Preparation method for low-voltage micro-arc oxidation ceramic film on aluminum alloy surface

A technology of aluminum alloy surface, micro-arc oxidation, applied in anodizing and other directions, can solve the problems of high cost, restrict development, large energy consumption, etc., and achieve the effect of short processing time, improve production efficiency, and reduce equipment power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

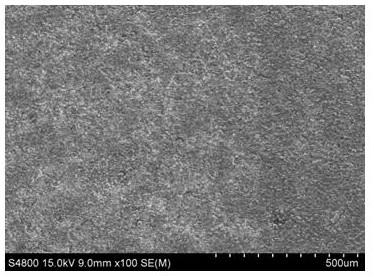

Image

Examples

Embodiment 1

[0021] 1. The raw material is uniformly made of 2024 aluminum alloy plate, which is cut into a square sample of 30 mm × 30 mm, and a small hole is punched on the edge of the sample for the connection of the wire and the sample.

[0022] 2. The pretreatment process of the sample before micro-arc oxidation is as follows:

[0023] Grind it step by step with water-based sandpaper to 1500#, polish it, put it into an ultrasonic vibration cleaner, clean it with deionized water and absolute ethanol, and dry it with a hair dryer.

[0024] 3. The electrolyte adopts silicate system, adding Na 2 SiO 3 8 g / L, H 3 BO 3 2.5 g / L, NaOH 0.75 g / L configuration solution. Add 0.1 g / L sodium dodecylsulfonate as a surfactant in the above electrolytic solution.

[0025] 4. Using self-made adjustable AC power supply, the micro-arc oxidation of 2024 aluminum alloy plate is carried out in a constant current mode. In the constant voltage mode, the initial voltage is 0V, the final voltage is 150V, a...

Embodiment 2

[0028] 1. The raw material is uniformly made of 2024 aluminum alloy plate, which is cut into a square sample of 30 mm × 30 mm, and a small hole is punched on the edge of the sample for the connection of the wire and the sample.

[0029] 2. The pretreatment process of the sample before micro-arc oxidation is as follows:

[0030] Grind it step by step with water-based sandpaper to 1500#, polish it, put it into an ultrasonic vibration cleaner, clean it with deionized water and absolute ethanol, and dry it with a hair dryer.

[0031] 3. The electrolyte adopts silicate system, adding Na 2 SiO 3 8 g / L, H 3 BO 3 2.5 g / L, NaOH 0.75 g / L configuration solution. Add 0.1 g / L sodium dodecylsulfonate as a surfactant in the above electrolytic solution. .

[0032] 4. Using self-made adjustable AC power supply, the micro-arc oxidation of 2024 aluminum alloy plate is carried out in a constant voltage mode. In constant voltage mode, the initial voltage is 0V, the final voltage is 180V, an...

Embodiment 3

[0034] 1. The raw material is uniformly made of 2024 aluminum alloy plate, which is cut into a square sample of 30 mm × 30 mm, and a small hole is punched on the edge of the sample for the connection of the wire and the sample.

[0035] 2. The pretreatment process of the sample before micro-arc oxidation is as follows:

[0036] Grind it step by step with water-based sandpaper to 1500#, polish it, put it into an ultrasonic vibration cleaner, clean it with deionized water and absolute ethanol, and dry it with a hair dryer.

[0037] 3. The electrolyte adopts silicate system, adding Na 2 SiO 3 10 g / L, H 3 BO 3 2 g / L, NaOH 1 g / L configuration solution. Add 0.1 g / L of sodium citrate as a surfactant to the above solution.

[0038] 4. Using self-made adjustable AC power supply, the micro-arc oxidation of 2024 aluminum alloy plate is carried out in a constant voltage mode. In the constant voltage mode, the initial voltage is 0V, the final voltage is 200V, and the oxidation time i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com