Welding method for aluminum and copper heterogeneous metal materials

A technology of dissimilar metals and welding methods, applied in welding equipment, metal processing equipment, manufacturing tools, etc., to achieve the effect of improving uneven thermal deformation and large residual stress of joints, improving mechanical properties, and improving large residual stress of joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The invention provides a welding method of 5mm thick 2024 aluminum alloy and red copper two dissimilar metal materials, comprising the following steps:

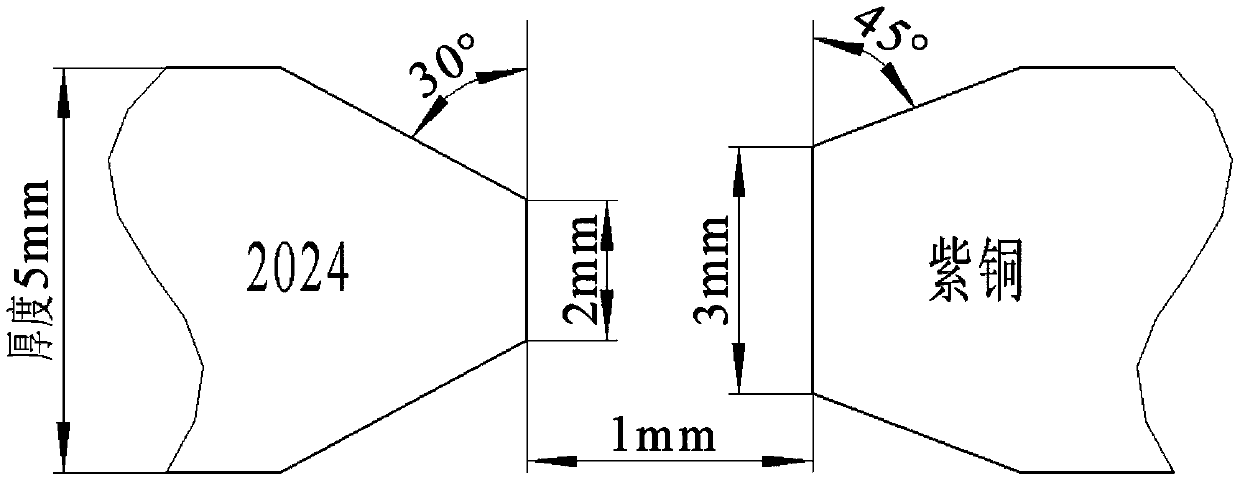

[0029] A. Use a file to make grooves on one side of two pieces of 2024 aluminum alloy and copper with a thickness of 5mm, remove oil and oxide film, and the final groove size is as follows: figure 1 As shown, the groove angle of the aluminum alloy is θ 1 =30°, after bevelling, the thickness direction dimension of the remaining butt joint in the middle is h 1 =2mm; the bevel angle of copper is θ 2 =45°, the thickness direction dimension of the remaining middle part after beveling is h 2 = 3mm.

[0030] B. Combine the aluminum alloy and the copper base material in pairs to form a butt joint, and number the first group and the second group respectively, and control the butt joint distance of d=1mm for both groups.

[0031] C. Perform pre-welding treatment on the copper base material in the first group, the voltage is ...

Embodiment 2

[0036] The invention provides a welding method of 8mm thick 2024 aluminum alloy and red copper two dissimilar metal materials, comprising the following steps:

[0037] A. Use a file to groove one side of two pieces of 2024 aluminum alloy and copper with a thickness of 8mm, remove oil and oxide film, and the final groove size is as follows: Figure 4 As shown, the groove angle of the aluminum alloy is θ 1 =45°, the thickness direction dimension of the remaining middle part after beveling is h 1 =3.5mm; the bevel angle of copper is θ 2 =60°, the thickness direction dimension of the remaining middle part after beveling is h 2 = 5mm.

[0038] B. Combine the aluminum alloy and the copper base material in pairs to form a butt joint, and number the third group and the fourth group respectively, and control the butt joint distance of d=1.5mm for both groups.

[0039] C. Perform pre-welding treatment on the copper base material in the third group, the voltage is 18V, the current is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com