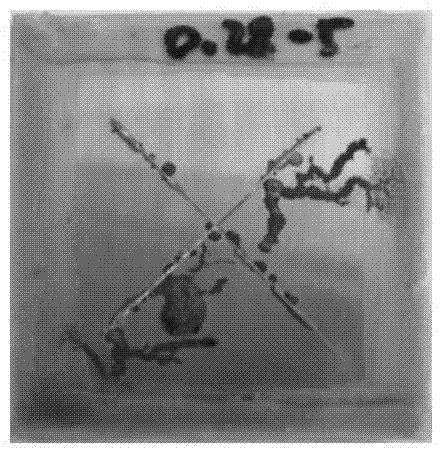

Aluminium alloy with intergranular corrosion resistance, metods of manufacture and its use

InactiveCN100549200CImprove corrosion resistanceReduce sensitivityHeat exchange apparatus5005 aluminium alloyGrain boundary

A corrosion-resistant aluminum alloy with controlled amounts of iron, manganese, chromium, and titanium, and containing copper, silicon, nickel, and zinc at no more than impurity levels. The chemical composition of the alloy is adjusted to match the electrolytic potential at the grain boundaries with the alloy matrix, thereby reducing intergranular corrosion. The alloy is particularly suitable for the production of tubes in heat exchangers using extrusion and brazing techniques.

Owner:ALUMINUM CO OF AMERICA

Molybdate-doped polypyrrole/epoxy resin self-healing coating and its preparation and application

InactiveCN105001759BExcellent self-healing performanceAvoid corrosionEpoxy resin coatingsEpoxyPolypyrrole

The invention relates to a molybdate doped polypyrrole / epoxy resin self-healing coating, a preparation method thereof and an application thereof, and belongs to the field of metal anti-corrosion coatings. The coating is composed of two parts, namely a polypyrrole / epoxy resin system mother liquor, and a polyamide curing agent. The polypyrrole / epoxy resin system mother liquor comprises molybdate doped polypyrrole, epoxy resin, an anti-settling agent, an anti-foaming agent, a levelling agent and an organic solvent. The molybdate doped polypyrrole is added in the organic solvent and then the mixture is uniformly dispersed in an ultrasonic dispersion instrument. After that, the anti-settling agent, the antifoaming agent and the levelling agent are added respectively, and are stirred on a magnetic stirring apparatus. Then the epoxy resin is added to form the uniformly dispersed polypyrrole / epoxy resin system mother liquor. The polyamide curing agent is added in the prepared mother liquor, and is stirred to be uniformly dispersed. In this way, a molybdate doped polypyrrole / epoxy resin self-healing coating can be obtained. The coating is sprayed or brushed onto the 2024 type aluminum alloy after being subjected to oil-removing treatment. After the drying and curing process of the coating at the room temperature, a molybdate doped polypyrrole / epoxy resin self-healing coating can be formed.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com