Production method of oxidation-colored electrophoresis-painted aluminum alloy section bars

An aluminum alloy profile and electrophoretic painting technology, applied in the field of aluminum alloy material processing, can solve the problems of easy paint peeling and poor corrosion resistance, and achieve the effects of stable composition, stable performance and improved comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

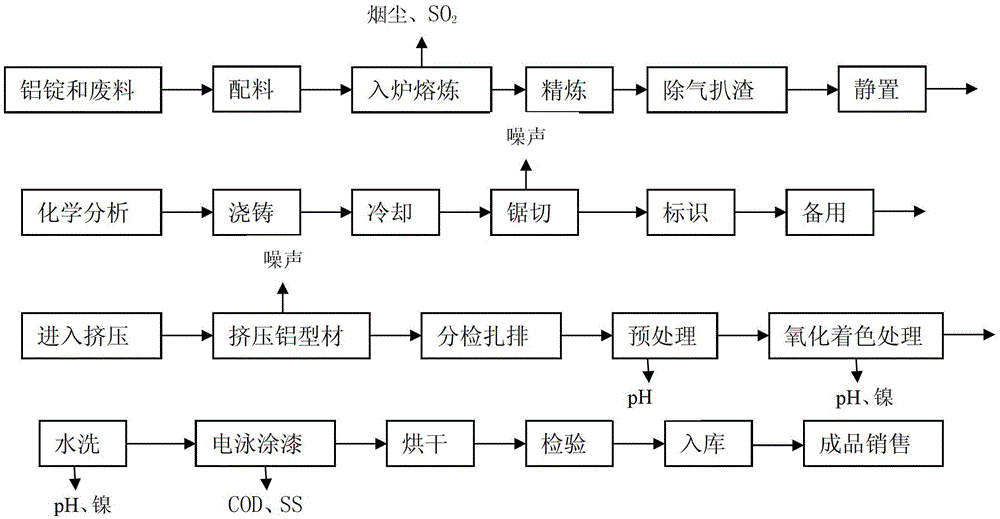

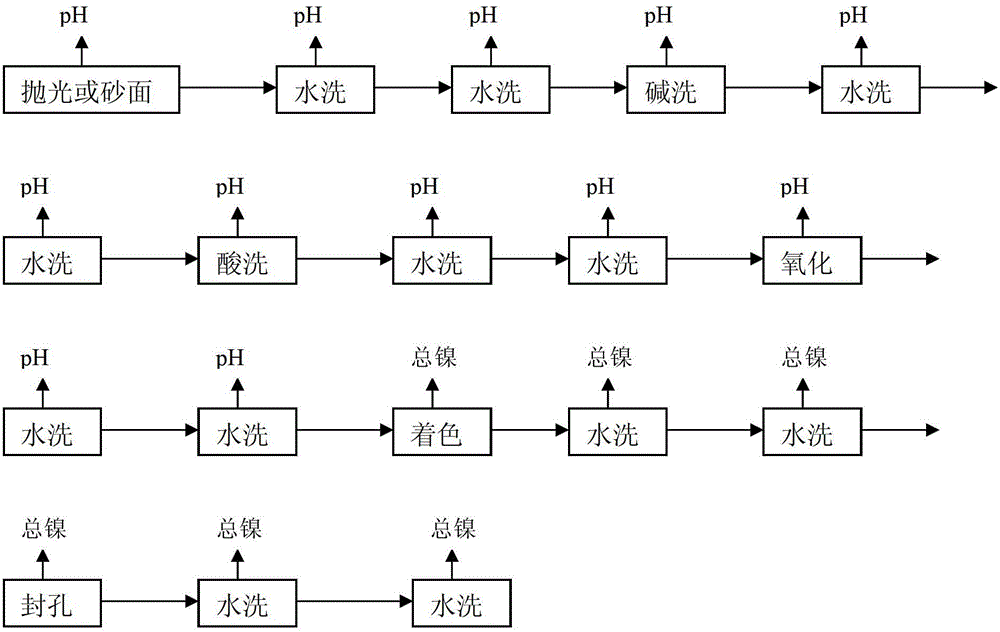

Method used

Image

Examples

Embodiment 1

[0030] (1) Aluminum ingot and other raw material ingredients

[0031] According to the following parts by weight of raw materials: 70 parts of aluminum ingots, 30 parts of recycled aluminum profile scraps and other waste aluminum, 8 parts of modified fly ash;

[0032] (2) Melting and casting aluminum alloy round ingots

[0033] Put aluminum ingots, recycled aluminum profile scraps and other scrap aluminum into the melting furnace for smelting. When it becomes a molten state, add modified fly ash to make it evenly distributed, and then add an appropriate amount of AlTiC grain refiner for smelting. Refining, by adding alloying elements, so that the mass percentage of each element is: Si ≤0.5%, Mg 1.2-1.8%, Fe ≤0.50%, Cu ≤3.8-4.9%, Mn 0.30-1.0%, Cr ≤0.10 %, Zn ≤0.25%, Ti ≤0.15%, total other elements ≤0.15%, and the rest is Al. Finally, the slag and gas in the melt are effectively removed by degassing and slagging;

[0034] (3) Casting and sawing

[0035] Before casting, let the molten al...

Embodiment 2

[0049] (1) Aluminum ingot and other raw material ingredients

[0050] According to the following parts by weight of raw materials: 60 parts of aluminum ingots, 40 parts of recycled aluminum profile scraps and other waste aluminum, 10 parts of modified fly ash;

[0051] (2) Melting and casting aluminum alloy round ingots

[0052] Put aluminum ingots, recycled aluminum profile scraps and other scrap aluminum into the melting furnace for smelting. When it becomes a molten state, add modified fly ash to make it evenly distributed, and then add an appropriate amount of AlTiC grain refiner for smelting. Refining, by adding alloying elements, the mass percentage of each element is: Si ≤0.5%, Mg 1.2-1.8%, Fe ≤0.50%, Cu ≤3.8-4.9%, Mn 0.30-1.0%, Cr ≤ 0.10%, Zn ≤0.25%, Ti ≤0.15%, total other elements ≤0.15%, the rest is Al, and finally the slag and gas in the melt are effectively removed by degassing and slagging;

[0053] (3) Casting and sawing

[0054] Before casting, let the molten aluminum s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com