2024 aluminum alloy laser selective melting forming method

A technology of laser selective melting and aluminum alloy, which is applied in the direction of additive manufacturing, energy efficiency improvement, additive processing, etc., and can solve the problems that 2024 aluminum alloy can not be integrally formed with complex inner cavity precision components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

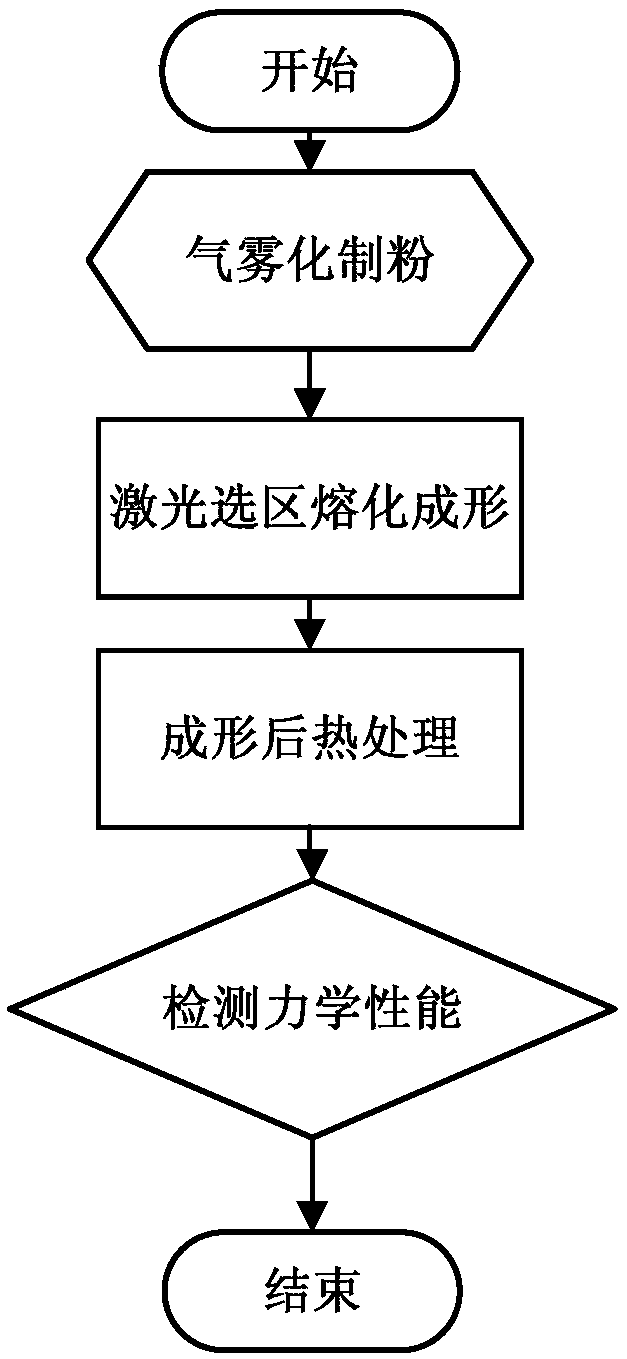

[0028] A 2024 aluminum alloy laser selective melting forming method, the steps of the method comprising:

[0029] (1) Utilize 2024 aluminum alloy rods for gas atomization and pulverization to obtain metal powders with particle sizes ranging from 15 μm to 53 μm;

[0030] (2) Using the powder obtained in step (1) to carry out selective laser melting and forming to obtain a 2024 aluminum alloy member whose shape meets the requirements;

[0031] (3) The 2024 aluminum alloy component obtained in step (2) whose shape meets the requirements is subjected to solution aging treatment to obtain a 2024 aluminum alloy component whose shape and mechanical properties meet the requirements.

[0032] In the step (1), the 2024 aluminum alloy bar is used as the raw material, and the gas atomization pulverization method is adopted, the atomization gas is argon, the pressure is 4.5MPa, the superheat of the molten metal is 200°C, and the flow rate of the molten metal is 18Kg per minute to obtain a...

Embodiment 2

[0037] A 2024 aluminum alloy laser selective melting forming method. 2024 aluminum alloy rods are used for gas atomization powder making to obtain metal powders with a particle size range of 15 μm to 53 μm; the obtained metal powders are used as raw materials, and the process parameters are laser power 220W, spot diameter 0.14mm, and scanning speed. 700mm / s, powder layer thickness 0.04mm, prepare 2024 aluminum alloy components, and then place them in a vacuum furnace for heat treatment, raise the temperature to a solid solution temperature of 510°C, keep warm for 1.5h, water quench and cool to the aging temperature, the aging temperature is 190°C, Keep warm for 12 hours and cool in air.

[0038] The obtained 2024 aluminum alloy components were tested for mechanical properties using the same batch of samples. The test methods were GB / T228.1 and GB / T228.2. The test results showed that the tensile strength at room temperature reached 525MPa~537MPa, and the yield strength reached ...

Embodiment 3

[0040] A 2024 aluminum alloy laser selective melting forming method. 2024 aluminum alloy rods are used for gas atomization powder making to obtain metal powders with a particle size range of 15 μm to 53 μm; the obtained metal powders are used as raw materials, and the process parameters are laser power 200W, spot diameter 0.12mm, and scanning speed. 600mm / s, powder layer thickness 0.03mm, prepare 2024 aluminum alloy components, and then place them in a vacuum furnace for heat treatment, heat up to a solid solution temperature of 500°C, hold for 1.5h, water quench and cool to an aging temperature of 180°C, hold for 12h, air cooled.

[0041] The obtained 2024 aluminum alloy components were tested for mechanical properties using the same batch of samples. The test methods were GB / T228.1 and GB / T228.2. The test results showed that the tensile strength at room temperature reached 541MPa~558MPa, and the yield strength reached 337MPa~ 352MPa, the elongation reaches 12.3% to 15.8%. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com