Stabilizing processing method of 5052 aluminium alloy

A stabilization treatment, aluminum alloy technology, applied in the direction of metal rolling, to achieve uniform and stable mechanical properties, reduce energy consumption, and improve product production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] First put the aluminum ingot into the crucible resistance furnace, when the aluminum ingot is melted, add the intermediate alloy and stir; then add Mg and Zn, slag and refine; stir and stand still, pour into the cast iron mold; Aluminum alloy ingots are hot-rolled and cold-rolled into aluminum alloy coils, and the aluminum alloy coils are cold-rolled to a thickness of 3.0mm; intermediate annealing is performed at a temperature of 550°C, and the holding time is 12 hours; the above-mentioned intermediate After the annealed aluminum alloy coil is cold-rolled with a cold deformation processing rate of 50%, a 5052 aluminum alloy coil with a thickness of 1.5 mm and stable performance is obtained.

Embodiment 2

[0022] First put the aluminum ingot into the crucible resistance furnace, when the aluminum ingot is melted, add the intermediate alloy and stir; then add Mg and Zn, slag and refine; stir and stand still, pour into the cast iron mold; Aluminum alloy ingots are hot-rolled and cold-rolled into aluminum alloy plates, and the aluminum alloy plates are hot-rolled to a thickness of 2.0mm; intermediate annealing is performed at a temperature of 530°C, and the holding time is 15 hours; after the above-mentioned intermediate annealing A 5052 aluminum alloy plate with a thickness of 1.2 mm and stable properties was obtained through cold rolling with a cold deformation processing rate of 40%.

Embodiment 3

[0024] First put the aluminum ingot into the crucible resistance furnace, when the aluminum ingot is melted, add the intermediate alloy and stir; then add Mg and Zn, slag and refine; stir and stand still, pour into the cast iron mold; Aluminum alloy ingots are hot-rolled and cold-rolled into aluminum alloy coils, and the aluminum alloy coils are first hot-rolled and then cold-rolled to a thickness of 1.0mm; intermediate annealing is performed at a temperature of 560°C, and the holding time is 12 Hours; the above-mentioned aluminum alloy coil after the intermediate annealing is subjected to cold rolling with a cold deformation processing rate of 35% to obtain a 5052 aluminum alloy coil with a thickness of 0.65 mm and stable performance.

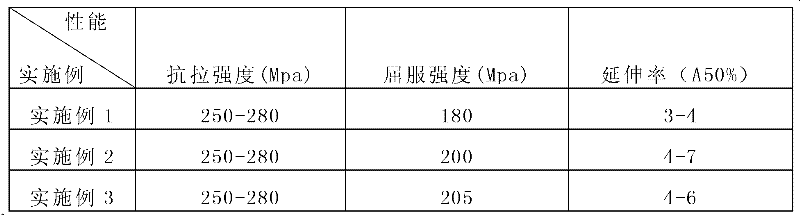

[0025] Through the above stabilization treatment, the alloy is in a completely recrystallized state, the grain size is uniform, and the final product obtains stable mechanical properties. The specific performance indicators are shown in Table ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com